Industrial aquaculture zero-emission resource recycling and purifying system and purifying process thereof

A resource recovery and purification system technology, applied in the field of agricultural aquaculture sewage treatment, can solve the problems of serious eutrophication, affecting product quality, destroying the ecological environment, etc., achieving the effect of high degree of automation, no need for frequent maintenance, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

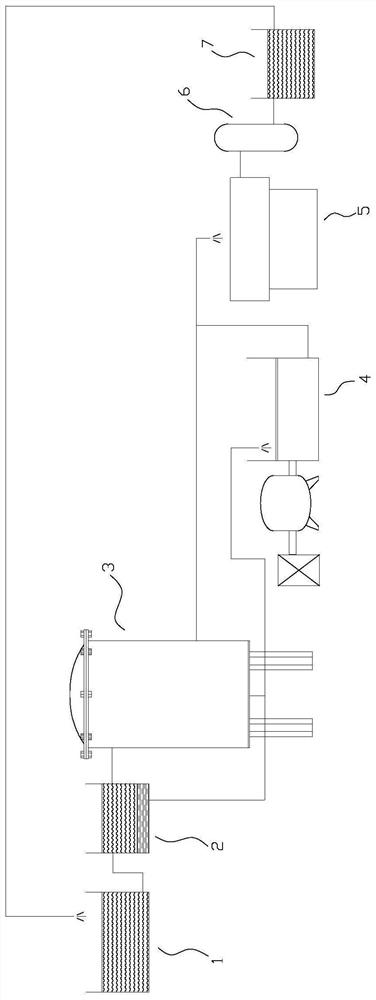

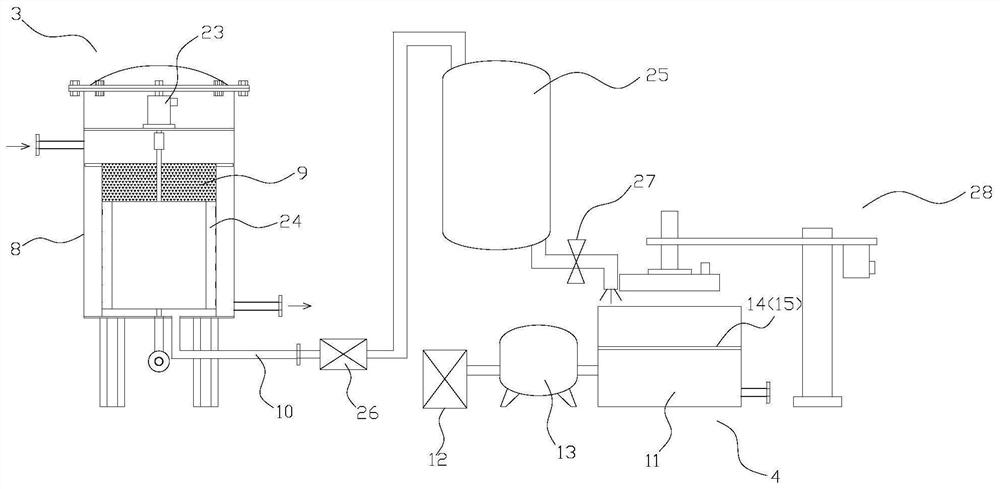

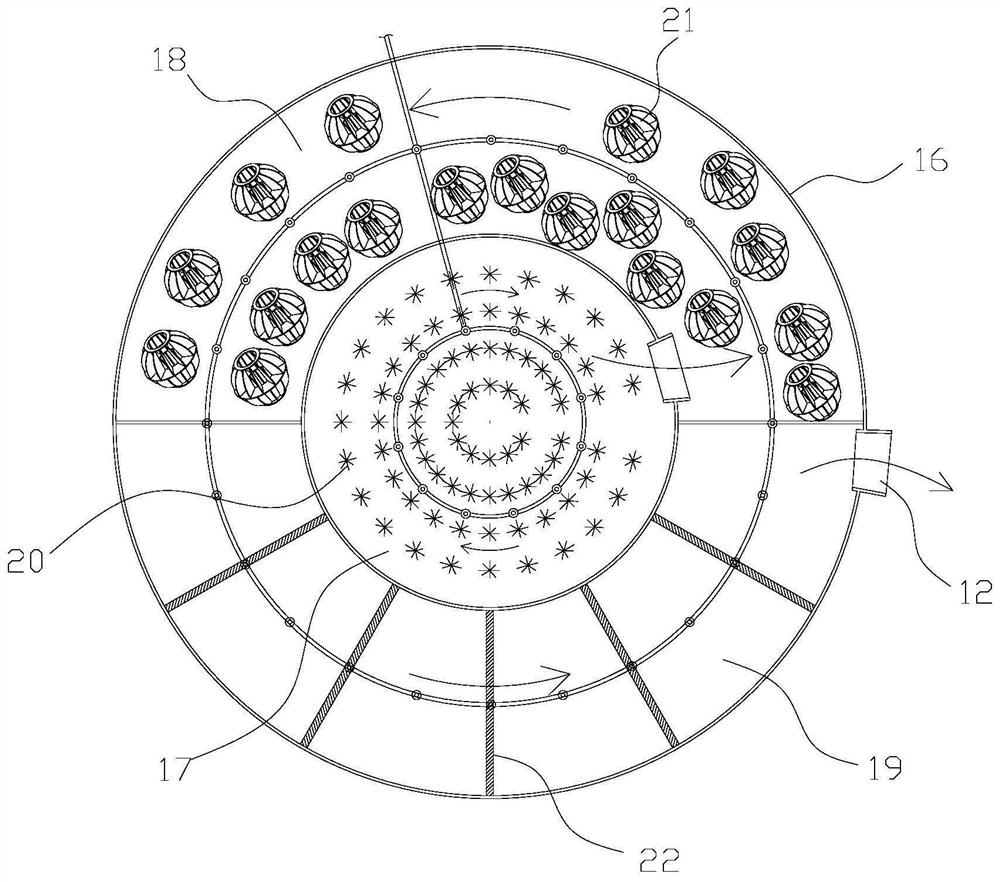

[0058] see Figure 1 to Figure 3, the embodiment of the present invention provides a zero-discharge resource recovery and purification system for industrial farming, including a culture pond 1, a sedimentation adjustment pond 2, a microfiltration device 3, a vacuum filtration device 4, a three-stage biological purification device 5, an ozone ultraviolet reaction Device 6, clear water tank 7; The water inlet of sedimentation adjustment tank 2 is connected with the mud discharge port of culture pond 1; The water inlet of microfiltration device 3 is connected with the outlet of sedimentation adjustment tank 2; It is connected with the concentrated liquid outlet 10 of the microfiltration device 3 and the sedimentation liquid outlet of the sedimentation adjustment tank 2; the water inlet of the three-stage biological purification device 5 is connected with the water outlet of the microfiltration device 3 and the vacuum suction filtration device 4; the ozone ultraviolet The reactor ...

Embodiment 2

[0078] see Figure 5 , this embodiment discloses a purification process using the purification system described in Embodiment 1, comprising the following steps:

[0079] 1) The fish feces and feed residues in the breeding pond 1 are collected and sent to the sedimentation adjustment tank 2 through the mud discharge port for sedimentation treatment; the sedimentation treatment is not limited to advection sedimentation, or the process of using chemical precipitation;

[0080] 2) The supernatant liquid above the sedimentation tank, which is partially dissolved with fish feces and feed residue, is input into the microfiltration device 3;

[0081] 3) The concentrated solution below the sedimentation tank is input into the vacuum filtration device 4 through the outlet of the sedimentation solution; the concentrated solution intercepted by the microfiltration device 3 is input into the vacuum filtration device 4 through the concentrated solution outlet 10;

[0082] 4) The filtrate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com