Full-automatic fruit and vegetable feeding and washing device

A cleaning device and automatic feeding technology, which is applied in application, food processing, food science, etc., can solve the problems of difficult cleaning of floating dust and pesticide residues on the surface of fruits and vegetables, decline in product quality, and low cleaning efficiency, so as to improve production efficiency and The effect of product quality, prevention of damage, and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

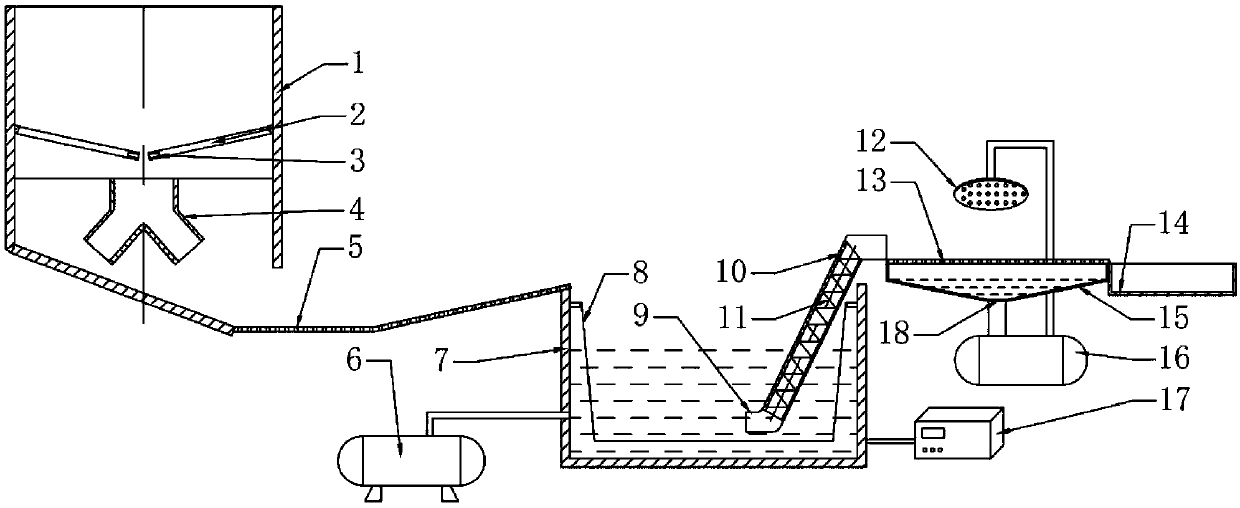

[0023] Combine below figure 1 The present invention will be described in detail.

[0024] A fully automatic fruit and vegetable feeding and cleaning device, comprising an automatic feeder 1, a weighing plate 2 is installed in the automatic feeding machine 1, a drop buffer device 4 is arranged below the weighing plate, and the automatic feeding The outlet below the machine 1 is provided with a first conveyor belt 5, and the discharge end of the first conveyor belt 5 is equipped with a decontamination tank 7, which is characterized in that a bottom and a decontamination tank 7 are installed in the decontamination tank 7. There is a raw material basket 8 with a distance at the bottom, an ultrasonic generator 17 is connected to the lower right of the decontamination tank 7, an air pump 6 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com