Dust removal ash conveying device and method for blast furnace

A blast furnace dust removal and conveying device technology, which is applied in conveying bulk materials, blast furnaces, conveyors, etc., can solve the problems of large power consumption, complex structure, and many failure points, and achieves recycling, high efficiency in conveying ash, and high operational efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

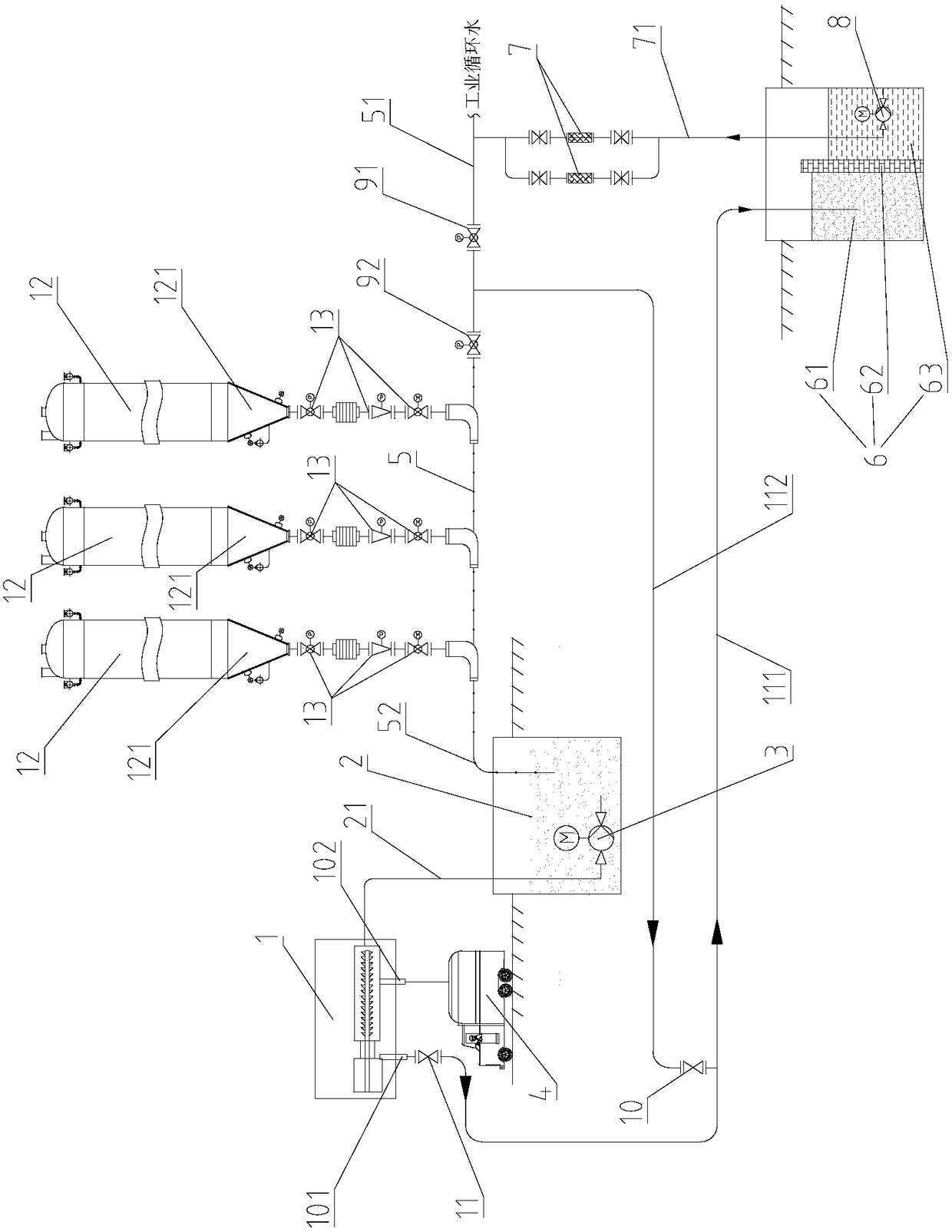

[0036] Such as figure 1 As shown, the present invention provides a blast furnace dust removal ash delivery device, comprising: a plurality of dust collectors 12 connected in parallel on an ash delivery pipeline 5, the first end 51 of the ash delivery pipeline 5 is connected with an industrial circulating water pipeline; mud pool 2 , which is connected to the second end 52 of the ash delivery pipeline 5, the first mud pump 3 is provided in the mud pool 2; the mud-water separation mechanism 1 is connected to the first mud pump 3 by the mud delivery pipeline 21, and the mud-water separation mechanism 1 has Water outlet 101 and mud outlet 102; Water recovery mechanism, it comprises settling tank 6 and the second mud pump 8 that is positioned at settling tank 6, settling tank 6 links to each other with the water outlet 101 of muddy-water separation mechanism 1 by outlet pipeline 111, the first The second mud pump 8 is connected with the first end 51 of the ash conveying pipeline 5 ...

Embodiment approach 2

[0048] Such as figure 1 and figure 2 As shown, the present invention also provides a blast furnace dust removal method, which adopts the blast furnace dust removal device of the first embodiment. The working principle and beneficial effect of the blast furnace dust removal device are the same as those of the first embodiment, and are not repeated here repeat. The blast furnace dedusting ash conveying method comprises the following steps:

[0049] Step A, ash conveying: convey the collected furnace ash to the ash conveying pipeline 5 through a plurality of dust collectors 12, and then convey the furnace ash in the ash conveying pipeline 5 through the industrial circulating water in the industrial circulating water pipeline to In the mud pool 2, furnace ash and industrial circulating water are mixed in the mud pool 2 to form mud. The blast furnace dust removal method of the present invention uses industrial circulating water to transport the furnace ash, does not need to use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com