System for evaporation and concentration by using waste heat of dryer

A technology of evaporative concentration and drying machine, which is applied in the field of evaporative concentration systems and waste heat recovery systems. It can solve the problems of low drying efficiency, large air volume, and low exhaust gas temperature, and achieve low steam and power consumption, which is beneficial to waste heat recovery and waste heat recovery. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

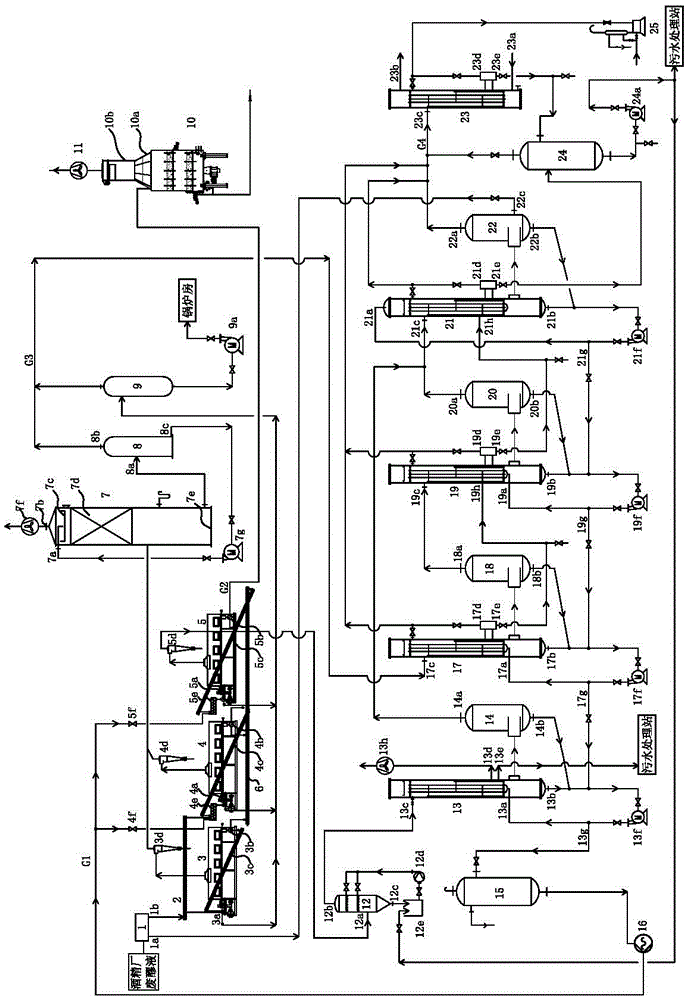

[0020] Such as figure 1 As shown, the present invention utilizes the waste heat of drier to carry out the system of evaporative concentration comprising the first tube bundle drier 3, the second tube bundle drier 4 and the third tube bundle drier 5 that materials are heated in series successively, separator 1 and alcohol plant waste The mash pipe is connected, the clear liquid outlet 1a of the separator 1 is connected with the inlet of the clear liquid concentration system, the outlet of the clear liquid concentration system is connected with the total concentrated liquid pipe G1, the wet alcohol slag outlet 1b of the separator 1 is connected with the feeding screw conveyor 2, the first outlet of the feeding screw conveyor 2 is connected to the inlet of the first feeding screw 3a of the first tube bundle dryer 3, and the outlet of the first tube bundle dryer 3 is connected to the first The inlet of the three-way material distribution valve 3b is connected, and the return port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com