Industrial wastewater treatment system and application thereof

A technology for industrial wastewater and treatment system, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., and can solve the problems of difficult treatment of catalytic cracking flue gas desulfurization wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

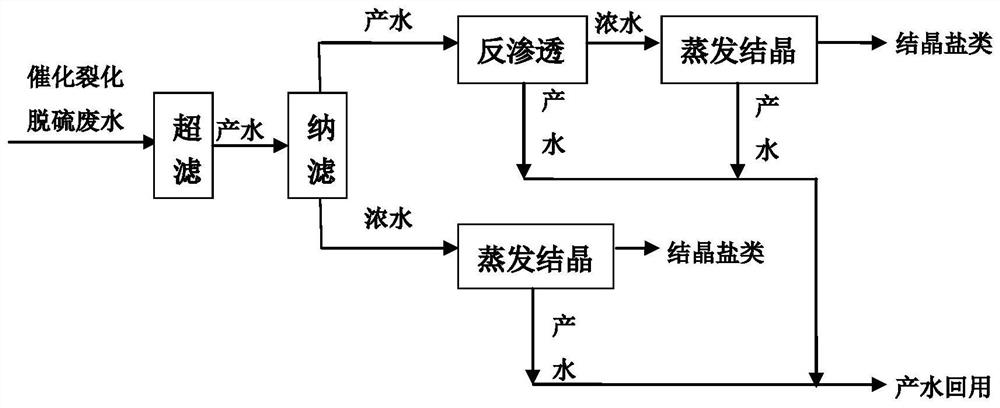

Image

Examples

Embodiment 1

[0048] In this example, the main water quality characteristics of the treated catalytic cracking flue gas desulfurization wastewater are: pH 7.5, influent conductivity 10000 μS / cm, COD 25 mg / L, total nitrogen 20 mg / L, and suspended solids 100 mg / L , oil content 1mg / L, Cl - Concentration 20mg / L, SO 4 2- Concentration 6000mg / L, Mg 2+ Concentration 2mg / L, Ca 2+ Concentration 5mg / L, Na + Concentration 3000mg / L, dissolved silicon concentration 5mg / L.

[0049] In this example, the processing system used was:

[0050] Ultrafiltration device using external pressure hollow fiber membrane module;

[0051] A nanofiltration device using a roll-type nanofiltration membrane module connected to an ultrafiltration device;

[0052] The reverse osmosis device and the four-effect evaporation crystallization device of the coiled reverse osmosis membrane module respectively connected with the nanofiltration device; and

[0053] MVR evaporative crystallizer connected with reverse osmosis de...

Embodiment 2

[0062] In this example, the main water quality characteristics of the treated catalytic cracking flue gas desulfurization wastewater are: pH 8.0, influent conductivity 13000 μS / cm, COD 35 mg / L, total nitrogen 30 mg / L, and suspended solids 150 mg / L , oil content 1.5mg / L, Cl - Concentration 30mg / L, SO 4 2- Concentration 6500mg / L, Mg 2+ Concentration 3mg / L, Ca 2+ Concentration 7mg / L, Na + Concentration 3500mg / L, dissolved silicon concentration 6mg / L.

[0063] In this example, the processing system used is the same as that in Example 1.

[0064] Utilize the above-mentioned treatment system to treat the above-mentioned catalytic cracking flue gas desulfurization wastewater, the treatment steps are:

[0065] The catalytic cracking flue gas desulfurization wastewater enters the ultrafiltration device, and the catalytic cracking flue gas desulfurization wastewater is subjected to ultrafiltration treatment under a pressure of 0.1 MPa, thereby removing solid suspended matter and m...

Embodiment 3

[0072] In this example, the main water quality characteristics of the treated catalytic cracking flue gas desulfurization wastewater are: pH 8.5, influent conductivity 15000 μS / cm, COD 45 mg / L, total nitrogen 20 mg / L, and suspended solids 200 mg / L , oil content 2.0mg / L, Cl - Concentration 50mg / L, SO 4 2- Concentration 7000mg / L, Mg 2+ Concentration 5mg / L, Ca 2+ Concentration 10mg / L, Na + Concentration 4000mg / L, dissolved silicon concentration 7mg / L.

[0073] In this example, the processing system used is the same as that in Example 1.

[0074] Utilize the above-mentioned treatment system to treat the above-mentioned catalytic cracking flue gas desulfurization wastewater, the treatment steps are:

[0075]The catalytic cracking flue gas desulfurization wastewater enters the ultrafiltration device, and the catalytic cracking flue gas desulfurization wastewater is subjected to ultrafiltration treatment under a pressure of 0.12 MPa, thereby removing solid suspended matter and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com