Raw material drying device for solid toilet cleaner production

A solid toilet cleaner and drying device technology, which is applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of insufficient mixing of hot air and materials, so as to prevent poor drying effect, improve the effect, Improve the effect of flow stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

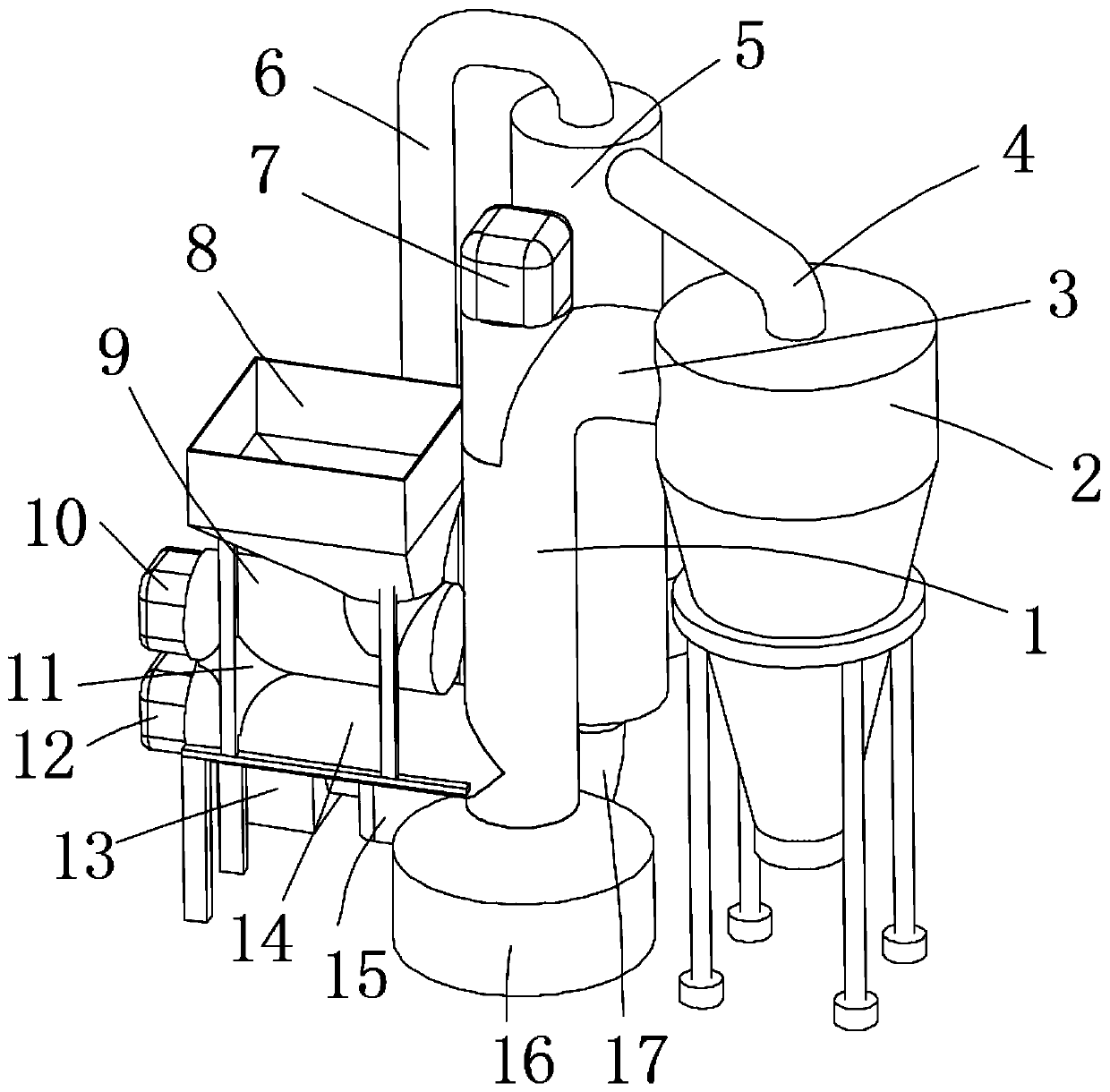

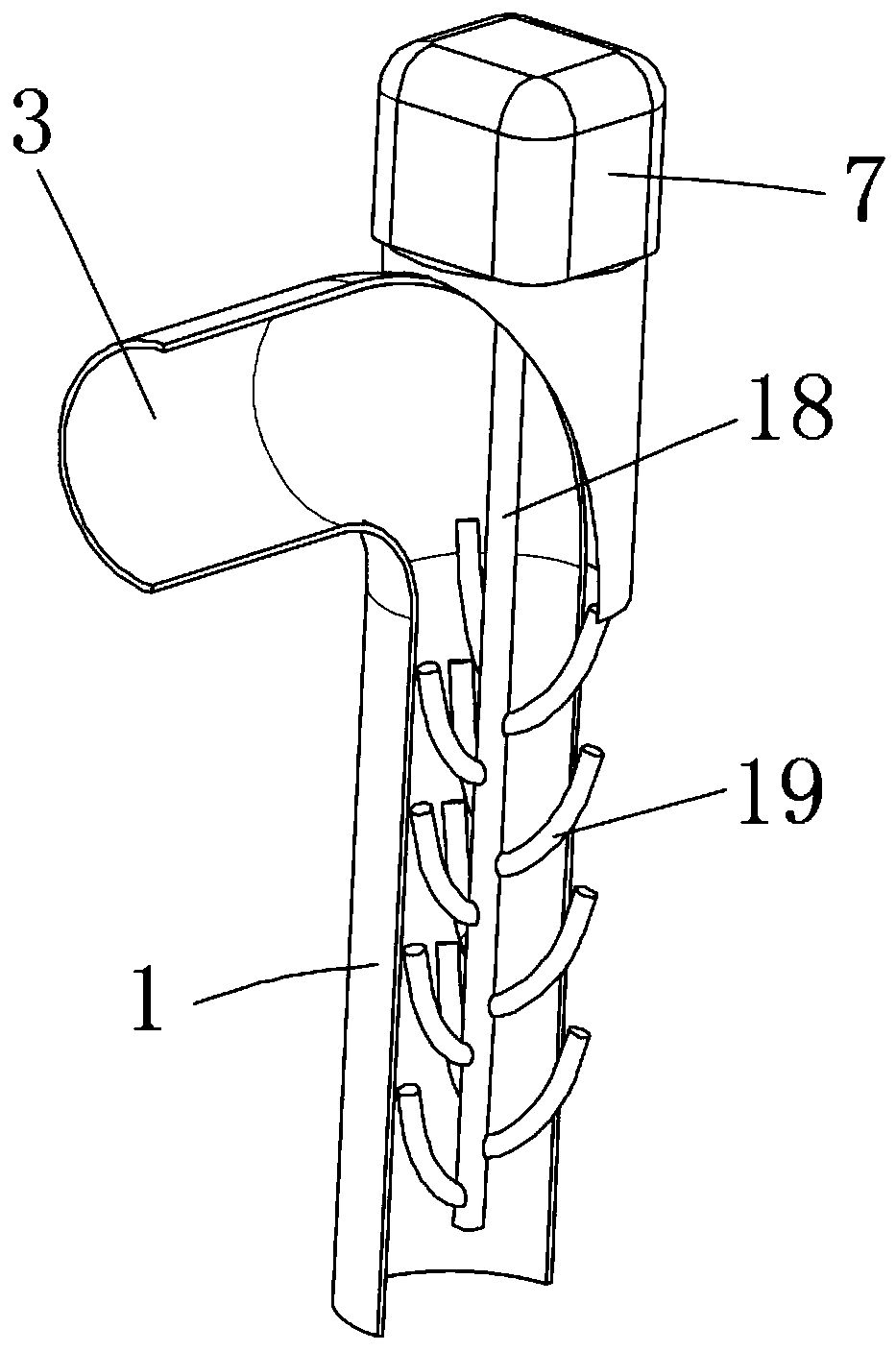

[0030] refer to figure 1 and Figure 5 , a raw material drying device for the production of solid toilet cleaner, comprising a drying cylinder 1, the top of the drying cylinder 1 is provided with a curved end 3, and the top inner wall of the drying cylinder 1 is connected with a stirring shaft 18 through a bearing, the stirring shaft The side outer wall of 18 is welded with stirring rod 