Patents

Literature

37 results about "Diethyl terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

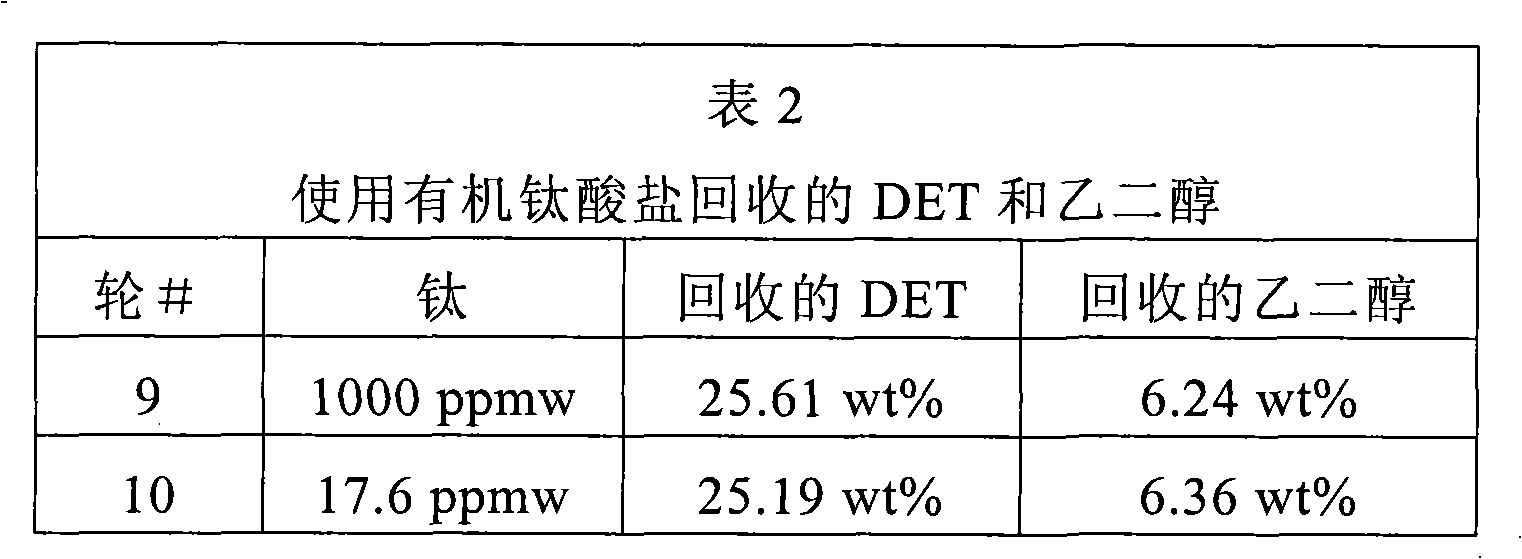

Ethanolysis of PET to Form DET and Oxidation Thereof

InactiveUS20090171113A1Wide rangeSimple handlingPreparation from carboxylic acid saltsOrganic compound preparationDiethyl terephthalateAcetic acid

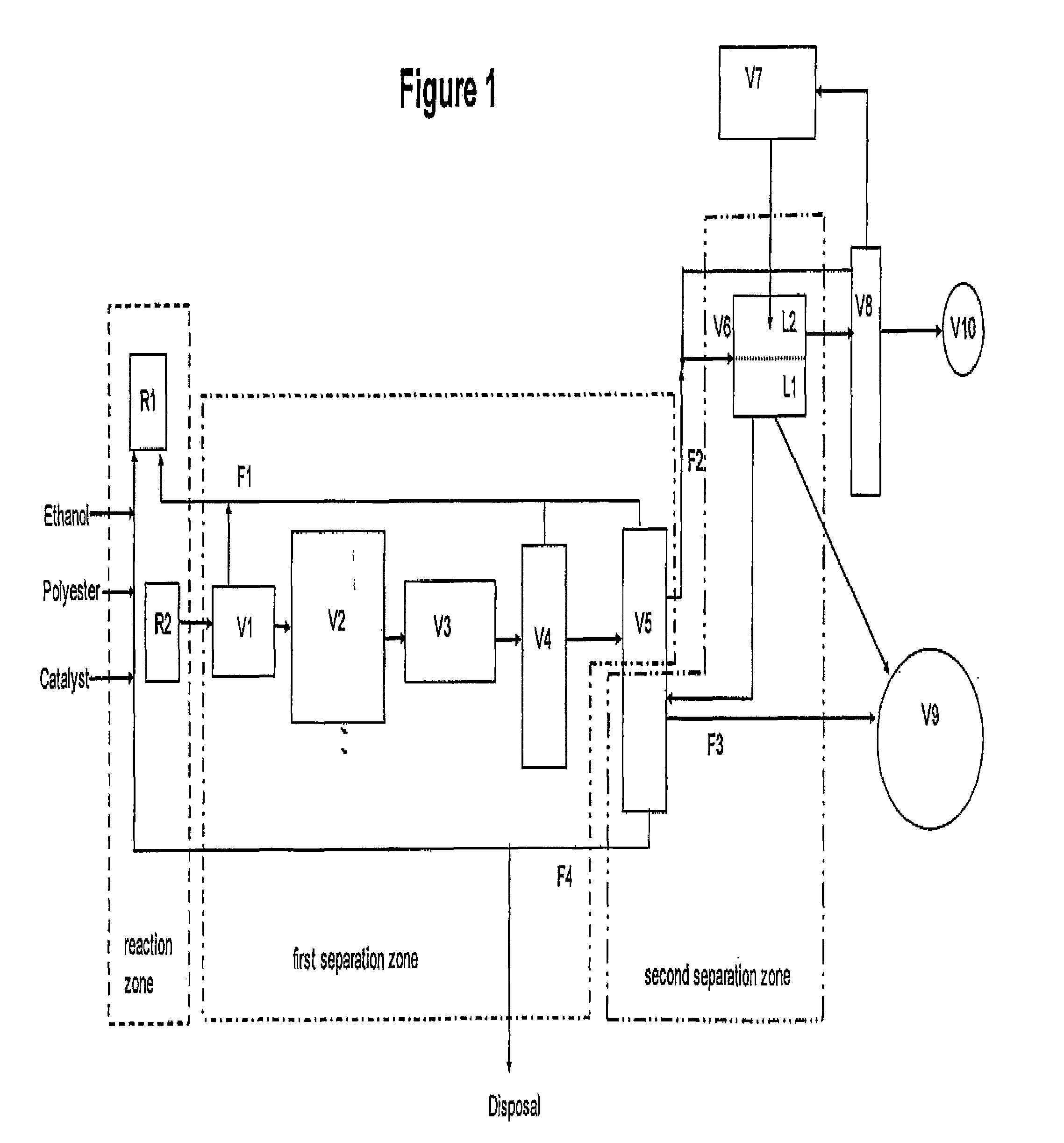

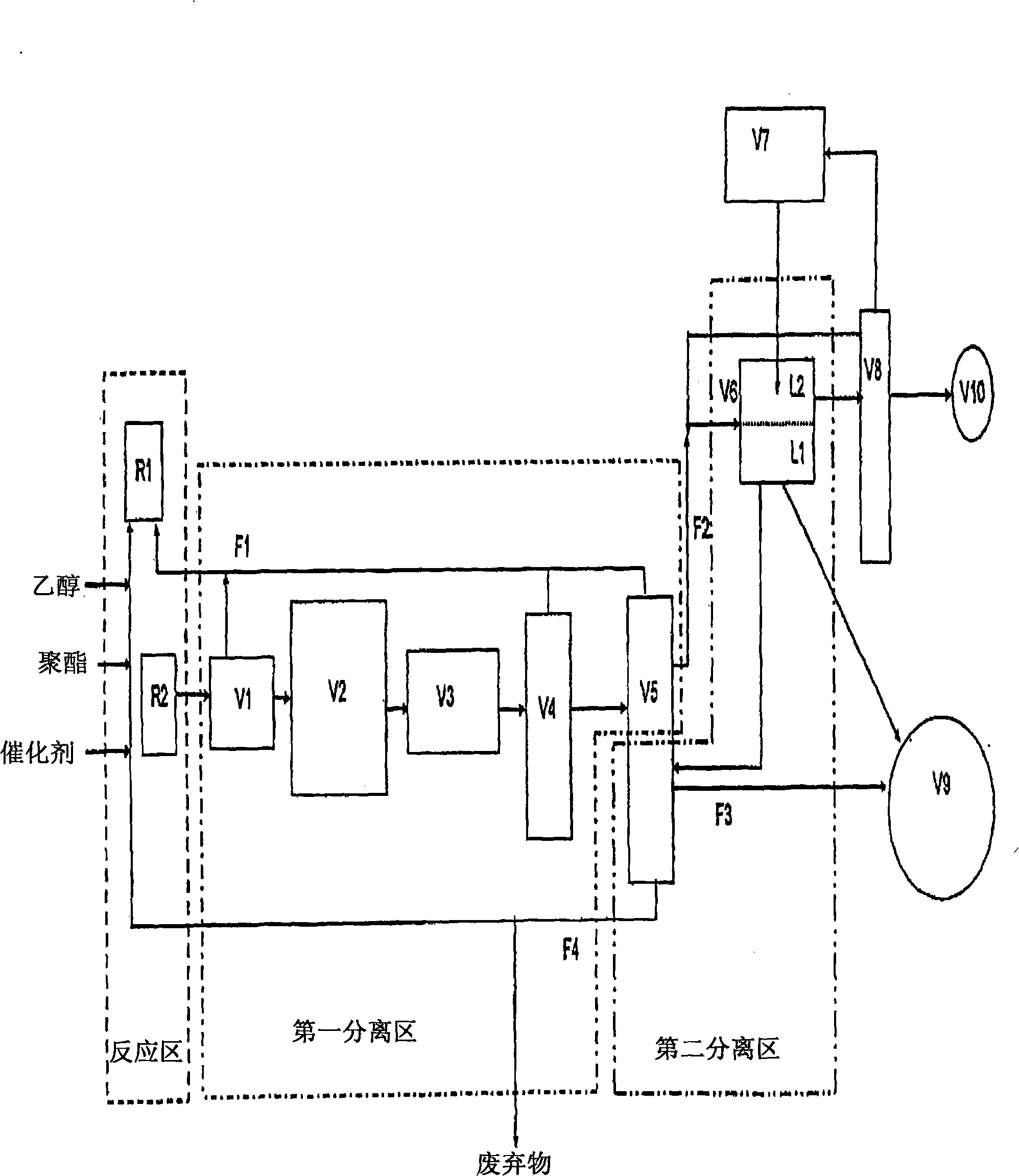

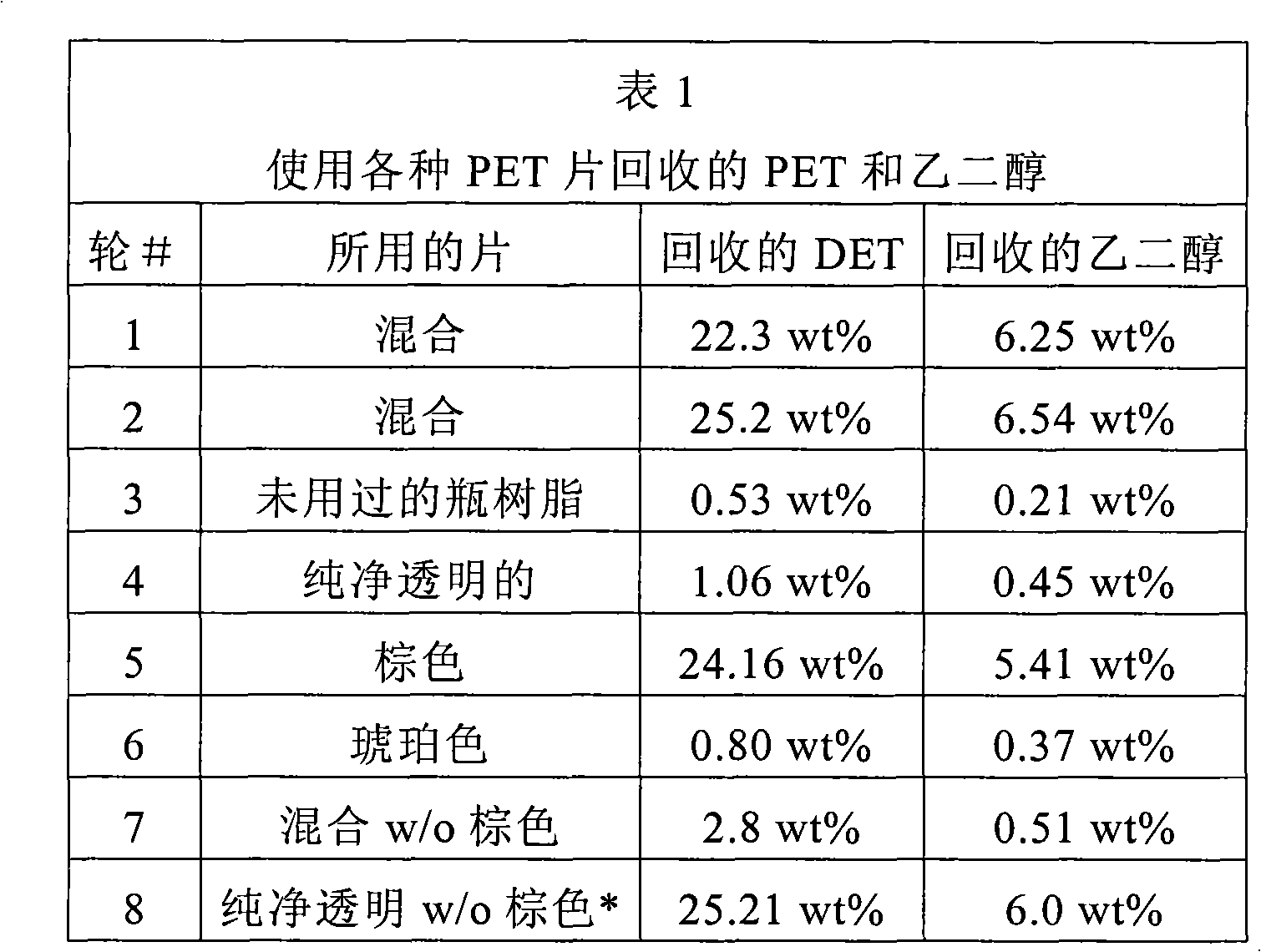

A process for ethanolysis of PET is disclosed wherein a feed comprising PET is reacted with ethanol and recovering ethylene glycol and an aromatic diethyl ester such as diethyl isophthalate and / or diethyl terephthalate. PET, or a terpolymer comprising terephthalate monomer and ethylene glycol monomers, is reacted with ethanol and ethanol, diethyl terephthalate, ethylene glycol and optionally diethyl isophthalate are recovered. Recovered diethyl components can be subjected to liquid-phase oxidation to produce aromatic carboxylic acid. Acetic acid may also produced via liquid-phase oxidation of recovered diethyl components. The aromatic carboxylic acid can be used to form polymer.

