Screw fastening device for probe card

A screw fastening and probe card technology, which is applied in the field of probe card production, can solve the problems of shutting down the screw fastening device for probe cards, reducing the production efficiency of probe cards, and increasing the workload of staff, and achieves The effect of expanding the use of space, reducing the workload, and improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] In some preferred embodiments, the preparation method of the rubber layer of the metal-rubber composite sealing plate includes the following steps:

[0064] (1) Add N,N-nickel di-n-butyl dithiocarbamate, calcium oxide, white carbon black, calcined kaolin, silane coupling agent, zinc stearate, petroleum wax, ethyl acetate into the mixer, and Mix at 80-90°C to obtain a mixed slurry;

[0065] (2) adding nitrile rubber and carbon fiber into the internal mixer for internal mixing for 40-60 minutes, then raising the temperature to 100-120°C for debinding to obtain mixed colloids;

[0066] (3) Add sulfur to step (2), knead on a two-roller mill, add sulfur, mix well, then add twin-screw extruder for granulation, put the obtained rubber masterbatch into a vulcanizer for vulcanization For molding, the vulcanization pressure is set at 12-14MPa, the vulcanization temperature is set at 120-135°C, and the vulcanization time is set at 60-80 minutes.

[0067] In some preferred embodi...

Embodiment 1

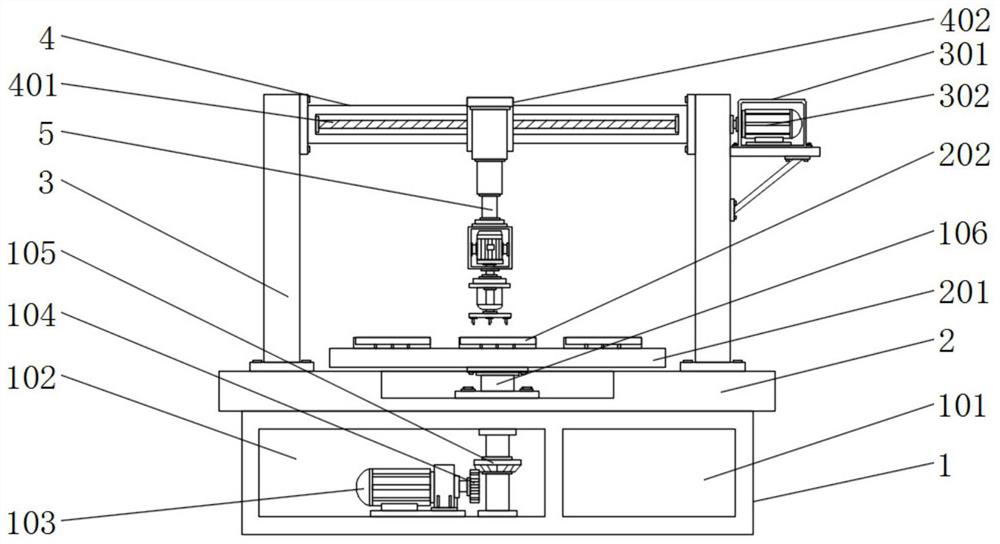

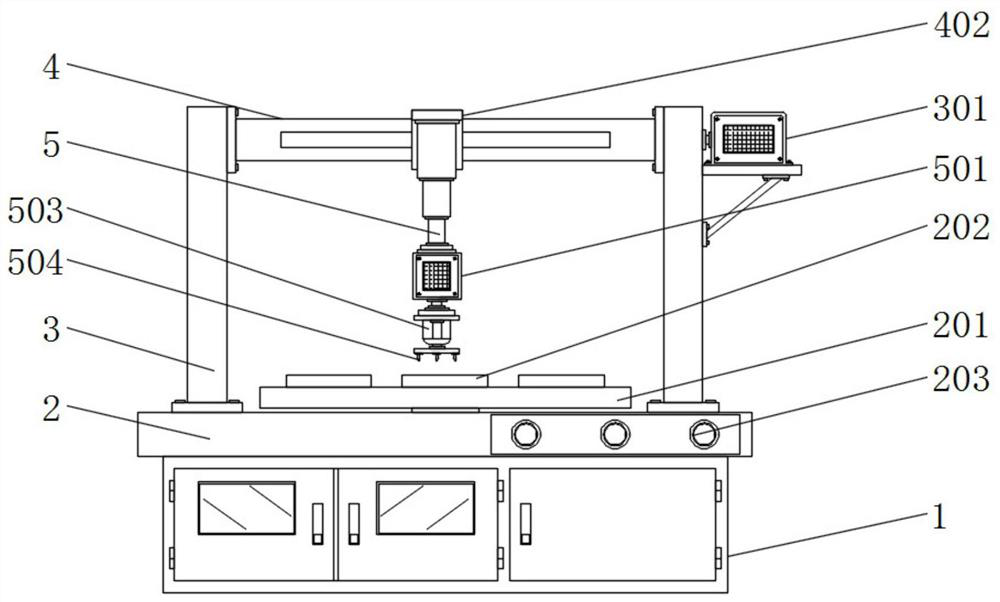

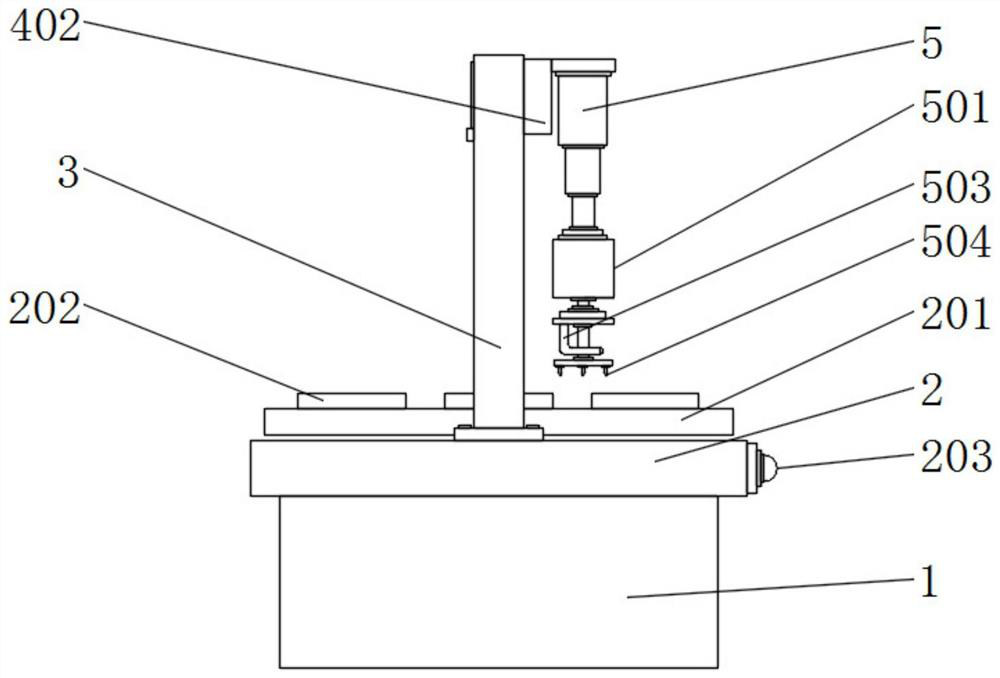

