Novel process for simultaneously recovering valuable metals and iron from mixed waste lithium ion batteries

A lithium-ion battery, hybrid technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as increased treatment costs and ammonia nitrogen pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

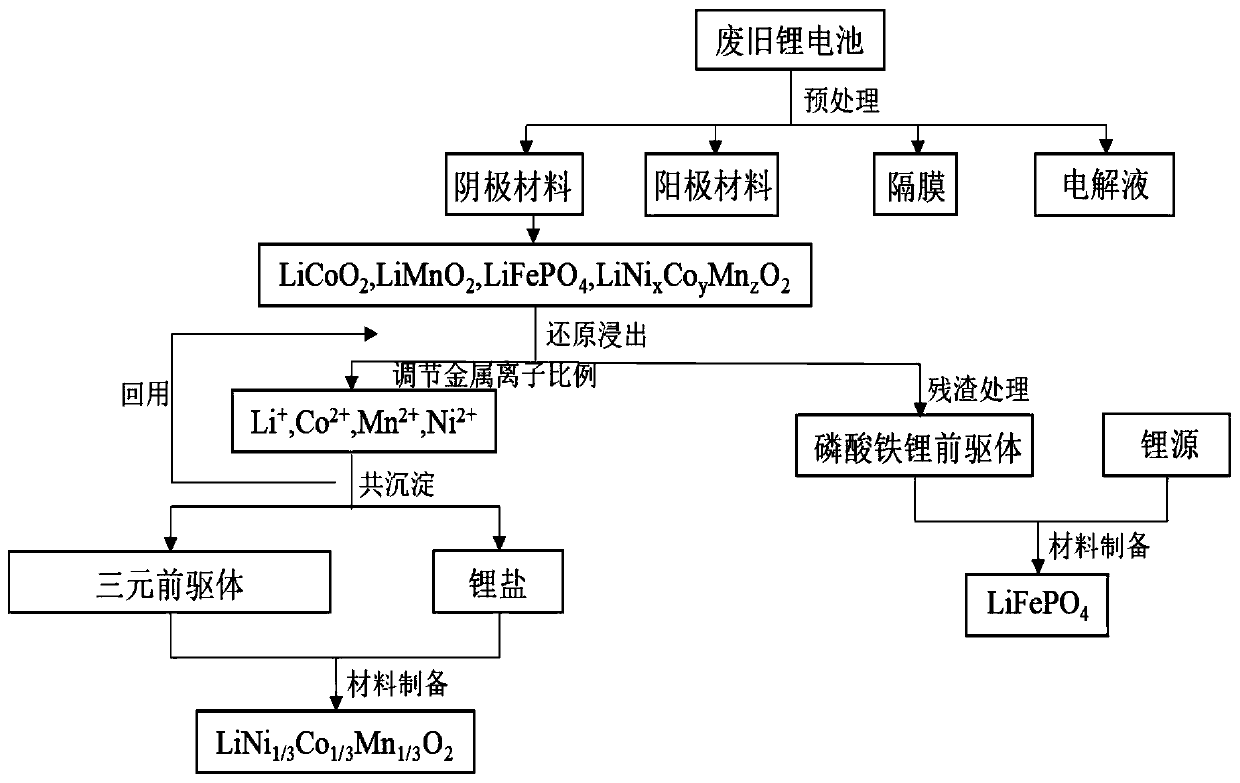

[0022] For a novel process for the simultaneous recovery of valuable metals and iron from hybrid spent lithium-ion batteries, the steps are as follows:

[0023] Take 1kg of waste lithium battery and carry out pretreatment procedures such as discharging, dismantling, and stripping to obtain 420g of positive electrode materials, wherein the detailed percentages of Co, Li, Mn, Ni and Fe are: 17.2%, 5.4%, 16.1%, 6.5% and 8.6%.