Owner:BP CORP NORTH AMERICA INC

Antistatic waterproof modified nylon 12 material for automobile plastic part

InactiveCN103665841AHigh hardnessExcellent electrical performanceDiethyl terephthalateHydrophobic silica

The invention belongs to the field of high polymer materials, and particularly relates to an antistatic waterproof modified nylon 12 material for an automobile plastic part. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 12, 7-9 parts of diethyl terephthalate, 15-18 parts of high-density polyethylene, 7-9 parts of ultrafine talcum powder, 3-4 parts of diaminodiphenylmethane, 2-3 parts of diammonium hydrogen phosphate, 6-8 parts of borax, 5-8 parts of rutile titanium white, 1-2 parts of hydrophobic silicon dioxide, 1.6-1.8 parts of antioxidant DSTP, 2-3 parts of stearic acid, 4-6 parts of dibutyl phthalate and 12-15 parts of assistant. According to the invention, the modified nylon 12 material combines the advantages of the raw materials such as the nylon 12, the high-density polyethylene and the like, and improves the performance of the traditional nylon 12 material. Besides, the raw materials such as the rutile titanium white, the hydrophobic silicon dioxide and the like are added, so that the prepared material is high in hardness, waterproof, dampproof, favorable in electric property, antistatic, heat-resistant, light-resistant and long in service life, and can be widely used in manufacturing of various automobile plastic parts.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

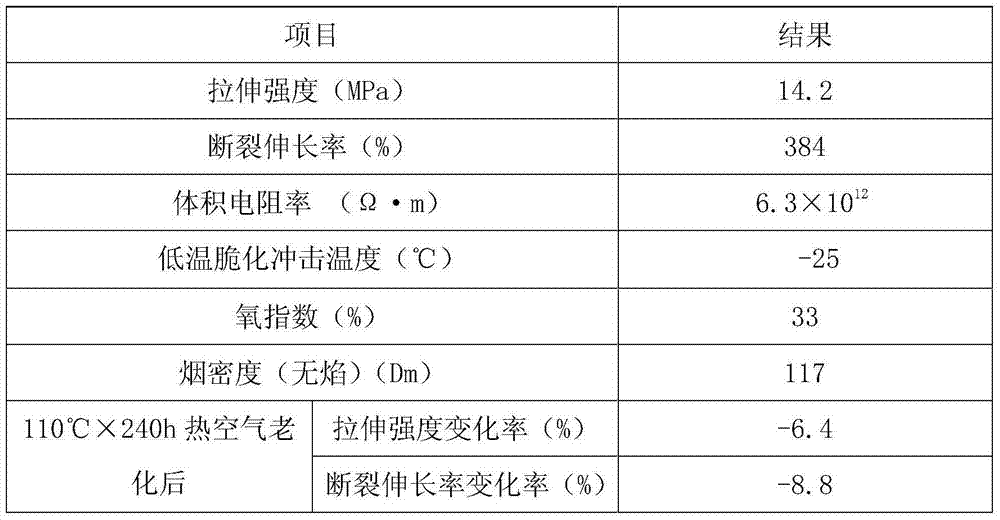

Ultraviolet-proof electric wire and cable material and preparation method thereof

InactiveCN103540052AImprove UV protection effectImprove light aging resistanceDiethyl terephthalateProcedure Agents

The invention discloses an ultraviolet-proof electric wire and cable material and a preparation method thereof. The ultraviolet-proof electric wire and cable material is prepared from the following raw materials in parts by weight: 80-90 of SG-2 type polyvinyl chloride (PVC), 20-30 of polyethylene terephathalate, 10-15 of bisphenol A polycarbonate, 1-2 of 4,4' diphenyl-methane-diisoc, 5-8 of jade powder, 3-6 of phosphoric aciddiphenyl ethylhexyl ester, 0.5-1.5 of lead sulfate tribasic, 2-3 of polyethylene wax, 1.5-2.5 of processing agent ACR-401, 1-1.5 of ultraviolet light absorber UV-531, 0.5-1 of ultraviolet light absorber UV-9, 10-15 of talcum powder, 4-8 of ammonium polyphosphate, 5-10 of nanosepiolite, 10-15 of magnesium sulfate crystal whiskers and 4-6 of composite fillers. The cable material not only has excellent ultraviolet-proof performance and improved light aging resistance, but also has good physical and mechanical performances, softness and tear resistance, corrosion resistance, high and low temperature resistance and acid-base resistance.

Owner:JING FENG GRP

Ethanolysis of PET to form DET and oxidation thereof

InactiveCN101351494APreparation by ester-hydroxy reactionOrganic compound preparationDiethyl terephthalateAcetic acid

A process for ethanolysis of PET is disclosed wherein a feed comprising PET is reacted with ethanol and recovering ethylene glycol and an aromatic diethyl ester such as diethyl isophthalate and / or diethyl terephthalate. PET, or a terpolymer comprising terephthalate monomer and ethylene glycol monomers, is reacted with ethanol and ethanol, diethyl terephthalate, ethylene glycol and optionally diethyl isophthalate are recovered. Recovered diethyl components can be subjected to liquid-phase oxidation to produce aromatic carboxylic acid. Acetic acid may also produced via liquid-phase oxidation of recovered diethyl components. The aromatic carboxylic acid can be used to form polymer.

Owner:BP CORP NORTH AMERICA INC

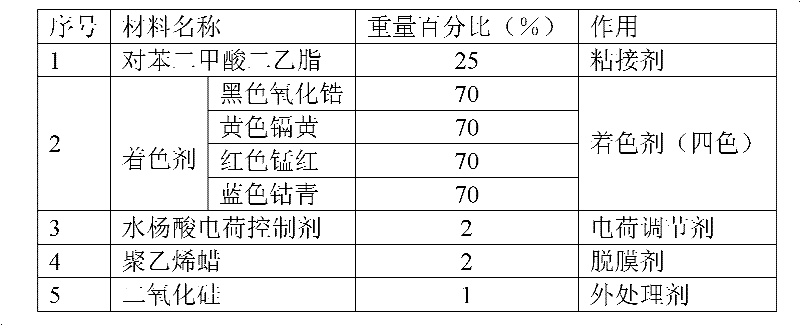

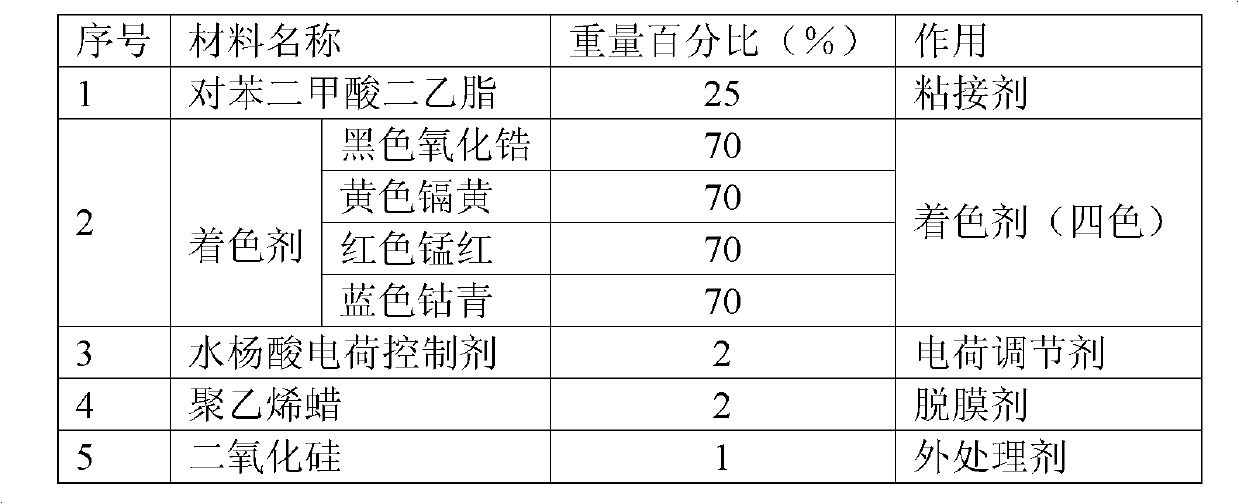

Preparation method of ceramic coloration toner for color laser printer

InactiveCN102645857AOvercome costsOvercoming quaternary coloringDevelopersDiethyl terephthalateCharge control

The invention discloses a preparation method of a ceramic coloration toner for a color laser printer, which relates to the ceramic coloration field. The method comprises pre-mixing diethyl terephthalate 25 parts, zirconia 70 parts, cadmium yellow 70 parts, manganese red 70 parts, cobalt ultramarine 70 parts, salicylic acid charge control agent 2 parts and polyethylene wax 2 parts according to weight percentage, and taking silica 1 part for use; extruding by using a double-screw extrusion machine, and performing coarse crushing and fine crushing on the extrudate; grading toner particles to control particle size D50 of the toner at 8.5+ / -0.5mum; and adding silica 1 part into the graded toner particles, mixing, and sieving by using a 120 mesh vibrating screen to obtain undersized product which is the ceramic coloration toner for the color laser printer. The method simplifies the process, lowers the cost, is convenient, and saves time and energy.

Owner:WUHAN POINTROLE TECH

Polyurethane composite resin paint resistant to friction and dirt as well as preparation method of paint

InactiveCN105131820AImprove wear resistanceImprove adhesionAntifouling/underwater paintsPaints with biocidesDiethyl terephthalateZirconate

The invention discloses a polyurethane composite resin paint resistant to friction and dirt as well as a preparation method of the paint. The paint is prepared from a polyurethane prepolymer, acrylate, diethyl phthalate, activated alumina, dipropyleneglycol dimethyl ether, hexamethyldisilazane, nanometer calcium zirconate, potassium metasilicate, polypropylene glycol, nanometer silicon dioxide, polyamide wax, an antioxidant CPPD, 2-amino-2-methyl-1-propyl alcohol, polyoxypropylene glycerol ether, pentaerythritol stearate, epoxidized soybean oil, jade powder, sodium bentonite, chlorinated paraffin and the like. Polyurethane, acrylate and the like are cooperatively adopted as film-forming materials, so that the paint has high film-forming, leveling, friction-resistant and dirt-resistant properties; under the action of polypropylene glycol, the added nanometer calcium zirconate can be uniformly and stably dispersed in the paint, so that the friction-resistant capability of the paint is further enhanced, the dispersing interface tension of nanometer silicon dioxide is reduced, the compatibility of nanometer silicon dioxide and nanometer calcium zirconate is improved, and then the adhesive force of the paint is increased.