[0080] see Figure 1-4 , an embodiment provided by the present invention: a screw fastening device for probe cards, including a support cabinet 1, a work surface 2, a support rod 3, a cross bar 4 and a hydraulic telescopic rod 5, and the inside of the support cabinet 1 A storage room 101 and an installation room 102 are provided. Through the storage room 101, the parts related to the operation can be stored, which is convenient for the staff to take during the operation, expands the space use range of the device, and supports the movable installation of the front of the cabinet 1. There is a movable protective door, and the movable protective door is equipped with a cooperating observation window;

[0081]The inside of the installation chamber 102 is placed with a first motor 103, the output end of the first motor 103 is rotatably connected with a transverse gear 105 through a longitudinal gear 104, and a rotating shaft 106 extending into the worktable 2 is installed through t...

Embodiment 2

[0086] A screw fastening device for probe cards, the structure of which is the same as that of Embodiment 1. The difference from Embodiment 1 is that the front sealing plates of the second motor housing 301 and the third motor housing 501 are made of metal-rubber composite sealing plates.

[0087] A raw material for preparing a rubber layer material for a metal-rubber composite sealing plate, comprising: 90 parts of nitrile rubber, 0.5 parts of N,N-nickel di-n-butyldithiocarbamate, 2 parts of calcium oxide, and gas phase 0.9 parts of French silica, 0.18 parts of calcined kaolin, 1.4 parts of γ-methacryloxypropyl trimethoxysilane, 3.2 parts of carbon fiber, 0.2 parts of zinc stearate, 2 parts of petroleum wax, 2.5 parts of sulfur, acetic acid 150 parts of ethyl ester.

[0088] The weight ratio of fumed white carbon black to calcined kaolin is 1:0.2.

[0089] The mesh number of the calcined kaolin is 1250 mesh.

[0090] The weight ratio of carbon fibers with an average length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com