Horizontal oil heating hollow blade bearing reaction kettle

A hollow blade and reactor technology, which is applied in chemical/physical/physical-chemical stationary reactors, pressure vessels used in chemical processes, and methods of chemically changing substances by using atmospheric pressure, which can solve the problem of poor heating effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

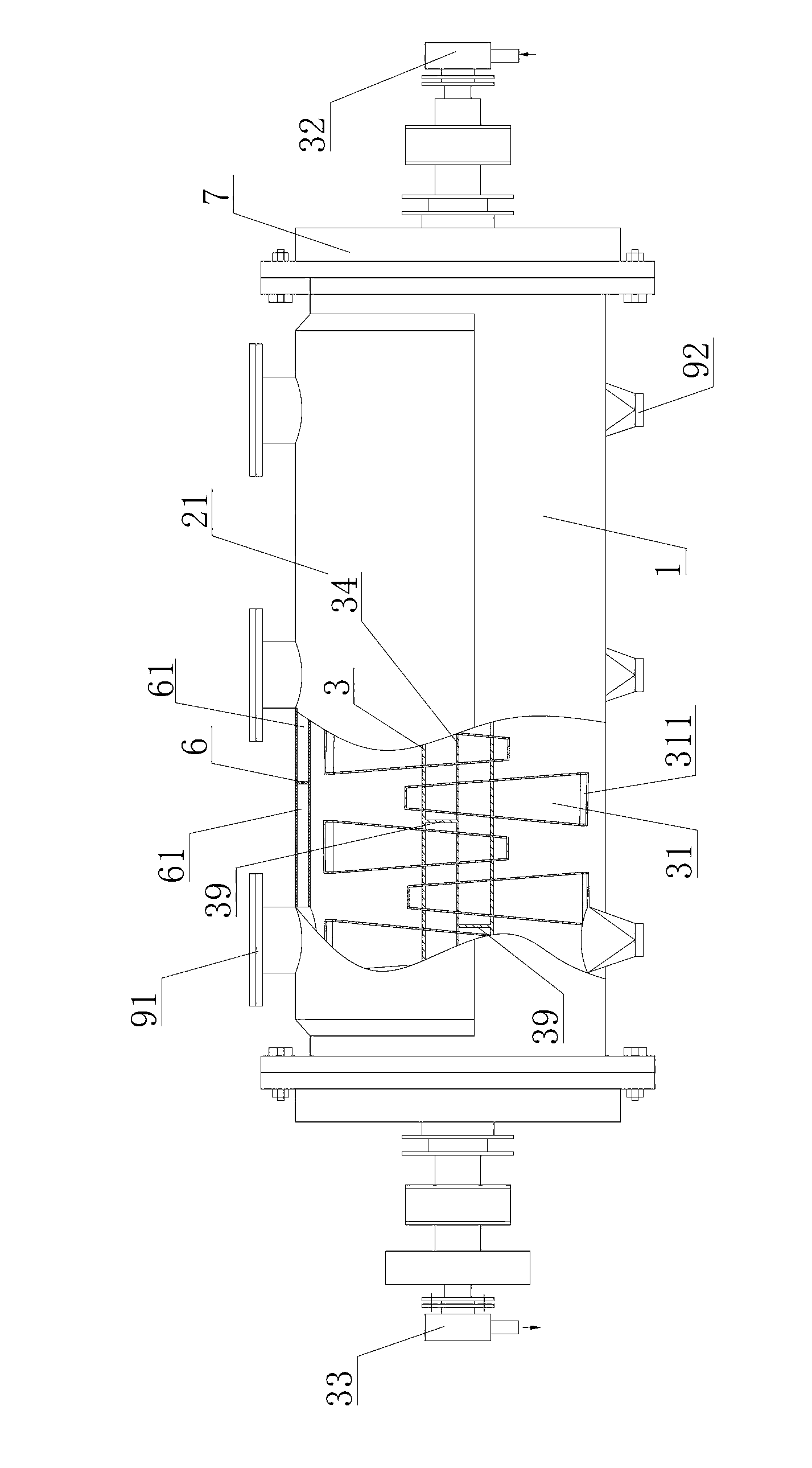

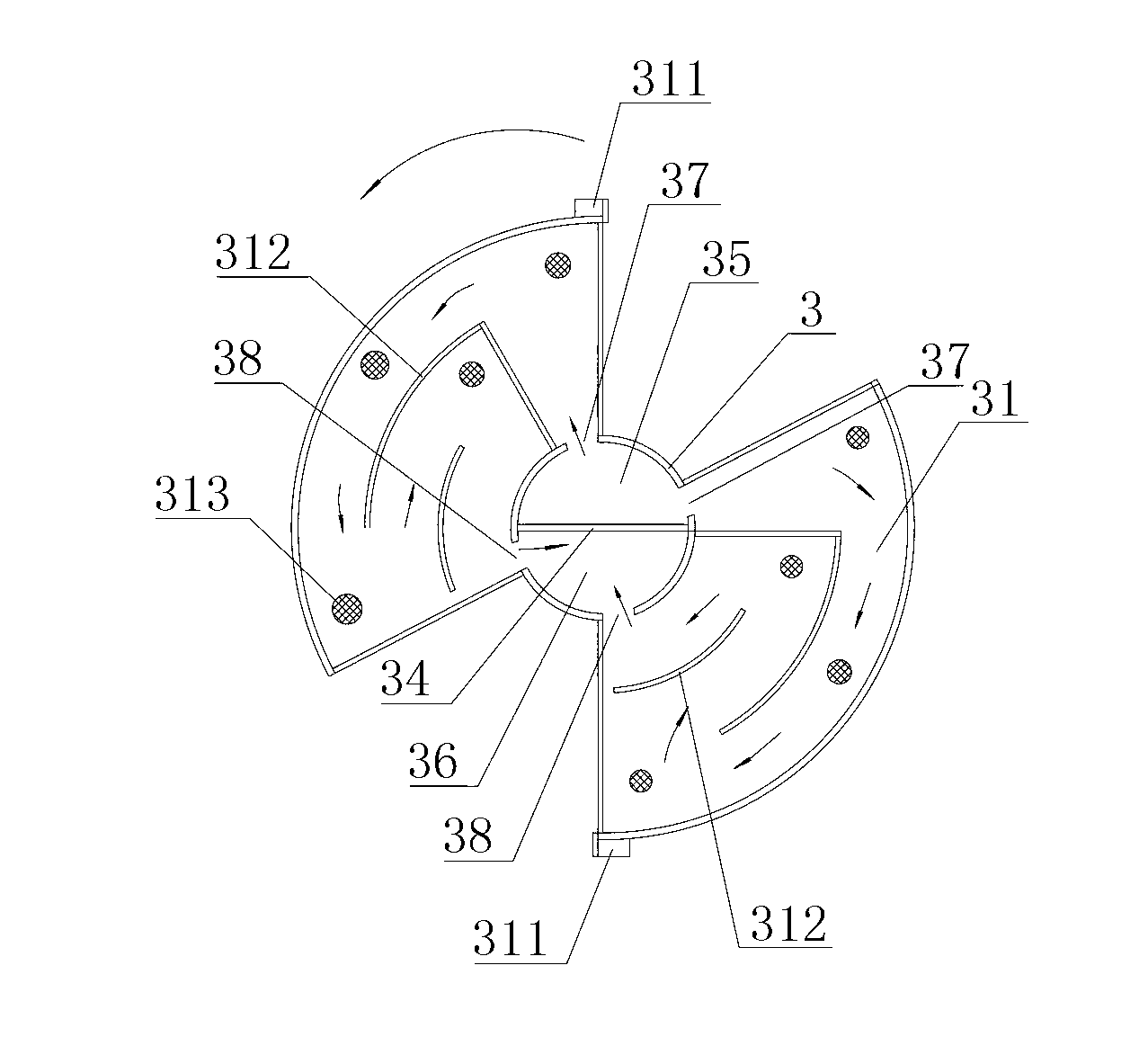

[0027] like figure 1 As shown, it is a partial cross-sectional view of an embodiment of the horizontal oil-heated hollow paddle pressure reactor of the present invention. The reactor cylinder 1 is placed horizontally, the upper part of the reactor cylinder 1 is provided with a feeding port 91 communicating with its inner cavity, and the lower part of the reactor cylinder 1 is provided with a discharge opening 92 communicating with its inner cavity, and the material After being fed into the inner cavity of the reactor cylinder body 1 from the feeding port 91, it can be discharged from the feeding port 92 after being stirred and heated.

