Improved unilateral bolt fastener convenient to assemble and disassemble

A unilateral bolt, convenient disassembly and assembly technology, applied in the direction of threaded fasteners, locking fasteners, bolts, etc., can solve the problems of inability to install, the fastening effect cannot meet the design requirements, and the tedious installation steps, etc., to achieve convenient The effect of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

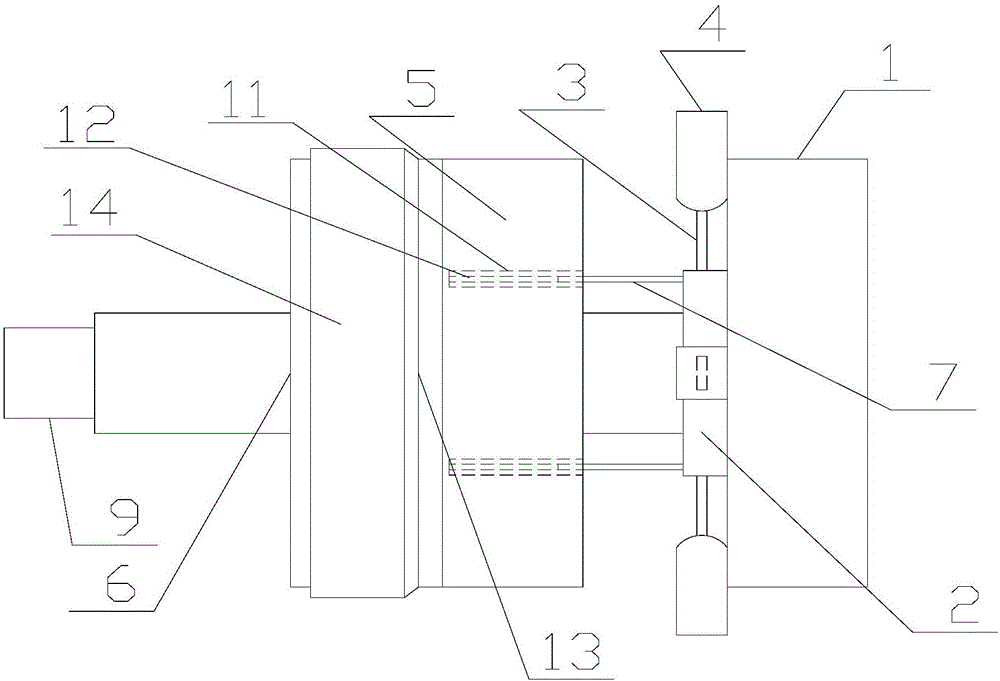

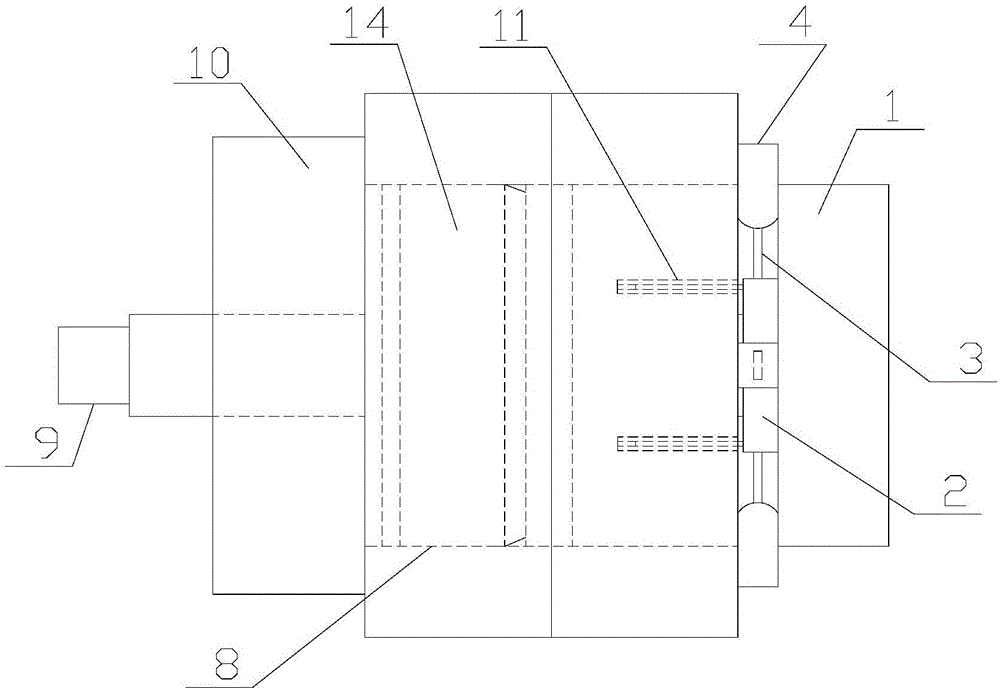

[0014] refer to figure 1 , 2 , the present invention is an improved unilateral bolt fastener that is easy to assemble and disassemble, including round head bolts 1, ring sleeves 2, several elastic bodies 3, several blocking bodies 4, compression sleeves 5, fastening bodies 6, and several rod bodies 7 , a number of slots 11, a number of rubber sleeves 12, an annular groove 13 and an annular rubber body 14, and the rod body of the round head bolt 1 is set with a threaded fastening body 6 and a slidable pressing body in turn from front to back. The tight sleeve 5 and the slidable ring sleeve 2, the fastening body 6 and the compression sleeve 5 are rotatably connected together, the fastening body 6 is provided with an annular groove 13, and the annular groove 13 is provided with a ring shaped rubber body 14, the outer diameter of the annular rubber body 14 is greater than the outer diameter of the fastening body 6, the front end of the ring sleeve 2 is provided with a rod body 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com