19, and the top outer wall of drying drum 1 is connected with stirring motor 7 by screw, and the output shaft of stirring motor 7 is connected to the top outer wall of stirring shaft 18 by shaft coupling, and the top outer wall of drying drum 1 The outer wall of the bottom end is fixedly connected with a heating cylinder 16, and one side of the outer wall of the heating cylinder 16 is plugged with an air guide pipe 17. Bracket 24, the top outer wall of bracket 24 is connected with electric heating pipe 25 by screw, one end of air guide pipe 17 is provided with blower mechanism, one side outer ...

Embodiment 2

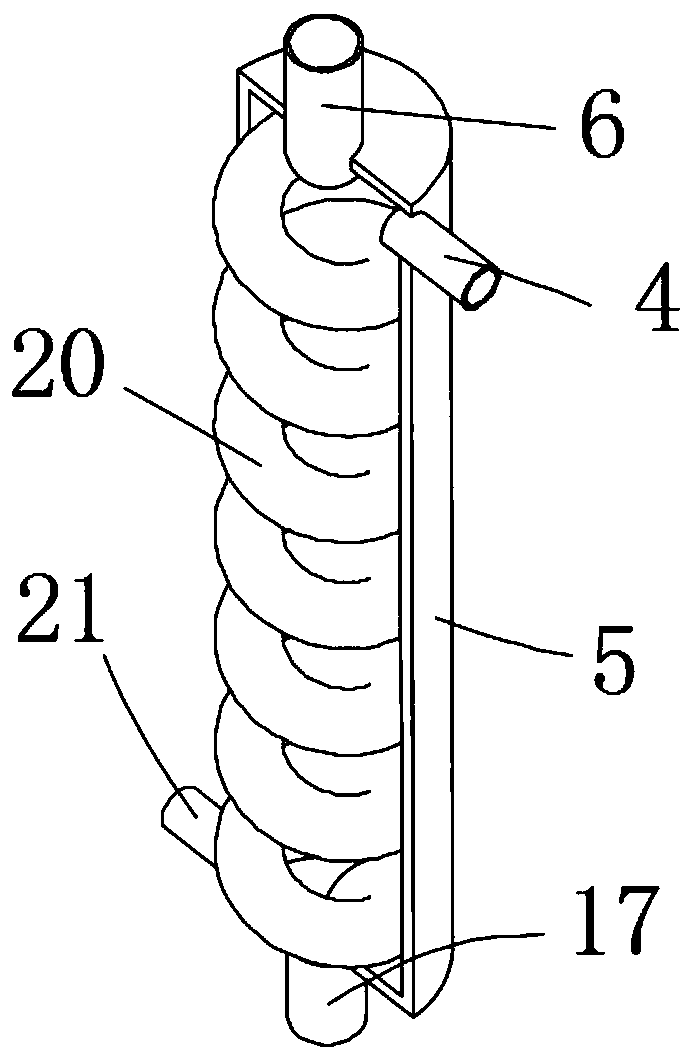

[0036] refer to figure 1 and image 3, a raw material drying device for the production of solid toilet cleaner, compared with embodiment 1, in order to improve the heating effect of the air in the heating cylinder 16, a preheating device is set between one end of the air guide pipe 17 and the outlet end of the blower 15 mechanism, one end of the air outlet pipe 4 is connected with a preheating cylinder 5, and the bottom of one side of the outer wall of the preheating cylinder 5 is provided with an exhaust pipe 21, and the air outlet end of the blower 15 is connected with an air inlet pipe 6, and one end of the air inlet pipe 6 is inserted into Connected to the top outer wall of the preheating tube 5, one end of the air guide tube 17 is plugged into the bottom outer wall of the preheating tube 5, and one end of the air intake tube 6 and one end of the air guide tube 17 are connected with the same preheating tube 20, the preheating tube 20 spiral tubular structure

[0037] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com