A kind of manufacturing method of special-shaped hollow thermal insulation polyester low elastic yarn

A polyester low elastic yarn and manufacturing method technology, applied in the field of textile production, can solve problems such as inability to prepare polyester fiber, affect melt viscosity, equipment friction, etc., improve far-infrared emission effect and health care effect, and reduce powder reaction contact area , Promote blood circulation and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

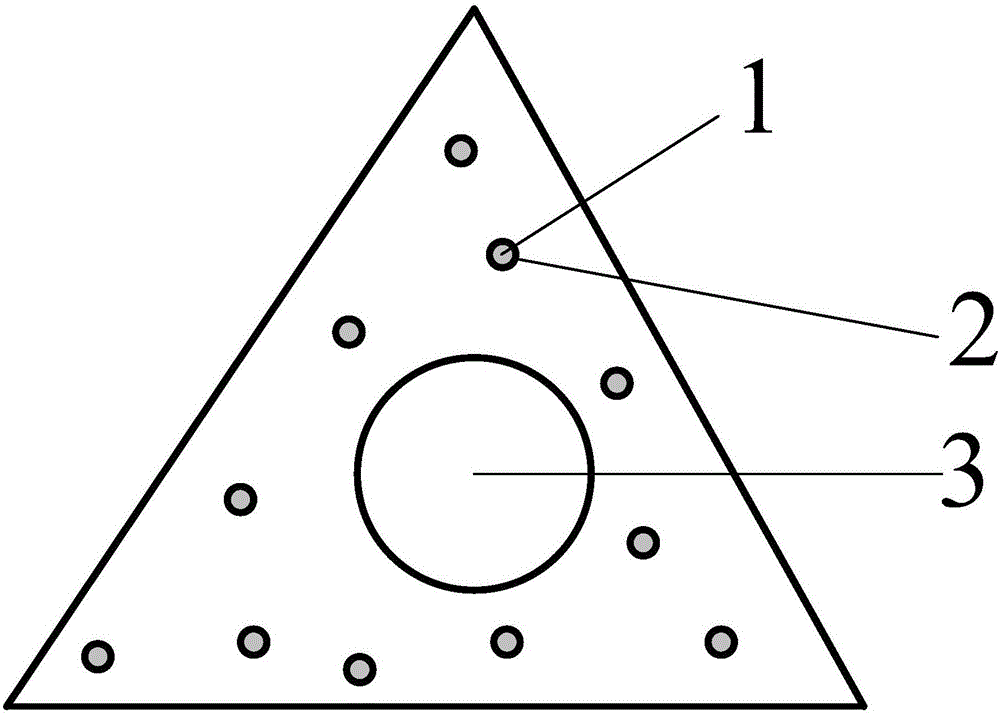

Image

Examples

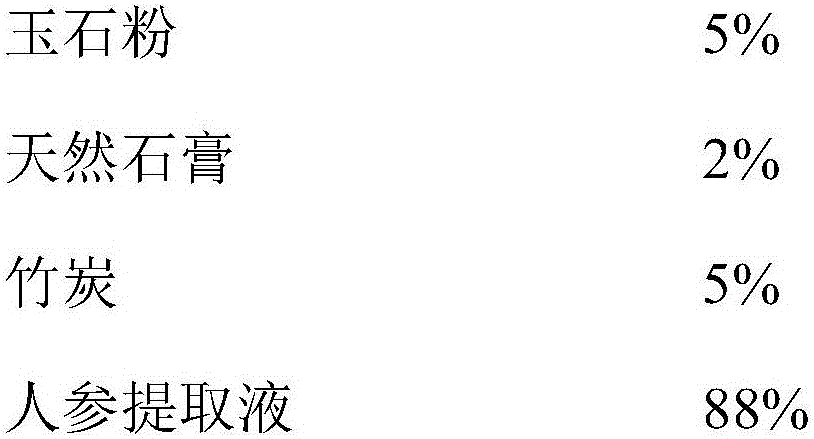

Embodiment 1

[0062] A method for manufacturing special-shaped hollow warm polyester low elastic yarn comprises the following steps:

