Shifter assembling device

A technology for assembling equipment and shifters, which is applied to metal processing equipment, instruments, measuring devices, etc. It can solve the problems of difficult work and the inability of the bush to be pressed into the workpiece, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

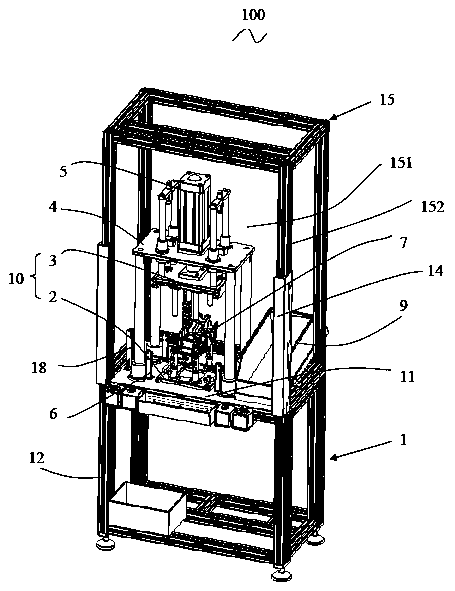

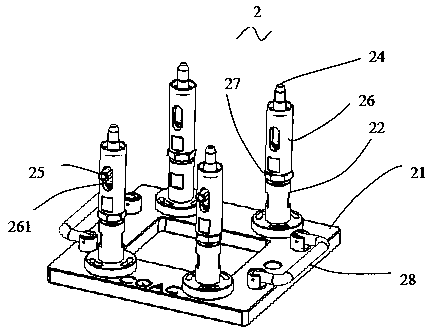

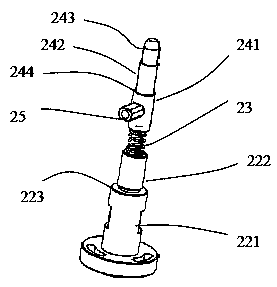

[0023] See Figure 1 to Figure 9 , the shifter assembly device 100 in an embodiment of the present invention is used to press-fit the bushing 8 into the workpiece 7 . The shifter assembly equipment 100 includes a frame 1, a clamp set 10 arranged on the frame 1 and a trip frame 4, a driving device 5 arranged on the trip frame 4, and a bushing arranged on the frame 1 for accommodating the bushing 8 The sleeve receiving device 9, the leakage detection device 6 used to detect whether the bushing 8 is missing, and the workpiece detection device 18 arranged on one side of the clamp group 10 to detect whether the workpiece 7 is installed. The clamp set 10 includes an upper clamp 3 fixed on the trip frame 4 and a lower clamp 2 opposite to the upper clamp 3 and located below the upper clamp 3 . The driving device 5 is used to drive the upper clamp 3 to move up and down. The lower fixture 2 is used to fix the workpiece 7 and the bushing 8 , and the upper fixture 3 is driven down by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com