Automatic powder recycling device

A technology for recycling device and powder, applied in chemical instruments and methods, additive manufacturing, separation of dispersed particles, etc., can solve problems such as reducing processing efficiency, equipment cannot perform continuous work, etc., and achieve the effect of improving efficiency and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

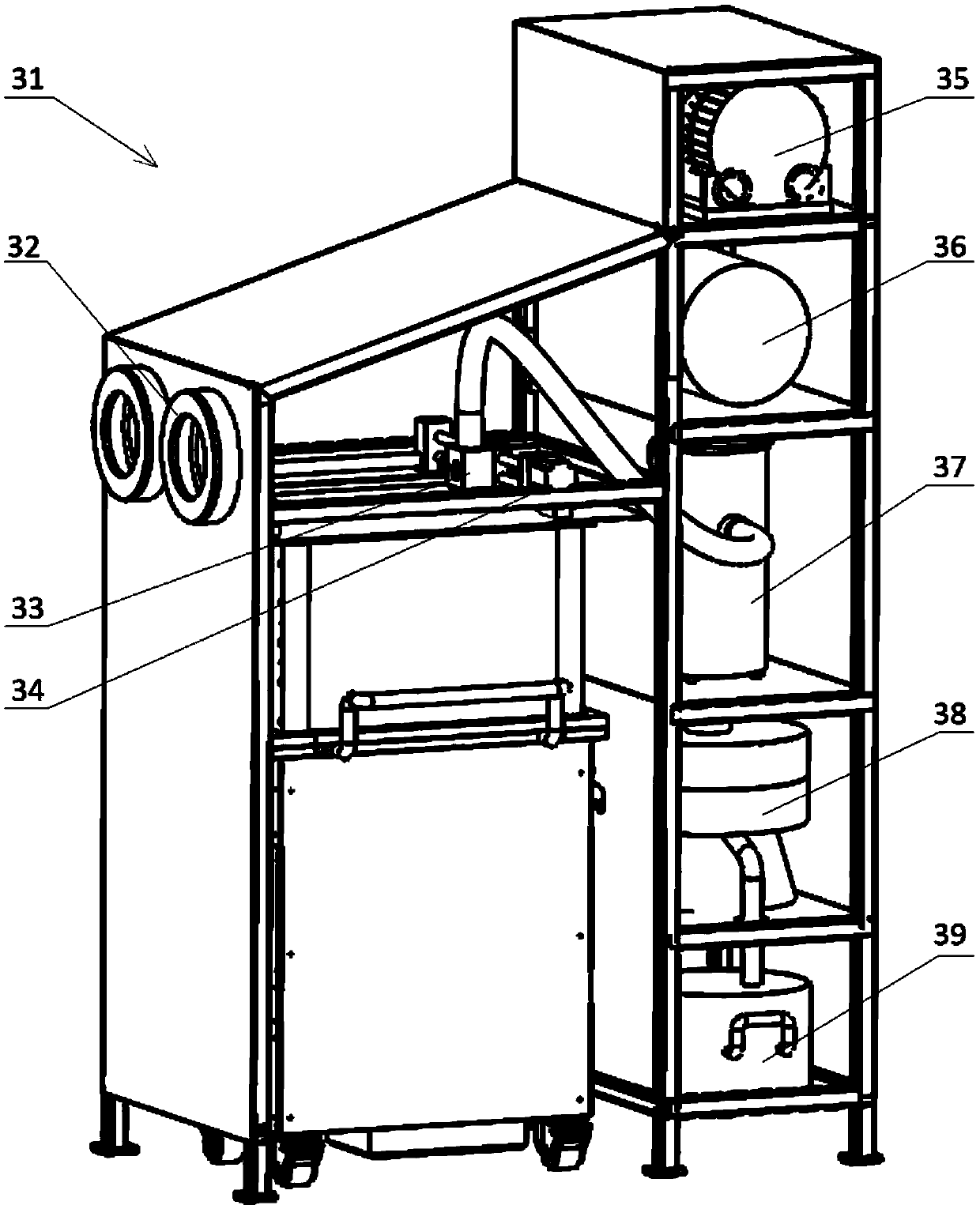

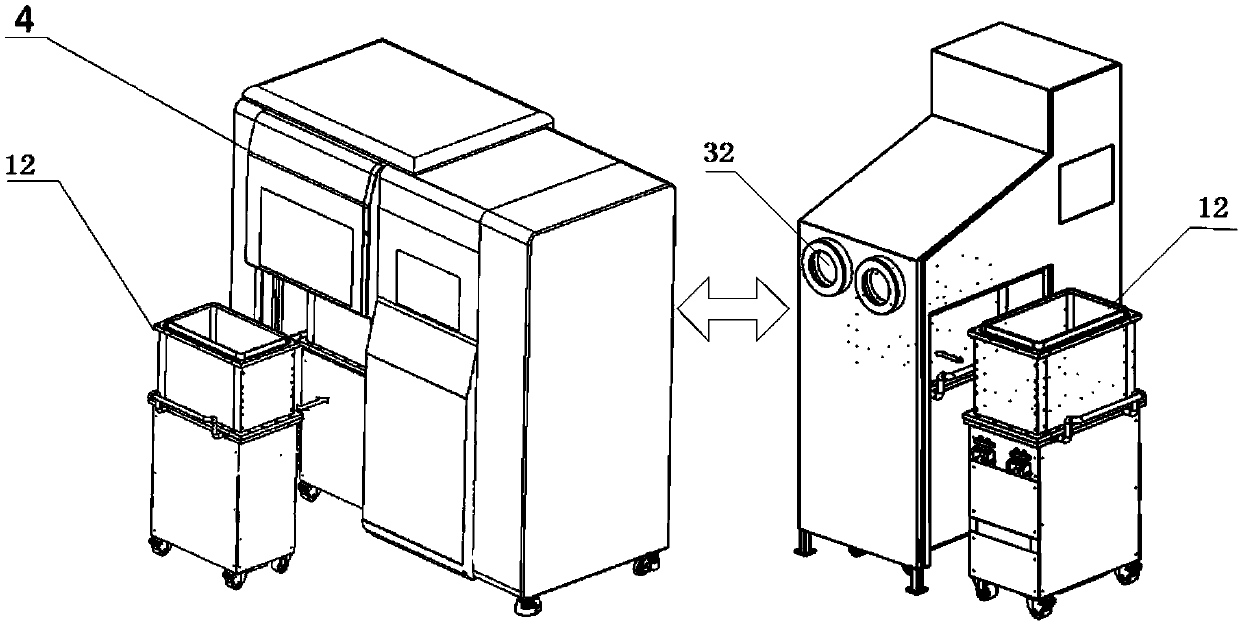

[0025] Such as Figure 1-3 shown. The invention discloses an automatic powder recovery device, which includes a box body 31, and the box body 31 includes two left and right boxes;

[0026] The left box is a glove box 32 without a bottom plate, and a mobile molding cylinder mechanism is placed in the glove box 32;