Owner:黄利锟

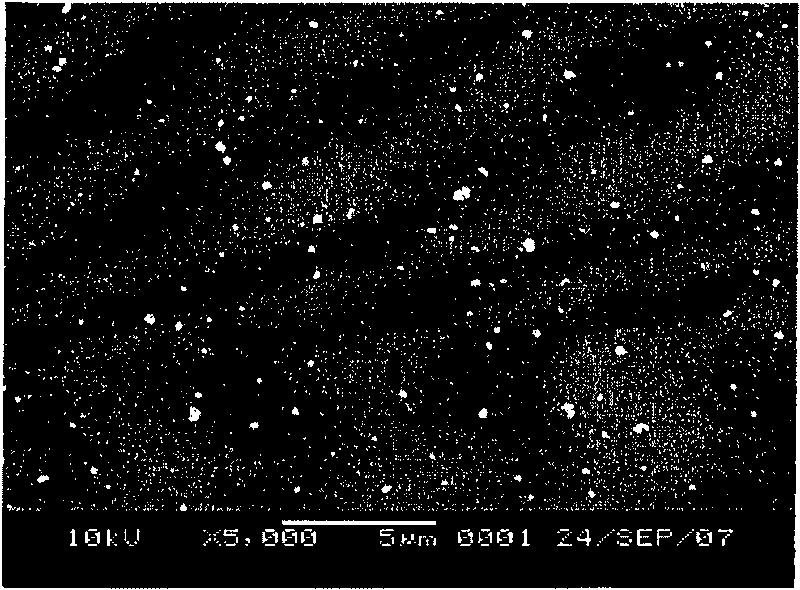

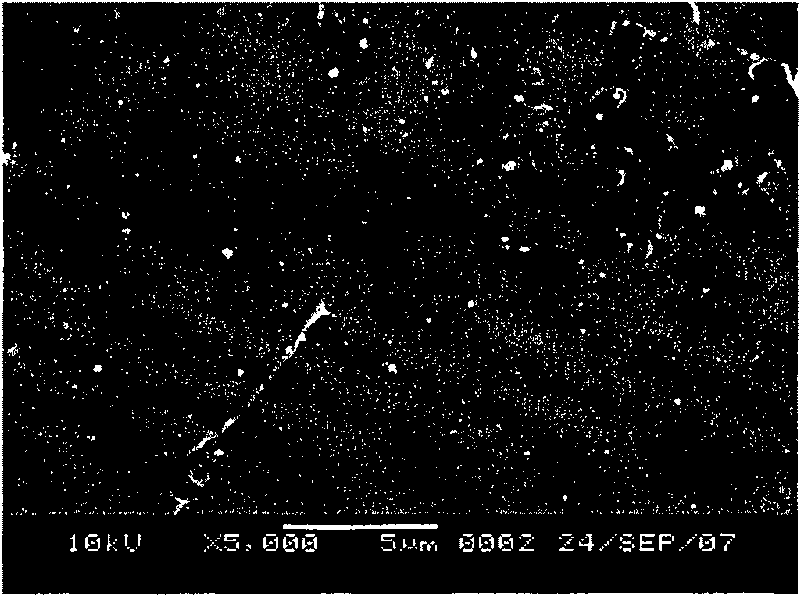

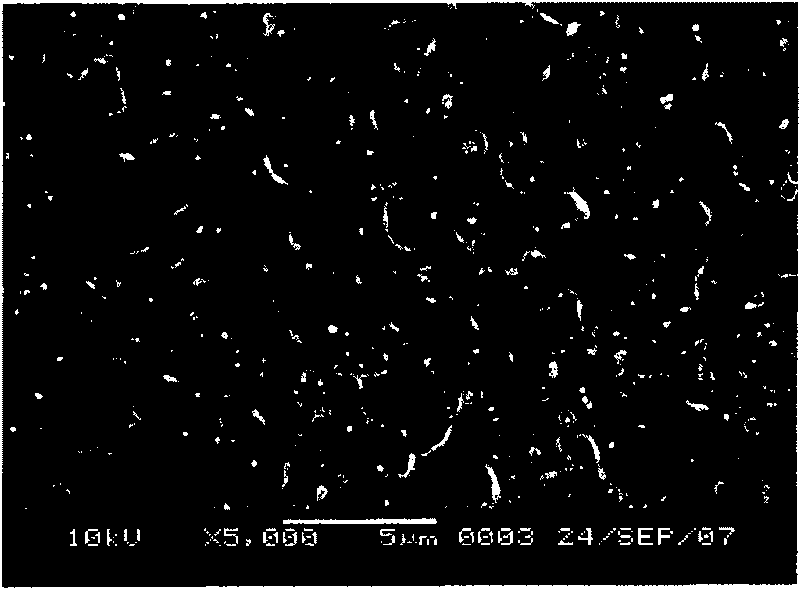

Bacterial strain for degrading diethyl terephthalate and application thereof

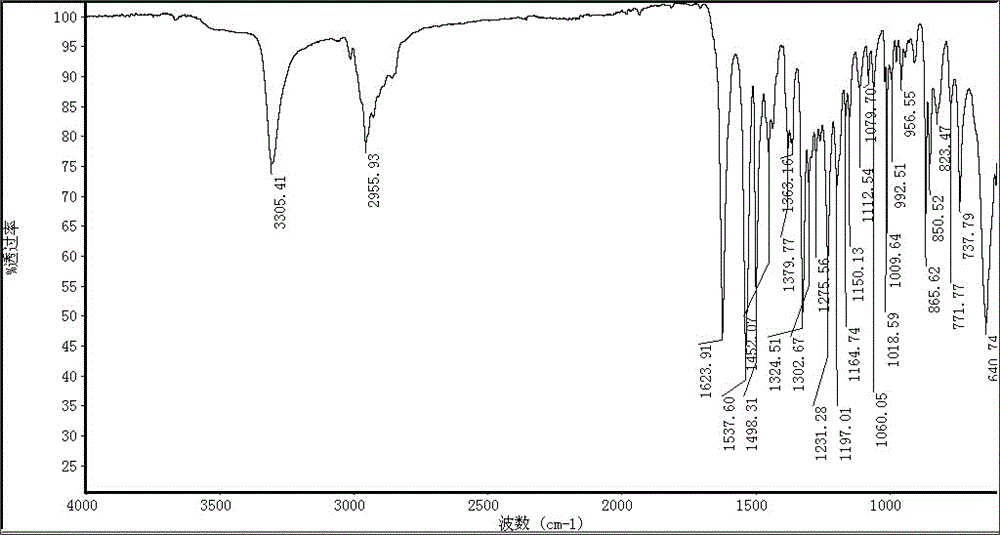

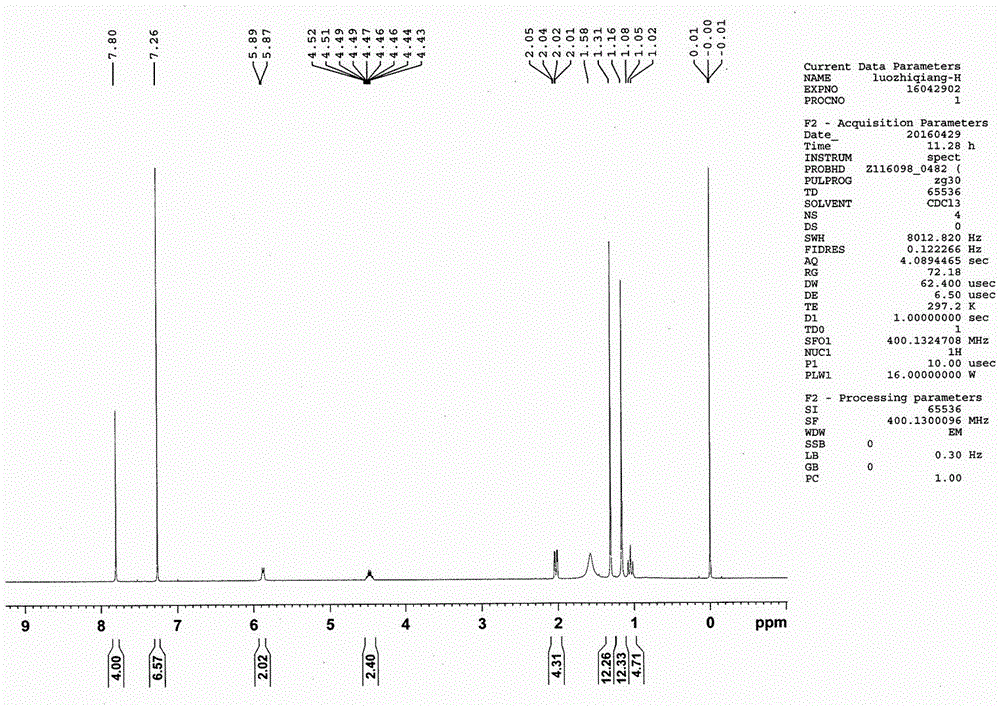

The invention discloses a bacterial strain for degrading diethyl terephthalate and application thereof. The bacterial strain is classified and named as Delftia sp., with the bacterial strain number being WL-3, the bacterial strain is preserved in China center for type culture collection, with the preservation number being CCTCC NO: M 2017136, and the preservation data being March 21, 2017. The invention further discloses application of the bacterial strain in degrading diethyl terephthalate. The bacterial strain WL-3 is aerobic microorganism, the optimal growth temperature is 30 DEG C, and the optimal growth pH is 7.0. The bacterial strain can completely degrade 1000mg / L diethyl terephthalate within 7 days and can use the same as a unique carbon source to grow to completely degrade metabolite of terephthalic acid. The bacterial strain disclosed by the invention has important application value on degrading the diethyl terephthalate, and the metabolite thereof, and biological treatment on industrial wastewater.

Owner:NANJING UNIV OF TECH

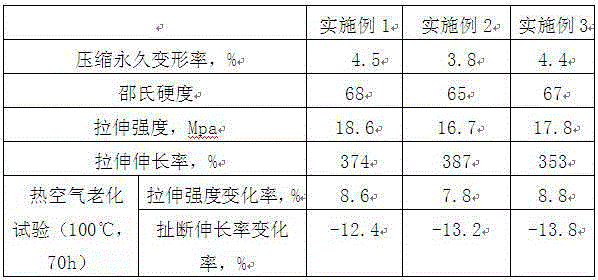

Butadiene-acrylonitrile rubber material for automobile engine shock absorption and preparation method thereof

InactiveCN105131375AImprove seismic performanceLarge energy loss coefficientDiethyl terephthalateAluminate

The invention discloses a butadiene-acrylonitrile rubber material for automobile engine shock absorption and a preparation method thereof. The butadiene-acrylonitrile rubber material is prepared from the following raw materials: butadiene-acrylonitrile rubber, natural rubber, acrylate rubber, tricaprin, diethyl terephthalate, distearoyl isopropoxy aluminate, triallyl isocyanurate, methyl ethyloxy silicone oil, carbon fiber, acrylic pulp, diamond micro-powder, nano-zinc oxide, dibutyltin dilaurate, benzoylacetone, sulphur, 1,4-cyclohexanedimethanol, tetrahydrofurfuryk oleate, tin antimony oxide, potassium titanate whiskers, sepiolite fabric, and the like. According to the butadiene-acrylonitrile rubber material for automobile engine shock absorption and the preparation method thereof, the components are simple, and the preparation technology is simple; carbon fiber, potassium titanate whiskers, and the like, are added in the rubber, so that the shock resistant effect of the rubber is improved, the energy loss coefficient of the rubber is increased, and the rebound resilience is reduced; diethyl terephthalate, acrylic pulp, and the like, are added and matched, so that abrasion resistance of the rubber is improved, the dosage of a plasticizer is decreased, and properties such as flexibility of the rubber are improved.

Owner:蔡逸

Static electricity resisting polyethylene terephthalate modified resin

InactiveCN101215373AHas antistatic propertiesMonocomponent polyesters artificial filamentArtifical filament manufactureDiethyl terephthalatePolyester

The invention relates to an improved resin of polyethylene glycol terephthalate with antistatic property, and the resin is prepared by ethylene glycol terephthalate and polyester ether which contains nanometer antimony and is doped with stannic oxide in the temperature between 260 DEG C to 280 DEG C, and in the vacuum between 20 Pa-100Pa, wherein, the polyester ether which contains nanometer antimony and is doped with stannic oxide is prepared by the mixture which is composed of ethylene glycol terephthalate and polyether and nanometer antimony which are doped with stannic oxide, and the mass resistivity of the improved resin of the polyethylene glycol terephthalate which is got is 1*107 ohms.cm-9*109 ohms. cm. The invention solves the permanence problem of anti-static function of polyester.

Owner:EAST CHINA UNIV OF SCI & TECH

Antibacterial anti-aging refrigerator door sealing strip and preparation method thereof

InactiveCN109054231AImprove anti-aging propertiesImprove antibacterial propertiesDomestic cooling apparatusLighting and heating apparatusFiberRefrigerator car

The invention discloses an antibacterial anti-aging refrigerator door sealing strip and a preparation method thereof. The antibacterial anti-aging refrigerator door sealing strip is prepared from a soft polyvinyl chloride jacket and a magnetic rubber strip, wherein the soft polyvinyl chloride jacket is prepared from the following raw materials: polyvinyl fluoride, acrylonitrile-butadiene-styrene copolymer, 24-28 parts of polyurethane resin, epoxy resin, glass fiber, glass cotton, ceramic fiber, calcium carbonate, graphite, polydiethyl terephthalate, a light stabilizer, an inorganic antibacterial agent, a plasticizer and an antioxidant; the magnetic rubber strip is prepared from the following raw materials: rubber, magnetic powder, calcium carbonate and graphite. The preparation method comprises the following steps: (S1) preparing the soft polyvinyl chloride jacket; (S2) preparing the magnetic rubber strip; (S3) tucking the magnetic rubber strip in the soft polyvinyl chloride jacket, and welding at an opening to obtain a primary finished product; (S4) soaking the primary finished product in antibacterial liquid for 48-56 h, and drying to obtain the antibacterial anti-aging refrigerator door sealing strip. According to the antibacterial anti-aging refrigerator door sealing strip and the preparation method thereof disclosed by the invention, the preparation process is simple and practical, the antibacterial anti-aging refrigerator door sealing strip is suitable for large-range popularization and application, and the raw materials are widely available.

Owner:安徽省星年华电气股份有限公司

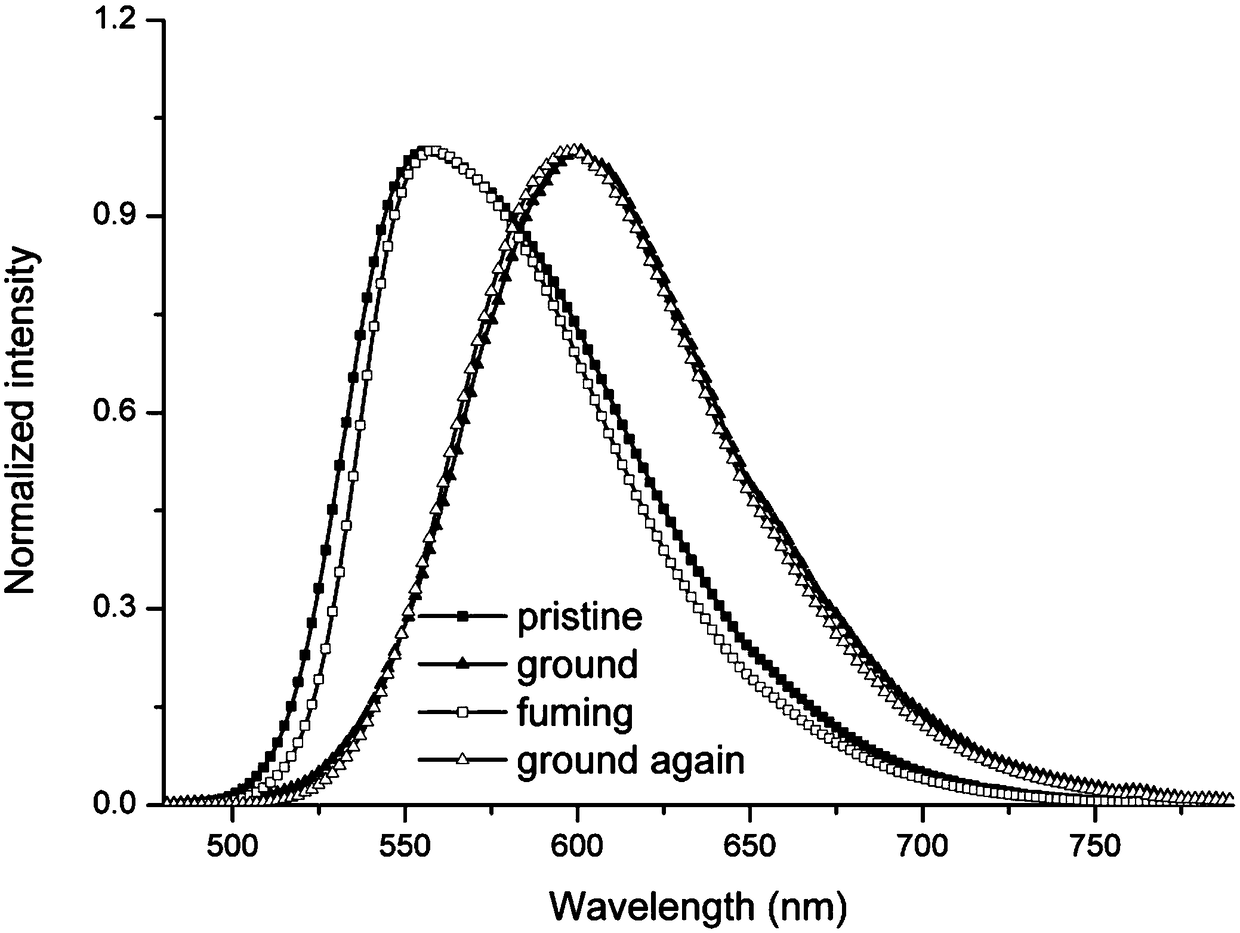

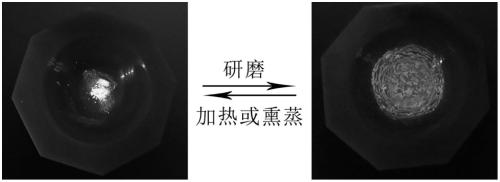

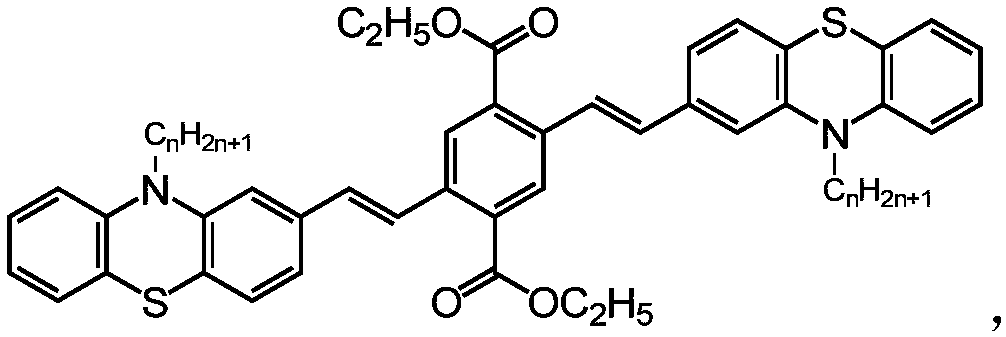

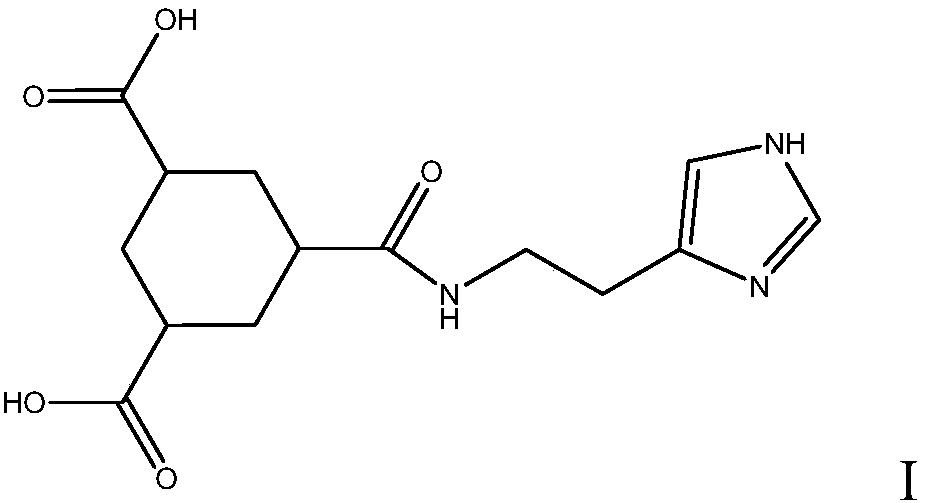

Mechanochromic diethyl terephthalate compound, as well as preparation method and application thereof

ActiveCN108947933AGood mechanochromic propertiesEasy to prepareOrganic chemistryTenebresent compositionsDiethyl terephthalateFluorescence

The invention provides a mechanochromic diethyl terephthalate compound, as well as a preparation method and application thereof. The compound has a structural formula as shown in the specification, wherein n is 2, 4, 6, 8, 12 and 16, can be applied to mechanochromic materials, information storage and landmark anti-counterfeiting and preparation of mechanochromic films. The preparation method is simple, and the film prepared by the method has excellent mechanochromic property, color under natural light and fluorescent color can be changed under mechanical force, and the film can be quickly restored to the original state under the atmosphere of an organic solvent or under a heating condition, so that the process has recyclability, which indicates that the compound can be recycled. The mechanochromic diethyl terephthalate compound has excellent optical stability, high repeatability and high contrast ratio, and has a wide application prospect in information storage and anti-counterfeitingaspects.

