Method for degrading polyethylene terephathalate

A technology of diethyl terephthalate and diethyl phthalate, which is applied in the field of degradation of diethyl terephthalate, can solve the problems of poor water solubility and difficult catalytic degradation, and achieves fast degradation speed and degradation effect. Good, targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

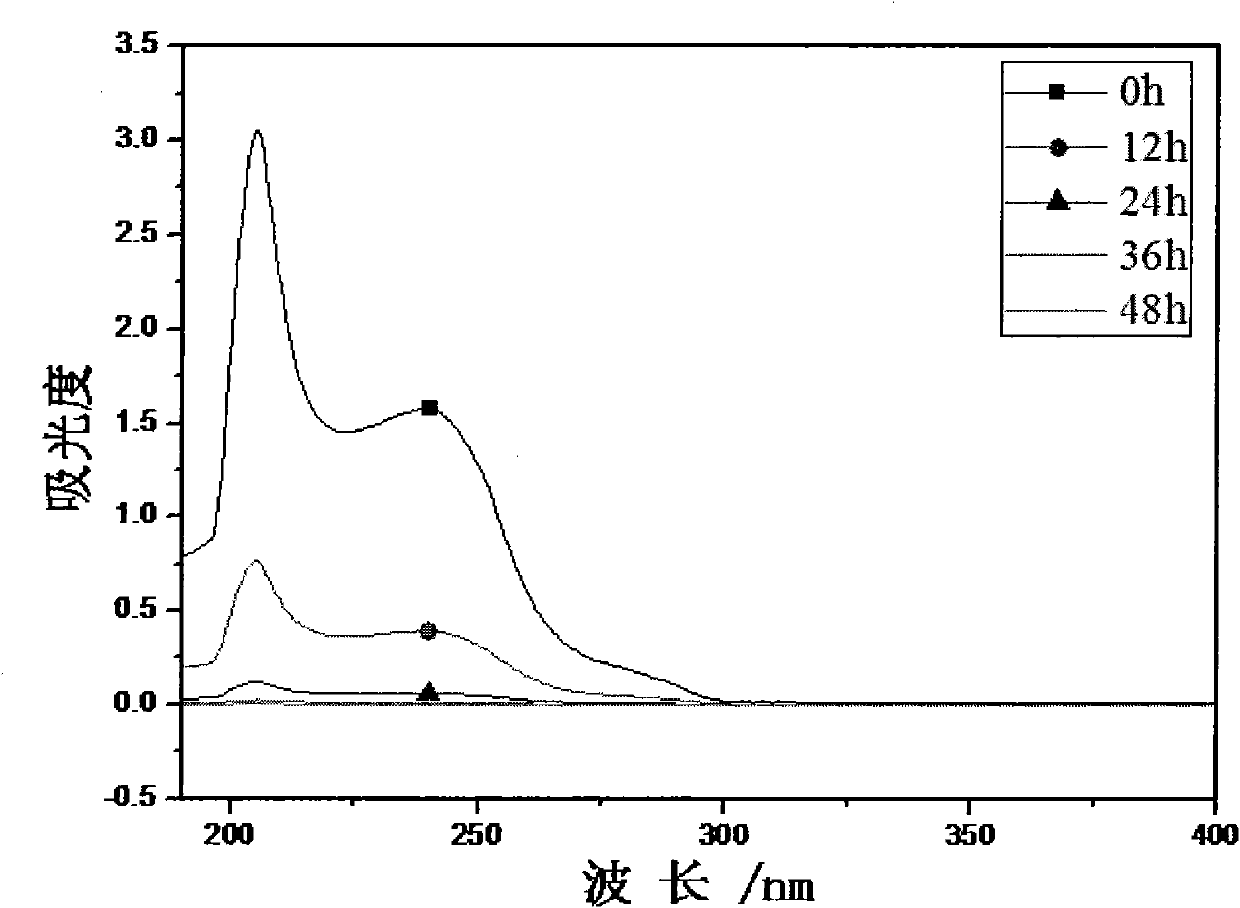

[0035] 1g / L DTP was used as the sole carbon source, and Comamonas testosteroni was used to degrade DTP.

[0036]The Comamonas testosteroni strains obtained by separation were cultivated for 12 hours at 30°C in a slant solid medium (compositions as mentioned above, the same below), and stored in the refrigerator for subsequent use; according to the composition of the liquid medium (compositions as mentioned above Said, the same below), the preparation DTP concentration is 5 parts of the substrate solution of 1g / L, every part of 50ml. Put them in five 150ml Erlenmeyer flasks respectively, bandage and sterilize (121°C, 25min), and cool down for later use; Shake the culture at 30°C and 200r / min to make it catalyze the degradation of the substrate DTP; start timing at zero time when there is no reaction, take out a bottle of degradation solution every 12h, inactivate it in a water bath at 95°C for 5min, add 10ml n-hexane after cooling Alkanes, shake fully, extract the undissolved ...