[0027] The right box body is a powder recovery box, and its interior is sequentially provided with a blower 35, a filter 36, a cyclone separator 37, a vibrating screen 38, and a powder collection bottle 39 connected by pipelines from top to bottom;

[0028] The upper side wall of the glove box 32 is provided with two windows that can extend into the arms, and rubber gloves are respectively installed in the windows;

[0029] A rubber tube is connected to the cyclone separator 37 , and a powder suction nozzle 33 is installed at the end of the rubber tube, and the powder suction nozzle 33 is placed in the glove box 32 .

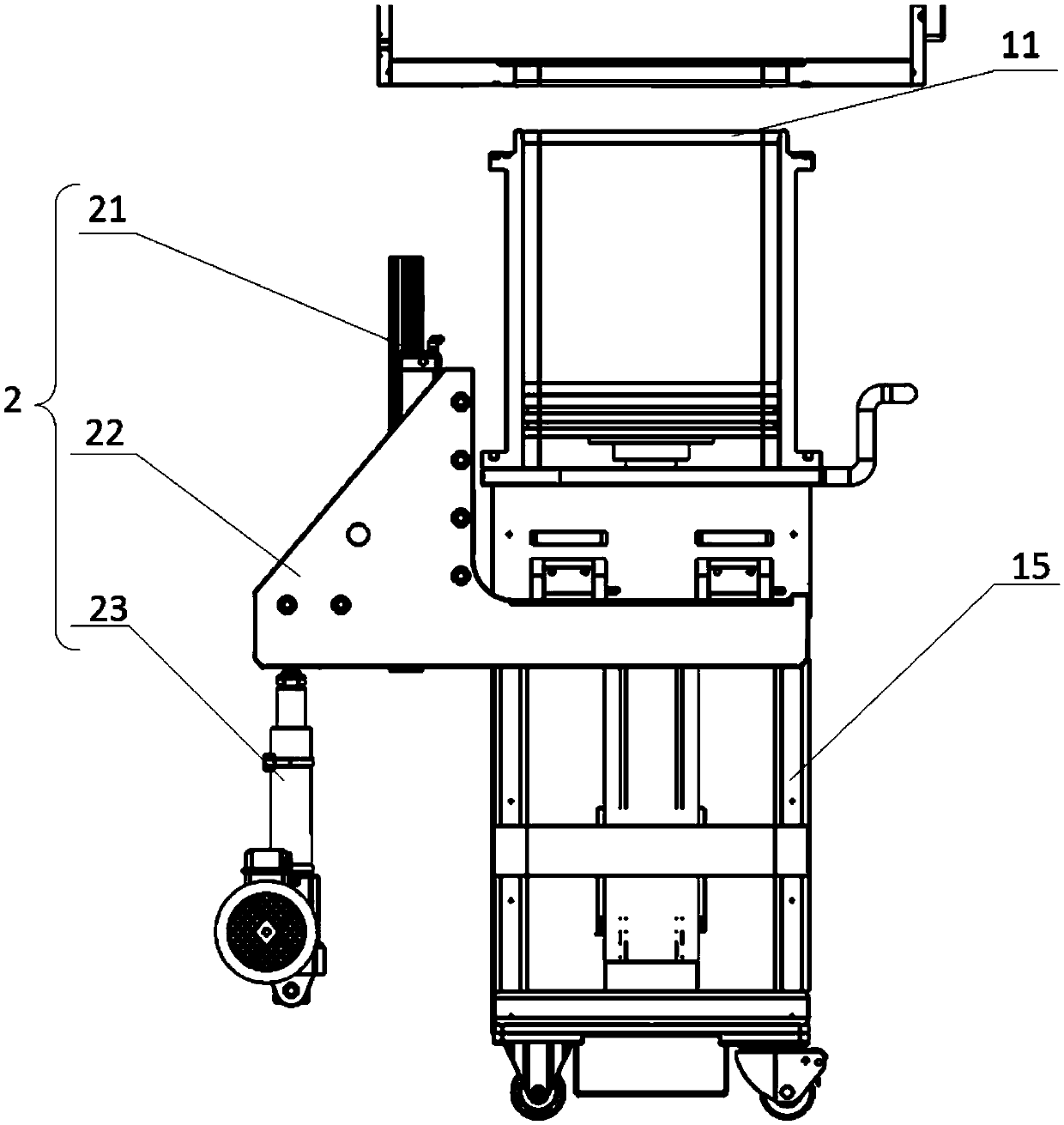

[0030] The mobile molding cylinder mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com