Owner:TIANJIN NORMAL UNIVERSITY

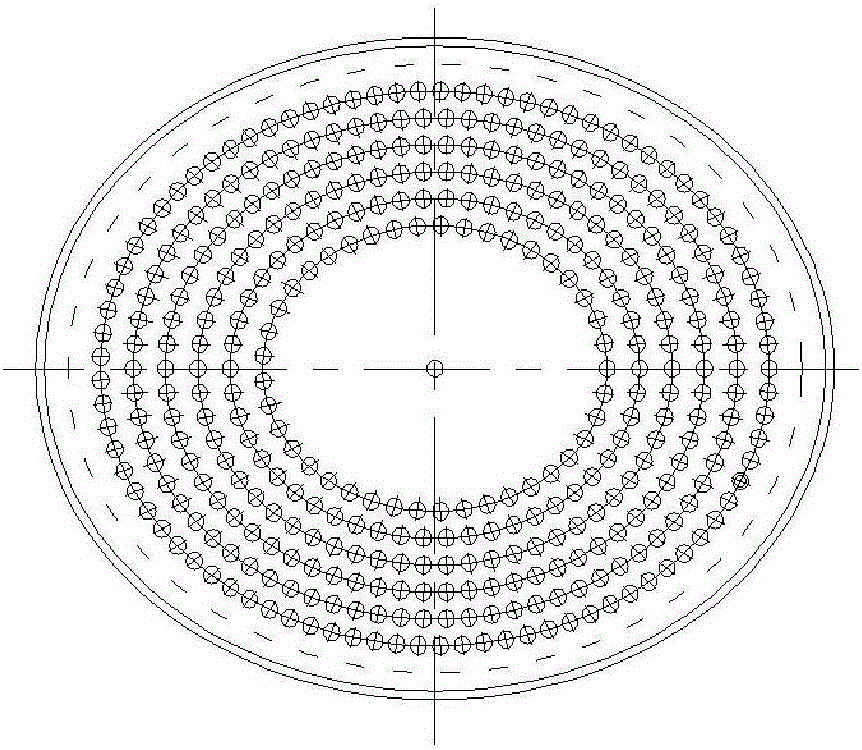

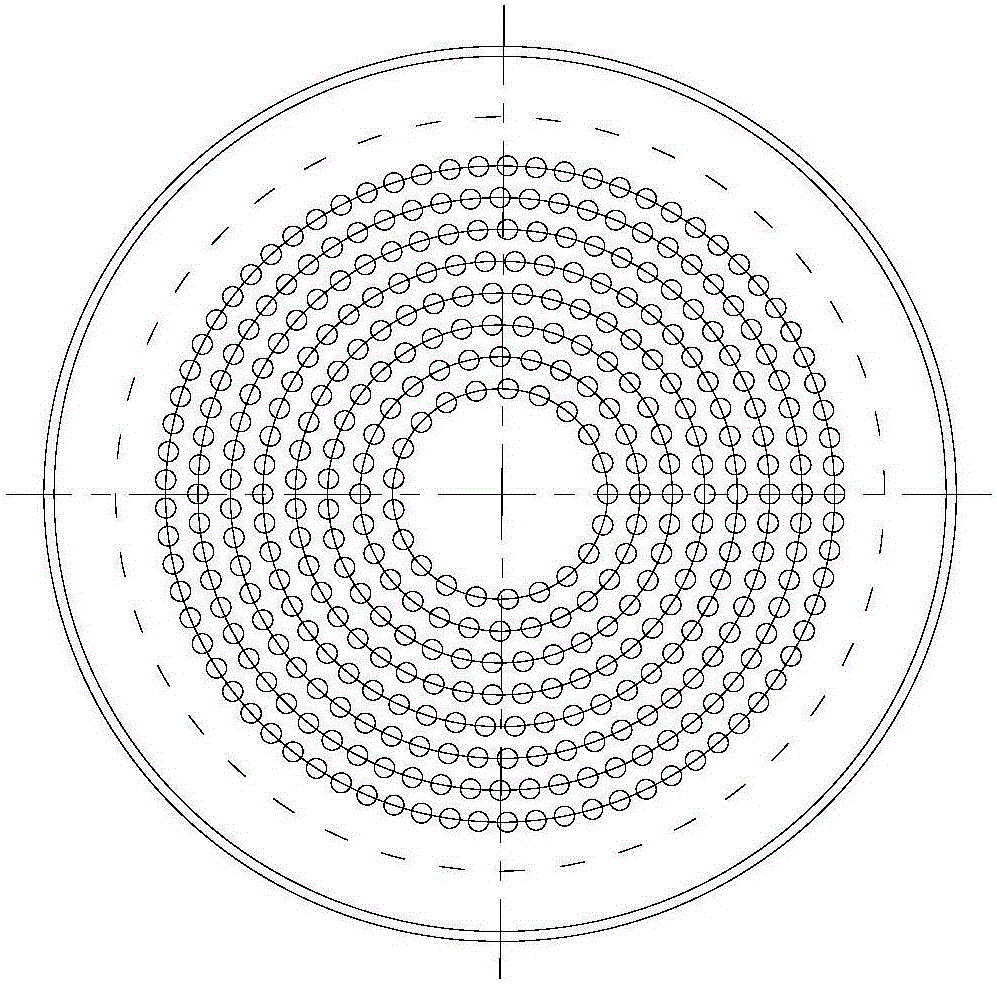

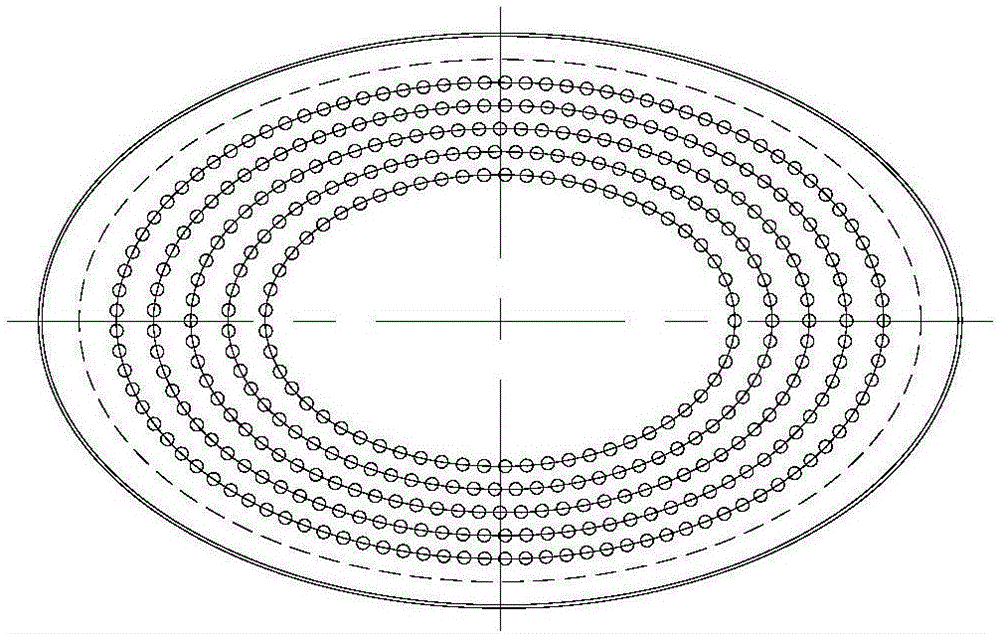

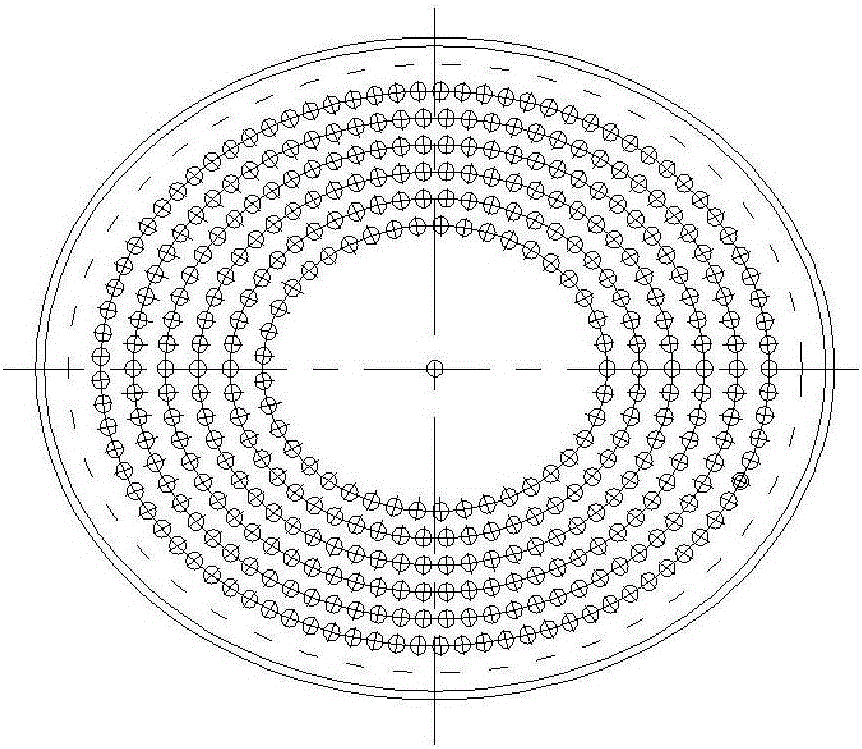

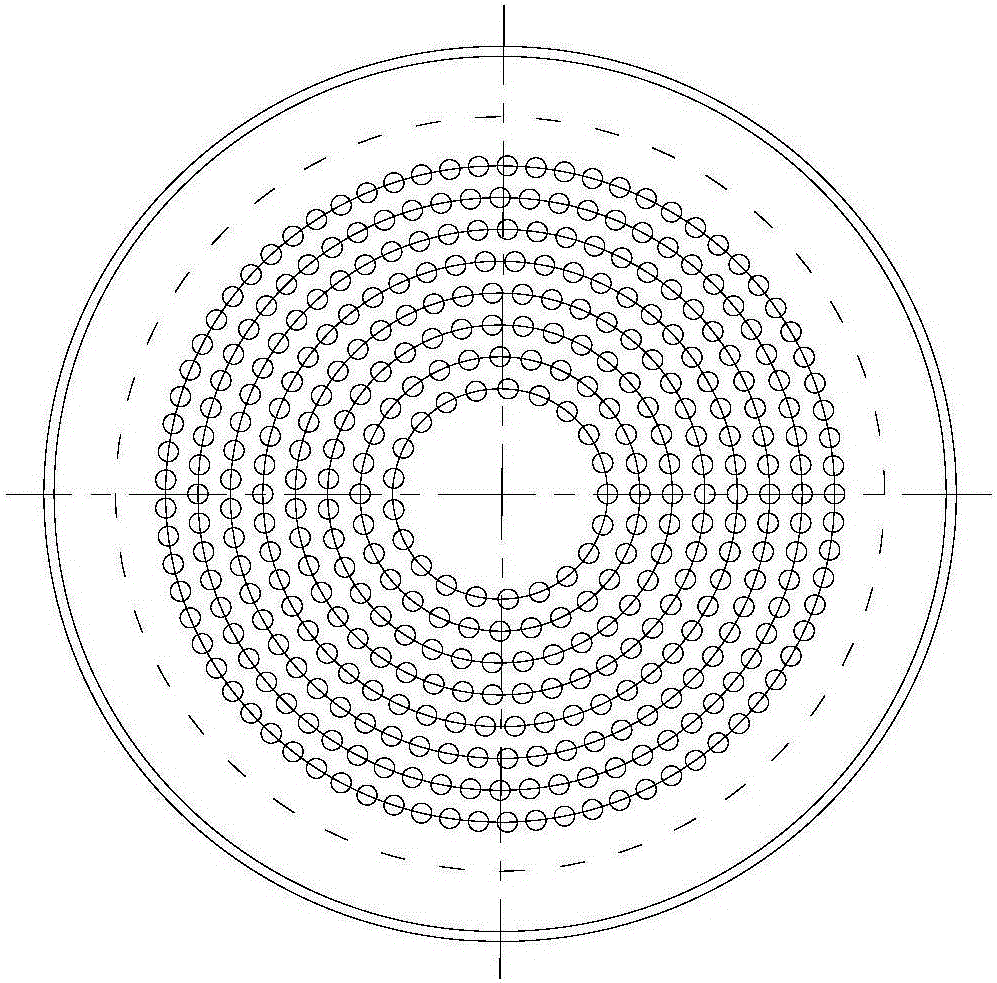

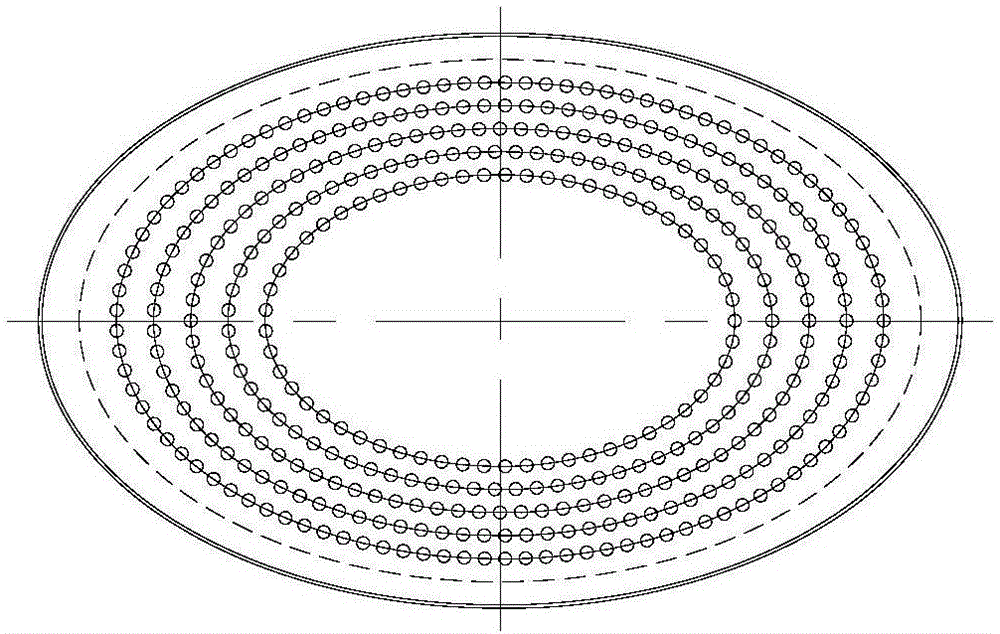

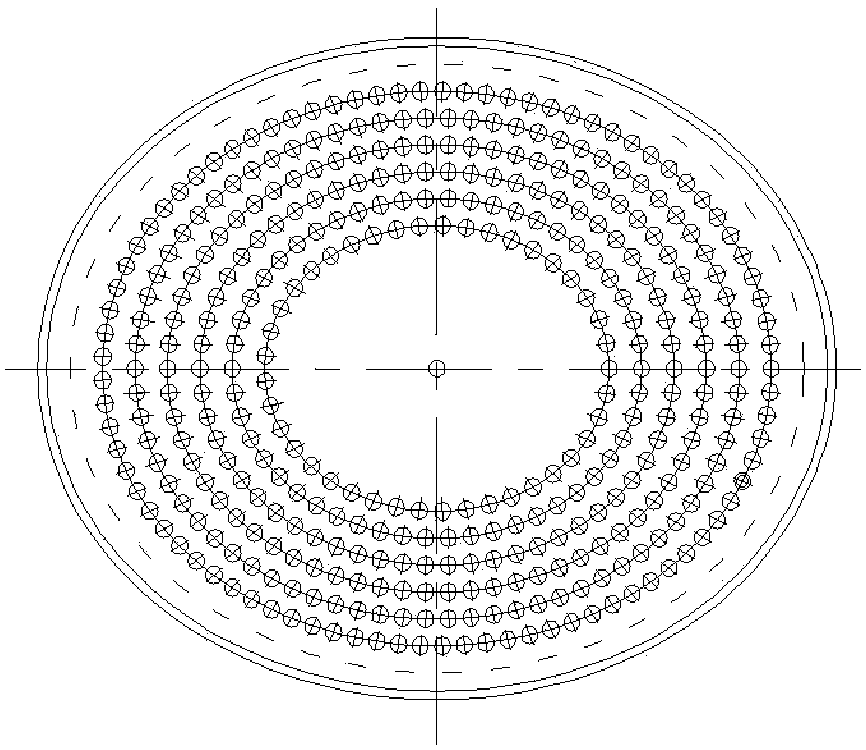

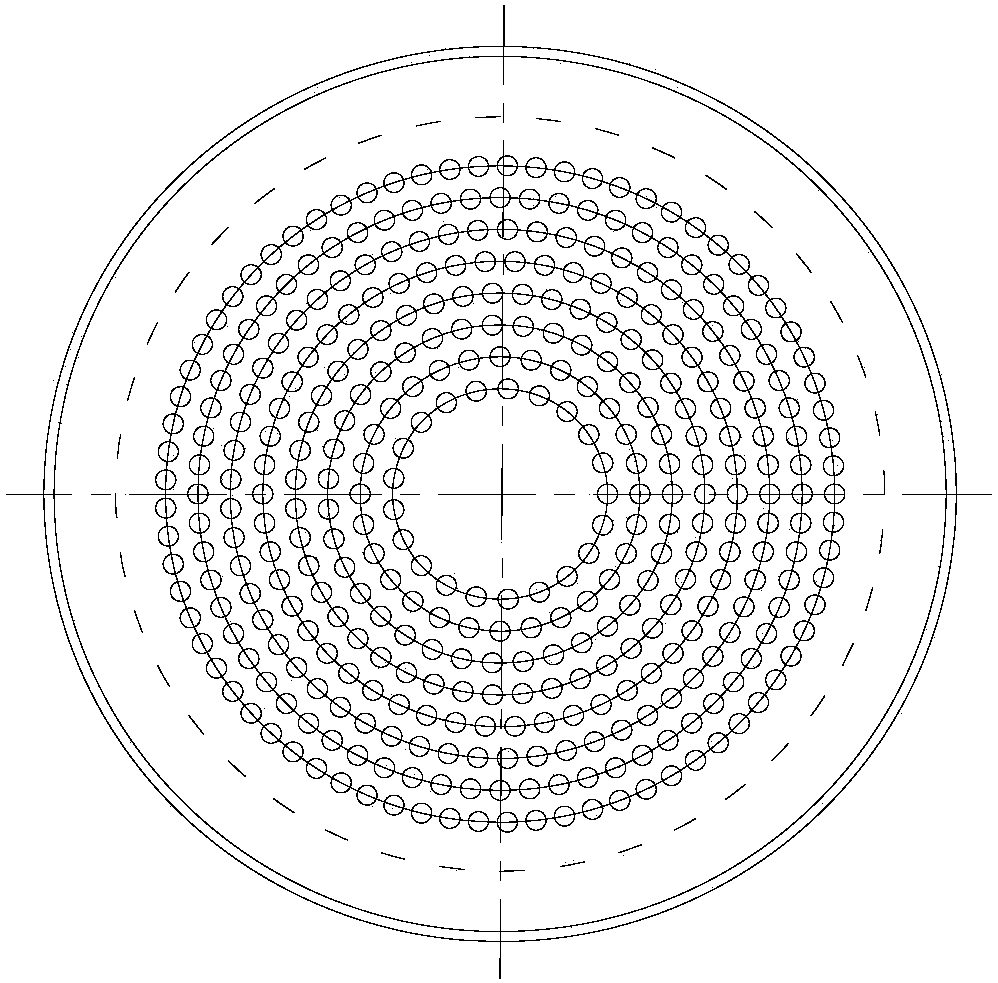

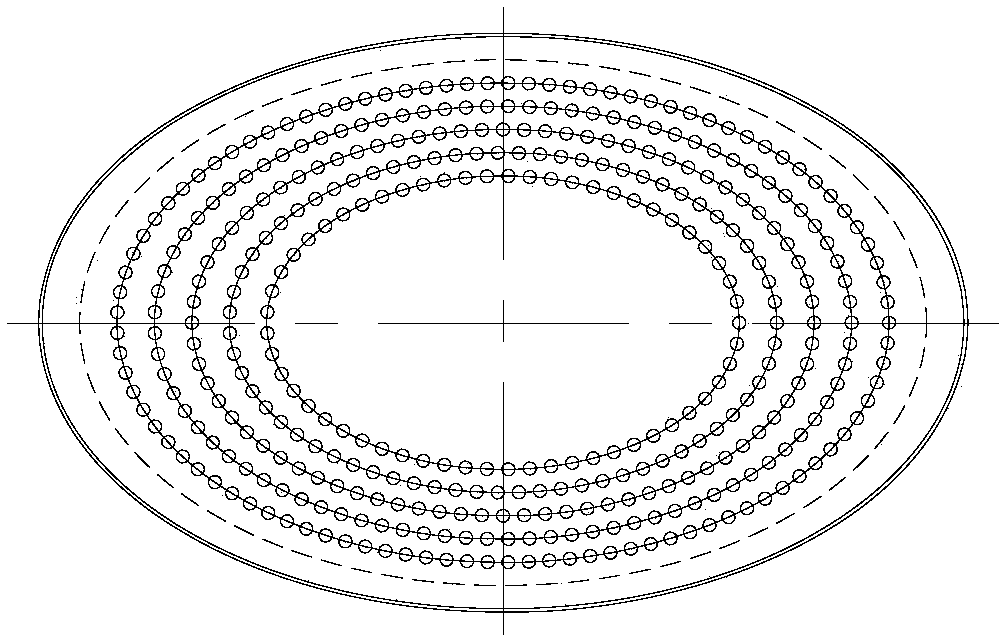

Porous PBT fiber HOY filament and preparation method thereof

ActiveCN106283252AIncreased access to polyester interiorIncreased free volumeSpinnerette packsMonocomponent copolyesters artificial filamentDiethyl terephthalateFiber

The invention relates to a porous PBT fiber HOY filament and a preparation method thereof. The method comprises the following steps: spinning modified PBT polyester by adopting a porous spinneret, so as to obtain porous PBT fiber HOY filaments. The spinneret orifices on the porous spinneret are arranged in an elliptical shape, namely the centers of the spinneret orifices are positioned on concentric ellipses, the concentric ellipses are a series of ellipses, and both long axes and short axes of all the ellipses are collinear. The porous PBT fiber HOY filament is prepared by metering, squeezing, cooling, oiling and winding the modified PBT polyester, and the preparation method of the modified PBT polyester comprises the steps: carrying out a reaction between terephthalic acid and 1,4-butanediol to prepare 1,4-butanediol -terephthalate, adding diethyl terephthalate prepared by carrying out a reaction between terephthalic acid and a dihydric alcohol containing branched chains, and continuously carrying out the reaction to obtain the modified PBT polyester. The fiber disclosed by the invention is excellent in performance, the linear density deviation rate is less than or equal to 0.2%, the breaking strength CV value is less than or equal to 2.5%, and the breaking elongation CV value is less than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

