Needle-shaped calcined petroleum coke production technology and calcining furnace for technology

A technology of calcining petroleum coke and production process, which is applied in the direction of furnace, crucible furnace, furnace type, etc., and can solve the problems of large burning loss, poor calcination effect, and the true density of the finished product can only reach 2.13

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

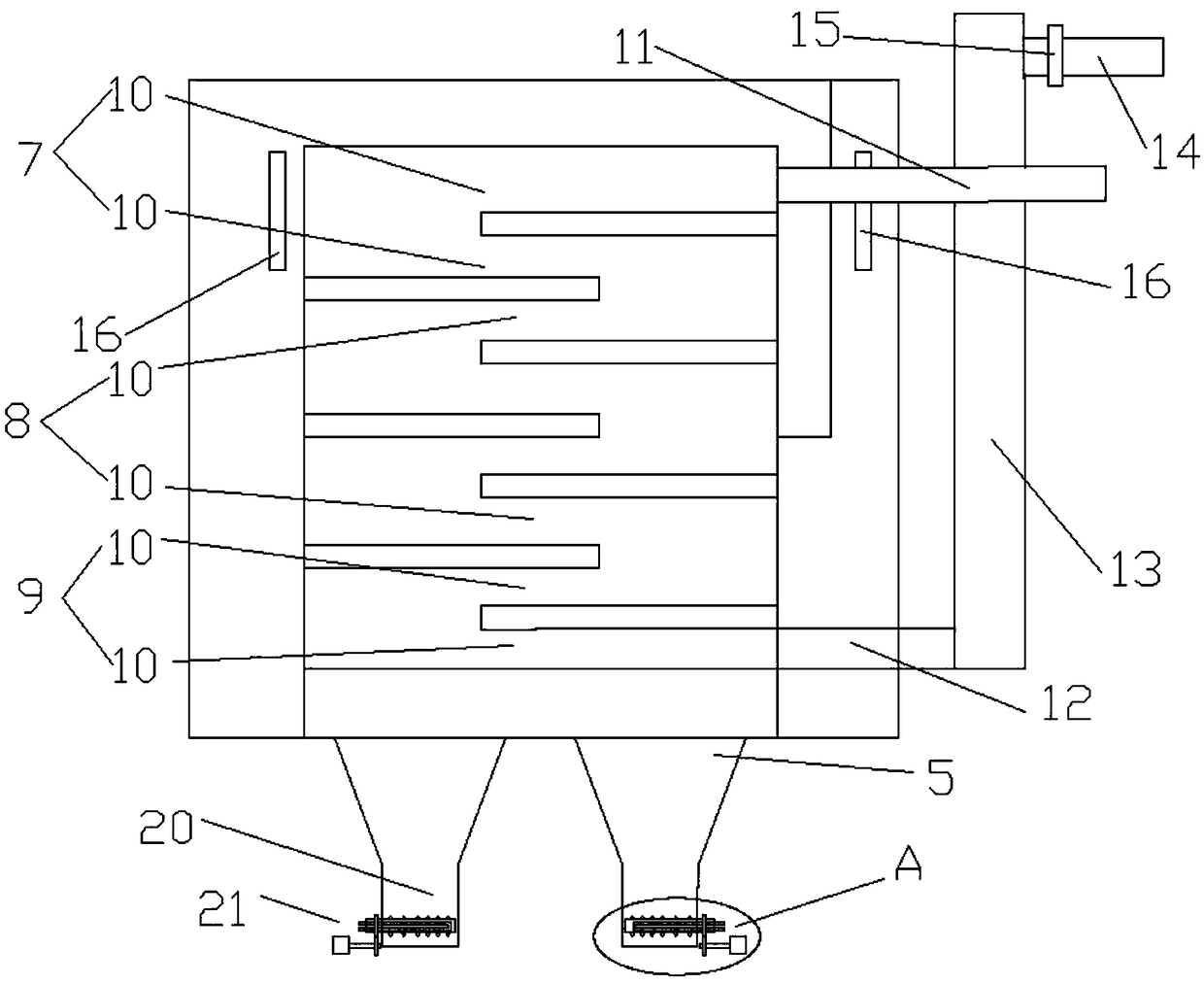

[0018] A production process of needle-shaped calcined petroleum coke, which uses a tank-type calciner for calcination, and feeds natural gas into the tank-type calciner to mix and burn with the volatile matter in the needle-shaped calcined petroleum coke so that the temperature of the calcined layer 8 reaches 1400 degrees Celsius. Compared with the traditional rotary kiln, which reduces burning loss, 1 ton of products calcined by the rotary kiln requires 1.5 tons of raw materials, while 1 ton of products calcined by this method only needs 1.32 tons of raw materials. The tank-type calciner used therein can be composed of the following structure, that is, a calciner for the production of needle-shaped calcined petroleum coke, and the specific structure is as follows:

