Heavy manipulator device for production line machining

An assembly line and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, metal processing, etc., can solve problems such as threats to the safety of workers around them, difficulties in processing high-quality parts, etc., and achieve practical functions, improve work efficiency, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

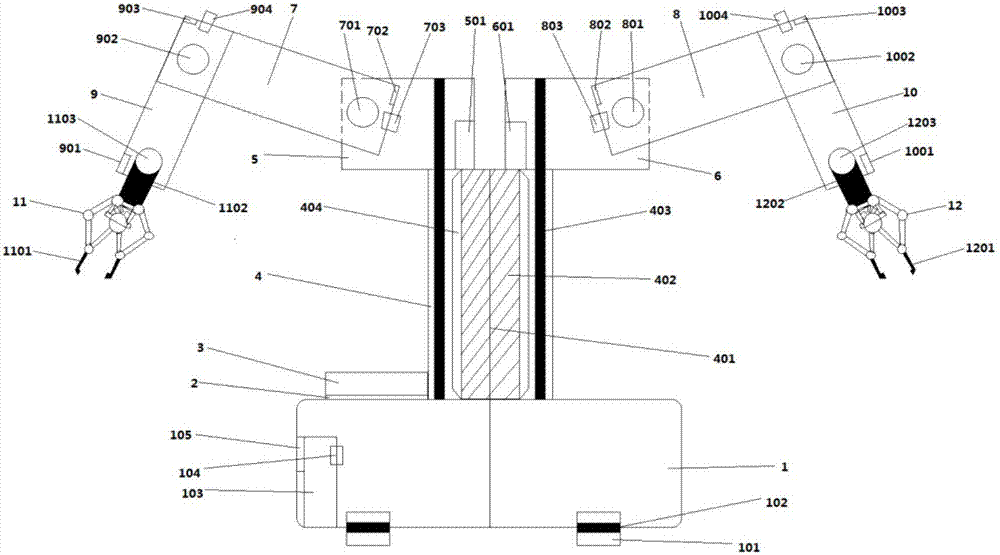

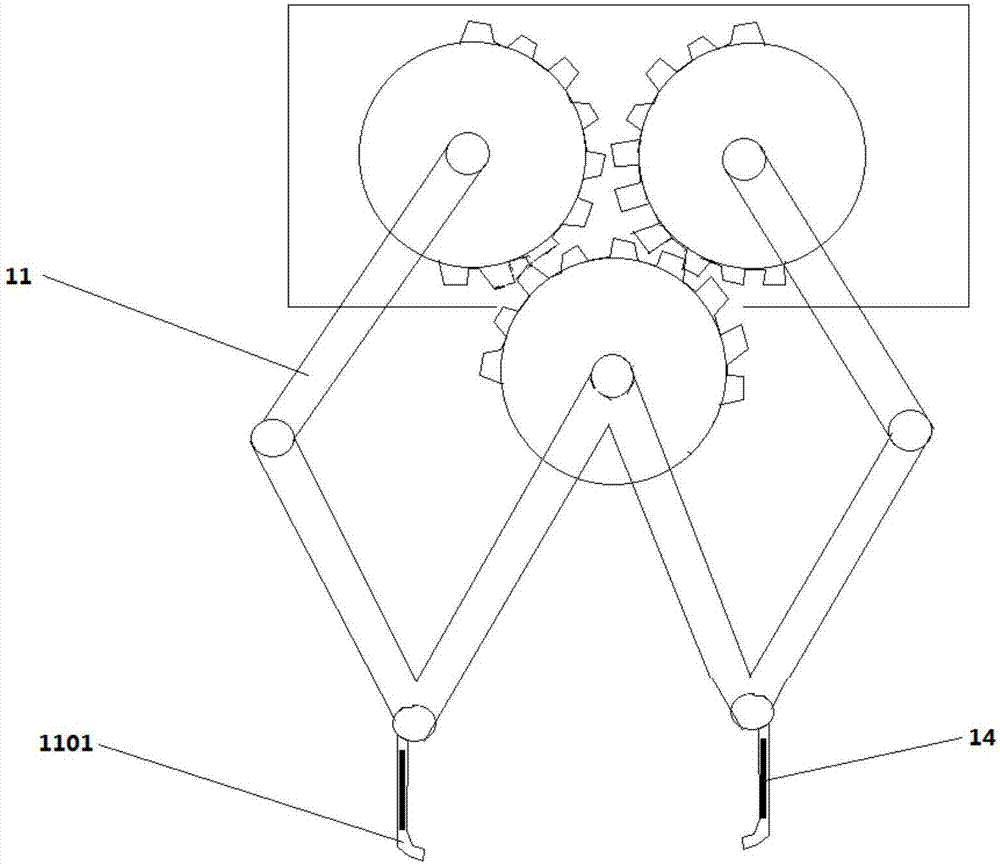

[0027] Example: such as figure 1 As shown, a heavy-duty manipulator device for assembly line processing mainly includes: base 1, drive motor mounting plate 2, drive motor 3, column 4, left arm seat 5, right arm seat 6, left arm 7, right arm Arm 8, left forearm 9, right forearm 10, left parallel claw 11, right parallel claw 12.

[0028] Such as figure 1 As shown, the driving motor mounting plate 2 is located on the upper surface of the base 1, and the driving motor 3 is installed on the driving motor mounting plate 2. The base 1 also includes: supporting wheels 101, supporting wheel bearings 102, host 103, magnetic tape 104, and screen 105 , the supporting wheel bearing 102 is located at the bottom of the base 1 and passes through the supporting wheel 101, the host 103 is installed inside the base 1, the magnetic tape 104 is installed on the host 103, the screen 105 is connected to the host 103 and is located on the outer surface of the base side superior.

[0029] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com