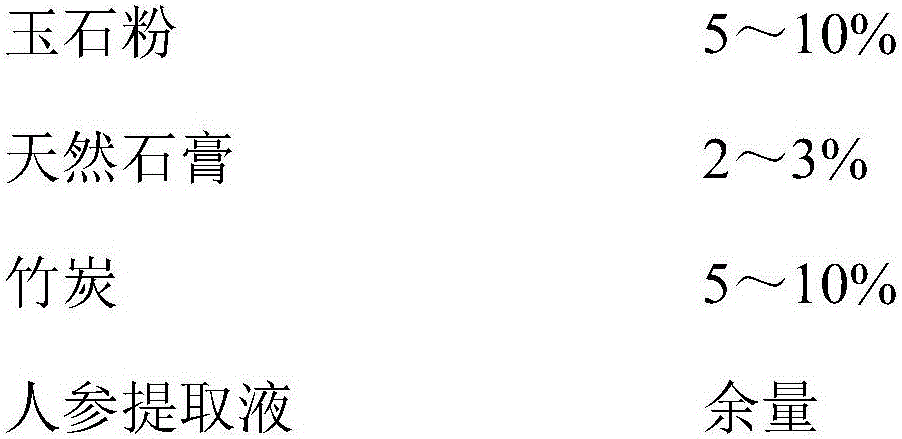

[0063] (1) Preparation of far-infrared and anion-emitting functional powders

[0064] Using jade powder, natural gypsum, bamboo charcoal, and ginseng extract as raw materials, first add bamboo charcoal, natural gypsum and jade powder into the ball mill in proportion, and use the method of dry powder ball mill to grind to prepare mixed mineral powder. Jade powder, natural gypsum Fully mix with bamboo charcoal, and fully contact and replace the minerals in jade powder, natural gypsum and bamboo charcoal during the grinding process, control the average particle size of the powder after grinding to 20-50 microns; then mix the mineral powder after grinding Soak the body in the ginseng extract for 20-45 days, then take it out and dry it naturally to get the pretreated mixed mineral powder, then place the pretreated mixed mineral powder in a nitrogen atmosphere at ...

Embodiment 2

[0086] A method for manufacturing special-shaped hollow warm polyester low elastic yarn comprises the following steps:

[0087] (1) Preparation of far-infrared and anion-emitting functional powders

[0088] Using jade powder, natural gypsum, bamboo charcoal, and ginseng extract as raw materials, first add bamboo charcoal, natural gypsum and jade powder into the ball mill in proportion, and use the method of dry powder ball mill to grind to prepare mixed mineral powder. Jade powder, natural gypsum Fully mix with bamboo charcoal, and fully contact and replace the minerals in jade powder, natural gypsum and bamboo charcoal during the grinding process, control the average particle size of the powder after grinding to 20-50 microns; then mix the mineral powder after grinding Soak the body in the ginseng extract for 20-45 days, then take it out and dry it naturally to get the pretreated mixed mineral powder, then place the pretreated mixed mineral powder in a nitrogen atmosphere at ...

Embodiment 3

[0104] A method for manufacturing special-shaped hollow warm polyester low elastic yarn comprises the following steps:

[0105] (1) Preparation of far-infrared and anion-emitting functional powders

[0106] Using jade powder, natural gypsum, bamboo charcoal, and ginseng extract as raw materials, first add bamboo charcoal, natural gypsum and jade powder into the ball mill in proportion, and use the method of dry powder ball mill to grind to prepare mixed mineral powder. Jade powder, natural gypsum Fully mix with bamboo charcoal, and fully contact and replace the minerals in jade powder, natural gypsum and bamboo charcoal during the grinding process, control the average particle size of the powder after grinding to 20-50 microns; then mix the mineral powder after grinding Soak the body in the ginseng extract for 20-45 days, then take it out and dry it naturally to get the pretreated mixed mineral powder, then place the pretreated mixed mineral powder in a nitrogen atmosphere at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com