Temperature difference power generation device and vehicle-mounted tail gas waste heat temperature difference power generation system

A technology of thermoelectric power generation and thermoelectric power generation module, which is applied in the directions of generators/motors, electrical components, and noise reduction devices, can solve the problems of low energy recovery rate and low power generation efficiency of thermoelectric power generation devices, etc., so as to improve energy utilization rate and improve Space utilization, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

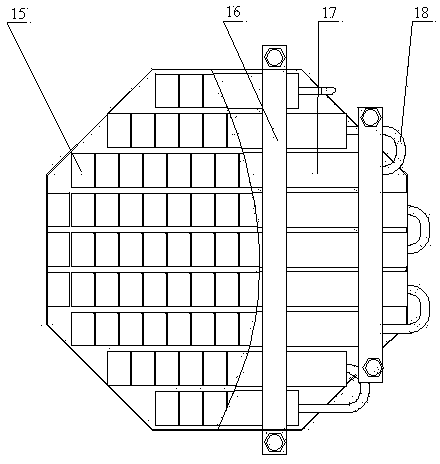

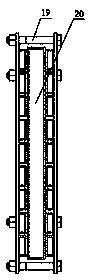

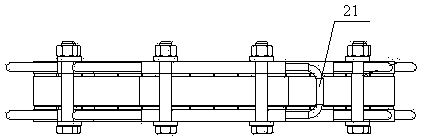

[0034] Such as Figure 1 ~ Figure 3 As shown, the thermoelectric power generation device includes an exhaust gas box 20 , a cooling water tank assembly, a thermoelectric power generation module assembly and a clamping plate 16 .

[0035] Such as Figure 4 As shown, the two ends of the exhaust box 20 are respectively provided with an intake manifold 8 and an exhaust manifold 11. The exhaust box 20 includes an air box body 26, a splitter fin 22, a guide fin 23 and a converging fin 24. The upper and lower surfaces of the box body 26 are regular octagons and are made of brass material. The diverter f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com