Independently constructed benefication complete equipment for annually producing bauxite with 200,000 tons

A complete set of equipment, bauxite technology, applied in flotation, solid separation, grain processing, etc., can solve the problems of water system not self-contained, low harvesting capacity, high construction cost, etc., to achieve scientific and reasonable structural design, Improve beneficiation efficiency and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

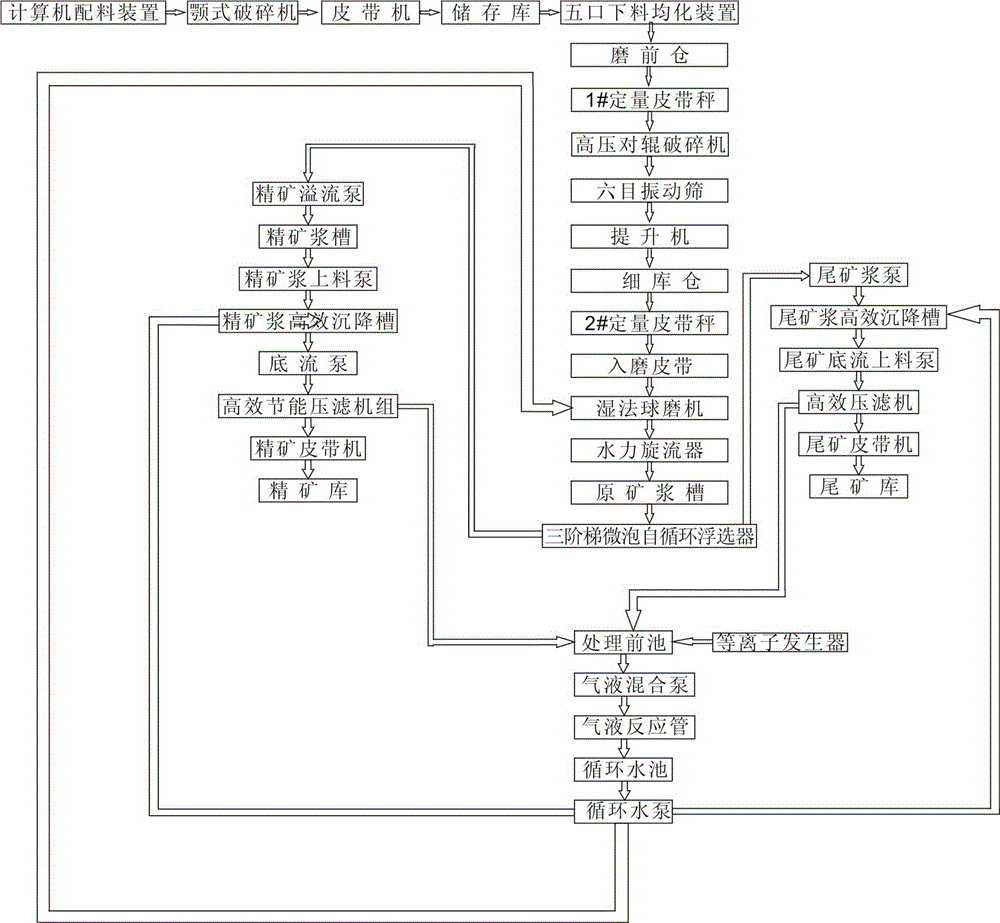

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment: figure 1 As shown, a complete set of bauxite beneficiation equipment with an annual output of 200,000 tons is constructed separately, which is composed of a material homogenization system, a grinding system, a flotation system, a concentrate discharge system, a tailings discharge system, water treatment and The composition of the circulatory system.

[0037] The material homogenization system is composed of a computer batching device, a jaw crusher, a belt conveyor, a storage warehouse, and a five-port material homogenization device connected in sequence. After the ore is sampled and tested, the computer batches it, and after being crushed by the jaw crusher, it is transported into the storage warehouse by the belt conveyor for storage and stacking. When it is used, it is discharged into the next process through the five-port homogenization system.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com