Antistatic corrosion-resistant polyimide film and production process thereof

A technology of polyimide film and production process, which is applied in the field of polyimide film and its production process, and can solve the problems of polyimide film erosion and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

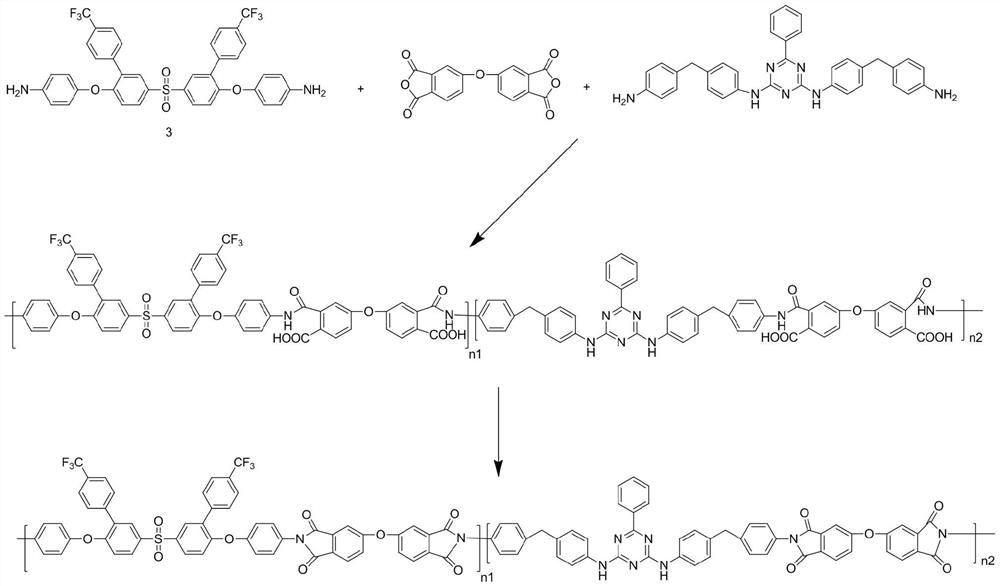

[0049] The fluorine-containing diamine monomer is prepared by the following steps:

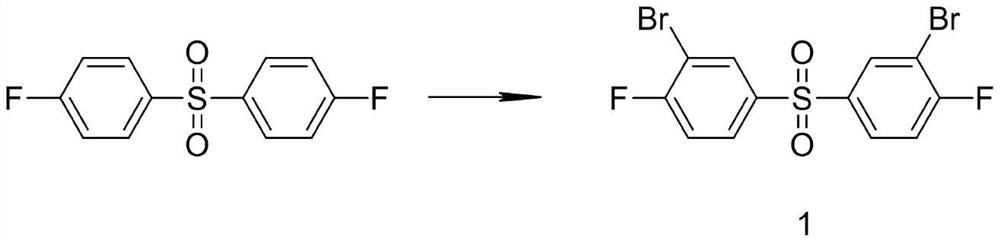

[0050] Step S1, dissolving 0.1 mol of 4,4'-difluorodiphenyl sulfone in 145 mL of concentrated sulfuric acid with a mass fraction of 98%, adding 0.2 mmol of N-bromosuccinimide, raising the temperature to 60°C, stirring evenly, and then Cool down to room temperature and react for 6 hours, then transfer to ice water to precipitate, filter, wash the filter cake twice with deionized water and n-hexane, and then recrystallize with toluene to obtain intermediate 1;

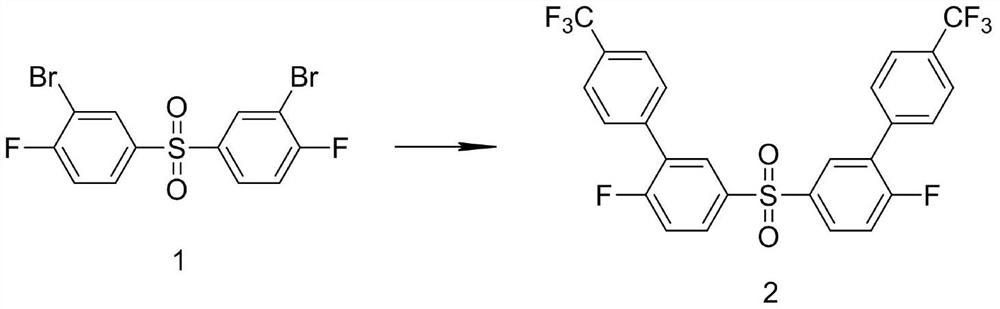

[0051] Step S2, add 0.05mol intermediate 1, 0.10mol4-trifluoromethylbenzeneboronic acid and 280mL toluene to the three-necked flask, after stirring and dissolving, add 280mL sodium carbonate solution with a mass fraction of 15% and 2g tetrakis(triphenyl Phosphine) palladium, heated to 120° C. for reflux reaction for 10 h, and then recrystallized with toluene to obtain intermediate 2;

[0052] Step S3, add 0.015 mol of intermediate 2, 0....

Embodiment 2

[0054] The fluorine-containing diamine monomer is prepared by the following steps:

[0055] Step S1, dissolving 0.12mol of 4,4'-difluorodiphenyl sulfone in 150mL of concentrated sulfuric acid with a mass fraction of 98%, adding 0.25mmol of N-bromosuccinimide, raising the temperature to 60°C, stirring evenly, and then Cool down to room temperature and react for 6 hours, then transfer to ice water to precipitate, filter, wash the filter cake twice with deionized water and n-hexane, and then recrystallize with toluene to obtain intermediate 1;

[0056] Step S2, add 0.055mol intermediate 1, 0.12mol4-trifluoromethylbenzene boronic acid and 300mL toluene to the three-necked flask, after stirring and dissolving, add 300mL sodium carbonate solution with a mass fraction of 15% and 2.3g tetrakis(triphenylene) Phosphine) palladium, heated to 120 ° C for 11 h under reflux, and then recrystallized with toluene to obtain intermediate 2;

[0057] Step S3, add 0.017mol of intermediate 2, 0.0...

Embodiment 3

[0059] The fluorine-containing diamine monomer is prepared by the following steps:

[0060] Step S1, dissolving 0.15 mol of 4,4'-difluorodiphenyl sulfone in 155 mL of concentrated sulfuric acid with a mass fraction of 98%, adding 0.3 mmol of N-bromosuccinimide to it, raising the temperature to 60°C, stirring evenly, and then Cool down to room temperature and react for 7 hours, then transfer to ice water to precipitate, filter, wash the filter cake three times with deionized water and n-hexane, and then recrystallize with toluene to obtain intermediate 1;

[0061] Step S2, add 0.06mol intermediate 1, 0.13mol4-trifluoromethylbenzene boronic acid and 310mL toluene to the three-necked flask, after stirring and dissolving, add 310mL of sodium carbonate solution with a mass fraction of 15% and 2.5g tetrakis(triphenyl Phosphine) palladium, heated to 120 ° C for 12 hours under reflux, and then recrystallized with toluene to obtain intermediate 2;

[0062] Step S3, add 0.02mol of inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com