Mixing/calcining Furnace

A calcination furnace and calcination technology, applied in furnaces, drum furnaces, furnace types, etc., can solve the problem of unstable gas production and achieve the effect of suppressing calcination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

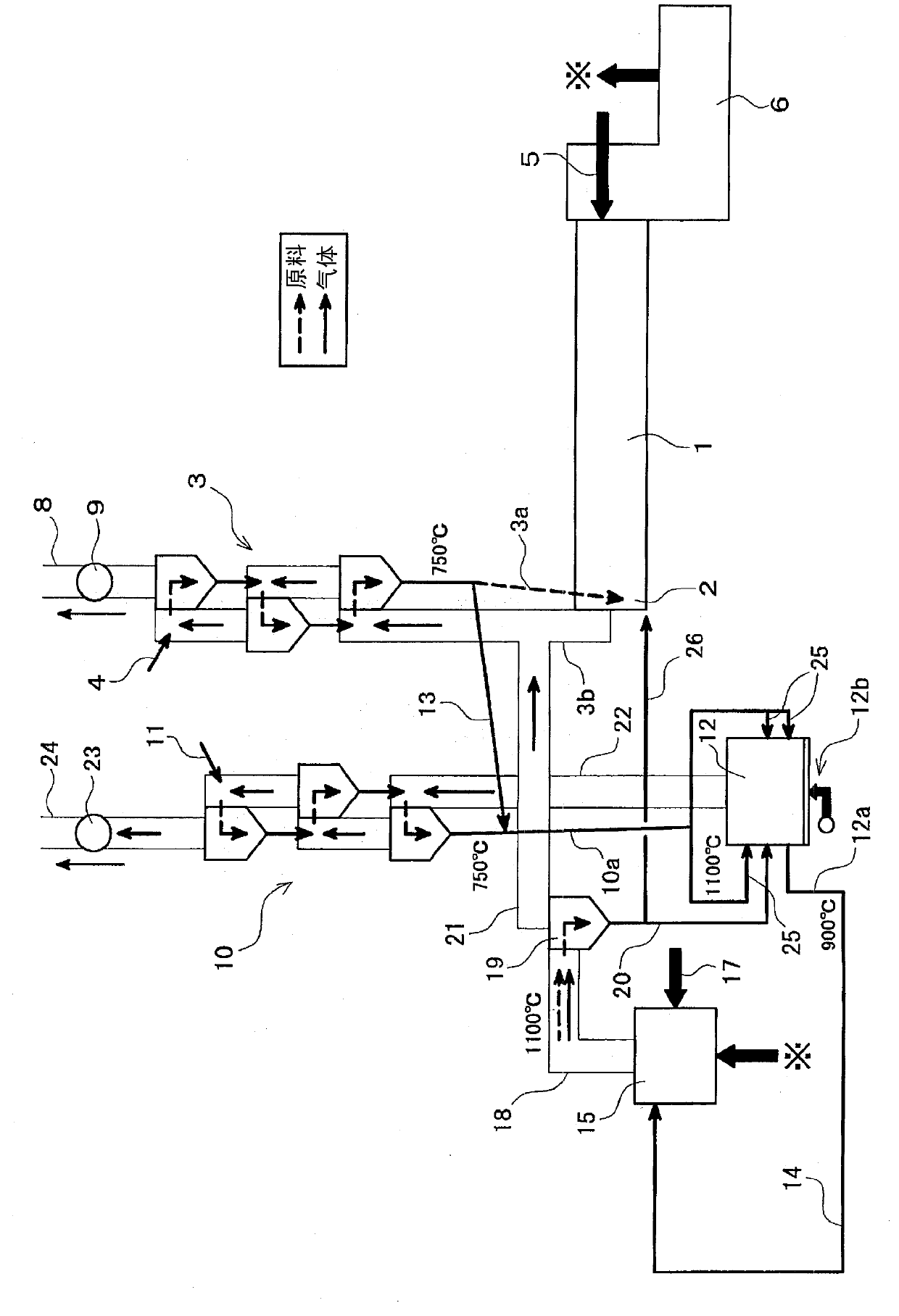

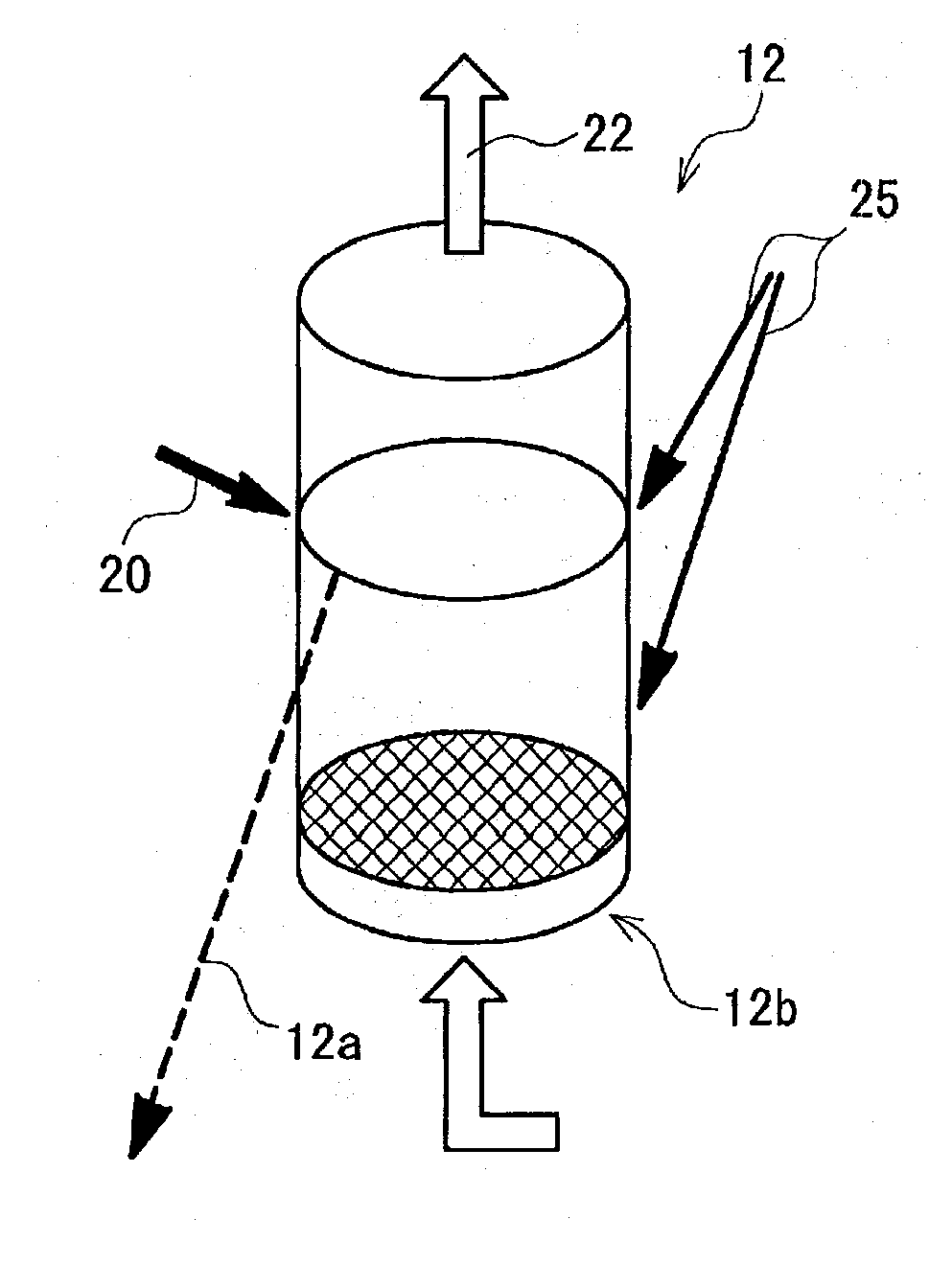

[0109] figure 1 Indicates that the hybrid calciner involved in the present invention is used for CO in cement manufacturing equipment 2 An embodiment of the gas recovery equipment, for the structure of the cement manufacturing equipment, due to the Figure 18 The structures shown are the same, and the description thereof will be simplified by attaching the same symbols.

[0110] exist figure 1 In , the symbol 10 is the second preheater 10 provided independently from the preheater (first preheater) 3 of the cement manufacturing apparatus.

[0111] The second preheater 10, like the above-mentioned first preheater 3, is composed of multi-stage cyclone separators arranged in series in the vertical direction, and the to-be-calcined object (before calcining) is supplied from the supply line 11 to the uppermost cyclone separator. cement raw materials). Furthermore, the bottom of the cyclone separator at the lowest stage of the second preheater 10 is connected to the upper end of...

no. 2 approach

[0148] Figure 9 Represents the CO in the cement manufacturing equipment involved in the present invention 2 An embodiment of the recovery equipment of gas n, for the structure of cement manufacturing equipment, due to the Figure 18 The structures shown are the same, and the description thereof will be simplified by attaching the same symbols.

[0149] exist Figure 9 In , the symbol 110 is the second preheater 110 provided independently from the preheater (first preheater) 3 of the cement manufacturing apparatus.

[0150] The second preheater 110, like the above-mentioned first preheater 3, is constituted by a multi-stage cyclone separator arranged in series in the vertical direction, and the cement raw material before calcining ( Cement raw materials before calcination) k. Furthermore, the bottom of the cyclone separator in the lowermost stage of the second preheater 110 is connected to the upper end of the delivery pipe 110 a , and the lower end of the delivery pipe 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com