Shifter assembling device

A technology for assembling equipment and shifters, applied in metal processing equipment, metal processing, hand-held tools, etc., can solve problems such as safety hazards, bushing deviation, missing bushings, etc., to reduce accidents and prevent missing installations Bushing, enhance the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

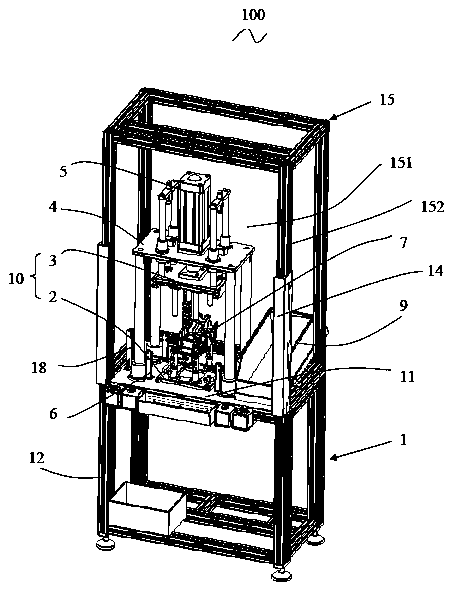

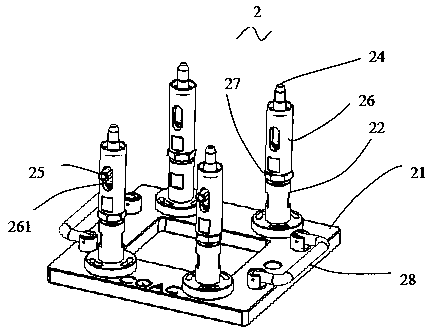

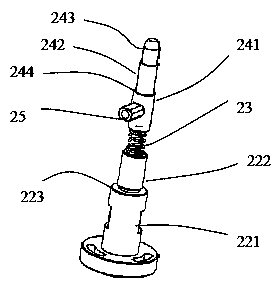

[0025] See Figure 1 to Figure 9 , the shifter assembly device 100 in an embodiment of the present invention is used to press-fit the bushing 8 into the workpiece 7 . The shifter assembly equipment 100 includes a frame 1, a clamp set 10 arranged on the frame 1 and a trip frame 4, a driving device 5 arranged on the trip frame 4, and a bushing arranged on the frame 1 for accommodating the bushing 8 The sleeve receiving device 9, the leakage detection device 6 used to detect whether the bushing 8 is missing, and the workpiece detection device 18 arranged on one side of the clamp group 10 to detect whether the workpiece 7 is installed. The clamp set 10 includes an upper clamp 3 fixed on the trip frame 4 and a lower clamp 2 opposite to the upper clamp 3 and located below the upper clamp 3 . The driving device 5 is used to drive the upper clamp 3 to move up and down. The lower fixture 2 is used to fix the workpiece 7 and the bushing 8 , and the upper fixture 3 is driven down by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com