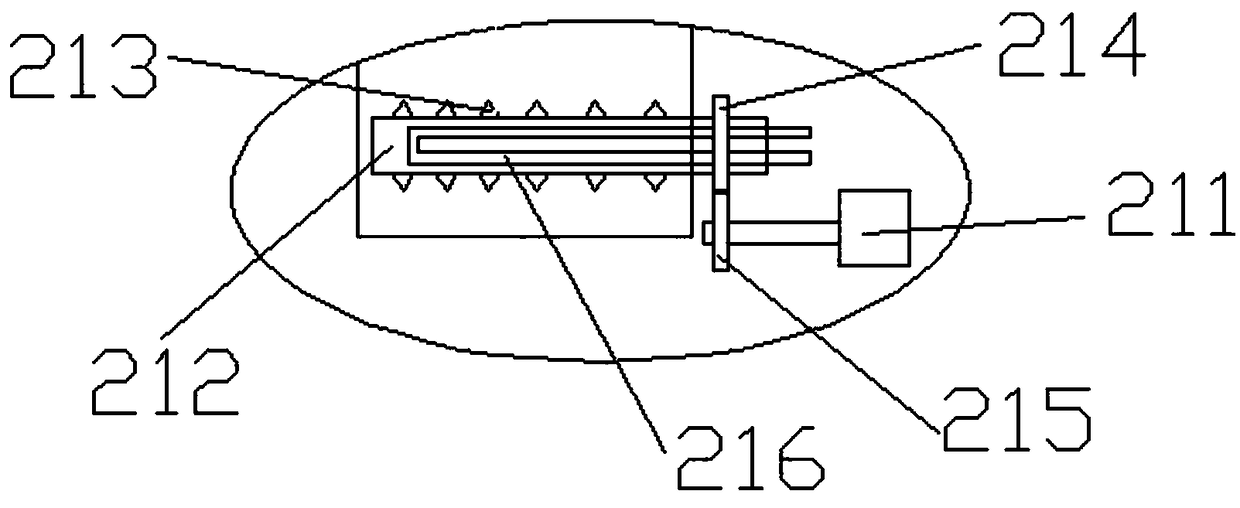

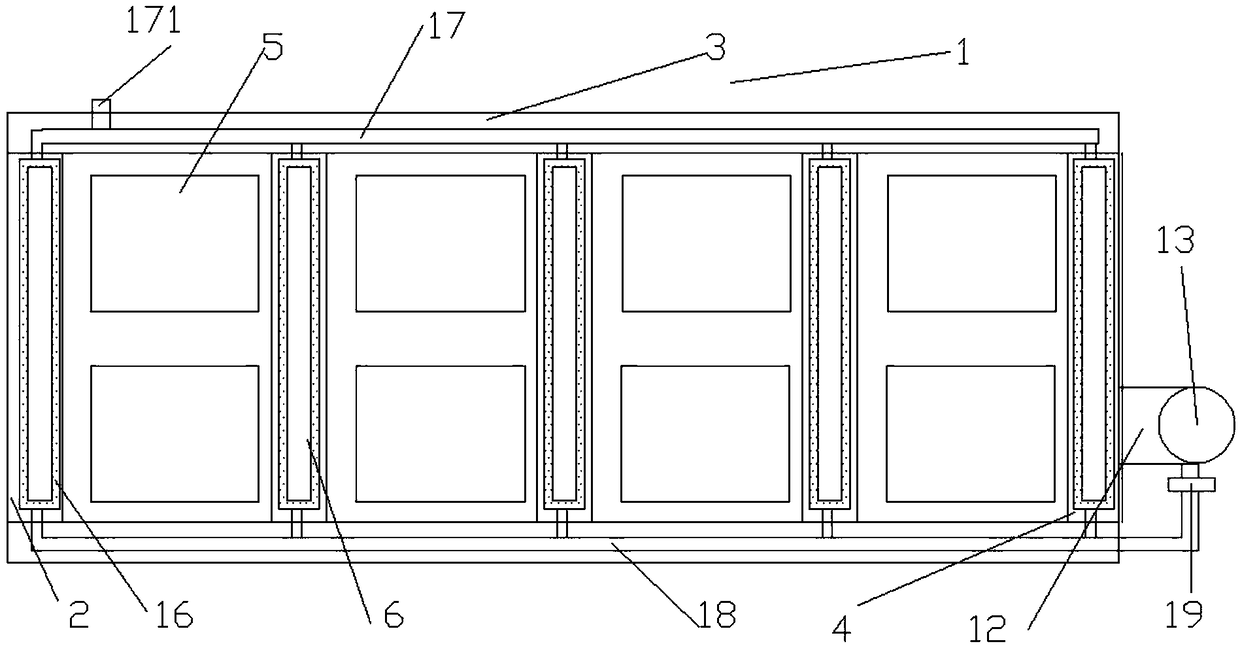

[0019] Such as Figure 1-3 As shown, a calciner for producing needle-shaped calcined petroleum coke includes a furnace body 1 and a flue, the furnace body 1 is made of refractory bricks, and the furnace body 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com