Lotus seed peel-grinding machine with abrasive belt

A technology of dermabrasion machine and abrasive belt, which is applied in the fields of shelling, pod removal, food science, etc. It can solve the problems of unable to meet the assembly line production mode, large loss of lotus seeds, and low production capacity, so as to achieve good peeling effect and good separation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

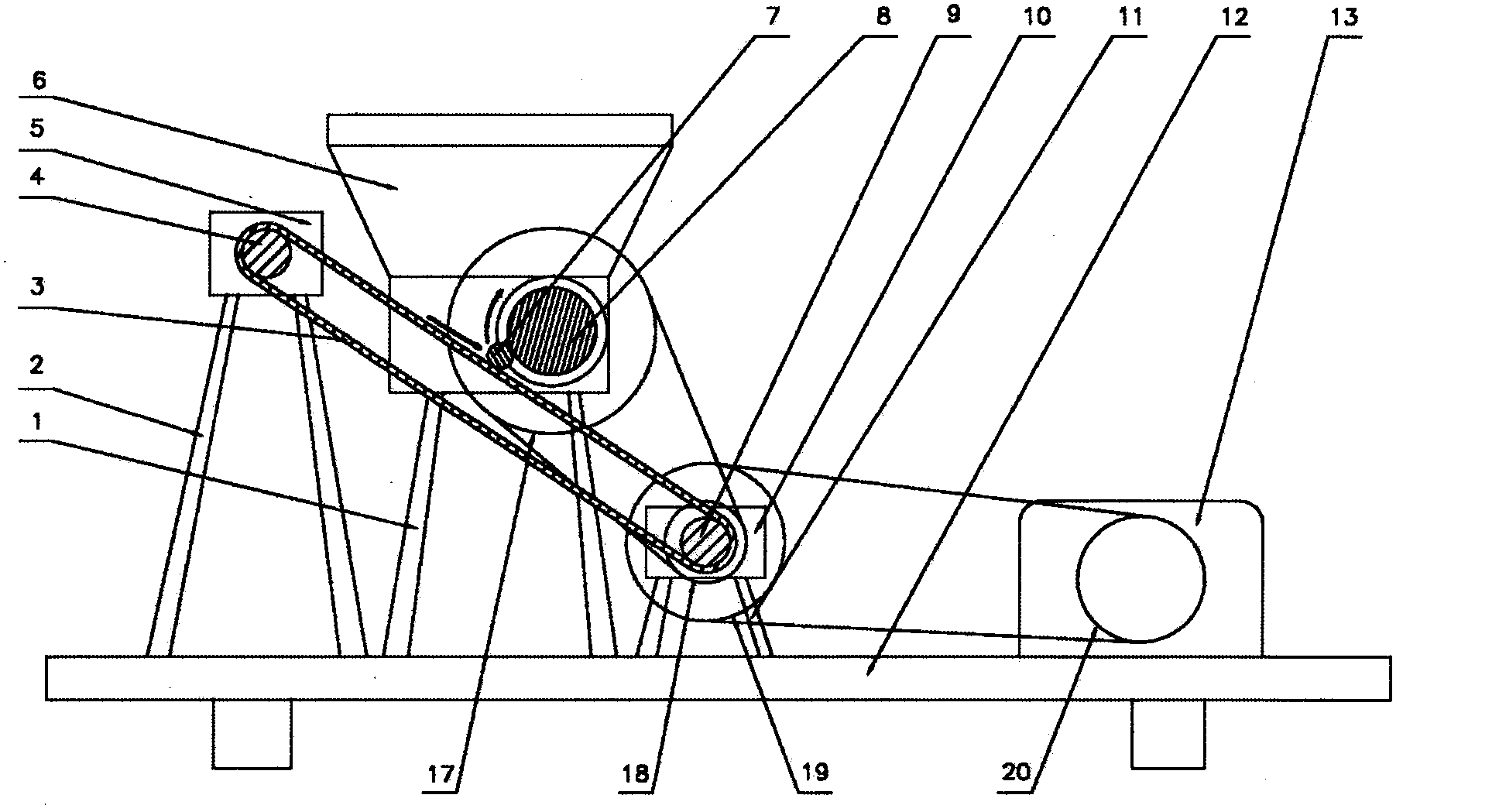

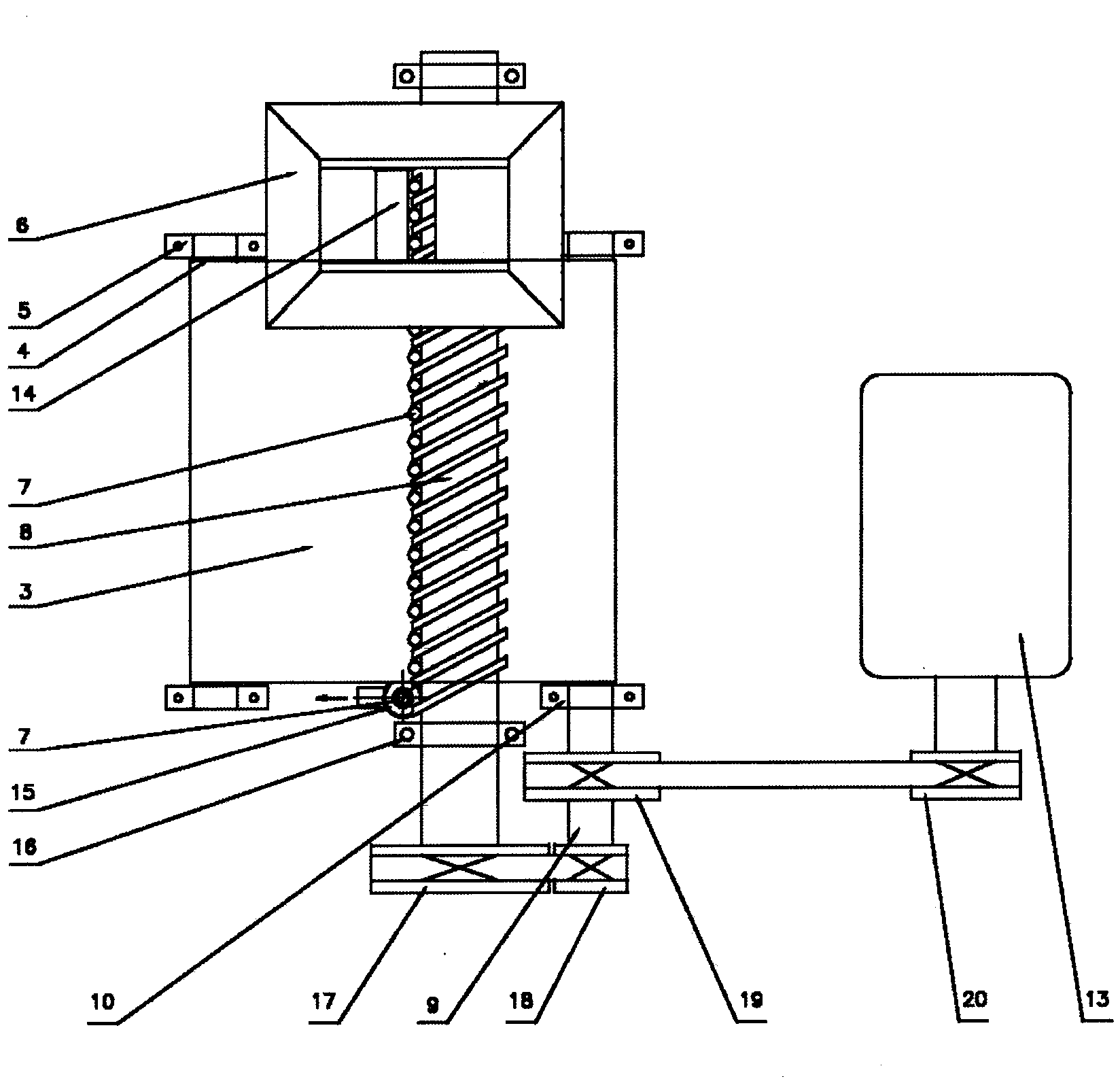

[0017] like figure 1 , figure 2 As shown, an abrasive belt lotus seed dermabrasion machine of the present invention is provided with a feeding hopper 6 on the workbench 12, a screw conveying rod 8 driven and rotated by a motor 13 is installed below the feeding hopper 6, and a movably installed polished rod 14 is connected to The screw conveying rods 8 are parallel and tangent to each other, and an abrasive belt 3 is arranged below the polished rod 14 and the screw conveying rod 8. The abrasive belt 3 driven by the motor 13 is in the same direction as the screw conveying rod 8. The three abrasive belts 3 constitute a work area for grinding the lotus seeds 7 dropped from the feeding hopper 6 , and a discharging hopper 15 is provided below the end of the screw conveying rod 8 . The screw conveying rod 8 rotates clockwise under the driving of the driving device, and the lotus seeds 7 are driven by the screw conveying rod 8 to realize the action of feeding into the microdermabras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com