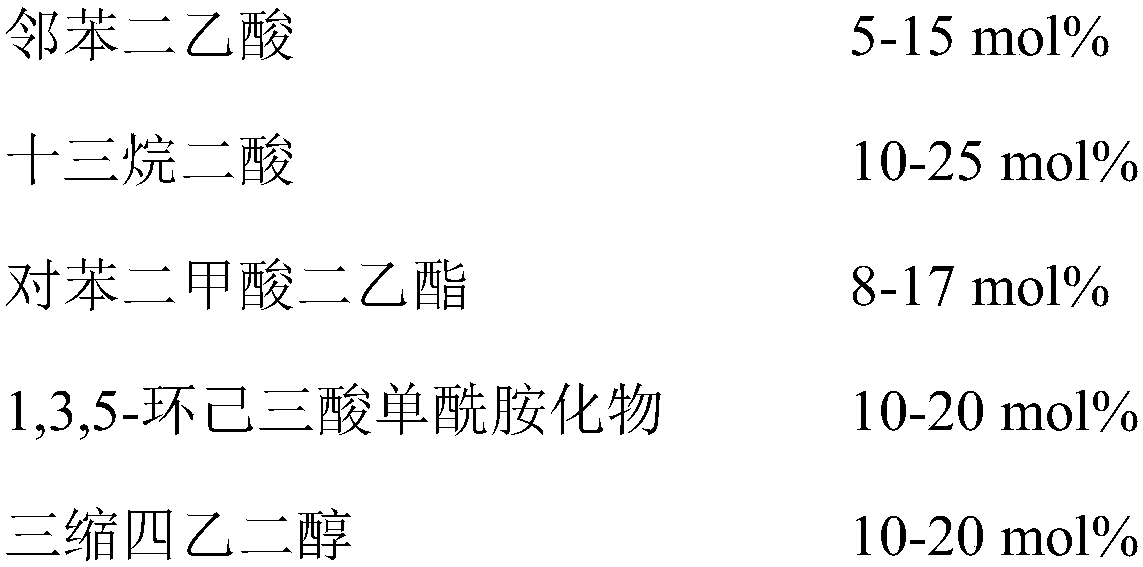

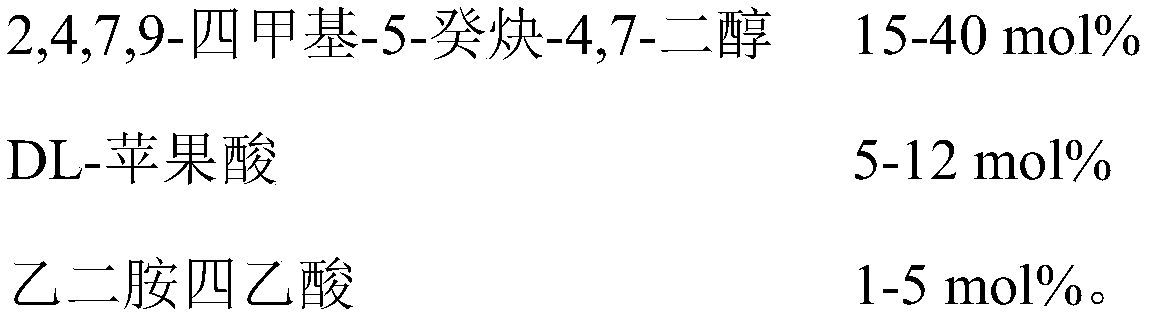

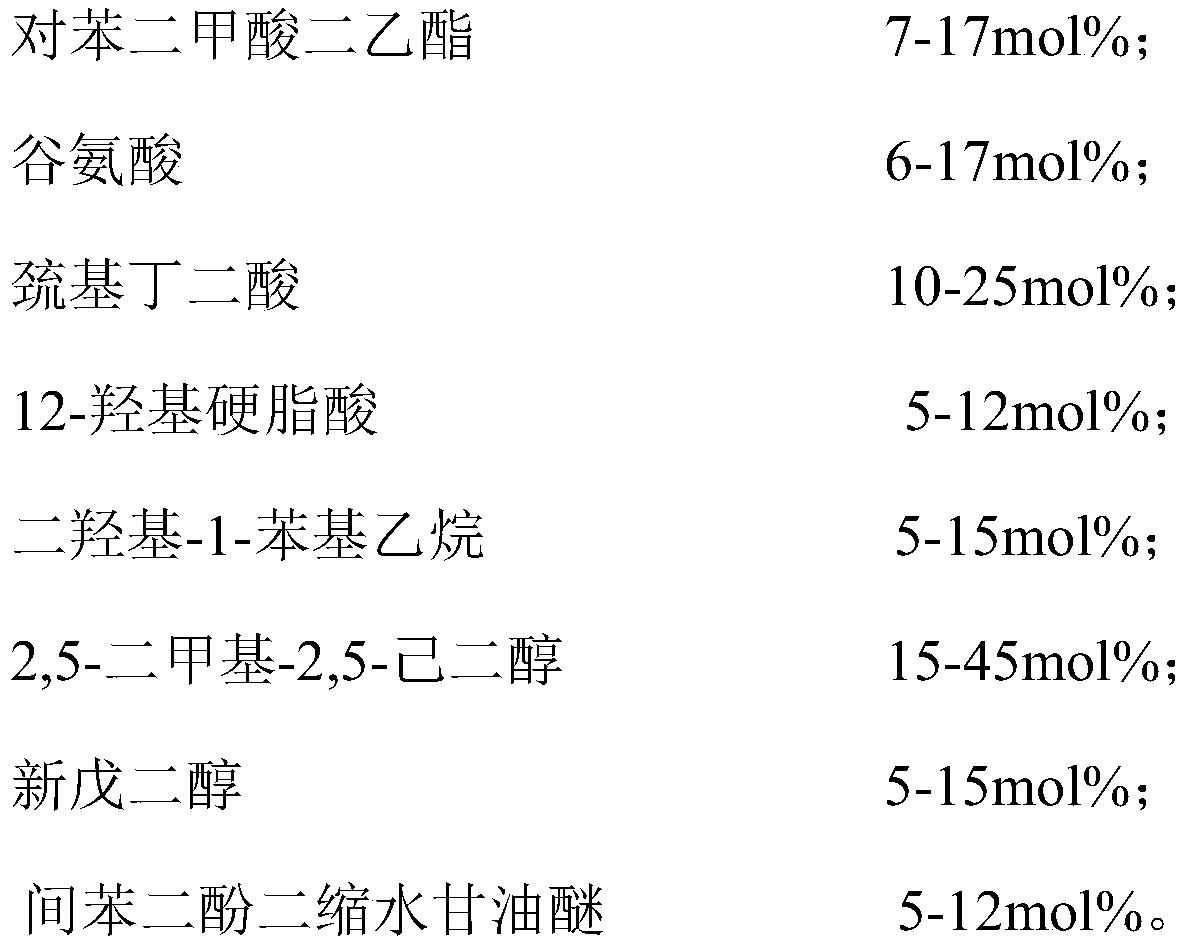

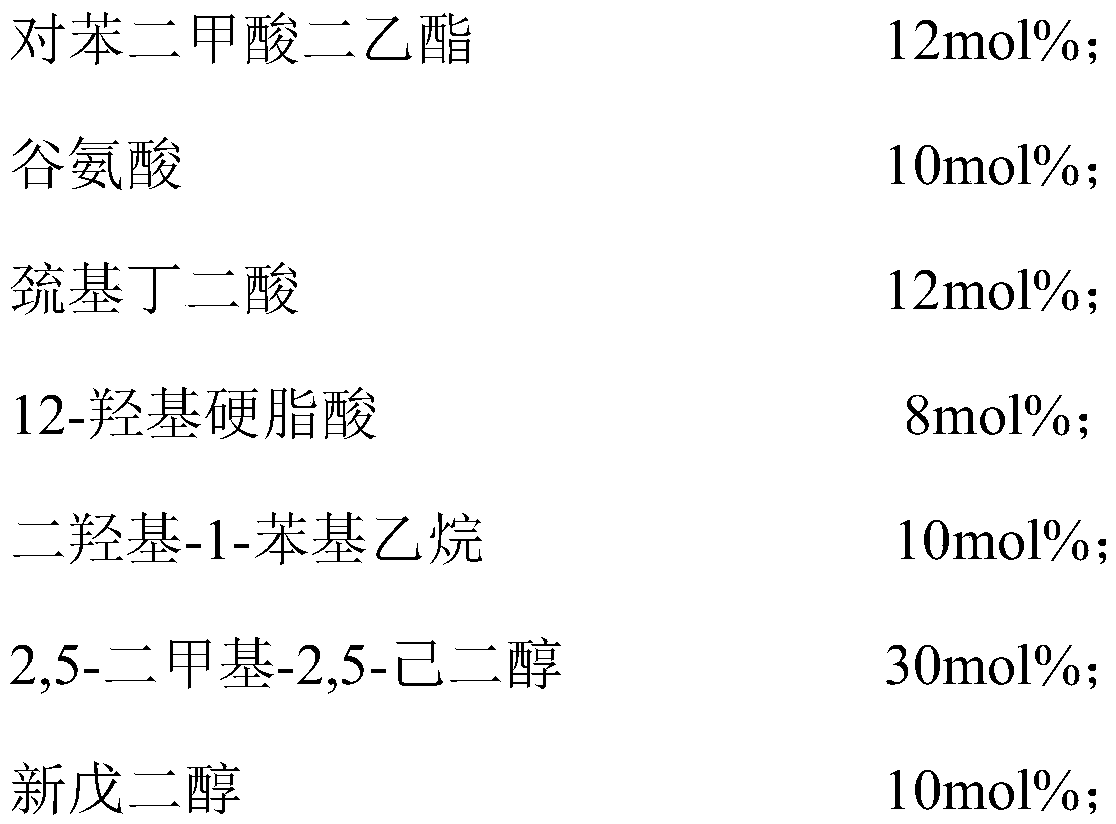

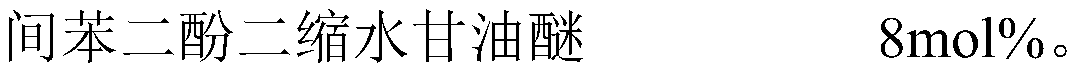

Low-temperature curing type polyester resin for powder coating and preparation method of low-temperature curing type polyester resin

ActiveCN108504160ALow softening pointHigh activityPowdery paintsDiethyl terephthalatePolymer science

The invention provides low-temperature curing type polyester resin for a powder coating and a preparation method of the low-temperature curing type polyester resin. The polyester resin is prepared from 1,2-phenylenediacetic acid, brassylic acid, diethyl terephthalate, 1,3,5-cyclohexanetricarboxylic acid mono-amidate, tetraethylene glycol, 2,4,7,9-tetramethyl-5-decyne-4,7-diol, DL-malic acid and ethylenediamine tetraacetic acid as main raw materials through copolymerization. The polyester resin contains imidazole catalytic functional groups in chain segments, so that a low-temperature curing accelerator is not required to be added, the polyester resin and the powder coating prepared from the same can be good in stability, the powder coating prepared from the polyester resin can be subjectedto low-temperature curing at 150 DEG C, a cured film is excellent, and the powder coating has good levelling property.

Owner:HUANGSHAN ZHENGJIE NEW MATERIALS

Porous soft superfine polyester fiber and preparation method thereof

ActiveCN106283263AImprove dyeing effectEasy to processArtificial thread manufacturing machinesFilament/thread formingYarnFiber

The invention relates to a porous soft superfine polyester fiber and a preparation method thereof. The method comprises the following steps: spinning modified polyester by adopting a porous spinneret, so as to obtain the porous soft superfine polyester fiber. The spinneret orifices on the porous spinneret are arranged in an elliptical shape, namely the centers of the spinneret orifices are positioned on concentric ellipses, the concentric ellipses are a series of ellipses, and both long axes and short axes of all the ellipses are collinear. The porous soft superfine polyester fiber is prepared by performing metering, squeezing, cooling, oiling and high-speed winding on modified polyester chips, and the preparation method of the modified polyester comprises the steps: carrying a reaction between terephthalic acid and ethylene glycol to prepare polyethylene terephthalate, adding diethyl terephthalate obtained after the reaction between terephthalic acid and a dihydric alcohol containing branched chains, and continuously carrying out the reaction, so as to obtain the modified polyester. The fiber disclosed by the invention is excellent in performance, the linear density deviation rate is less than or equal to 0.5%, the breaking strength CV value is less than or equal to 4.0%, the breaking elongation CV value is less than or equal to 8.0%, and the yarn unevenness CV value is less than or equal to 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of epoxidized polyester resin and its preparation method and application

ActiveCN108503814BLow acid valueImprove stabilityPowdery paintsPolyester coatingsDiethyl terephthalatePolymer science

Owner:黄山市向荣新材料有限公司

Flame retardant polypropylene modified resin and its preparation technology

InactiveCN103951875AImprove flame retardant performanceImprove mechanical propertiesDiethyl terephthalatePolymer science

The invention discloses a flame retardant polypropylene modified resin. The flame retardant polypropylene modified resin is prepared by using the following raw materials, by weight, 80-110 parts of PP, 10-20 parts of chlorinated polypropylene, 2-4 parts of polyethylene terephathalate, 40-56 parts of modified PP, 2-3 parts of polycarbonate, 1-2 parts of stearic acid, 0.01-0.3 parts of an antioxidant 1076, 0.1-0.3 parts of butyl benzyl phthlate, 0.3-0.5 parts of tributyl citrate, 0.3-0.5 parts of zinc naphthenate, 0.2-0.4 parts of magnesium naphthenate, 1-2 parts of a silane coupling agent KH550 and 50-55 parts of a compound flame retardant. The flame retardant polypropylene modified resin prepared in the invention has a good flame retardation property and excellent mechanical performances, and the cooperation of the modified PP and the compound flame retardant can realize a good flame retardation property.

Owner:芜湖同达新材料科技有限公司

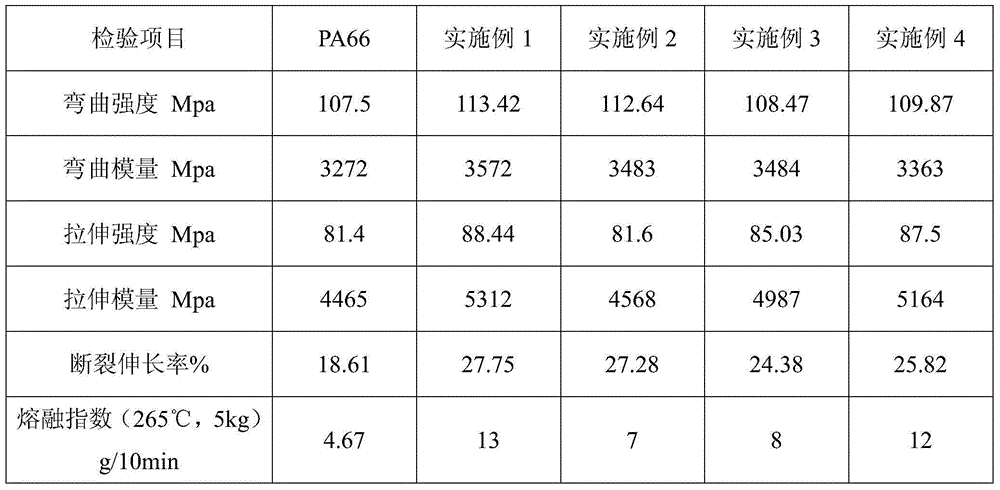

Aromatic hyperbranched polyester for nylon processing and preparation method thereof

InactiveCN104530394AFully contactedSmall molecule reductionDiethyl terephthalateDimethyl terephthalate

The invention relates to hyperbranched polyester and particularly relates to aromatic hyperbranched polyester for nylon processing and a preparation method thereof. The polyester is prepared from an aromatic monomer and pentaerythritol by adopting a melting process under the effect of a catalyst, wherein the aromatic monomer is dimethyl terephthalate, dimethyl phthalate, dimethyl isophthalate, diethyl terephthalate, diethyl phthalate, diethyl isophthalate, dibutyl terephthalate, dibutyl phthalate or diisobutyl phthalate. The molar ratio of pentaerythritol to aromatic monomer is (1:1)-(1:4). The polyester has the characteristics of high-temperature resistance and high strength; when the polyester is applied to nylon processing, the mechanical properties and processability of nylon can be remarkably improved; and the preparation method provided by the invention is simple and easy to realize.

