Method and device for sintering lime

A calcination device and lime technology, applied in lime production, etc., can solve the problems of low thermal efficiency of the lime kiln system, reduce thermal efficiency and product quality of the lime kiln system, affect productivity, etc., achieve large-scale continuous production, save energy, and improve operations rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

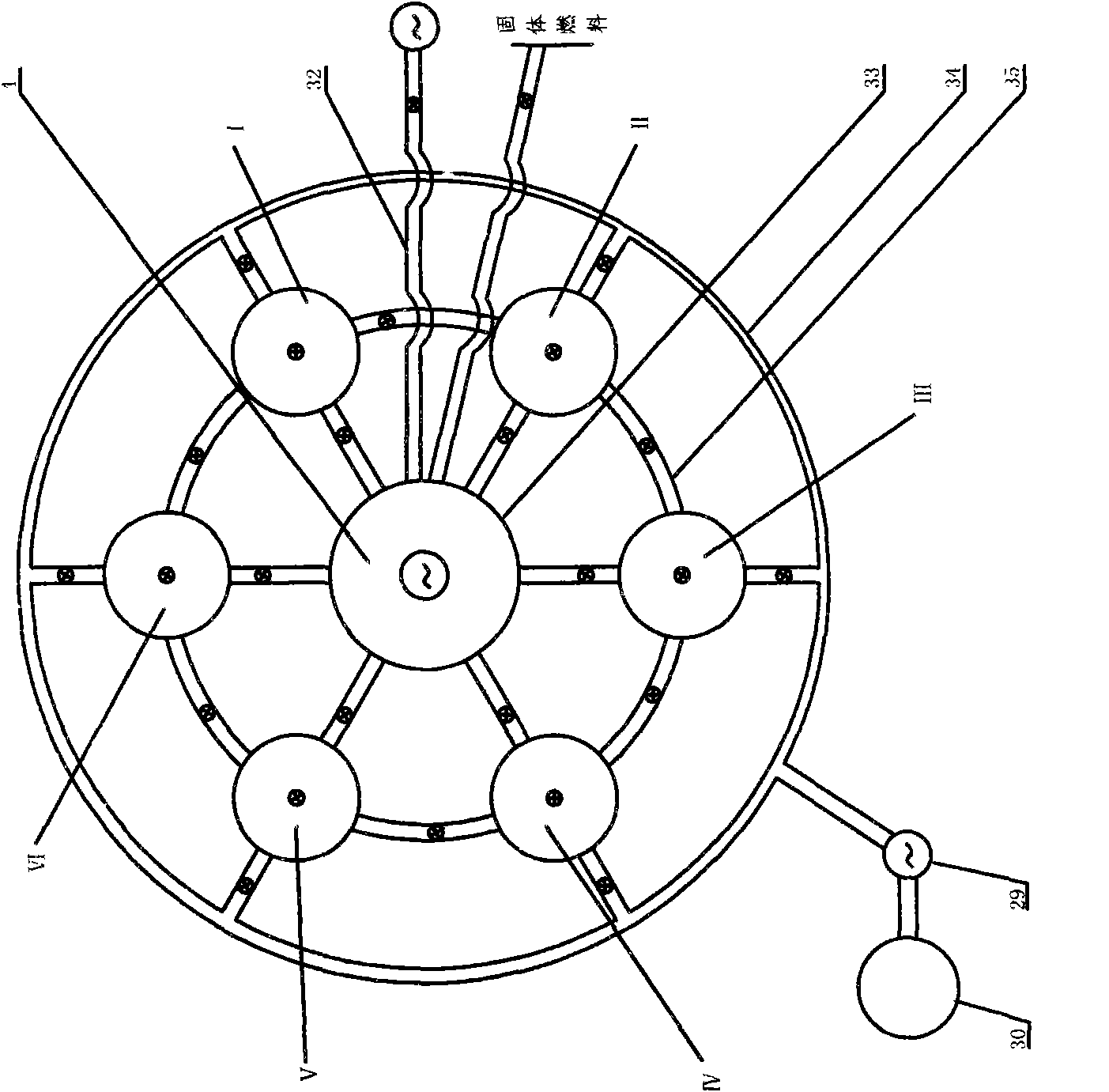

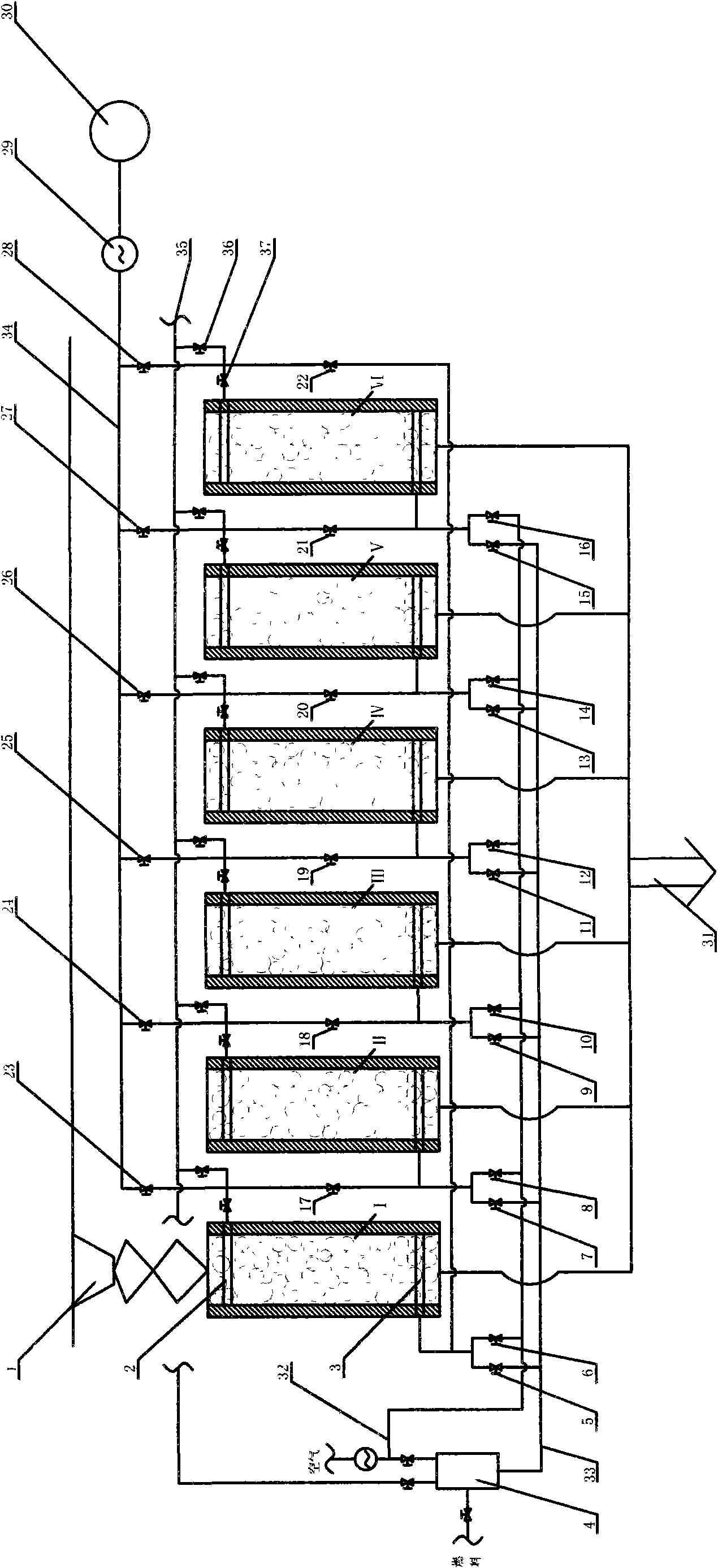

[0023] Examples of the invention are figure 1 , figure 2 , The kiln body is arranged in a ring shape. For the sake of simplicity, the figure 2 shown in the description. This system is mainly composed of feeding device 1, kiln body I, II, III, IV, V, VI, combustion chamber 4, unloading device 44, discharge channel 31, flue gas pipeline 33, waste gas pipeline 34, air pipeline 32, common pipeline 35 etc. are formed. A suction beam 2 is arranged in the kiln body, and the calcining device is an intake beam 3, and its quantity is determined according to the size, height and production load of the lime burning kiln, such as Figure 8 shown. The valve 36 in the common pipeline 35 is normally closed, and the valve 37 is normally open. Only when a certain kiln body is overhauled or the calcination sequence of the kiln is adjusted, the corresponding valve 37 is opened and the valve 36 is closed.

[0024] The lower part of the kiln body is equipped with intake beams 3, or installe...