Embodiment 2

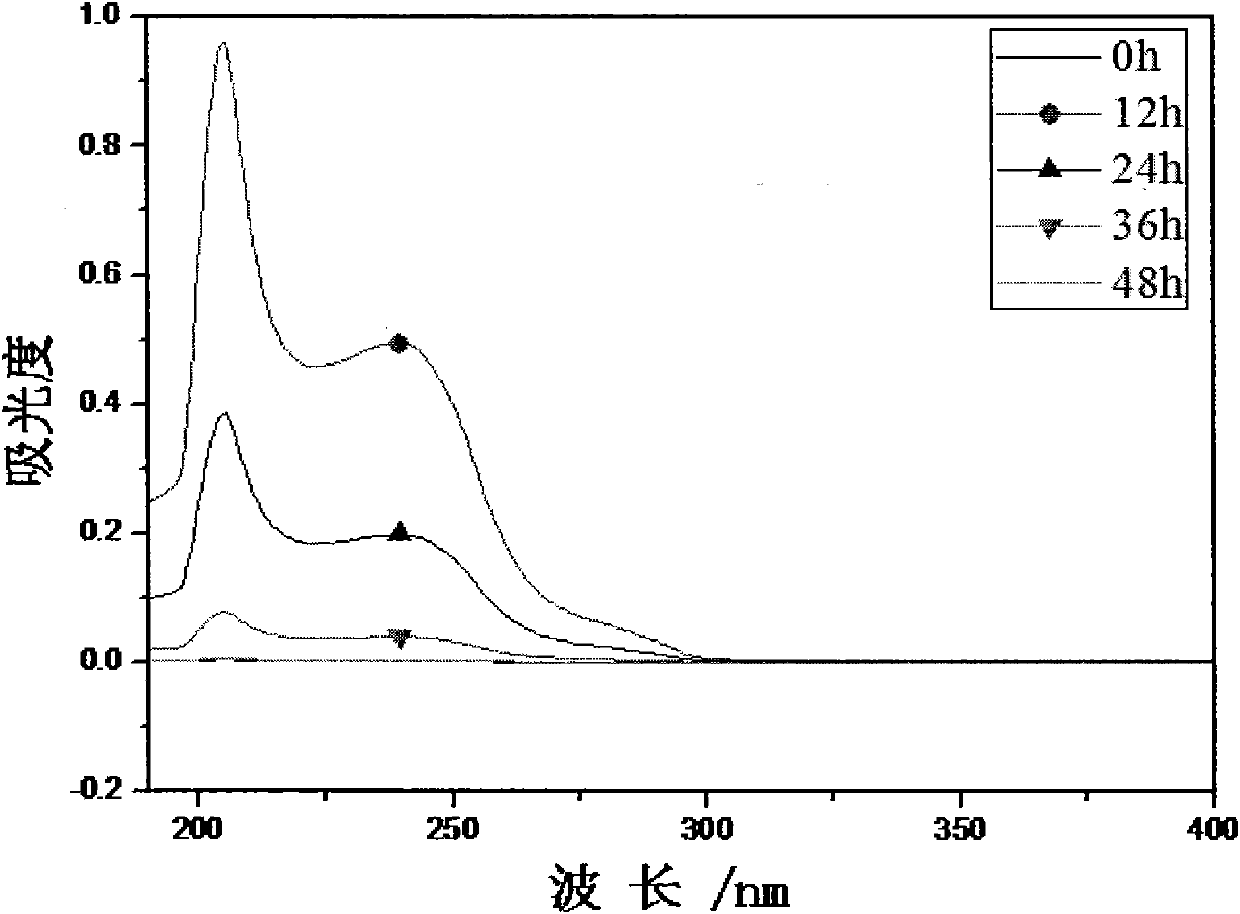

[0041] 3g / L DTP was used as the sole carbon source, and Comamonas testosteroni was used to degrade DTP.

[0042] Cultivate the isolated strains at 34°C in a slant solid medium for 15 hours, and store them in the refrigerator for later use; prepare 7 substrate solutions with a DTP concentration of 3g / L according to the composition of the liquid medium, each 50ml. Put them in seven 150ml Erlenmeyer flasks, wrap and sterilize (121°C, 25min), and cool down for later use; transfer the bacteria in the slant culture medium to the substrate solution to be degraded to prepare the degradation solution, and Shake culture at 34°C and 200r / min to make it catalyze the degradation of the substrate DTP; start timing from the unreacted zero hour, take out a bottle of degradation solution every 12h, inactivate it in a water bath at 95°C for 5min, add 10ml n-hexane after cooling Alkanes, shake fully, extract the undissolved DTP, after standing for defoaming, take the liquid in the n-hexane layer...

