Uniform distribution device for lime kiln

A technology for uniform distribution and lime kiln, applied in the field of lime kiln, can solve the problems of incapable of realizing efficient and rational production of lime kiln, reducing the service life of the kiln, uniform lime distribution, etc., to improve construction efficiency, easy operation, uniform and effective The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

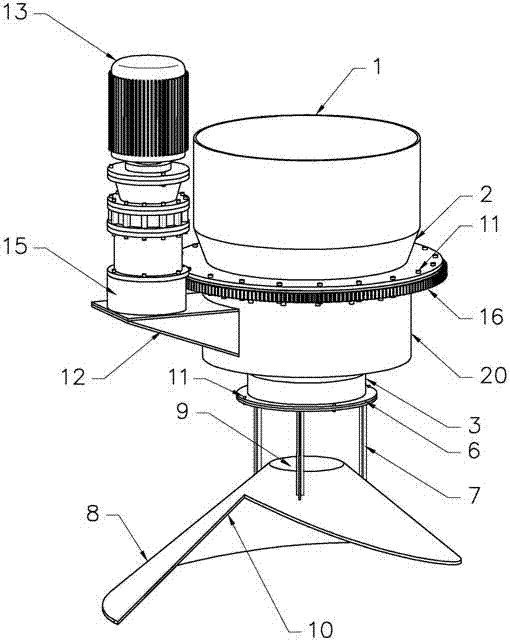

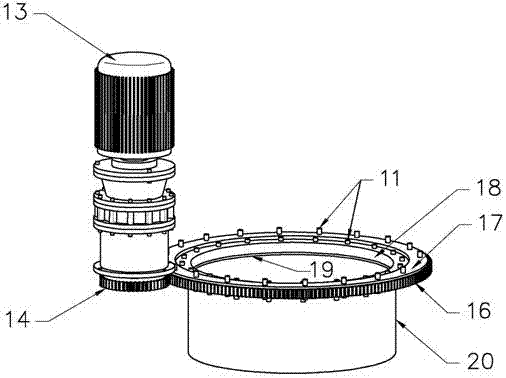

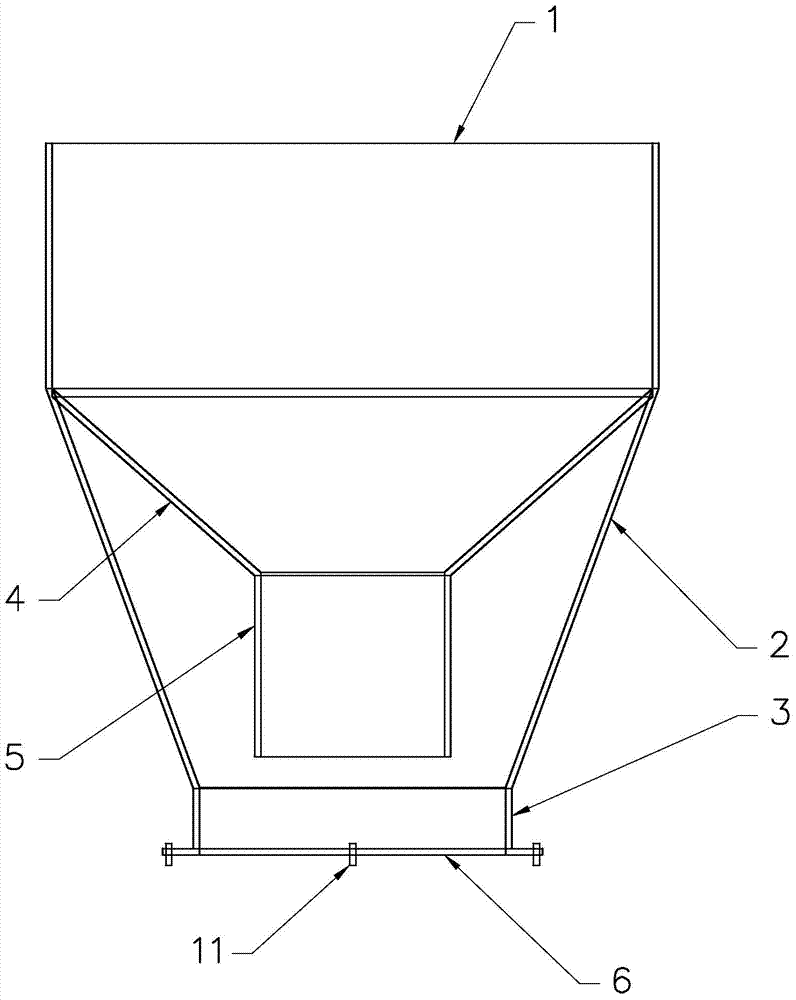

[0022] In order to facilitate the understanding of those skilled in the art, the following Figure 1-5 The present invention is further described.

[0023] A uniform material distribution device for a lime kiln mainly includes a feeding device, a transmission device and a discharging device. The feeding device mainly includes a feeding hopper 1, a conical bucket I2, and a discharge port I3. The feeding hopper 1 is circular and cylindrical, and the lower part of the feeding hopper 1 is provided with a conical bucket I2, and a conical bucket I2 The lower part is provided with a discharge port I3, which is circular and cylindrical, and the bottom of the discharge port I3 is provided with a flange 6; the discharge device mainly includes a connecting frame 7, a distribution hopper 8, and a flange 6. The flange 6 at the mouth of the discharge device is connected to the flange 6 at the bottom of the discharge port I3 of the feed device, and the two are connected by bolts 11; the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com