Method for removing water in continuous esterifying process

A technology for removing water and esterification, applied in chemical instruments and methods, preparation of organic compounds, formation/introduction of carboxylate groups, etc., can solve the problems of increasing excess component circulation and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

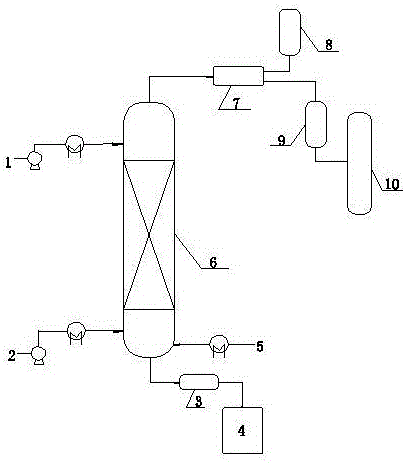

[0033] Preparation of ethyl laurate

[0034] Add D008 strongly acidic ion resin catalyst into the fixed bed reactor 6. Make lauric acid into 1 mol / L ethanol solution, add it from the upper part of the fixed bed reactor 6 at a rate of 1.0 mL / min, and add ethanol from the lower part of the fixed bed reactor at a rate of 0.5 mL / min. The carrier gas was nitrogen at a flow rate of 100 mL / min. The ethanol solution of lauric acid and the preheater temperature of ethanol are both 100°C, the temperature of the nitrogen preheater is 150°C, and the temperature of the fixed bed reactor is 100°C. The final yield of ethyl laurate is ≥99.2%.

Embodiment 2

[0036] Diethyl terephthalate

[0037] Add SO to the fixed bed reactor 4 2- / TiO 2Solid superacid catalyst. Terephthalic acid was made into a 1 mol / L ethanol solution, which was added at a rate of 1.0 mL / min from the upper part of the fixed-bed reactor, and ethanol was added at a rate of 1.0 mL / min from the lower part of the fixed-bed reactor. The carrier gas was argon with a flow rate of 15 mL / min. The temperature of the ethanol solution of terephthalic acid, ethanol and argon is all 120°C. The temperature of the fixed bed reactor was 120°C. The final conversion rate of terephthalic acid is ≥99.0%, and the selectivity of diethyl terephthalate is ≥98.5%.

Embodiment 3

[0039] Poly(hexanediol adipate)

[0040] Add H into the fixed bed reactor 3 PW 12 o 40 ·nH20 heteropolyacid catalyst. Mix adipic acid and hexanediol in equimolar amounts to prepare a dioxane solution with a single component concentration of 0.5 mol / L, and add it from the upper part of the fixed-bed reactor at a rate of 1.0 mL / min. The carrier gas was argon with a flow rate of 15 mL / min. The preheater temperature of the mixed solution was 150°C, and the preheating temperature of the argon gas was 200°C. The temperature of the fixed bed reactor was 150°C. The final reaction produces poly(hexanediol adipate) with a number average molecular weight of 2123.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com