Embodiment 3

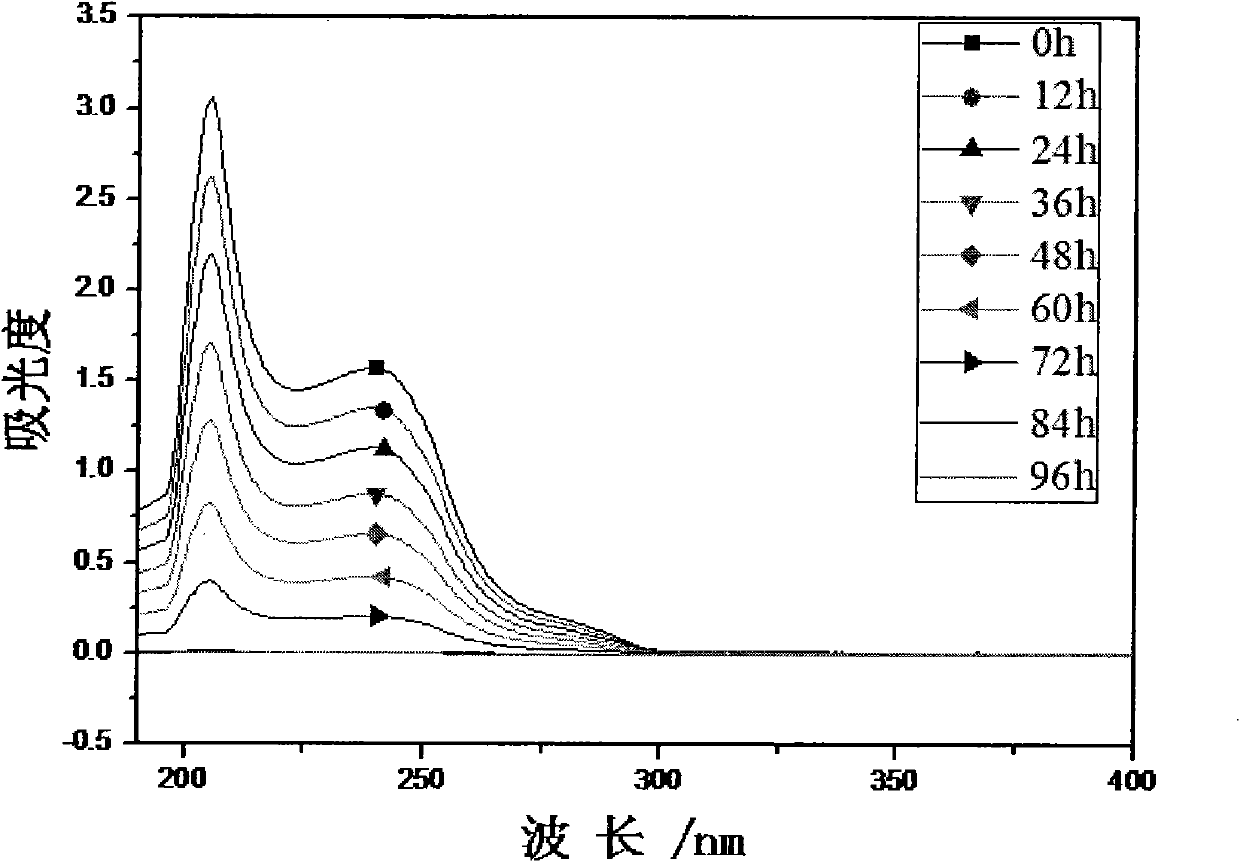

[0047] 5g / L DTP was used as the sole carbon source, and Comamonas testosteroni was used to degrade DTP.

[0048] Cultivate the isolated Comamonas testosteroni strains at 37°C in a slant solid medium for 18 hours, and store them in the refrigerator for later use; prepare 9 parts of a substrate solution with a DTP concentration of 5g / L according to the composition of the liquid medium, 50ml per serving. Put them in nine 150ml Erlenmeyer flasks, bandage and sterilize (121°C, 25min), and cool down for later use; transfer the strains in the slant culture medium to the substrate solution to be degraded to prepare the degradation solution, and Shake the culture at 37°C and 200r / min to make it catalyze the degradation of the substrate DTP; start timing from the unreacted zero hour, take out a bottle of degradation solution every 12h, inactivate it in a water bath at 95°C for 5min, add 10ml n-hexane after cooling Alkanes, shake fully, extract the undissolved DTP, after static defoamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com