A control method of ammonia injection branch pipe in scr system based on flow rate and nox concentration monitoring

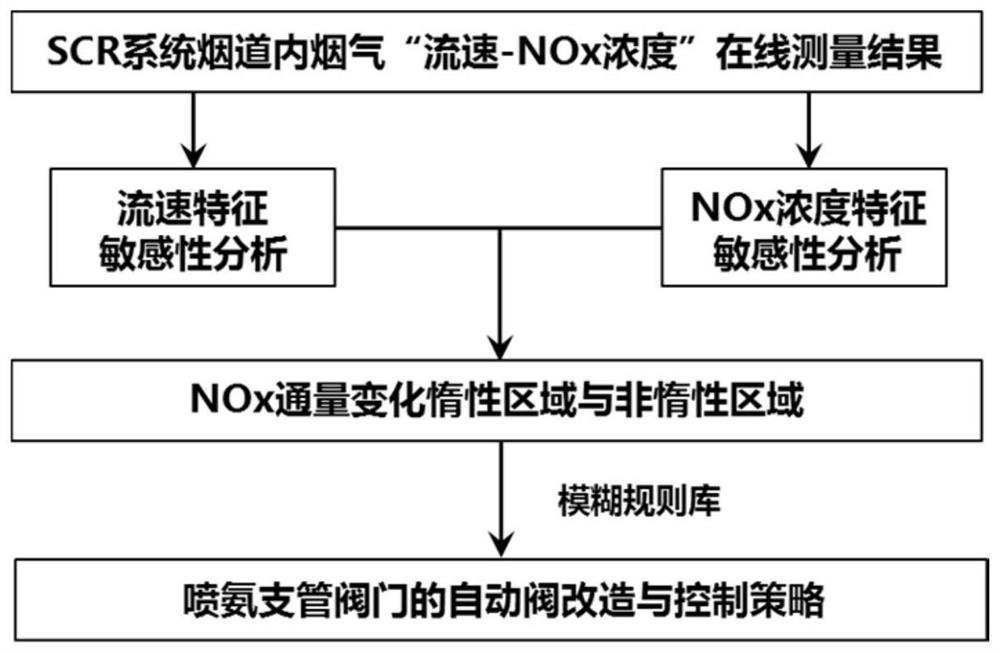

A technology of SCR system and control method, which is applied in the field of automatic control of ammonia injection branch pipes of SCR system, can solve the problems of poor matching degree of ammonia nitrogen mixing in SCR system, ammonia escape, poor correspondence between front-end ammonia injection unit and outlet measurement unit, etc. Utilization rate, the effect of reducing ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

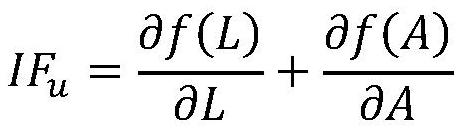

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings. This embodiment case is implemented on the premise of this technical solution. It should be understood that the embodiment case is to illustrate the present invention, but the protection scope of the present invention is not limited to the embodiment case.

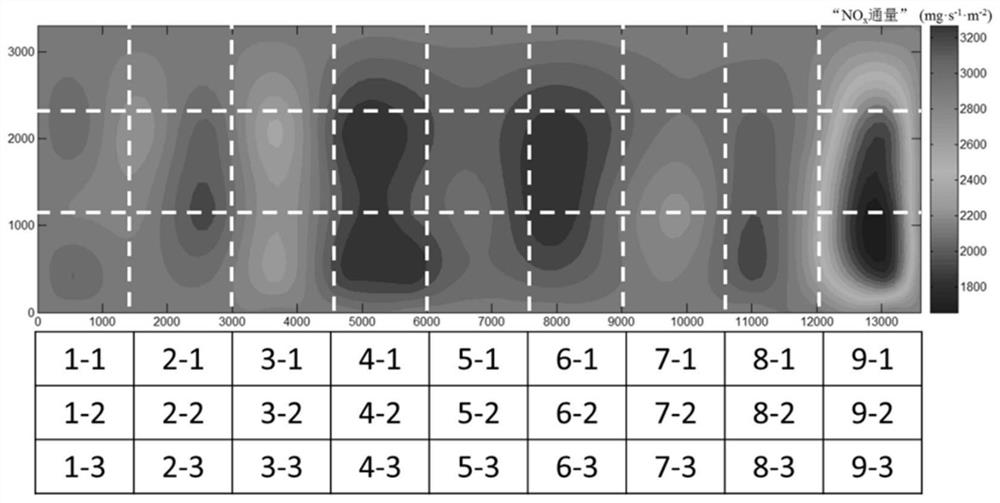

[0046] This implementation case relies on the SCR system of a 600MW coal-fired unit, which is equipped with front and rear wall hedging boilers, and adopts urea hydrolysis to produce ammonia. The cross-sectional size of the flue before the ammonia injection grille of the SCR system of the unit is 13500mm × 3200mm. Based on the principle of electrostatic induction related velocity measurement and UV differential absorption spectroscopy (DOAS) technology, it is designed and installed with on-line measurement equipment for flue gas flow rate and NOx concentration, which can obtain real-time injection The flue gas flow ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com