Clamping and pressing device for pipe connection

A pipe and pressing technology, which is applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems such as the inability to realize the automatic work of the pressing device, the inability to improve the working efficiency of the tube pressing, and the reduction of the structural flexibility of the pressing device. , to achieve the effect of automating work, improving flexibility, and shortening the process of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

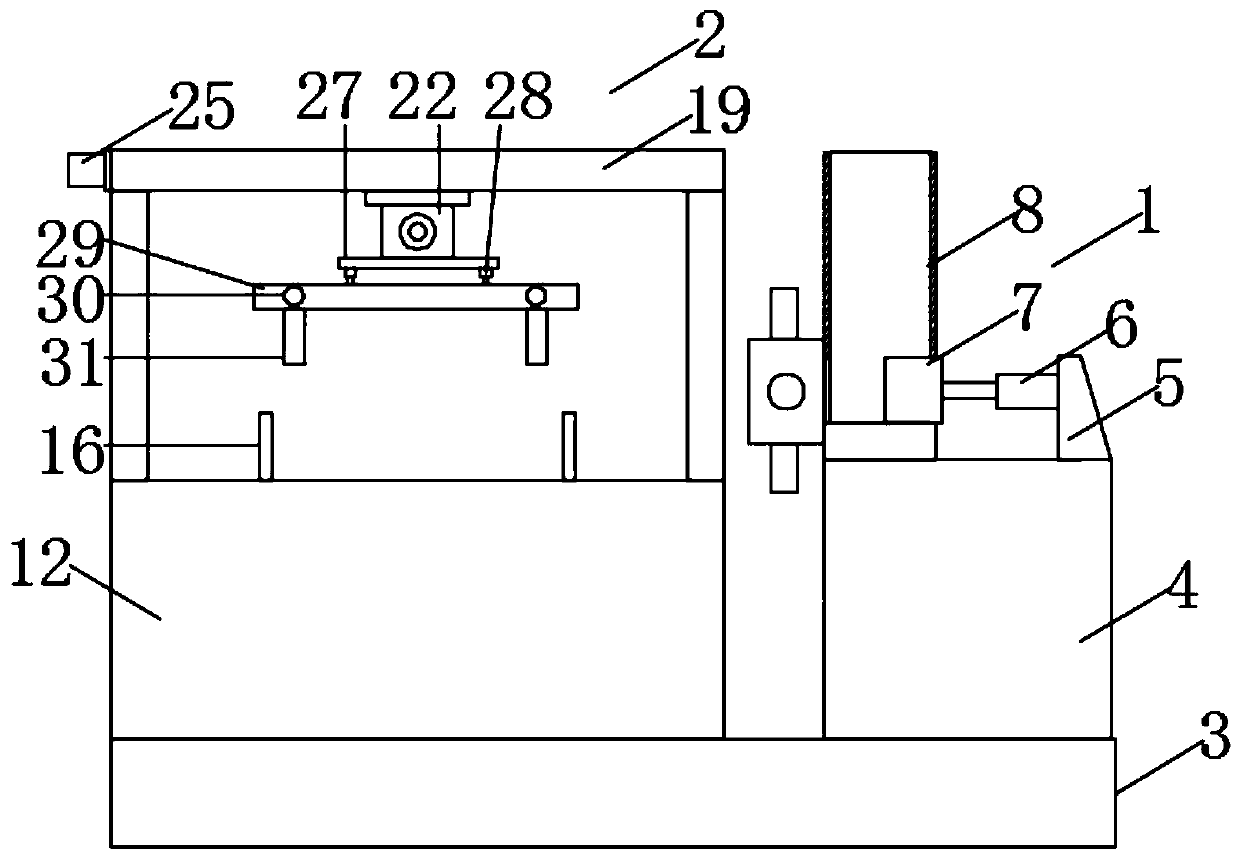

