A kind of method for preparing hexamethylenediamine intermediate 6-aminocapronitrile by fractional gas phase method

A technology of aminocapronitrile and gas phase method, which is applied in the field of preparing hexamethylenediamine intermediate 6-aminocapronitrile by graded gas phase method, and can solve the problems of high selectivity of 6-aminocapronitrile, high conversion rate of caprolactam, and low molar ratio of caprolactam, etc. problem, to achieve high 6-aminocapronitrile selectivity, high conversion rate of caprolactam, and prolong catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

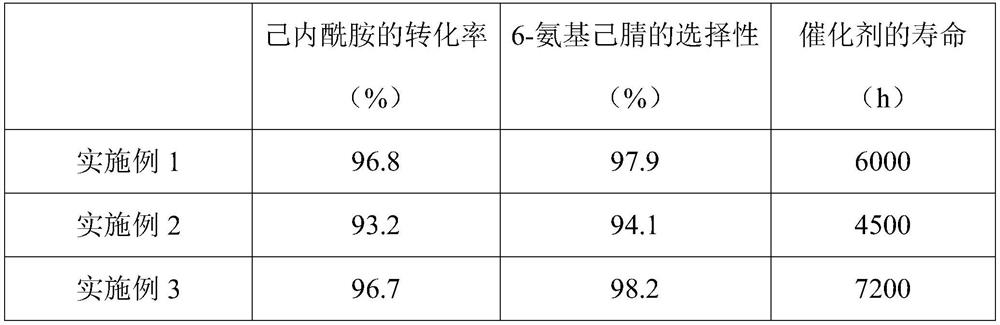

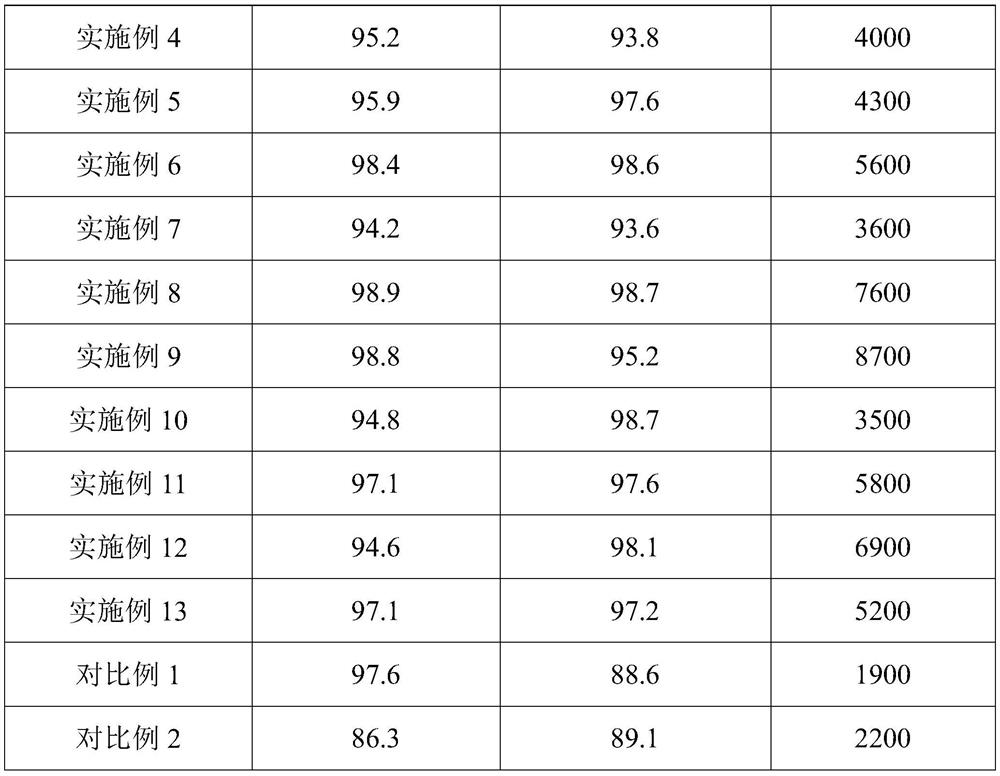

Examples

Embodiment 1

[0062] The present embodiment provides a method for preparing 6-aminocapronitrile by fractional gas-phase method, said method comprising the steps of:

[0063] (1) Ammonia and the first part of caprolactam are mixed and vaporized, and then passed into the first fixed-bed reactor (a total of 4 fixed-bed reactors connected in series, counted as 4 fixed-bed reactors, each fixed-bed reactor The catalyst of the same weight is loaded inside), and the reaction is carried out under the action of the first reaction temperature, the first reaction pressure and the first catalyst, to obtain the first reaction discharge;

[0064] (2) The i-th reaction output and the i+1 part of caprolactam are passed into the i+1 section fixed-bed reactor, and the value range of i is 1≤i≤3 and i is a natural number; the i+1th reaction temperature , the i+1th reaction pressure and the i+1th catalyst are reacted to obtain the i+1th reaction discharge;

[0065] Wherein, the i+1 reaction discharging material...

Embodiment 2

[0070] The difference between this example and Example 1 is that the number of fixed bed reactors is 2, the first reaction temperature and the second reaction temperature are 350°C and 375°C respectively, and the first reaction pressure and the second reaction pressure are 0 MPa and 0.3MPa, the molar ratios of silicon, aluminum and phosphorus in the first catalyst and the second catalyst are 1:0.8:0.2 and 1:0.8:0.6, and all the others are the same as in Example 1.

Embodiment 3

[0072] The difference between this example and Example 1 is that the number of fixed bed reactors is 5, the first reaction temperature to the fifth reaction temperature are 350°C, 375°C, 400°C, 425°C and 450°C respectively, and the first The reaction pressure to the 5th reaction pressure is 0MPa, 0.3MPa, 0.6MPa, 0.9MPa and 1.2MPa respectively, and the molar ratio of silicon, aluminum and phosphorus in the first catalyst to the fifth catalyst is 1:0.8:0.2, 1: 0.8:0.3, 1:0.8:0.45, 1:0.8:0.68 and 1:0.8:1.01, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com