Oxygen-enriched combustion-supporting and pulverized coal pure-oxygen compensation energy conservation system of rotary kiln

An oxygen-enriched combustion-supporting and energy-saving system technology, applied in rotary drum furnaces, furnaces, combustion methods, etc., can solve the problems of poor quality of cement products, energy waste, and low output, and achieve the effects of reducing emissions, improving benefits, and fully calcining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

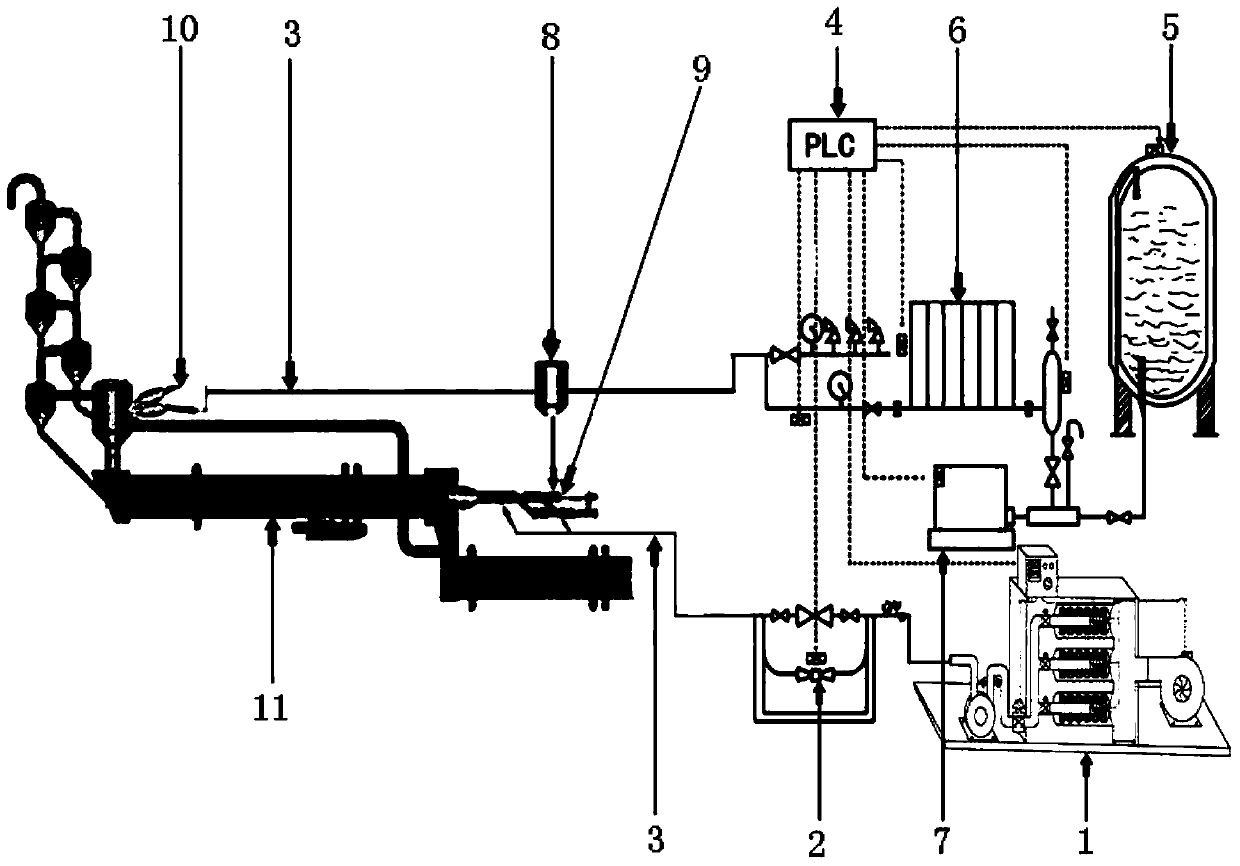

[0009] Such as figure 1 As shown, the rotary kiln oxygen-enriched combustion-supporting, pulverized coal pure oxygen compensation energy-saving system includes a dry-process rotary kiln combustion system 11, a PLC intelligent system 4, a magnetic energy oxygen generator 1 and a liquid oxygen storage tank 5, and the magnetic energy oxygen generator 1 The output end of the pressure regulating system 2 is connected to the pressure regulating system 2, and the pressure regulating system 2 is connected to the kiln head coal injection pipe terminal 9 of the dry rotary kiln combustion system 11 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com