Fastening member assembling machine capable of automatically controlling various torque values

A technology for assembling machines and fasteners, which is used in manufacturing tools, metal processing, metal processing equipment, etc. It can solve the problems of inability to record detection data in real time, low bolt tightening accuracy, etc., to reduce the number, wide application range, The effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

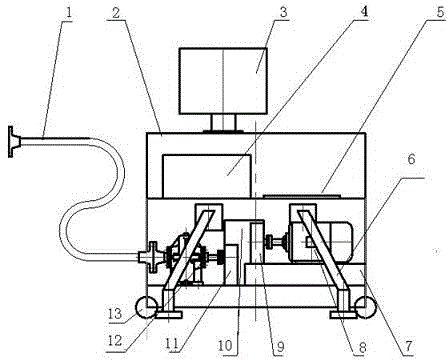

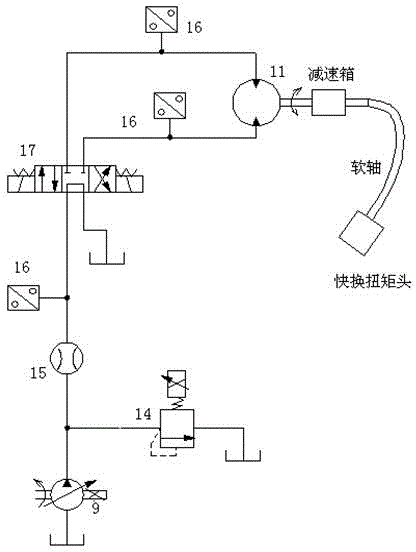

[0018] The fastener assembly machine that automatically controls various torque values adopts a mobile structure. The fastener assembly machine can be divided into three parts: mechanical part, hydraulic part and control part. The hydraulic part and the control part are fixed on the mechanical part through a certain shock absorption method, and are pushed to various working positions with the mechanical part. Considering the size of the bolts used by most equipment, and considering the utilization rate and economy of the equipment, it is determined that the bolts with torque requirements less than 600Nm shall be fastened by hydraulic drive, and the bolts with torque requirements above 600Nm shall be fastened by electric drive. . For some occasions that need to be used for specific equipment, the tightening range of hydraulic and electric drives can be adjusted according to the size of the equipment bolts. The tightening torque values of all bolts can be preset before the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com