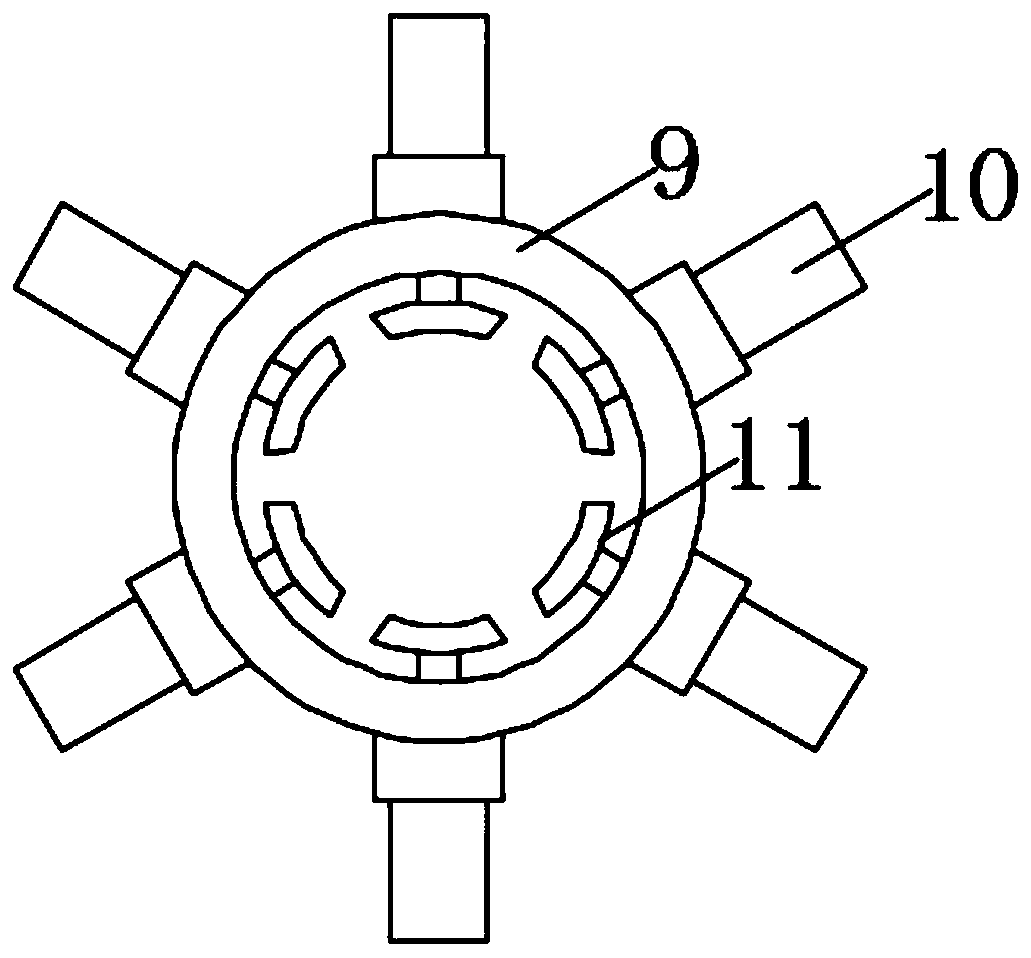

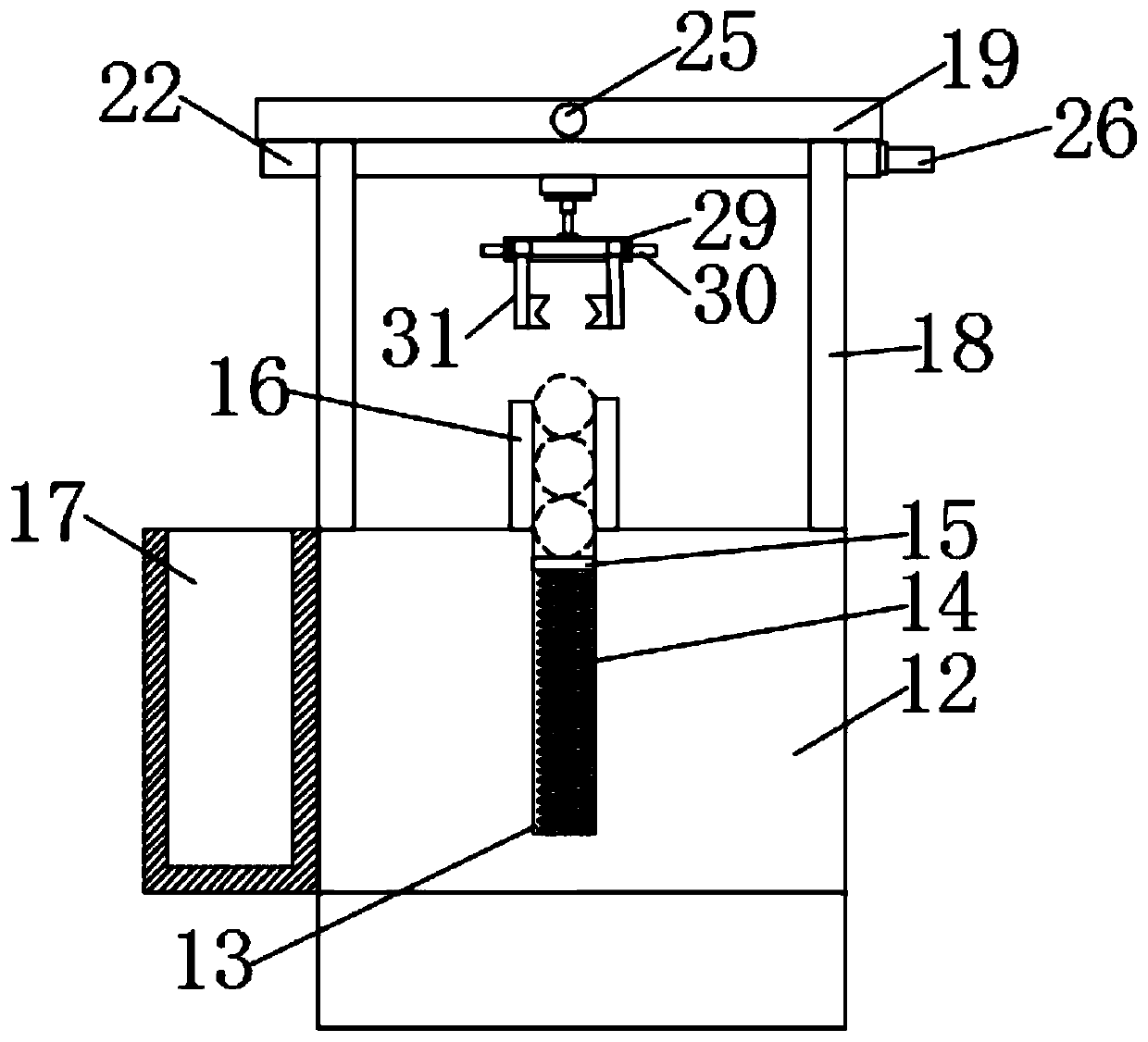

[0026] like Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a pressing device for pipe material connection, including a pressing mechanism 1, a feeding mechanism 2 and a fixed base 3, and one end of the top of the fixed base 3 is provided with a feeding material Mechanism 2, the end of the top of the fixed base 3 away from the feeding mechanism 2 is provided with a clamping mechanism 1, and the clamping mechanism 1 consists of a fixed table 4, a fixed block 5, a feeding cylinder 6, a feeding push block 7, and a material storage mechanism. The chute 8, the clamping ring 9, the hydraulic cylinder 10 and the clamping block 11 are composed, one end of the top of the fixed base 3 is fixedly connected with a fixed table 4, and one end of the top of the fixed table 4 is fixedly connected with a fixed block 5, and The other end of the top of the fixing table 4 is fixedly connected with a material storage chute 8 , the side of the fixing block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com