Anti-static seat of public transport bus

An anti-static, automotive technology, applied to thigh cushions, etc., can solve problems such as fire, leakage, and failure to consider static fire sources, etc., to achieve the effect of improving social safety benefits and group safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with specific embodiments.

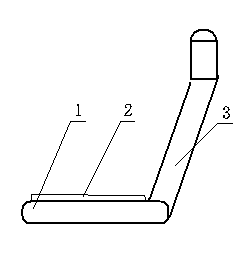

[0015] A bus antistatic seat according to the present invention is provided with a seat part 1, a backrest 3 is arranged above the seat part 1, and an antistatic cushion 2 is arranged above the seat part 1. Antistatic cushion 2 adopts antistatic acrylic board, antistatic polyvinyl chloride board, antistatic polycarbonate board or polyethylene terephthalate board material. Antistatic cushion 2 can be circular, rectangular or polygonal. A metal bracket is arranged below the seat portion 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com