Cooling device in biomass carbonizing furnace

A technology of cooling device and carbonization furnace, which is applied in the direction of biofuel, coke oven, special form of dry distillation, etc. It can solve the problems of complex structure, unsatisfactory cooling effect, and inability to effectively save energy, so as to achieve good cooling effect and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

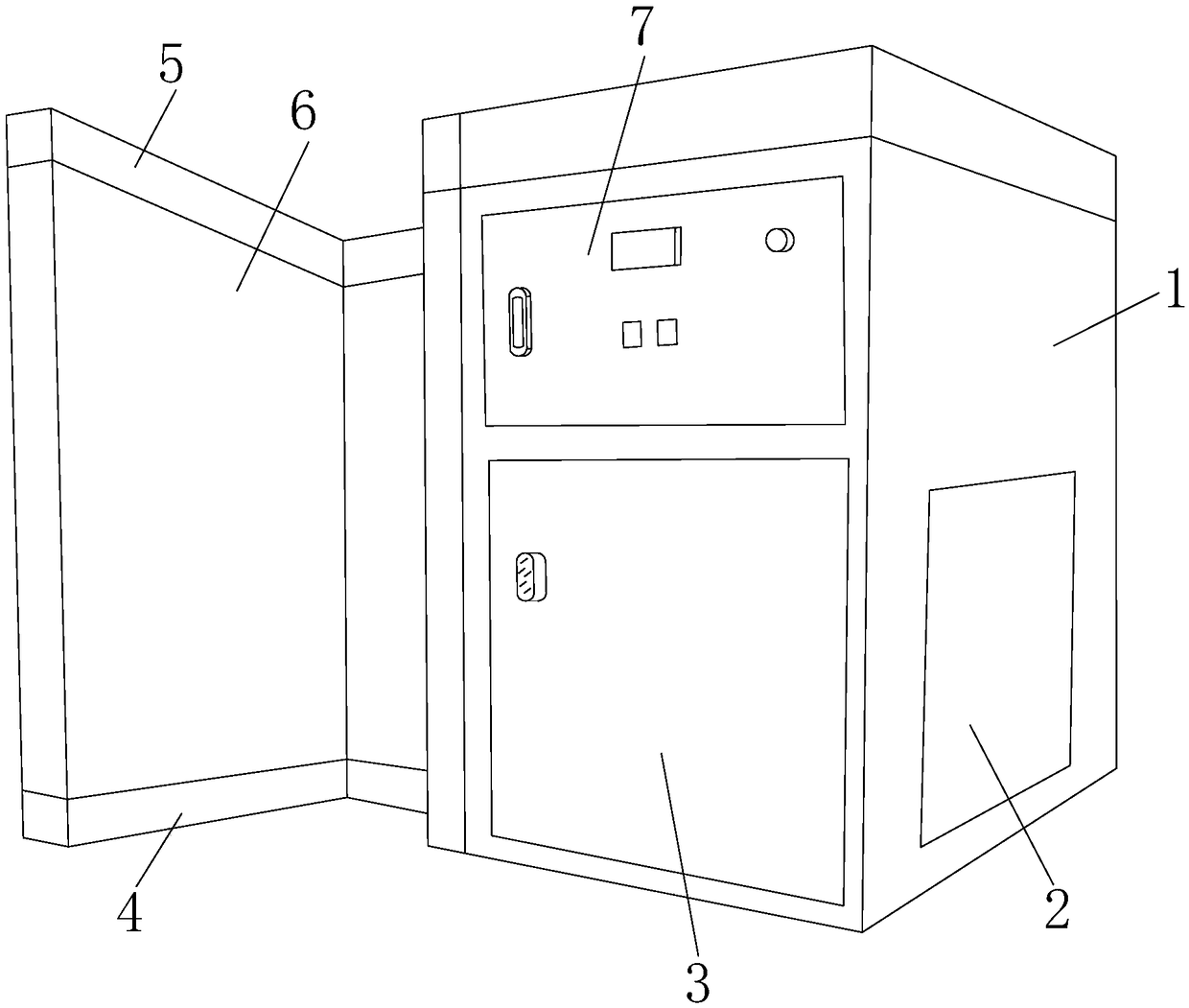

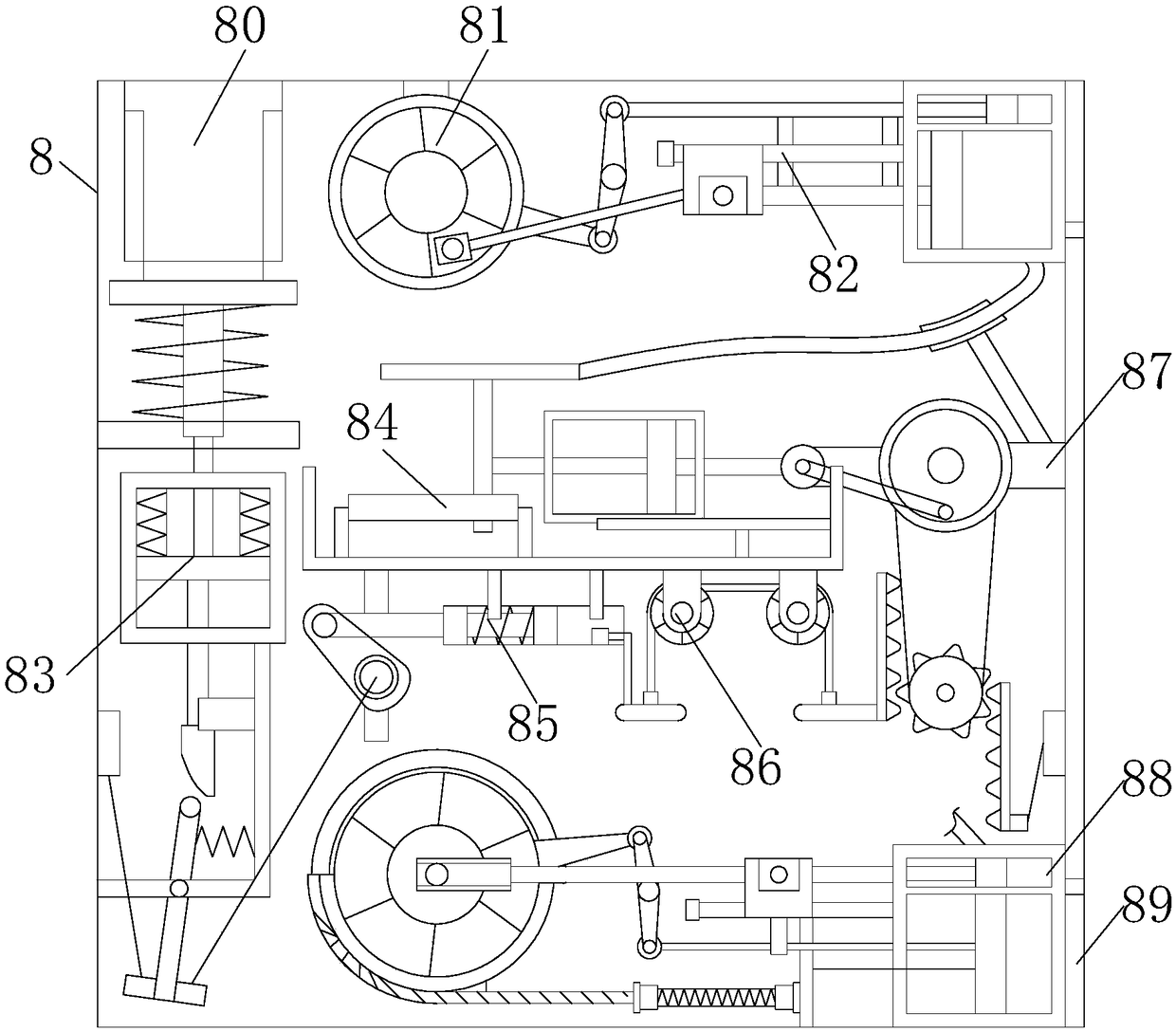

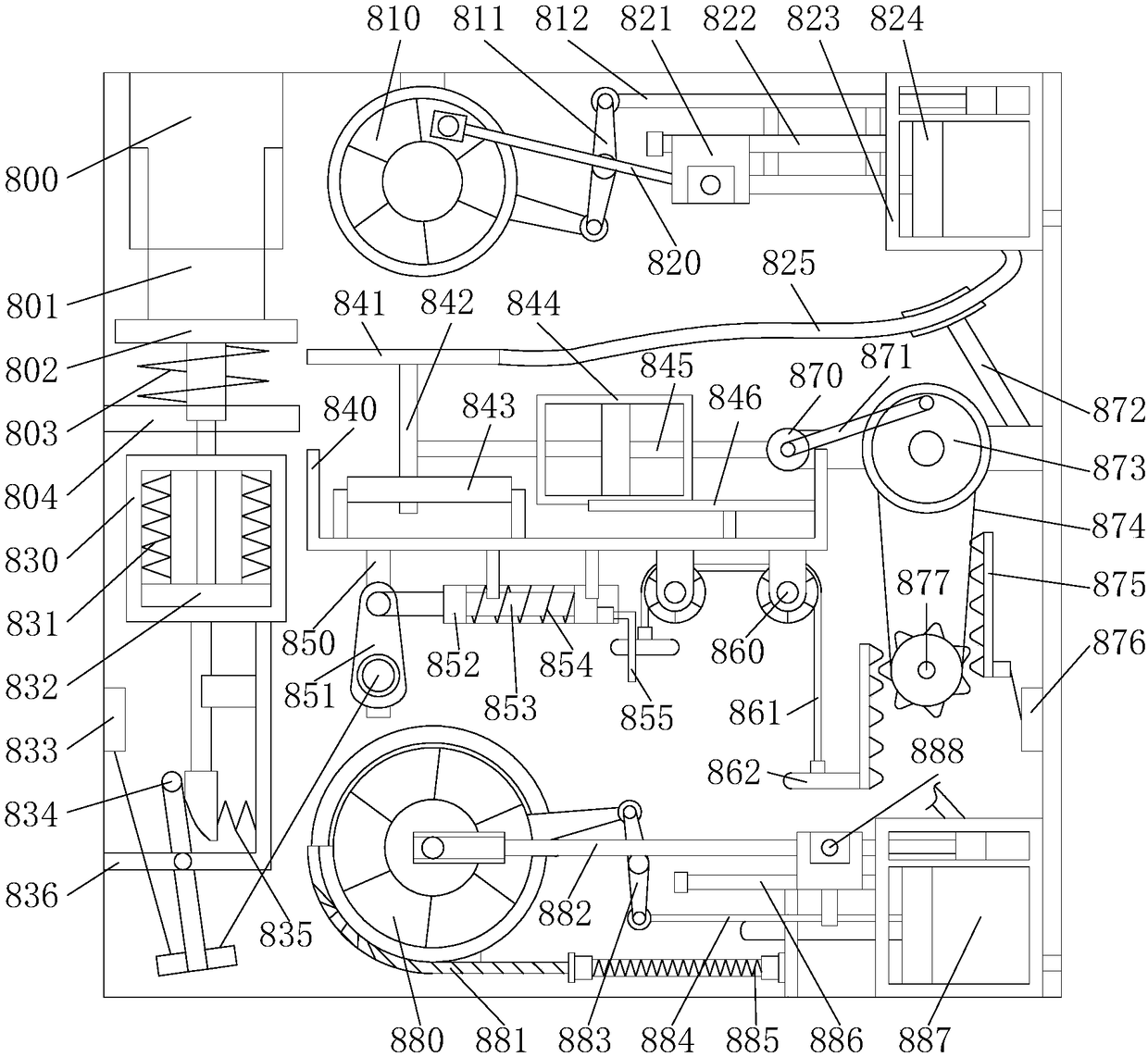

[0025] see Figure 1-Figure 3 , the present invention provides a cooling device in a biomass carbonization furnace: its structure includes an integrated heat dissipation box 1, a radiator 2, a storage bin 3, a cooling frame bottom groove 4, a cooling frame upper cover 5, a cooling frame 6, and a control panel 7 , the internal cooling device 8, the integrated cooling box 1 is equipped with a radiator 2, the storage bin 3 and the control panel 7 form an upper and lower structure, and the storage bin 3 and the control panel 7 are respectively embedded in the integrated cooling box 1 , the cooling frame 6 is a U-shaped structure, the cooling frame 6 is connected with the integrated cooling box 1, the two form an integrated structure, the cooling frame upper cover 5 is nested on the upper end of the cooling frame 6, the The cooling frame bottom groove 4 is installed at the bottom of the cooling frame 6, the cooling frame bottom groove 4, the cooling frame upper cover 5, and the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com