Intelligent clamping device of numerically controlled machine tool

A clamping device, CNC lathe technology, applied in positioning device, clamping, metal processing mechanical parts, etc., can solve the problems of high manufacturing cost, low work efficiency, laborious operation, etc., and achieve low manufacturing cost and realize automatic work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

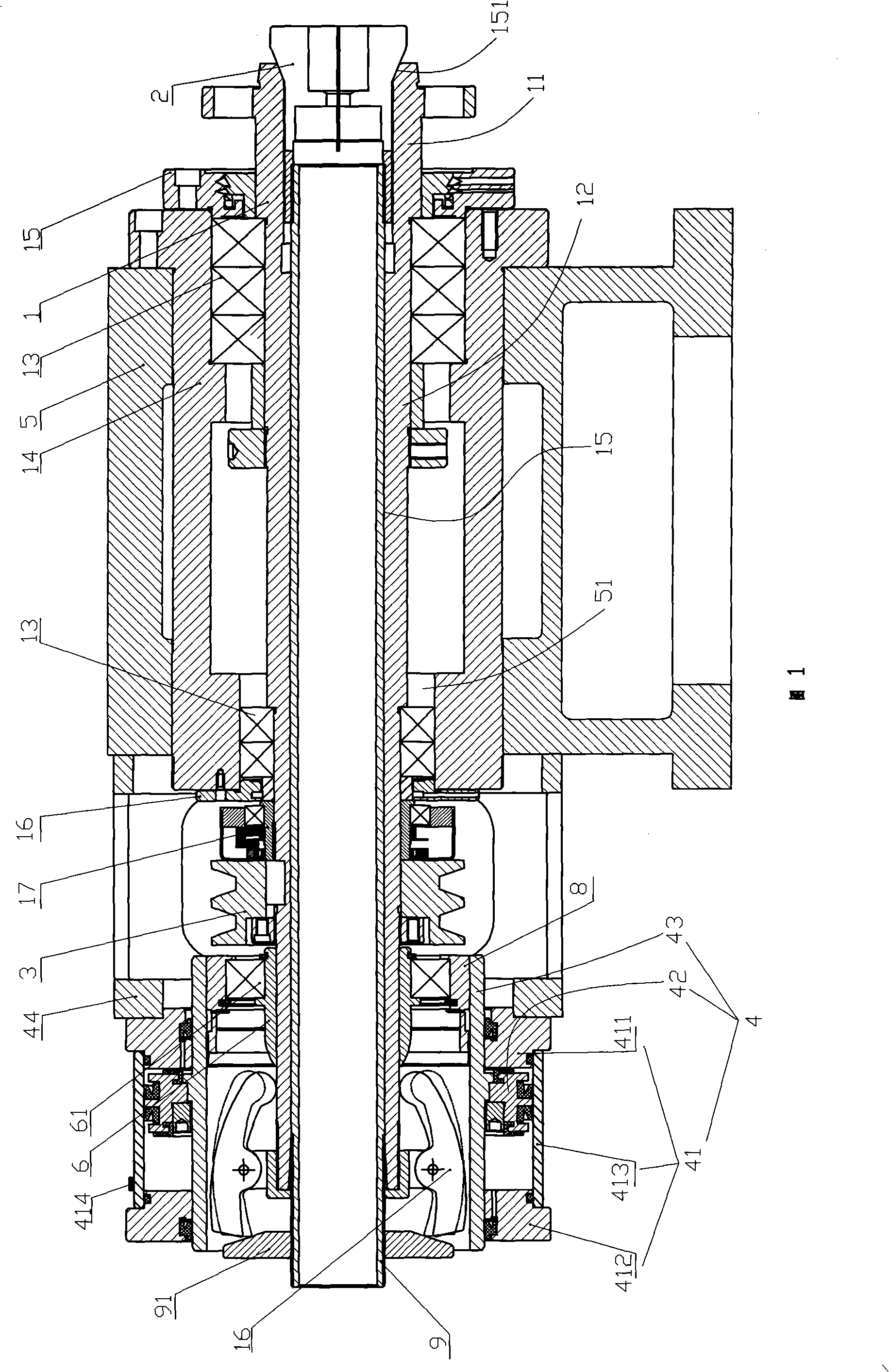

[0015] As shown in Figures 1 and 2, it is an intelligent clamping device for a CNC lathe. The entire clamping device includes a hollow rotating spindle 1, a chuck 2 for clamping a workpiece, a pulley 3 connected to a power motor, and a piston. Cylinder 4.

[0016] The rotating spindle 1 includes a head 11 and a trunk 12, wherein the front section of the trunk 12 is flexibly connected to a spindle sleeve 14 through several rolling bearings 13 and is positioned in the mounting hole 51 of the head of the bed 5, while the rotating spindle head 11 is The installation hole 51 protruding from the head of the bed, here, in order to ensure the lubrication of the movable connection between the main shaft body 12 and the main shaft sleeve 14, the main shaft front cover 15 and the Main shaft back cover 16 realizes oil seal. The said pulley 3 is installed in the middle part of the main shaft body part 12, and the pulley 3 is connected to the power motor by a belt, and is used to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com