Owner:WEIHAI CY DENDRIMER TECH

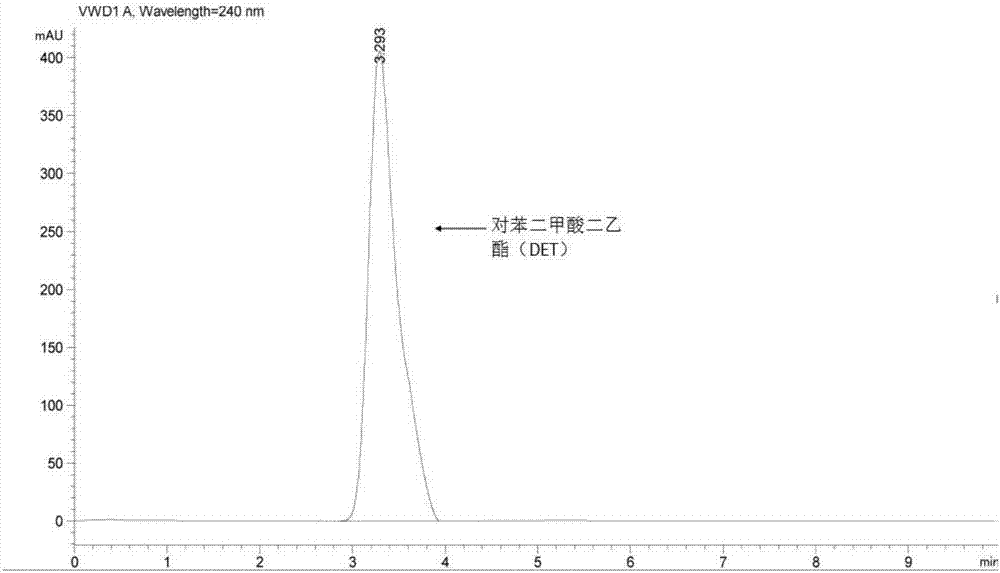

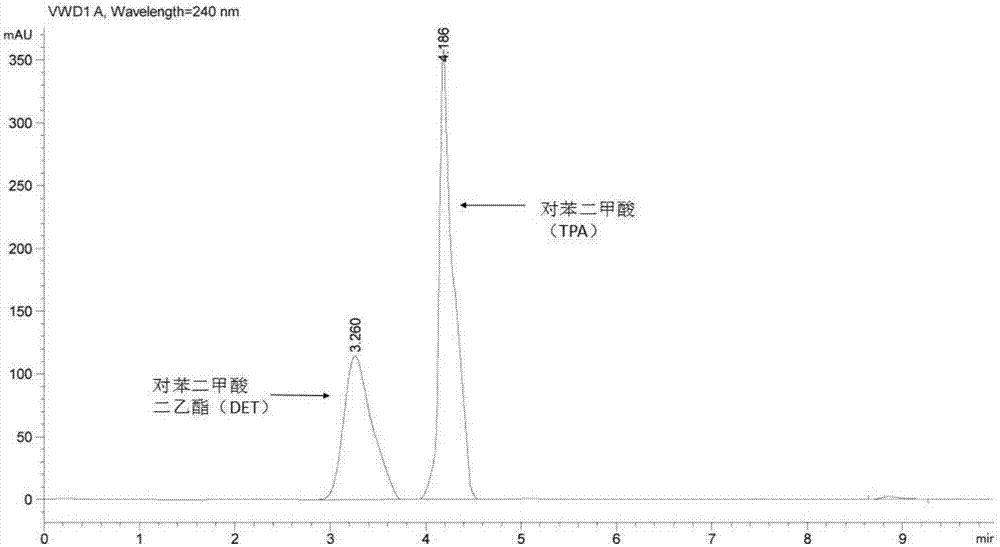

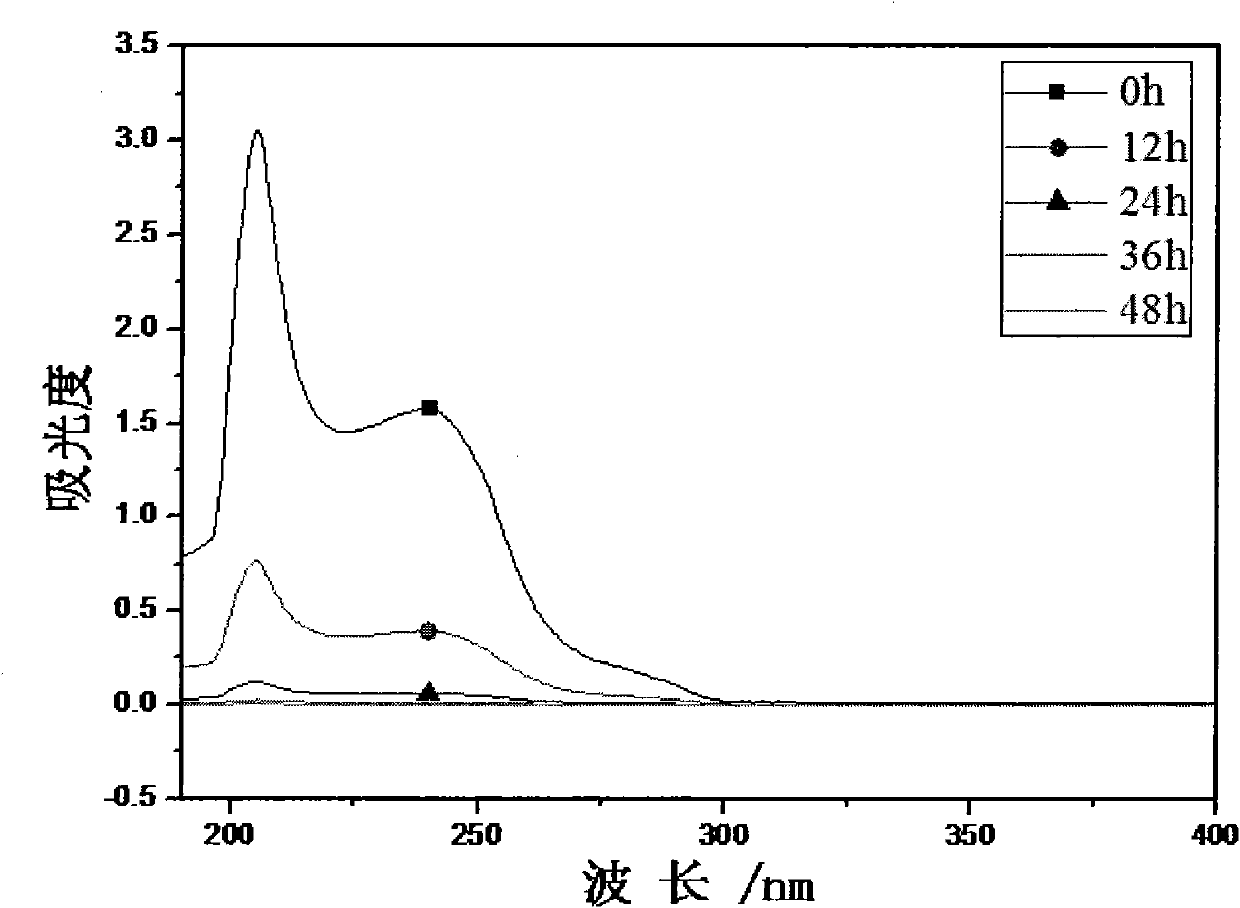

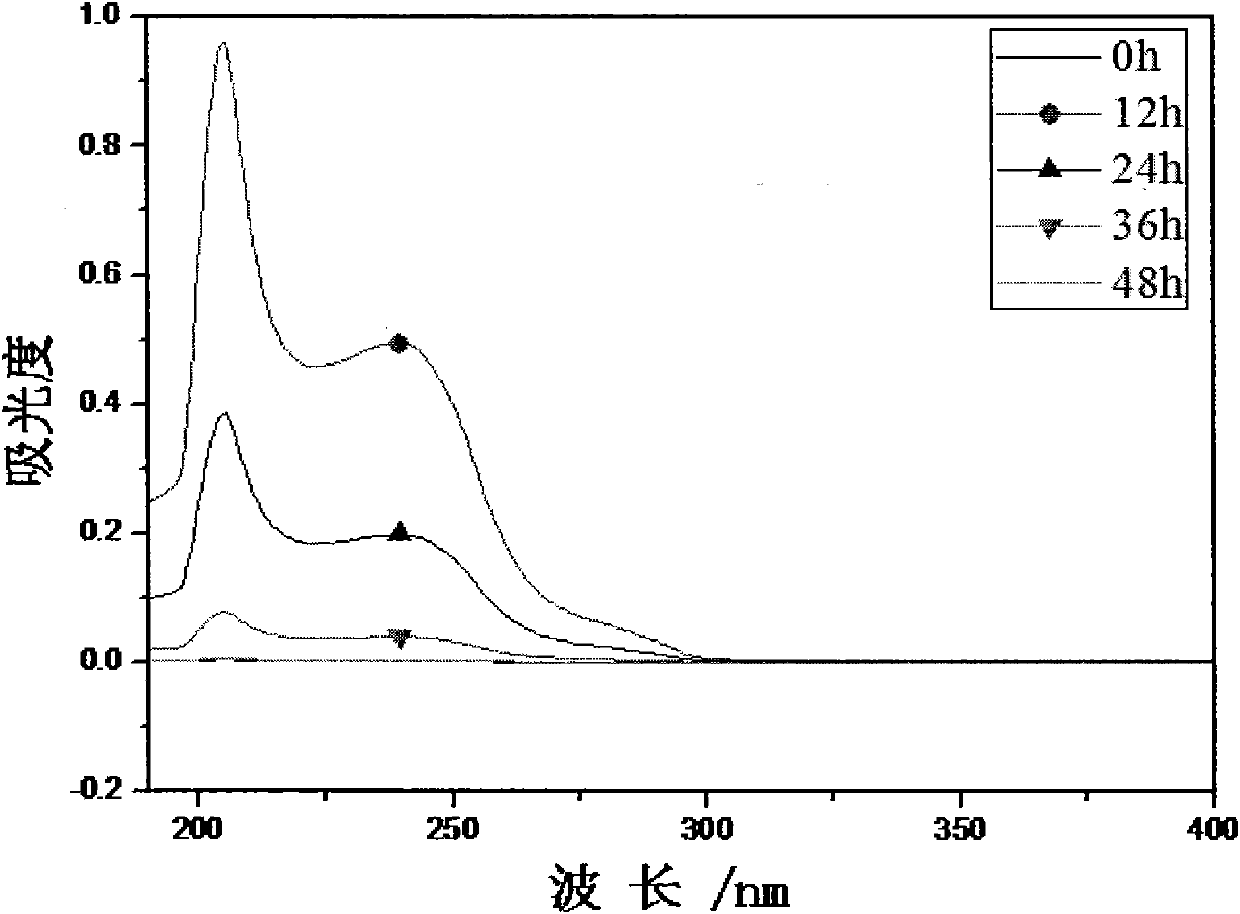

Method for degrading polyethylene terephathalate

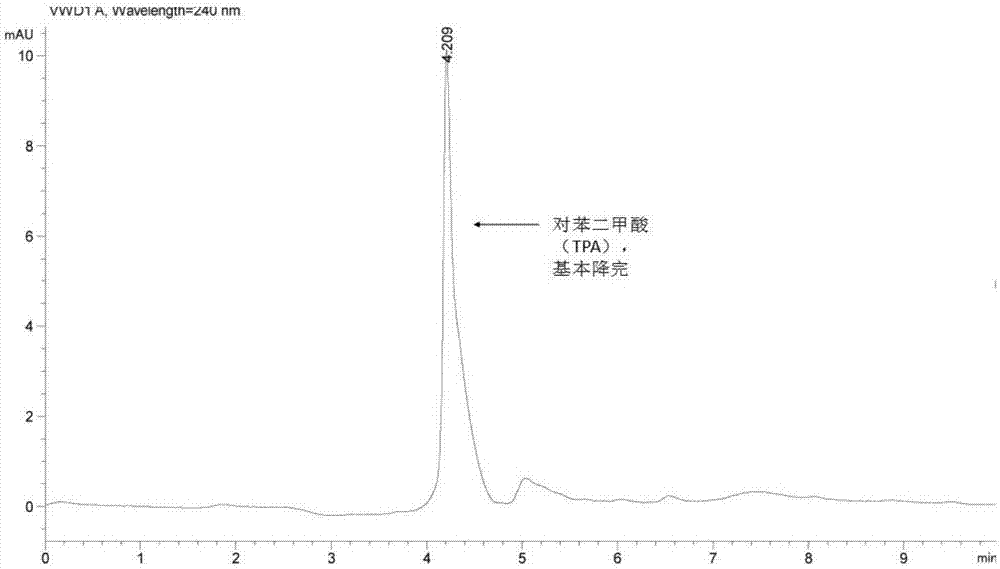

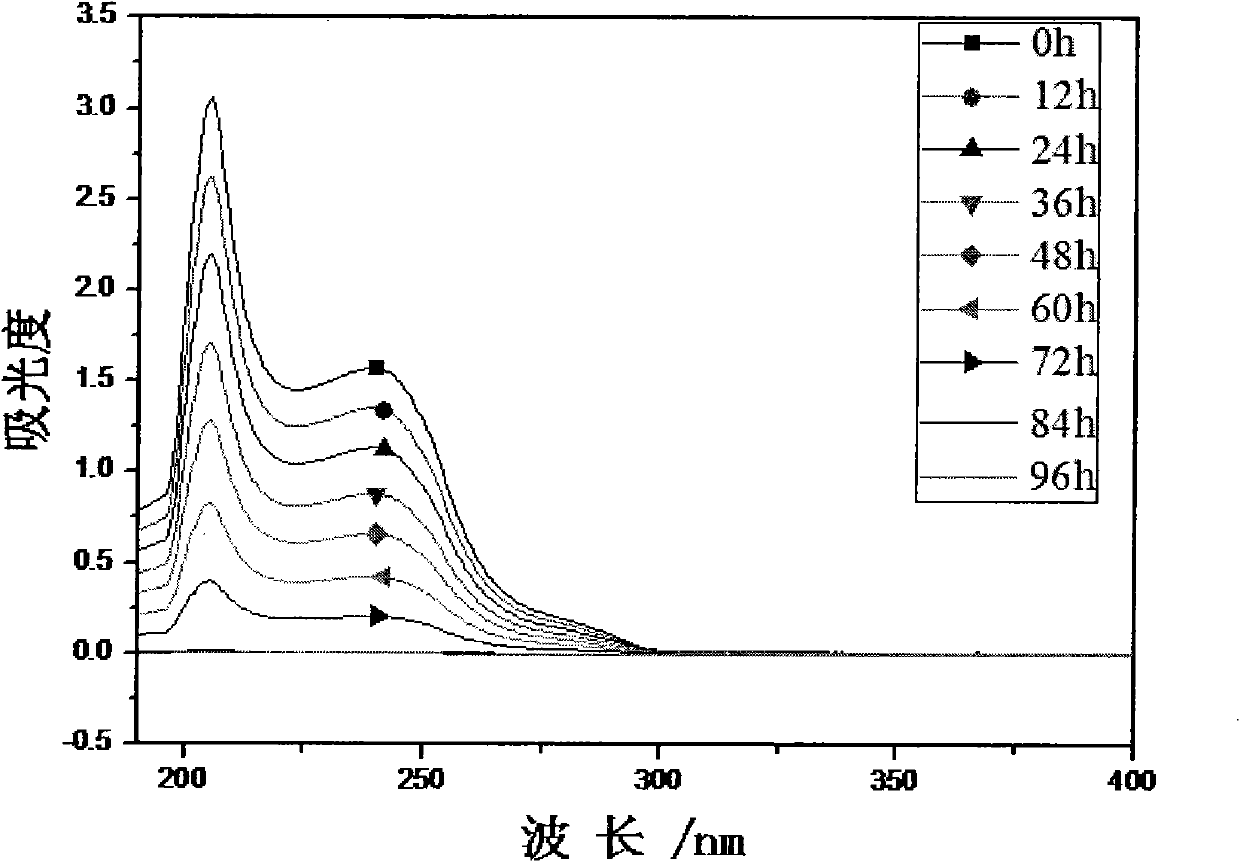

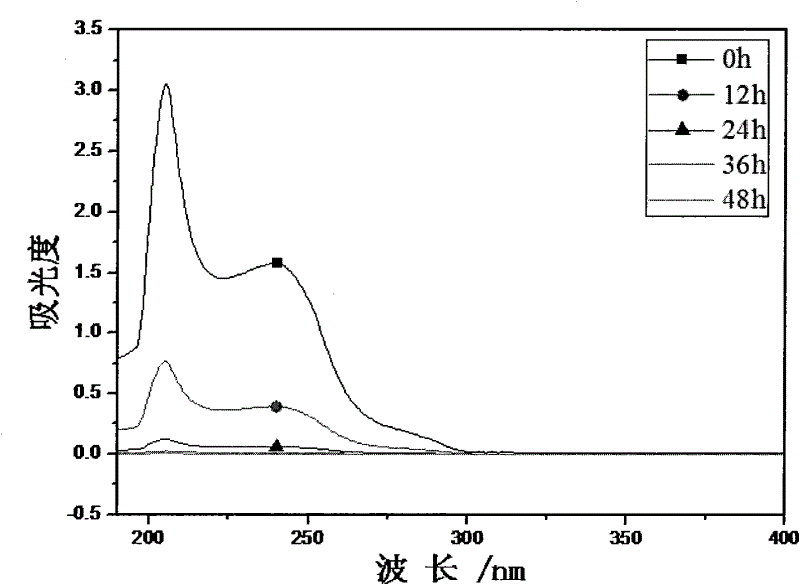

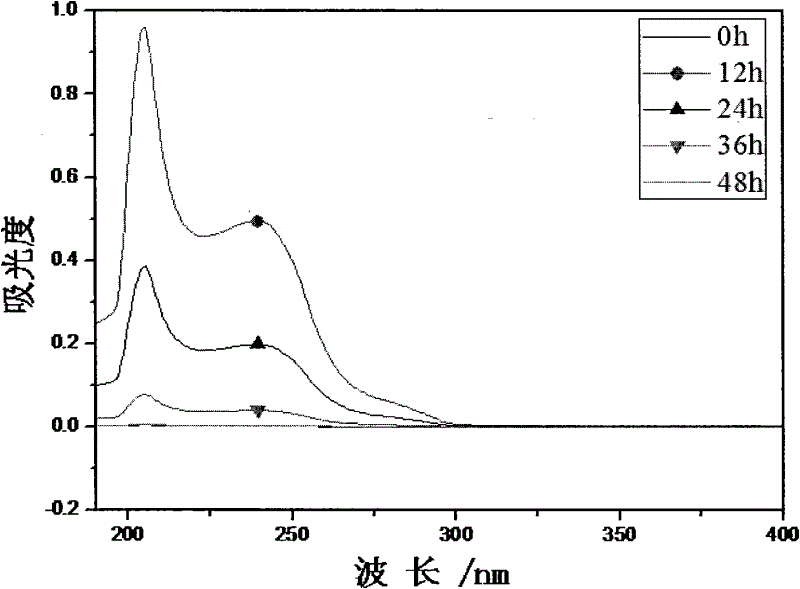

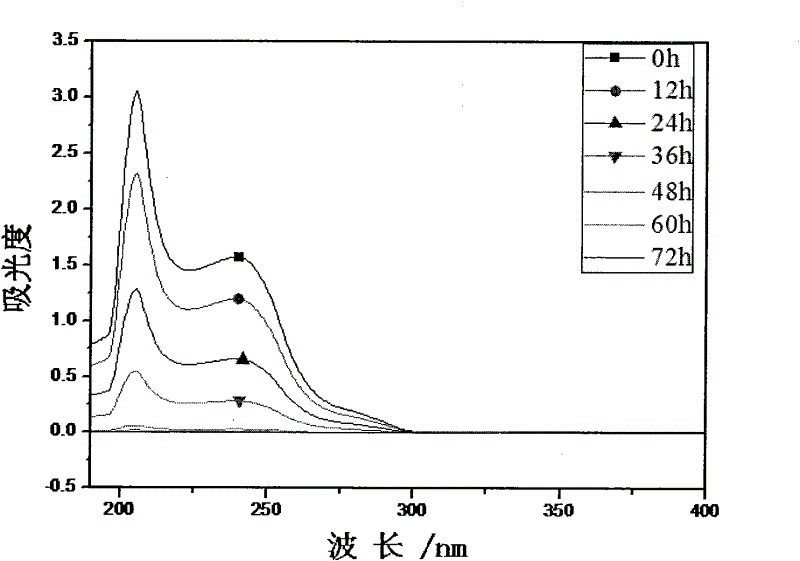

The invention discloses a method for degrading polyethylene terephathalate. The method mainly includes the following steps: 1, strain culture: comamonas testoseroni strain is cultured for 12-18h in a solid medium with inclined surface at 30-37 DEG C; 2, substrate solution preparation: 5-9 parts of substrate solution with the concentration of 1-5g / L are prepared, each part is 50ml and is respectively placed into a 150ml conical flask, and packing up and sterilizing for 25min are carried out at 121 DEG C; 3, substrate degradation: the strain in the step 1 is inoculated into the substrate solution in the step 2, so as to obtain degradation liquor, and shake culture is carried out at the rotating speed of 200r / min and at the temperature of 30-37 DEG C, so as to catalyze degradation on the substrate; 4, substrate degradation ratio detection: 400-190nm wavelength scanning is adopted, and variation of substrate content is judged according to absorption peak at 240nm; 5, substrate degradation product detection: 400-190nm wavelength scanning is adopted, and variation of degradation intermediate product content is judged.

Owner:TIANJIN POLYTECHNIC UNIV

Polyester-based film for laminating metal plate

InactiveUS20180056631A1Excellent aroma retaining propertyImprove corrosion resistanceSynthetic resin layered productsDomestic containersDiethyl terephthalatePolyester

It is provided that the polyester-based film which has excellent aroma retaining property and corrosion resistance, and can be adhered to a metal plate at a low temperature. A polyester-based film for laminating a metal plate formed from a composition containing a polyester-based resin mainly consisting of ethylene terephthalate, wherein the polyester-based resin has a total content of ethylene terephthalate units and diethylene terephthalate units of not less than 95% by mol and not more than 98% by mol, in 100% by mol of the total constituent units of the polyester, and the content of indeterminate inorganic fine particles is 0.5 to 2.0% by mass, in 100% by mass of the composition.

