Full-cycle comprehensive utilization integrated complete production line for ardealite and by-products of ardealite

A by-product, full-cycle technology, applied in the field of industrial gypsum treatment technology, can solve the problems of less than 20% effective utilization rate, heavy burden on production enterprises, and environmental pollution, etc., so as to improve the effective utilization rate of resources, improve the purity, and avoid the environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

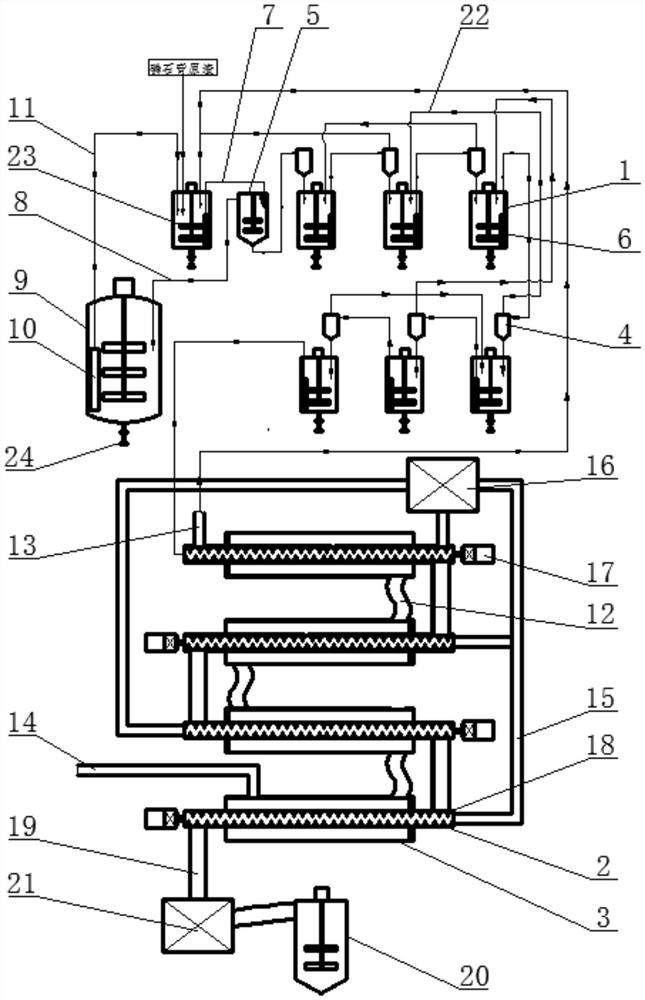

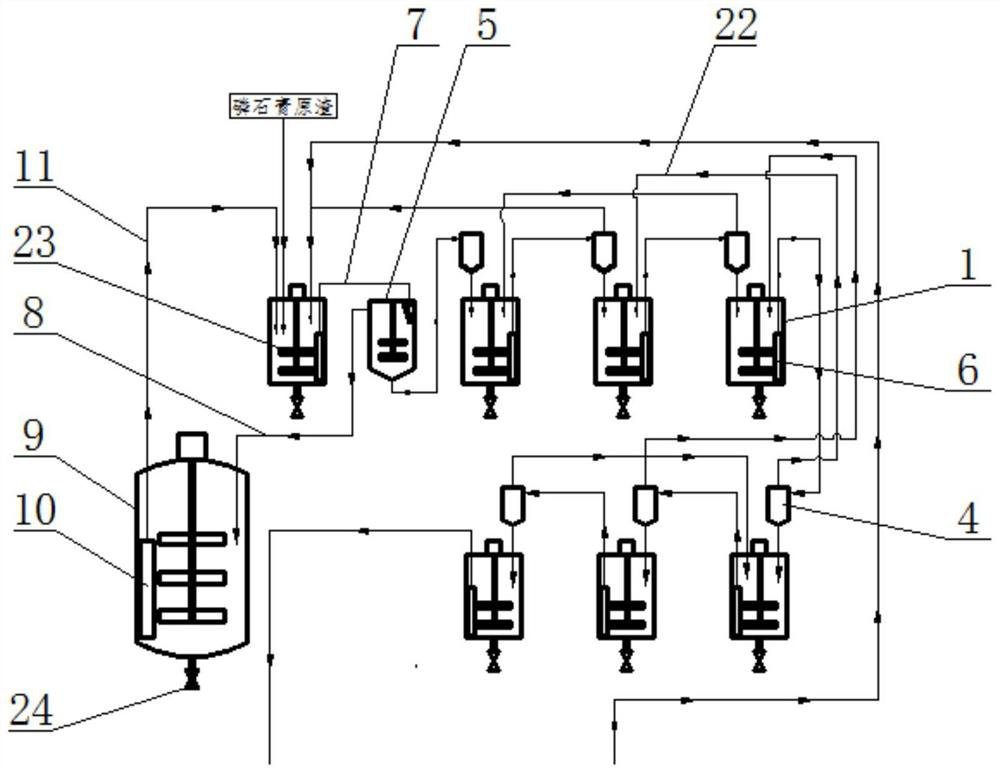

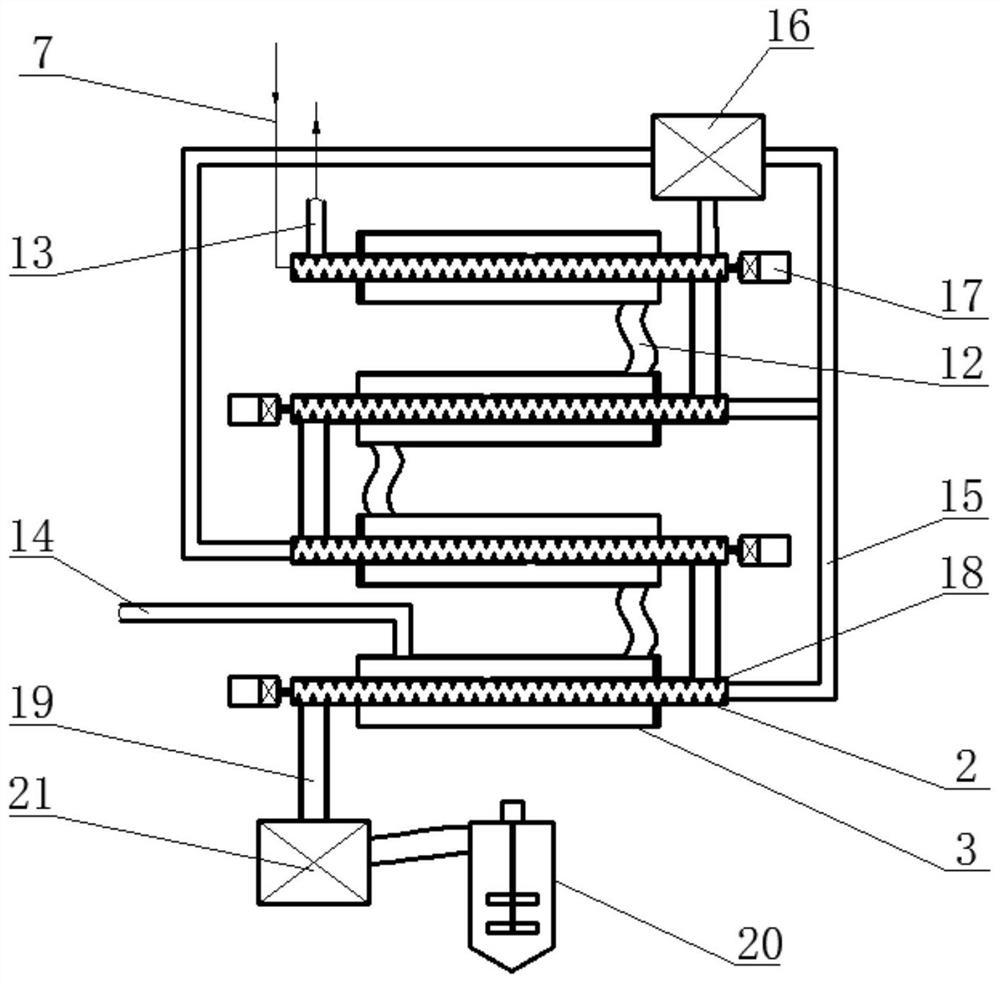

[0029] like Figure 1 to Figure 7 As shown, the present invention provides an integrated complete production line for full cycle comprehensive utilization of phosphogypsum and its by-products, including multiple purification tanks 1, multiple calciner cylinders 2 and multiple heat exchange cylinders 3, each calciner cylinder 2 and each The heat exchange cylinders 3 are in one-to-one correspondence and the calciner cylinder 2 is accommodated in the heat exchange cylinder 3. A plurality of calciner cylinders 2 are connected in series end to end, and a solid-liquid separator 4 is arranged between two adjacent purification tanks 1. The first A thickener 5 is also arranged between the purification tank 1 and the first solid-liquid separator 4, and a slurry pump 6 is placed in each purification tank 1, and the output end of the slurry pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com