Static electricity resisting polyethylene terephthalate modified resin

A technology of polyethylene terephthalate and diethyl phthalate, which is applied in the field of modified polyester and can solve problems affecting polyethylene terephthalate, restricting application fields, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

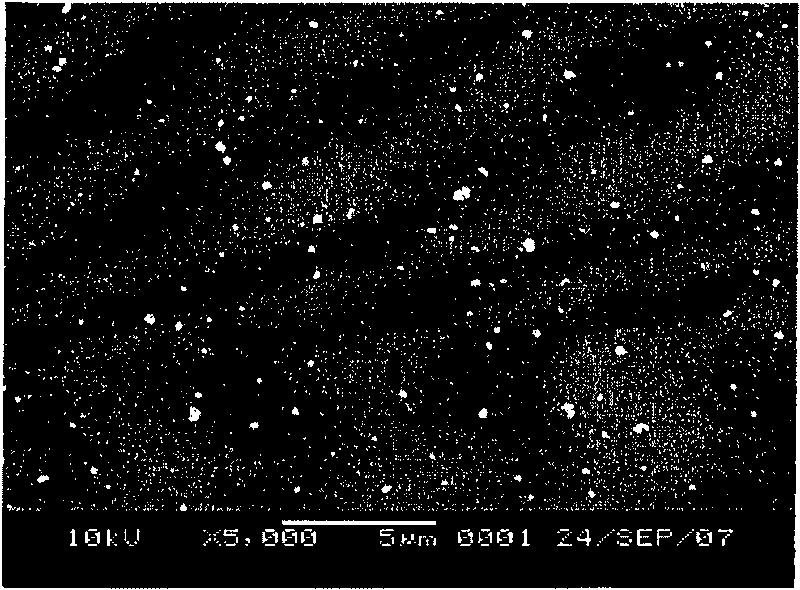

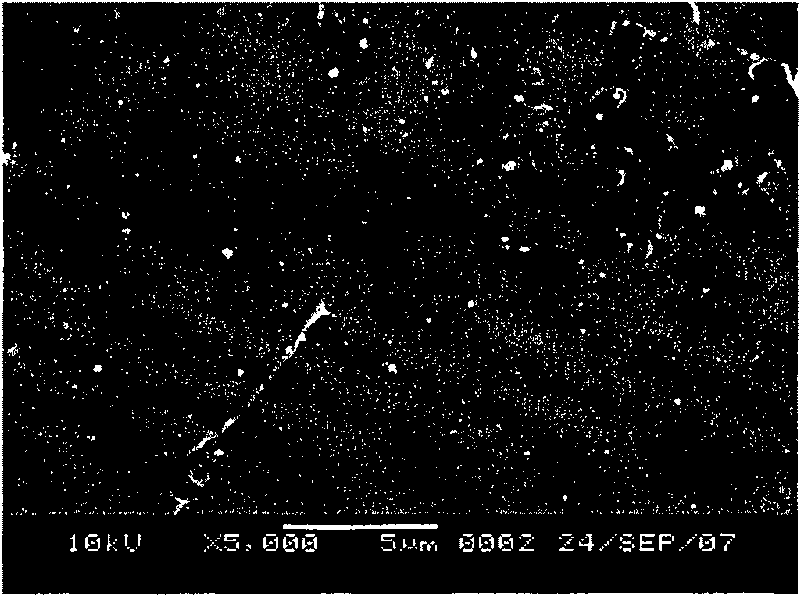

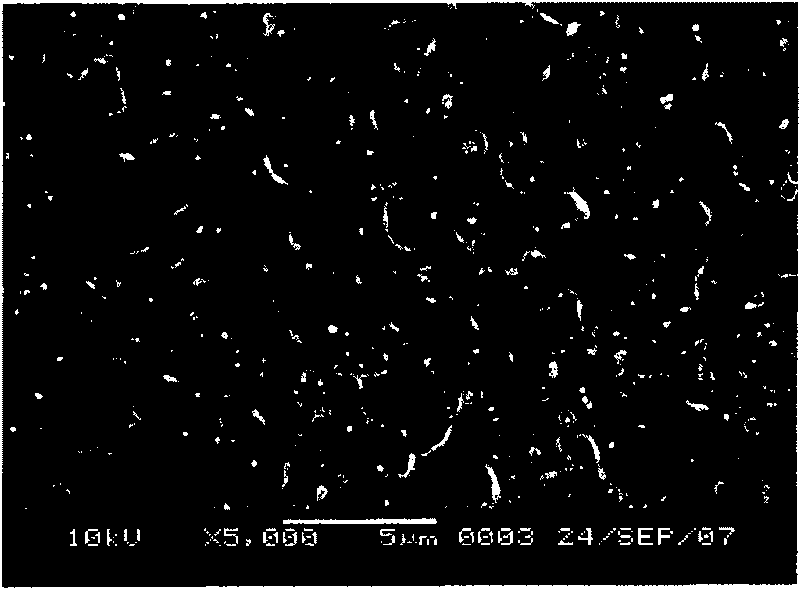

Image

Examples

preparation example Construction

[0014] I. Contain the preparation of the polyether of nano-antimony doped tin oxide:

[0015] Will C 2 ~C 10 Aliphatic dibasic acid, molecular weight (1~9)×10 3 Polyethylene glycol, toluenesulfonic acid (catalyst) and antioxidant 1010 or antioxidant 330 are placed in a polymerization reactor and reacted at 100°C to 180°C for 1 to 2 hours. In the initial stage of the polycondensation reaction, the reaction pressure is controlled at not higher than 0.2MPa; while in the late stage of the polycondensation reaction, it is controlled below -0.1MPa. Nano antimony-doped tin oxide (ATO) is dispersed in the prepared polyether melt, and the amount of ATO is 5% to 40% of the weight of the polyether to obtain the polyether containing nano-antimony doped tin oxide. Among them, antimony-doped tin dioxide (ATO) nanoparticles were prepared by chemical precipitation (Qin Changyong, Gu Hongchen. New multifunctional ATO ultrafine conductive powder materials. Shanghai Chemical Industry, 2000, 2...

Embodiment 1

[0025] Add 50g PEG6000, 0.9g malonic acid, 0.1g p-toluenesulfonic acid, 1g antioxidant 1010 into a 2L reaction kettle, blow the kettle 3 times with nitrogen, fill with 0.15MPa nitrogen, heat at 130°C for 30 minutes, add 10g Nano-antimony-doped tin oxide was continued to be heated for 20 minutes, vacuumed to -0.1MPa, vacuumed for 50 minutes, and the discharged material was naturally cooled to obtain polyether containing nano-antimony-doped tin oxide.

