Horizontal bearing press-in equipment

A bearing and horizontal technology, which is applied in the field of horizontal bearing pressing equipment, can solve the problems of substandard bearing pressing, low production efficiency, and increased production cost, so as to ensure the assembly effect, save manpower and material resources, and reduce defective products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

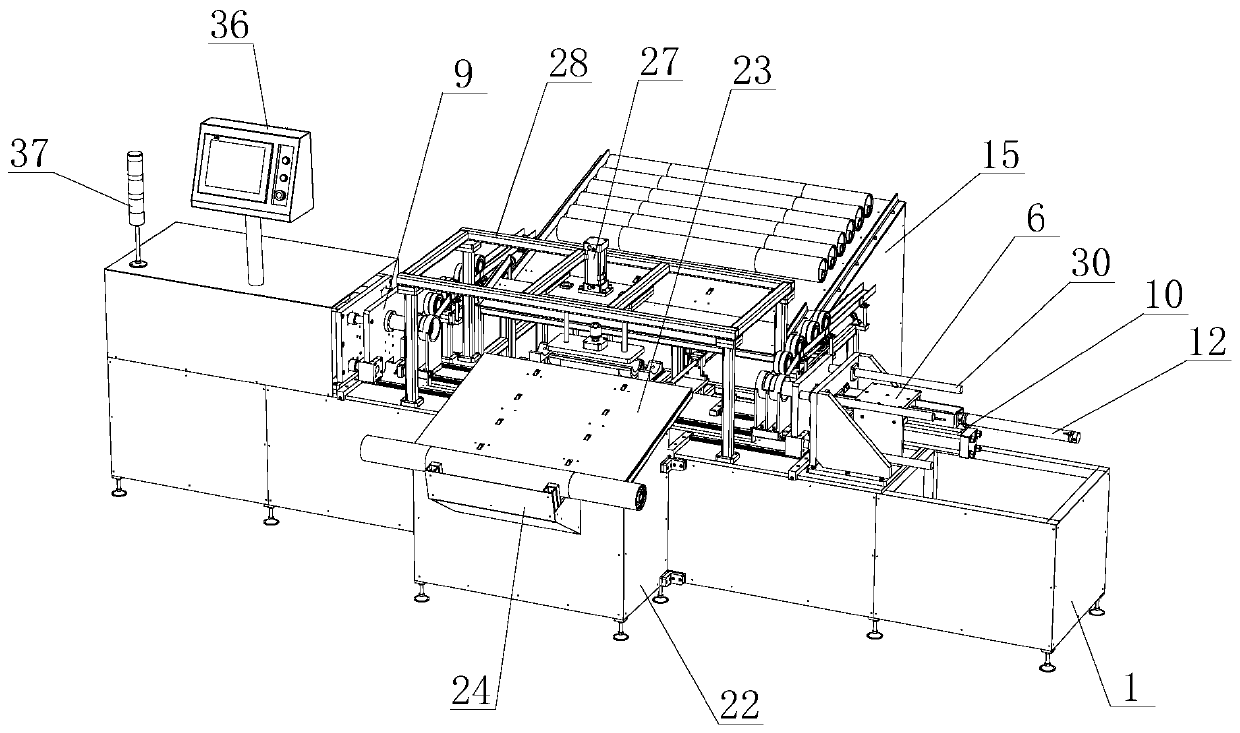

[0028] Example: such as figure 1 As shown, a horizontal bearing press-in equipment includes a frame 1. A pressure bearing mechanism is arranged on the frame 1. A product unloading mechanism and a roller feeding mechanism are respectively arranged on the front and rear sides of the frame 1. The two parts of the roller feeding mechanism Both sides are equipped with bearing feeding mechanism;