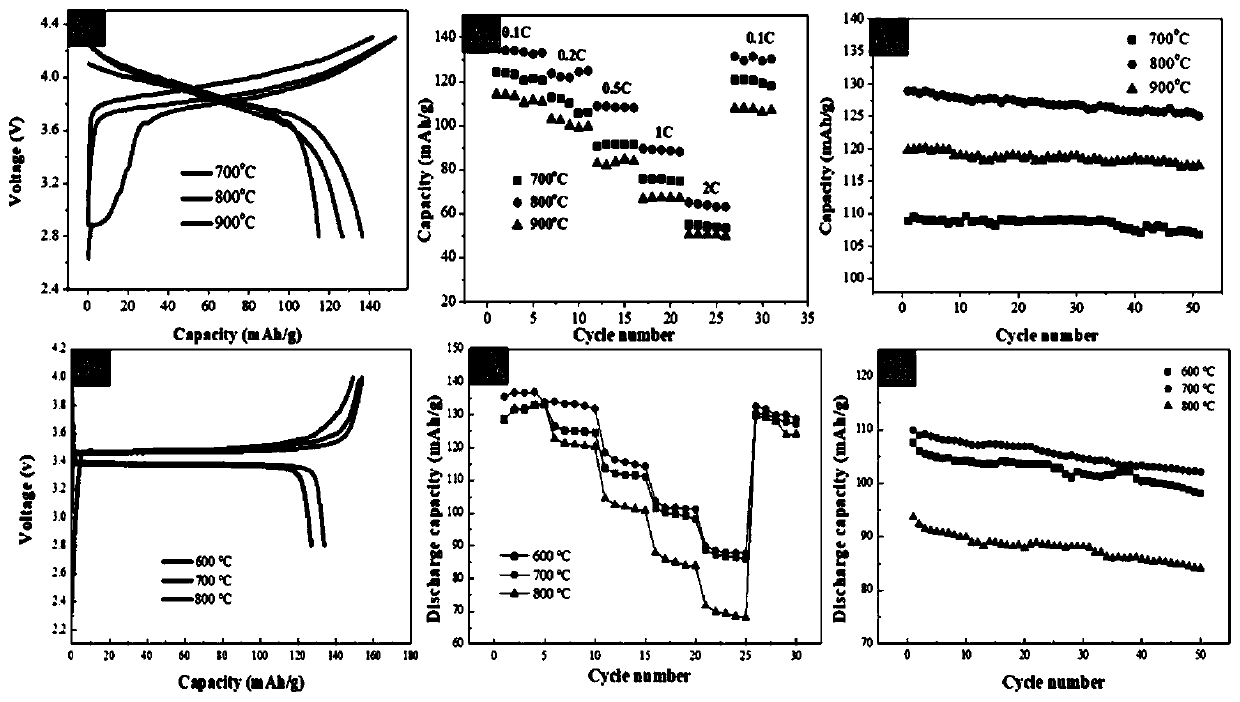

[0024] The positive electrode material is leached, the leaching temperature is 40°C, the leaching time is 40min, the liquid-solid ratio is 30mL / g, the acid concentration is 2mol / L, and the reducing agent dosage is 4%. After leaching, filter to obtain Co, Li, Mn, Ni mixed solution and iron compound residue. Adjust the content of metal ions in the leaching solution, then precipitate the metal ions, reuse the acid, then calcinate the precipitate at 600°C, and obtain synthetic LiNi after grinding 1 / 3 co 1 / 3 mn 1 / 3 o 2 Material. Lithium source is added to...

Embodiment 2

[0026] For a novel process for the simultaneous recovery of valuable metals and iron from hybrid spent lithium-ion batteries, the steps are as follows:

[0027] Take 3kg of waste lithium batteries, carry out pretreatment procedures such as discharging, dismantling, and stripping, and obtain 1.26kg of positive electrode materials, of which the detailed percentages of Co, Li, Mn, Ni and Fe are: 17.2%, 5.4%, 16.1%, 6.5% and 8.6%.

[0028] The positive electrode material is leached, the leaching temperature is 50° C., the time is 80 min, the liquid-solid ratio is 30 mL / g, the acid concentration is 1 mol / L, and the amount of reducing agent is 2%. After leaching, filter to obtain Co, Li, Mn, Ni mixed solution and iron compound residue. Adjust the content of metal ions in the leaching solution, then precipitate the metal ions, reuse the acid, then calcinate the precipitate at 900°C, and obtain synthetic LiNi after grinding 1 / 3 co 1 / 3 mn 1 / 3 o 2 Material. FePO obtained after lea...

Embodiment 3

[0030] For a novel process for the simultaneous recovery of valuable metals and iron from hybrid spent lithium-ion batteries, the steps are as follows:

[0031] Take 0.5kg of waste lithium battery, carry out pretreatment procedures such as discharging, dismantling, and stripping, and obtain 210g of positive electrode materials, of which the detailed percentages of Co, Li, Mn, Ni and Fe are: 17.2%, 5.4%, 16.1%, 6.5% and 8.6%.

[0032] The positive electrode material is leached, the leaching temperature is 80°C, the leaching time is 50min, the liquid-solid ratio is 30mL / g, the acid concentration is 6mol / L, and the reducing agent dosage is 8%. After leaching, filter to obtain Co, Li, Mn, Ni mixed solution and iron compound residue. Adjust the content of metal ions in the leaching solution, then precipitate the metal ions, reuse the acid, then calcinate the precipitate at 800°C, and obtain synthetic LiNi after grinding 1 / 3 co 1 / 3 mn 1 / 3 o 2 Material. Lithium source is added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com