Embodiment 2

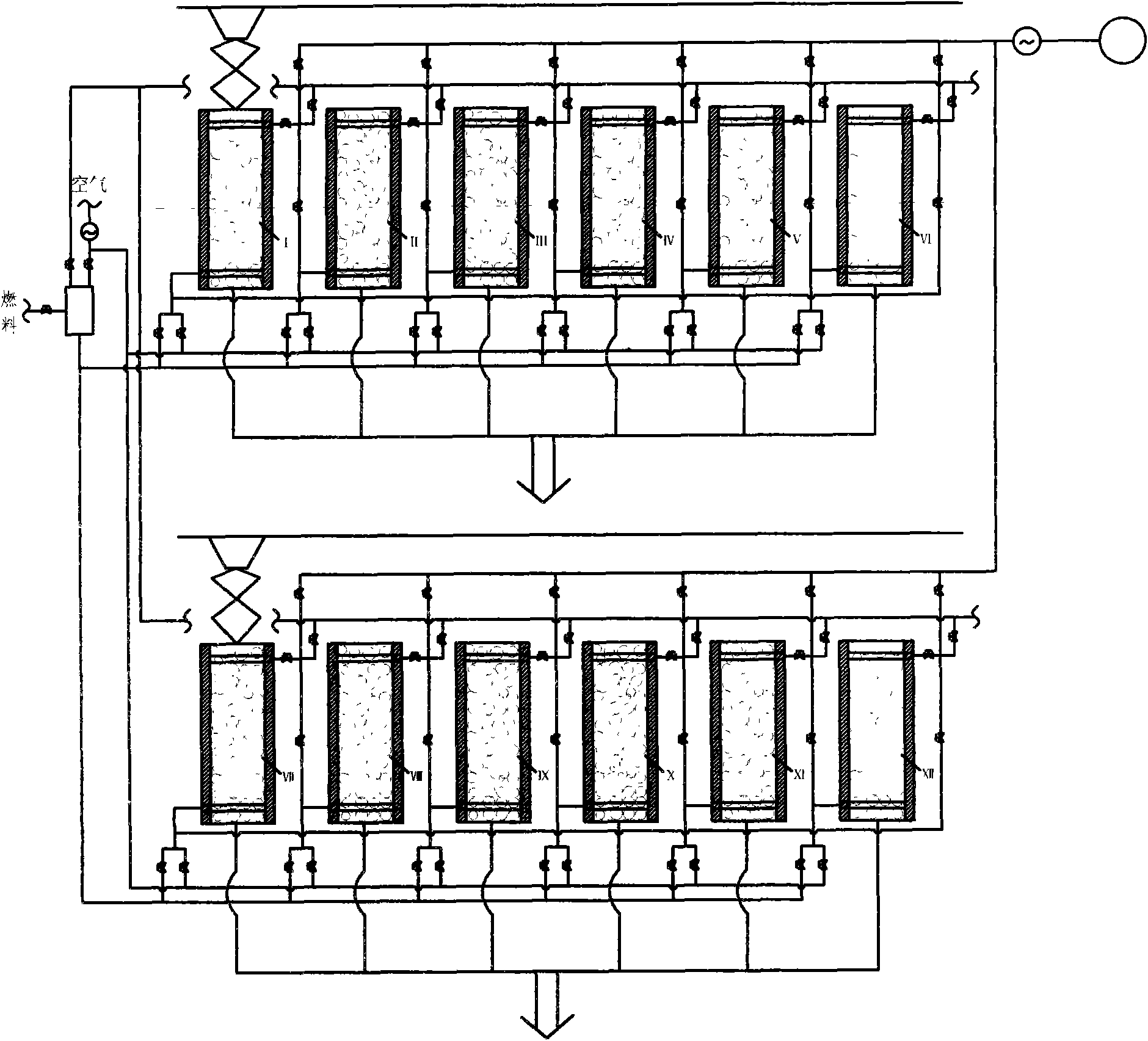

[0028] Examples of the invention are image 3 As shown, the kiln body is arranged in a matrix kiln body. The high-temperature flue gas generated by this system selectively opens the valve to pass through according to the needs of the entire process, that is, when one or more kiln bodies are calcined, one or more kiln bodies are preheating, and one or more kiln bodies are While cooling, one or more kiln bodies are discharging finished ash and loading limestone.

[0029] The other processes and process conditions of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0031] Examples of the invention are Figure 9 As shown, the calcining device is a combustion beam 45 (such as Figure 10 As shown), the combustion beam is provided with a burner 48, and the system has a fuel pipeline 47. The working principle of this system is: fuel enters the fuel pipeline of the combustion beam 45 through the fuel pipeline 47, and the combustion-supporting air enters the air pipeline of the combustion beam from the air pipeline 32, and the calcined limestone is mixed and burned at the burner. The high-temperature flue gas after calcining limestone goes out from the suction beam and enters another limestone kiln waiting for preheating to preheat the limestone in the kiln. The cooling air enters the kiln body from the combustion beam burner to cool the calcined lime, and the preheated air after cooling the lime product can be used as a combustion-supporting gas, and enters the combustion beam through the common pipeline 35 for combustion.

[0032] The kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com