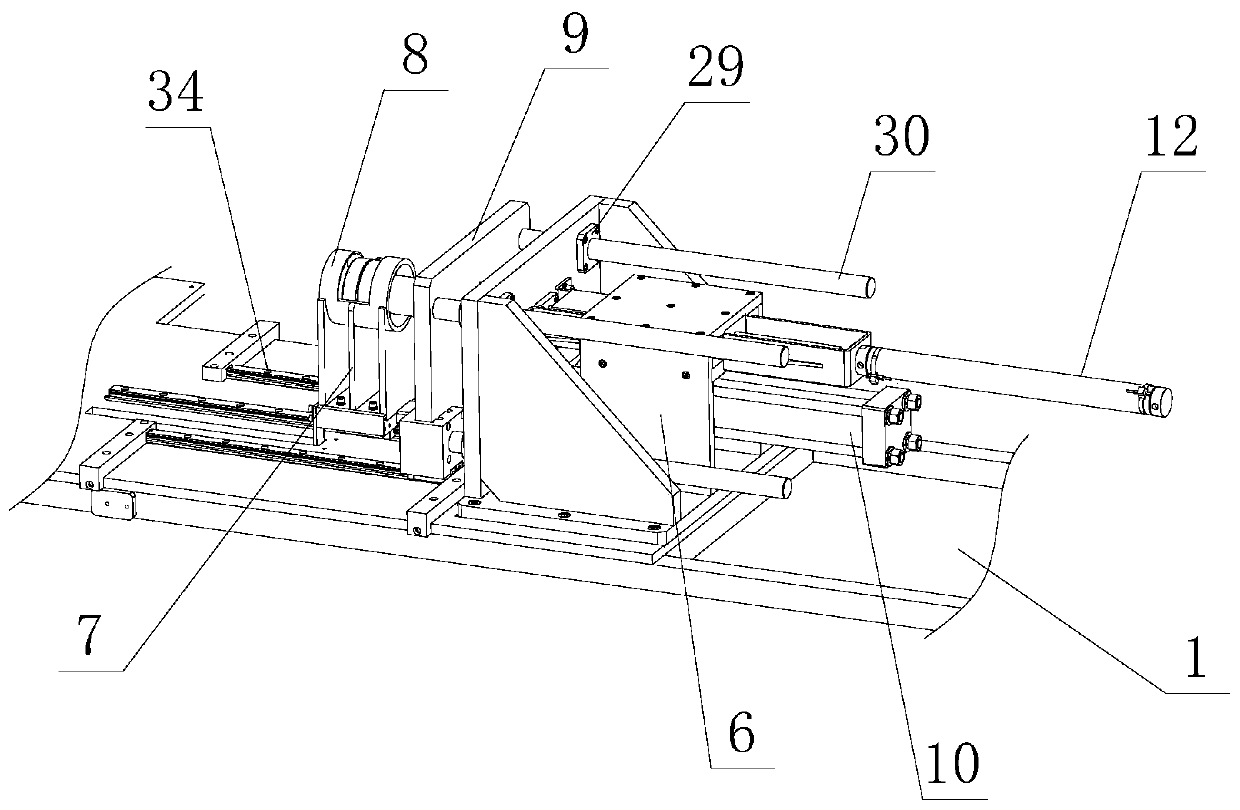

[0029] The pressure bearing mechanism includes a transposition assembly and two press-fit assemblies, and the two press-fit assemblies are respectively arranged on the left and right sides of the transposition assembly;

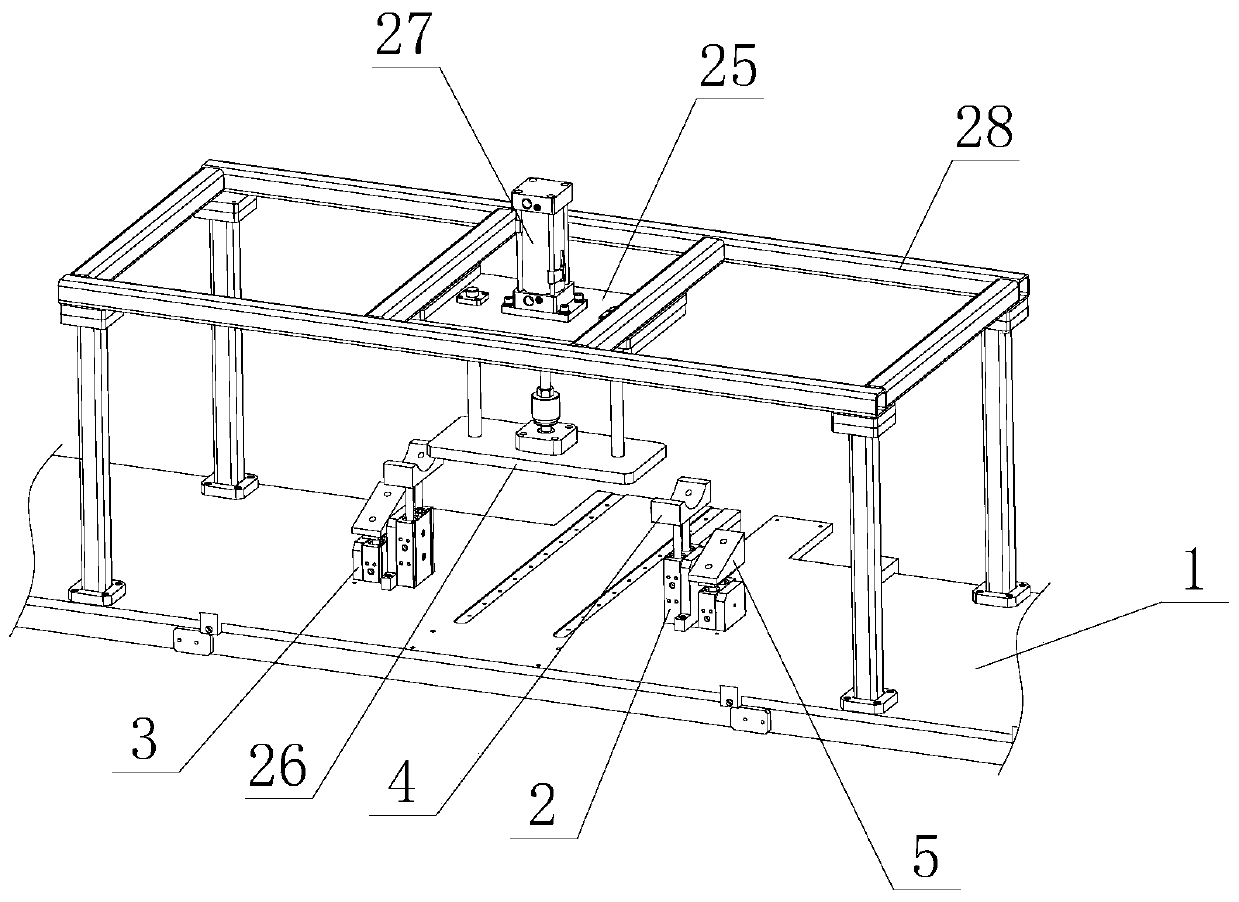

[0030] like figure 2 As shown, the transposition assembly includes two oppositely arranged lifting units. The lifting unit includes a first jacking cylinder 2, a second jacking cylinder 3, a roller support block 4 and a push block 5, and the first jacking cylinder 2 and the second jacking cylinder The jacking cylinder 3 is installed vertically on the frame 1 in turn, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com