Method and device for microwave calcination of uranium chemical concentrate

A chemical concentrate and calcining technology, which is applied in the field of microwave calcined uranium chemical concentrate, can solve the problems of unrealized continuous industrial feeding and discharging, large-scale production, environmental impact of harmful flue gas emission, and low utilization rate of energy and heat. The efflux of harmful impurities and gases, the improvement of energy efficiency, the effect of high degree of digitization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

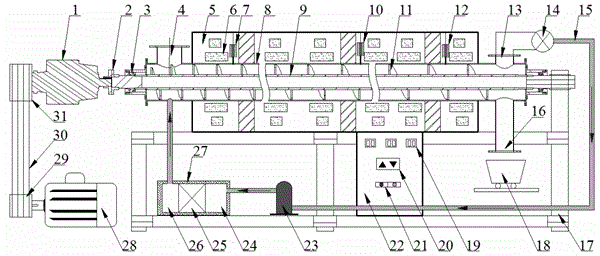

Image

Examples

Embodiment 1

[0028] The method for microwave calcining uranium chemical concentrate, its specific steps are as follows:

[0029] (1) First, add uranium chemical concentrate into the microwave calcination chamber at a feed rate of 300kg / h, control the stirring speed in the microwave calcination chamber to 20r / min, and then feed high-temperature waste heat flue gas to cool the uranium chemical concentrate Preheat to a temperature of 400°C; the uranium chemical concentrate is ammonium diuranate (ADU); 3 / h;

[0030] (2) Carry out three-stage calcination of the preheated uranium chemical concentrate: first, during the first stage of calcination: control the microwave output power to 20kW at a heating rate of 80°C / min, the calcination temperature to 840°C, and the calcination time to 5min ; Then in the second stage of microwave calcination process: adjust the microwave output power to 55kW, the calcination temperature to 870°C, and the calcination time to 5min; finally carry out the third stag...

Embodiment 2

[0039] The method for microwave calcining uranium chemical concentrate, its specific steps are as follows:

[0040] (1) First, add the uranium chemical concentrate into the microwave calcination chamber at a feed rate of 100kg / h, control the stirring speed in the microwave calcination chamber to 10r / min, and then feed the high-temperature waste heat flue gas to cool the uranium chemical concentrate Preheating to a temperature of 300°C; the uranium chemical concentrate is ammonium uranyl tricarbonate (AUC); the temperature of the high-temperature waste heat flue gas is 600°C, and the flow rate is 1m 3 / h;

[0041] (2) Carry out three-stage calcination of the preheated uranium chemical concentrate: first, during the first stage of calcination: control the microwave output power to 25kW at a heating rate of 60°C / min, the calcination temperature to 800°C, and the calcination time to 6min ; Then in the second stage of microwave calcination process: adjust the microwave output powe...

Embodiment 3

[0050] The method for microwave calcining uranium chemical concentrate, its specific steps are as follows:

[0051] (1) First, add the uranium chemical concentrate into the microwave calcination chamber at a feed rate of 400kg / h, control the stirring speed in the microwave calcination chamber to 30r / min, and then feed high-temperature waste heat flue gas to cool the uranium chemical concentrate Preheating to a temperature of 500°C; the uranium chemical concentrate is ammonium uranyl tricarbonate (AUC); the temperature of the high-temperature waste heat flue gas is 800°C, and the flow rate is 15m 3 / h;

[0052] (2) Carry out three-stage calcination of the preheated uranium chemical concentrate: first, during the first stage of calcination: control the microwave output power to 35kW at a heating rate of 100°C / min, the calcination temperature to 850°C, and the calcination time to 3min ; Then in the second stage of microwave calcination process: adjust the microwave output power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com