[0028] What adopt to material in this embodiment is double heating mode:

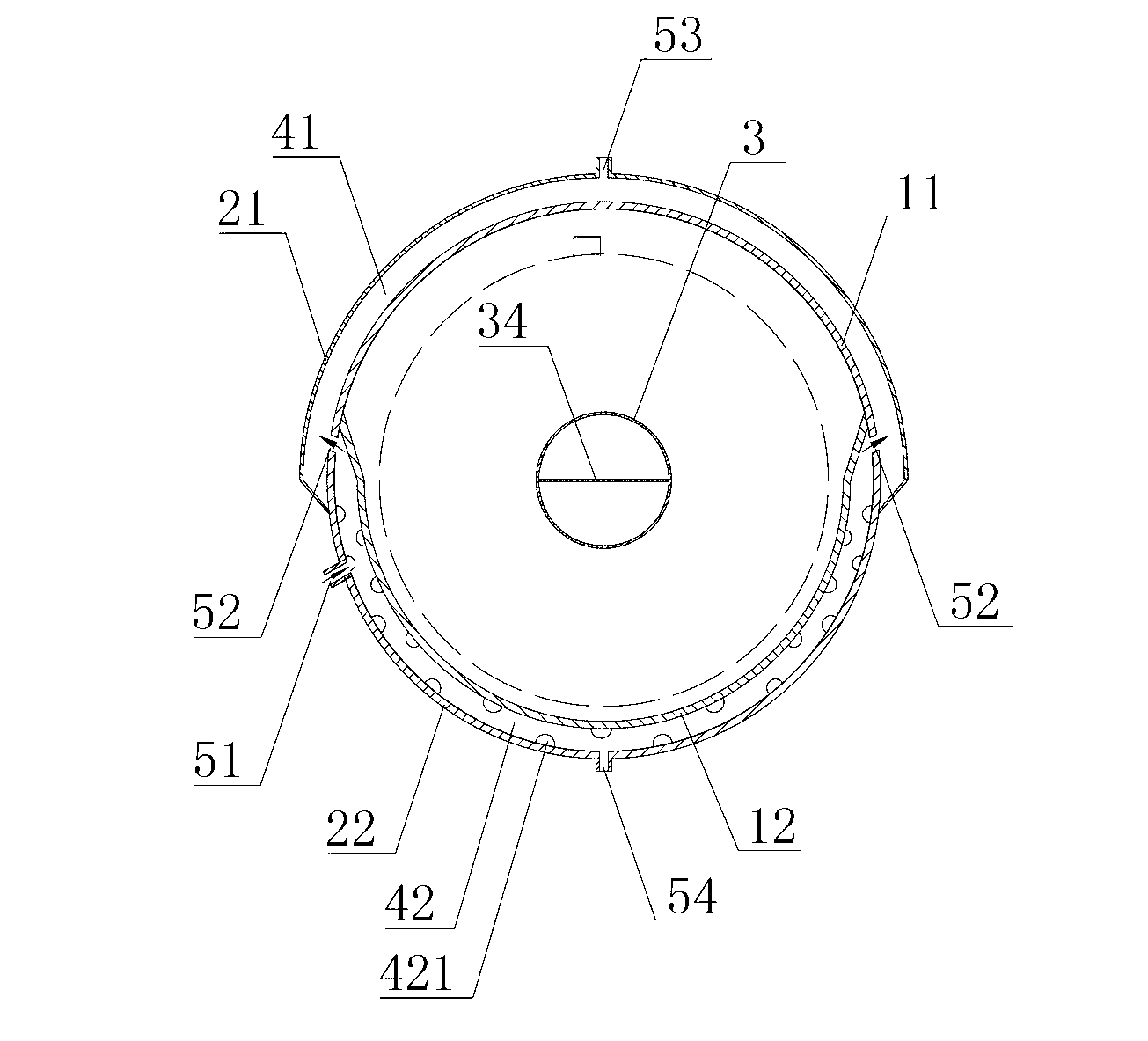

[0029] 1. Jacket heating. like figure 2 As shown, jacket heating is a commonly used technical means in this technical field. In this embodiment, an upper jacket 21 positioned on the outer surface of the reactor cylinder 1 is fixed on the upper half of the reactor cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com