Rotary kiln for producing petroleum coke

A rotary kiln and petroleum coke technology, applied in the field of rotary kiln, can solve the problems of reducing the thermal conductivity of the cylinder, increasing energy consumption, and poor sealing, and achieve the effect of prolonging the heat exchange time, increasing the movement time, and improving the calcination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

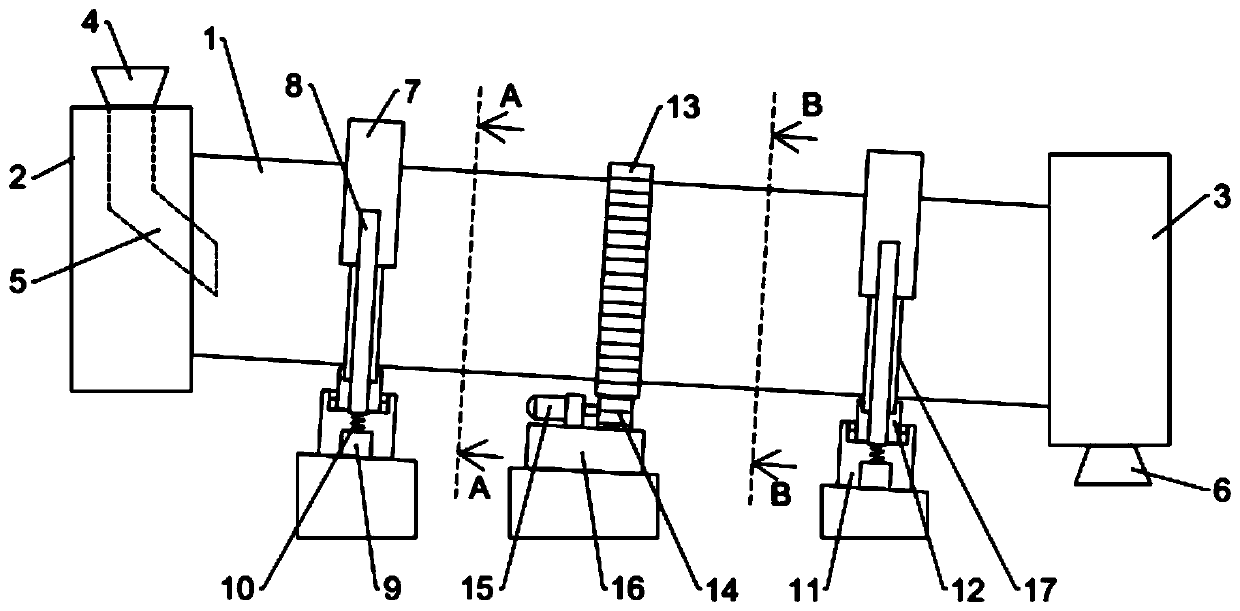

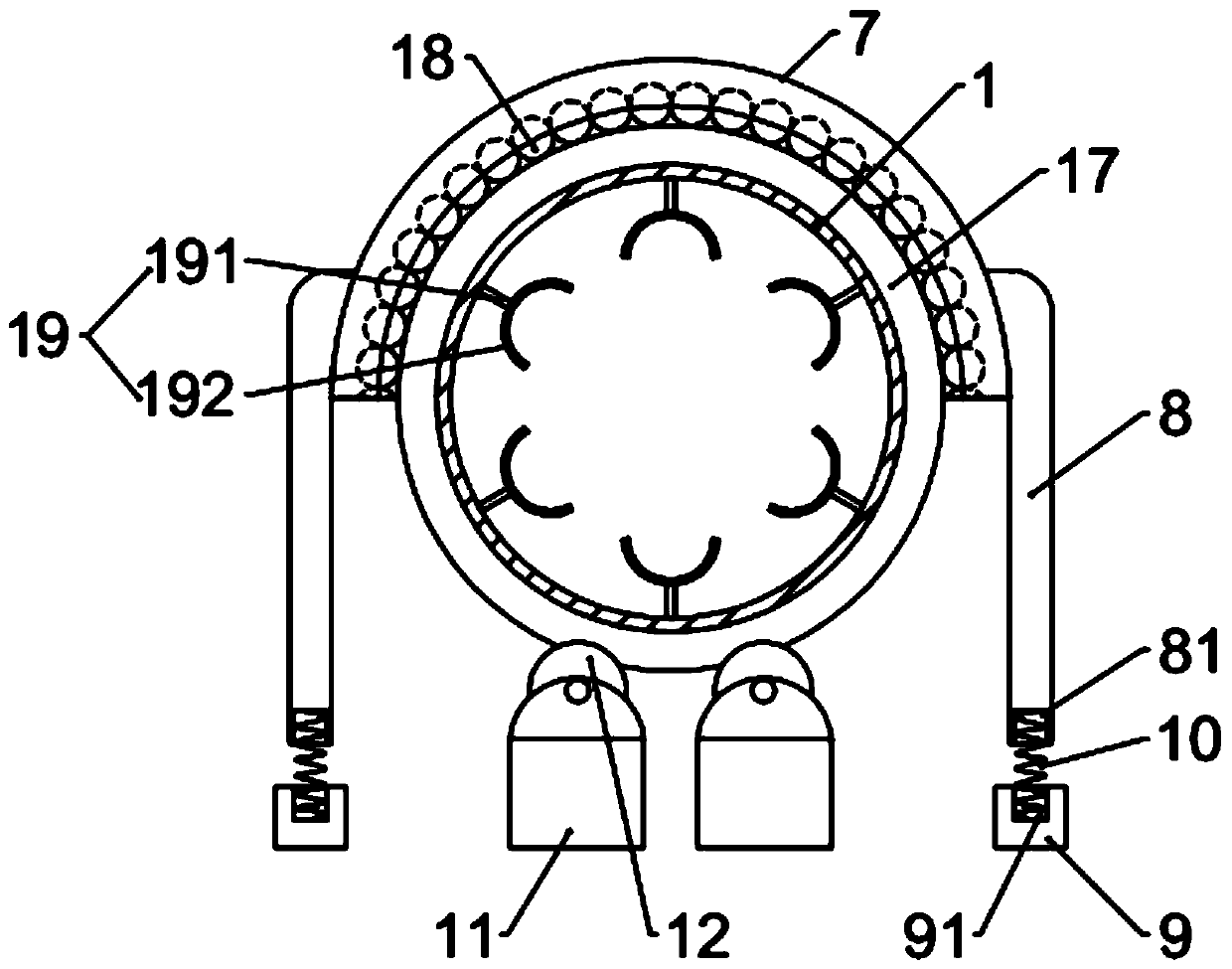

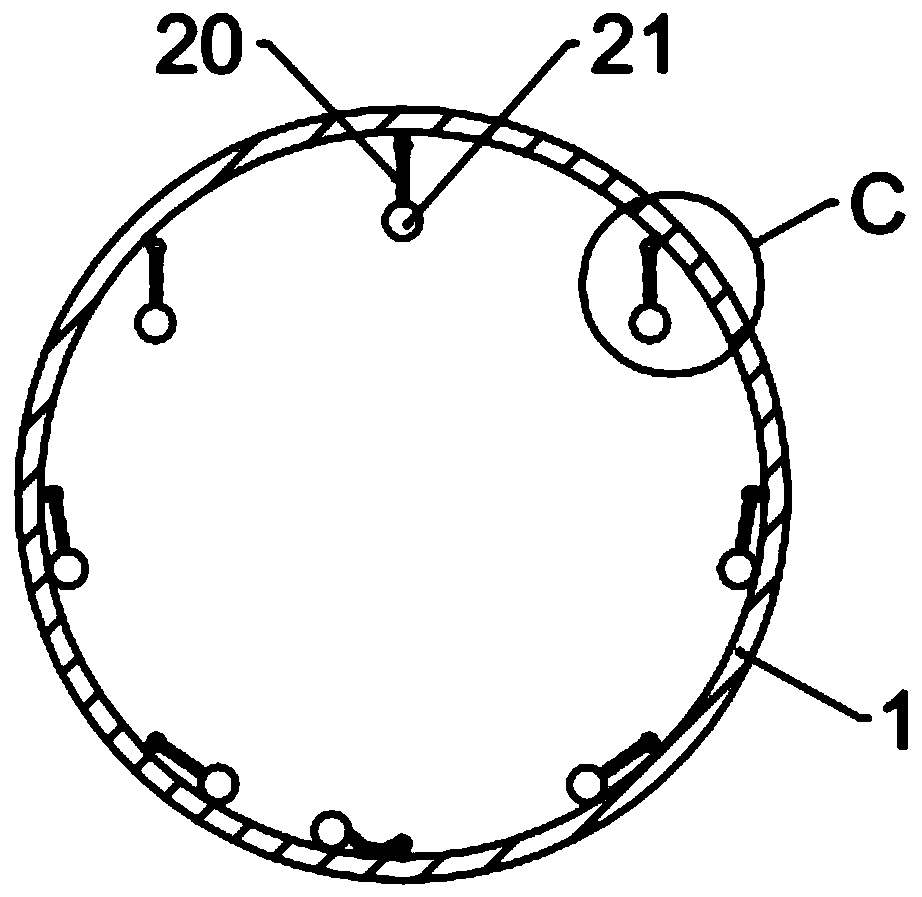

[0024] Such as Figure 1 to Figure 4 As shown, a rotary kiln for petroleum coke production includes a cylinder body 1; a number of tires 17 are sheathed on the outside of the cylinder body 1 and are fixedly connected with the tires 17. The upper half of the cover has a limit cover 7, and the limit cover 7 is provided with a number of rollers 18 arranged in turn to form a semicircle. The supporting columns 8 are arranged symmetrically on both sides of the cylinder body 1 , the bottom of the supporting columns 8 is connected with a damping spring 10 , and the bottom of the damping spring 10 is connected with a base 9 .

[0025] The bottom of support column 8 is provided with upper installation groove 81, and the top of base 9 is provided with lower installation groove 91, and the two ends of damping spring 10 are respectively fixed in upper installation groove 81 and lower installation groove 91, can improve the shock absorption spring. 10 installation stability.

[0026] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com