[0026] Add 830g of terephthalic acid, 363ml of ethylene glycol, 0.282g of antimony trioxide, 0.0173g of cobalt acetate, and 14μl of trimethyl phosphate into a 2L reaction kettle, heat to 100°C and stir for 40 minutes, blow the kettle with nitrogen for 3 Once, fill with 0.15MPa nitrogen, heat to 240°C for esterification and dehydration for 2 hours and 50 minutes, discharge 175ml of water, add the above-mentioned polyether containing nano-antimony doped tin oxide, stir for 15 minutes, and control the vacuum to -0.1MPa within 1 hour,...

Embodiment 2

[0029] Add 100g PEG6000, 1.8g malonic acid, 0.1g p-toluenesulfonic acid, 1g antioxidant 1010, and 10g nano antimony-doped tin oxide into a 2L reaction kettle, blow the kettle with nitrogen for 3 times, and fill with 0.1MPa nitrogen, Heating at 110°C for 40 minutes, evacuating to -0.1MPa, and evacuating for 1 hour, and cooling the discharged material naturally to obtain a polyether containing nanometer antimony-doped tin oxide.

[0030] Add 830g of terephthalic acid, 363ml of ethylene glycol, 0.282g of antimony trioxide, 0.0173g of cobalt acetate, and 14μl of trimethyl phosphate into a 2L reaction kettle, heat to 100°C and stir for 40 minutes, blow the kettle with nitrogen for 3 Once, fill with 0.15MPa nitrogen gas, heat to 240°C for 2.5 hours for esterification and dehydration, 173ml of water is discharged, add the above-mentioned polyether containing nano-antimony doped tin oxide, and then blow the kettle with nitrogen for 3 times, and vacuumize to -0.1 within 1 hour MPa, eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com