Owner:TOYO TOYOBO CO LTD

Cosmetic for removing acne marks and stains

The invention relates to a cosmetic for removing acne marks and stains. The cosmetic is characterized by being prepared from the following components in percentage by weight: 0.1 to 10.0 percent of diethyl terephthalate, 1.0 to 30.0 percent of nicotinamide, 1.0 to 20.0 percent of betaine salicylate and the balance of ethanol. The cosmetic disclosed by the invention has the effects of quickly removing acne, removing the acne marks, removing the stains and beautifying, and meanwhile, the cosmetic has the functions of exfoliating and moisturizing; compared with existing acne removing products, the acne removing effect is lasting, the acne mark removing effect is obvious, and the cosmetic can be conveniently and directly used in a formula.

Owner:刘金凤

Multifunctional cable for municipal ecological landscape construction

InactiveCN106046712ASoft textureExcellent flame retardantInsulated cablesCable/conductor manufactureDiethyl terephthalateDecabromodiphenyl ether

The invention relates to a multifunctional cable for municipal ecological landscape construction. The multifunctional cable comprises a plurality of copper alloy conductive wires and a plurality of protective sleeves, wherein the copper alloy conductive wires are arranged in parallel; each copper alloy conductive wire is enwrapped by the protective sleeve, and the protective sleeve comprises the following components: polyethylene terephathalate, chloroprene rubber adhesive, calcium rosinate, butyl carbitol, sesame oil, polyether modified silicone oil, nut oil, dibenzofuran, zinc pyrithione, potassium sorbate, propiconazole, bamboo pulp, camellia powder, potassium fluotitanate, magnesite powder, copper phthalocyanine, shell powder, aluminium potassium sulfate, flake graphite powder, triphenyl phosphate, phosphotriester, hexabromocyclododecane, decabromodiphenyl ether, oxidized polyethylene, 1-methoxy-2-propanol, 2, 2-dipyridine, 2-thiol benzothiazole, 2-mercapto benzimidazole, 4, 4'-diaminodiphenyl and N, N'-m-phenylenedimaleimide. The multifunctional cable improves the using performance of a product.

Owner:李斌

Epoxy-resin composite material

The invention discloses an epoxy resin composite material, which is prepared from the following raw materials in parts by weight: epoxy resin, rice straw ash, sodium lauryl sulfate, fumed silicon dioxide, polytetrafluoroethylene, propylene glycol methyl ether acetic acid Ester, o-hydroxybenzophenone, water emulsion polyethylene wax, diethyl terephthalate, polyethylene glycol monomethyl ether, n-butanol, polyvinyl alcohol, appropriate amount of water. Beneficial effects of the invention: the production cost is reduced and the performance of the product is improved, and has the advantages of high mechanical performance, high toughness, excellent tensile performance and bending performance, anti-aging, waterproof and heat preservation, and the like.

Owner:SICHUAN MEIDENG FURNITURE CO LTD

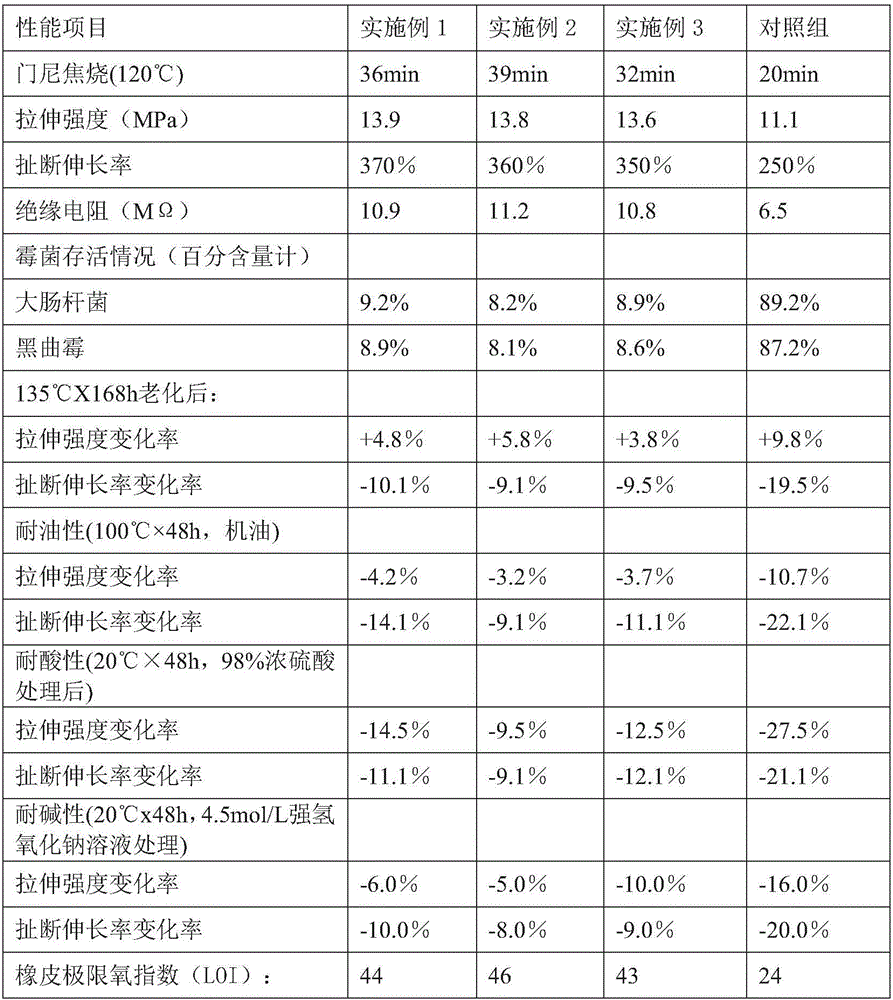

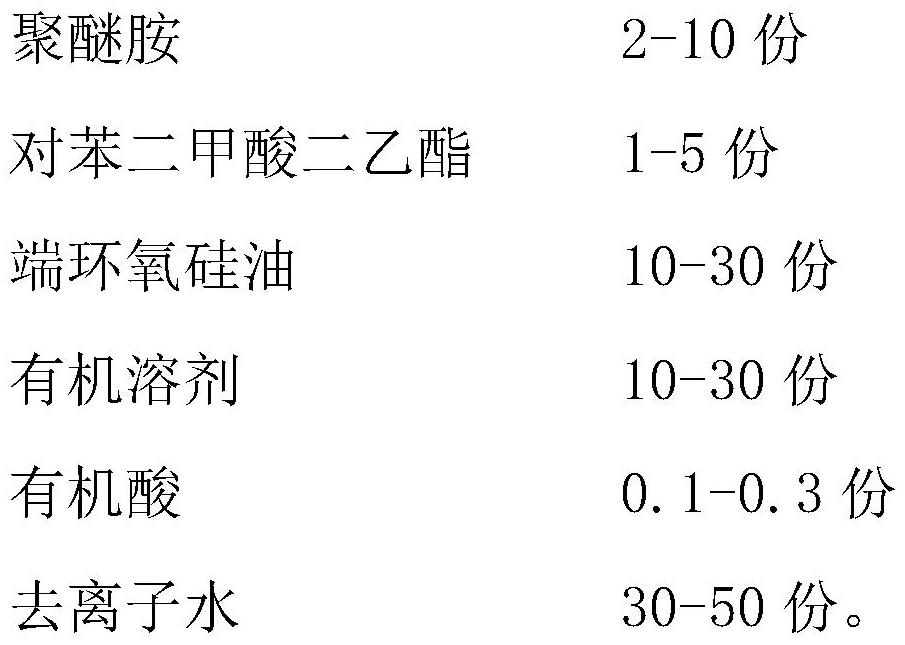

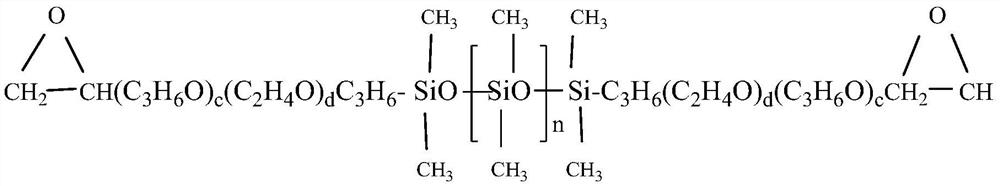

Novel soft and smooth silicone oil for polyester and preparation method of novel soft and smooth silicone oil

ActiveCN114541146ASoft touch styleDelicate touch styleGrip property fibresDiethyl terephthalateEpoxy

The invention discloses novel soft and smooth silicone oil for polyester and a preparation method of the novel soft and smooth silicone oil. The novel soft and smooth silicone oil comprises the following raw materials in parts by mass: 2-10 parts of polyether amine, 1-5 parts of diethyl terephthalate, 10-30 parts of epoxy-terminated silicone oil, 10-30 parts of an organic solvent, 0.1-0.3 part of organic acid and 30-50 parts of deionized water. According to the novel soft and smooth silicone oil for terylene adopting the structure and the preparation method of the novel soft and smooth silicone oil, special polyether amine is prepared through amidation of diethyl terephthalate and polyether amine, epoxy-terminated polyether siloxane with medium and small molecular weight and the special polyether amine are subjected to polycondensation, and the prepared soft and smooth silicone oil for terylene can endow various terylene fabrics with softness, elasticity and elasticity. The handfeel is soft, smooth and fine.

Owner:浙江联胜新材股份有限公司

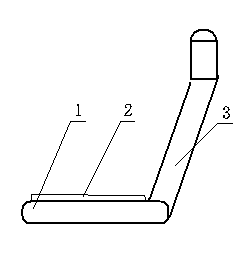

Anti-static seat of public transport bus

InactiveCN103158591AImprove group safetyAvoid it happening againThigh restsDiethyl terephthalateFiber

The invention relates to an anti-static seat of a public transport bus. The public transport bus uses natural gas, liquefied petroleum gas, and gasoline and other volatile fuels, but plastics are often used in a seat design and an electrostatic fire source is not taken into consideration, and clothes of people are mostly made of chemical fibers which generate electrostatic sparks when the clothes rub with the plastic seat. The anti-static seat of the public transport bus comprises a seat part, a backrest is arranged above the seat part, and an anti-static cushion is arranged on the seat part. The anti-static cushion is made of anti-static acrylic plates or anti-static polyvinyl chloride plates or anti-static polycarbonate plates or poly (diethyl terephthalate) plate materials. The anti-static cushion is round or rectangular or polygonal. A metal support is arranged under the seat part. The anti-static seat of the public transport bus is designed and considered for the public transport bus and other more dangerous working environments where the natural gas, the liquefied petroleum gas, and the gasoline and other volatile fuels are used, the electrostatic fire source which generates through the rub between the clothes and the seat is prevented from occurring, and group safety of the public transport bus is improved.

Owner:XIAN CHUANGNIER AUTOMOBILE ELECTRONICS TECH

Method for preparing modified PEF copolyester from citric acid-based aromatic diester

The invention relates to a method for preparing modified PEF copolyester by using 2, 3-diphenyl-diethyl terephthalate, which is used for preparing the PEF copolyester by using dimethyl acetone dicarboxylate and cinnamyl aldehyde as raw materials and zinc acetate and antimonous oxide as catalysts under the conditions of high temperature and high vacuum, and comprises the following steps: 1) preparing the 2, 3-diphenyl-diethyl terephthalate from the diethyl acetone dicarboxylate; and 2) preparing the modified PEF copolyester from the 2, 3-diphenyl-diethyl terephthalate. The preparation method has the advantages that the PEF polyester is wide in raw material source, low in price, renewable and low in production cost; the PEF polyester modification synthesis process is simple, easy to operate,environmentally friendly, high in yield and beneficial to industrial production; the prepared modified PEF copolyester material is good in thermal stability and adjustable in performance, structure and function diversification is easy to achieve, the performance of the modified PEF copolyester material can be comparable with that of polyester based on petroleum raw materials, and the modified PEFcopolyester material has the possibility of large-scale production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Synthesis of stabilizing agent with polyamide

InactiveCN106831539AAchieve preparationSuitable for industrial productionOrganic chemistryDiethyl terephthalateDimethyl terephthalate

The invention relates to a method for synthesizing a polyamide stabilizing agent N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-1,4-phthalic diamide. The method comprises the following steps: enabling dimethyl terephthalate or dimethyl terephthalate and 2,2,6,6-tetramethyl-4-aminopiperidine serving as raw materials to react for 1-2 hours at 190 DEG C without using a solvent or a catalyst; heating to 220-240 DEG C, reacting for 3-6 hours, and directly performing aminolysis to prepare N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-1,4-phthalic diamide.

Owner:XIANGTAN UNIV

Method for degrading polyethylene terephathalate

The invention discloses a method for degrading polyethylene terephathalate. The method mainly includes the following steps: 1, strain culture: comamonas testoseroni strain is cultured for 12-18h in a solid medium with inclined surface at 30-37 DEG C; 2, substrate solution preparation: 5-9 parts of substrate solution with the concentration of 1-5g / L are prepared, each part is 50ml and is respectively placed into a 150ml conical flask, and packing up and sterilizing for 25min are carried out at 121 DEG C; 3, substrate degradation: the strain in the step 1 is inoculated into the substrate solution in the step 2, so as to obtain degradation liquor, and shake culture is carried out at the rotating speed of 200r / min and at the temperature of 30-37 DEG C, so as to catalyze degradation on the substrate; 4, substrate degradation ratio detection: 400-190nm wavelength scanning is adopted, and variation of substrate content is judged according to absorption peak at 240nm; 5, substrate degradationproduct detection: 400-190nm wavelength scanning is adopted, and variation of degradation intermediate product content is judged.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of ceramic coloration toner for color laser printer

Owner:WUHAN POINTROLE TECH

Static electricity resisting polyethylene terephthalate modified resin

InactiveCN101215373BHas antistatic propertiesMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterDiethyl terephthalate

The invention relates to an improved resin of polyethylene glycol terephthalate with antistatic property, and the resin is prepared by ethylene glycol terephthalate and polyester ether which containsnanometer antimony and is doped with stannic oxide in the temperature between 260 DEG C to 280 DEG C, and in the vacuum between 20 Pa-100Pa, wherein, the polyester ether which contains nanometer antimony and is doped with stannic oxide is prepared by the mixture which is composed of ethylene glycol terephthalate and polyether and nanometer antimony which are doped with stannic oxide, and the massresistivity of the improved resin of the polyethylene glycol terephthalate which is got is 1*107 ohms.cm-9*109 ohms. cm. The invention solves the permanence problem of anti-static function of polyester.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of porous soft superfine denier polyester fiber and preparation method thereof

ActiveCN106283263BImprove cooling effectImprove fiber propertiesArtificial thread manufacturing machinesFilament/thread formingYarnFiber

The invention relates to a porous soft superfine polyester fiber and a preparation method thereof. The method comprises the following steps: spinning modified polyester by adopting a porous spinneret, so as to obtain the porous soft superfine polyester fiber. The spinneret orifices on the porous spinneret are arranged in an elliptical shape, namely the centers of the spinneret orifices are positioned on concentric ellipses, the concentric ellipses are a series of ellipses, and both long axes and short axes of all the ellipses are collinear. The porous soft superfine polyester fiber is prepared by performing metering, squeezing, cooling, oiling and high-speed winding on modified polyester chips, and the preparation method of the modified polyester comprises the steps: carrying a reaction between terephthalic acid and ethylene glycol to prepare polyethylene terephthalate, adding diethyl terephthalate obtained after the reaction between terephthalic acid and a dihydric alcohol containing branched chains, and continuously carrying out the reaction, so as to obtain the modified polyester. The fiber disclosed by the invention is excellent in performance, the linear density deviation rate is less than or equal to 0.5%, the breaking strength CV value is less than or equal to 4.0%, the breaking elongation CV value is less than or equal to 8.0%, and the yarn unevenness CV value is less than or equal to 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com