High-speed robot for production assembly line system

A production line and robot technology, applied in the field of robots, can solve problems such as the need to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

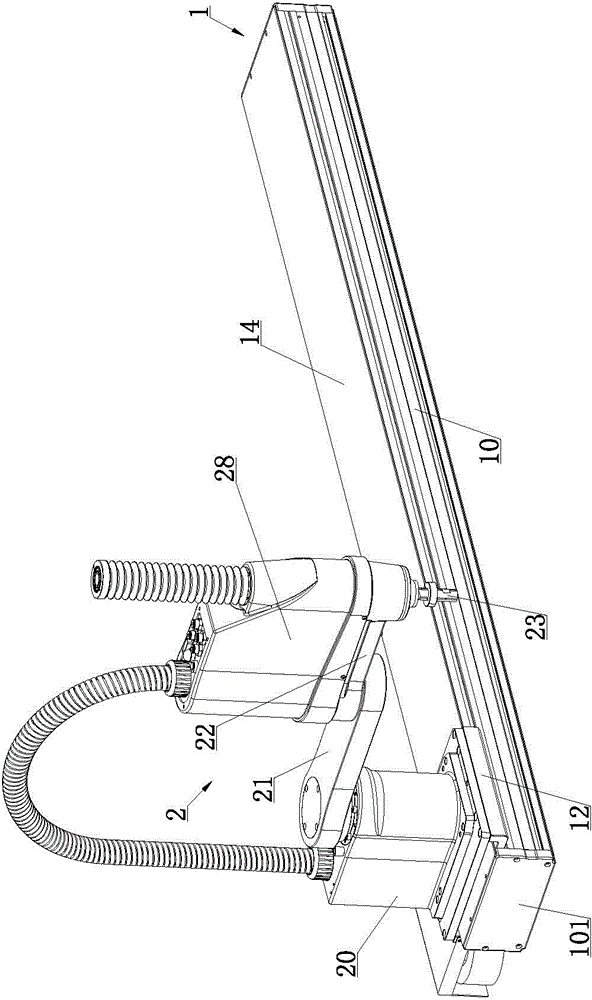

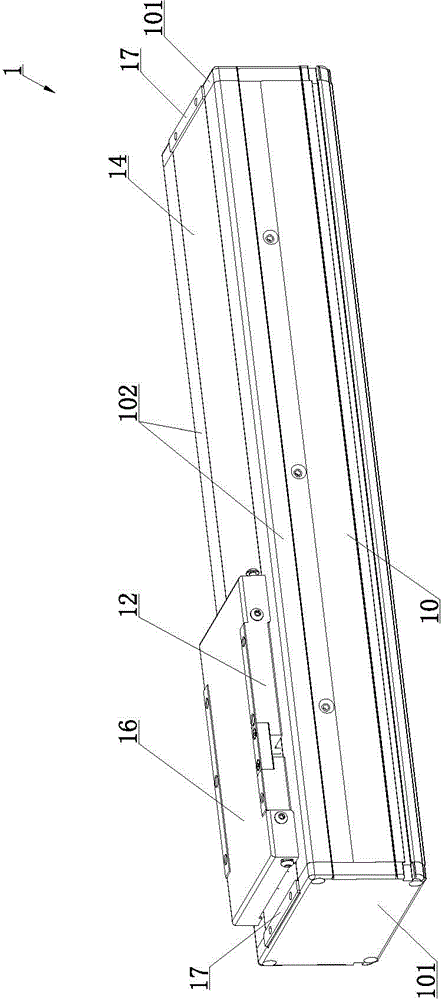

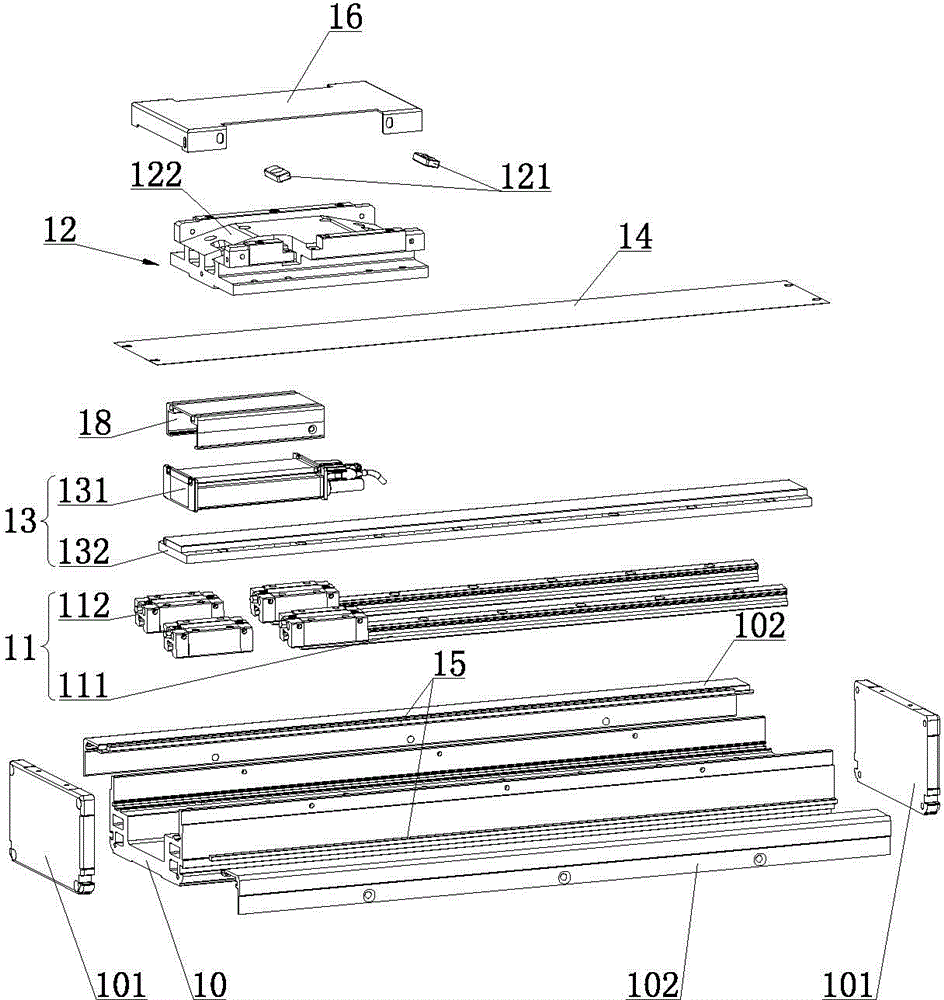

Embodiment 1

[0042] Such as Figure 1 to Figure 8 As shown, the high-speed robot of the production line system of the present invention includes a single-axis manipulator 1. The single-axis manipulator 1 includes a base 10, a linear slide 11, and a work slide 12. The end of the base 10 is provided with an end cover 101, and the base 10 A side cover 102 is provided on the side, the guide rails 111 of the linear slide rail 11 are fixedly installed on both sides of the base 10, the work slide 12 is connected with the slider 121 of the linear slide 11, and the base 10 is provided with a work slide for driving the work slide 12 moving linear motor 13, a four-axis manipulator 2 is arranged above the work slide 12, the four-axis manipulator 2 includes a base 10, a first cantilever 21, a second cantilever 22, and a screw rod 23, the base 10 and the work slide 12 is fixedly connected, the base 10 is equipped with a first rotation driving device 24, the first end of the first cantilever 21 is located ...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the reducer 251 is a harmonic reducer; the harmonic reducer has high load carrying capacity, large transmission ratio, small size, light weight, high transmission efficiency and long life. The advantages of smooth transmission, no impact, no noise, and high motion accuracy; ensuring the first rotation driving device 24 to control the rotation of the first cantilever 21 and the second rotation driving device 25 to control the rotation of the second cantilever 22 better.

[0059] The rest of this embodiment is the same as the first embodiment, and the unexplained features in this embodiment adopt the explanation of the first embodiment, and will not be repeated here.

[0060] In summary, it can be seen that the present invention has the above-mentioned excellent characteristics, so that it can improve the efficiency and practicability that is not available in the prior art in use, and become a product of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com