A kind of antibacterial and antistatic foamed elastomer material and preparation method thereof

An elastomer material, anti-static technology, applied in the field of foamed elastic materials, can solve the problems of bacteria breeding, EVA foam material does not have conductivity, affect the appearance and performance of the material, and achieve excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

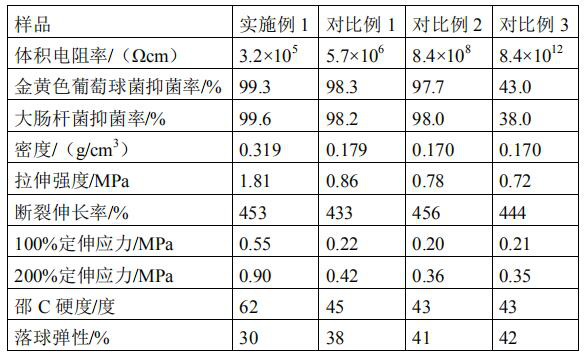

Embodiment 1

[0020] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0021] (1) Weigh 15g of nano-antimony tin oxide, heat at 60°C for 4 hours, dry, and grind to obtain antimony tin oxide powder (average particle size 0.05 μm);

[0022] (2) Mix 100g of dodecyloxymethyltributylphosphorous chloride and 0.15g of polyvinyl alcohol into an aqueous solution with a concentration of quaternary phosphonium salt of 4mg / mL, and place tin antimony oxide in it to absorb to saturation (quaternary phosphonium Salt is kept in excess), filtered, heated at 60°C for 4 hours, dried, and ground to obtain quaternary phosphonium salt modified tin antimony oxide conductive filler;

[0023] (3) Then add a solution of 1.5 g of vinyl triperoxy-tert-butylsilane and 30 g of ethanol (the mass ratio of silane to quaternary phosph...

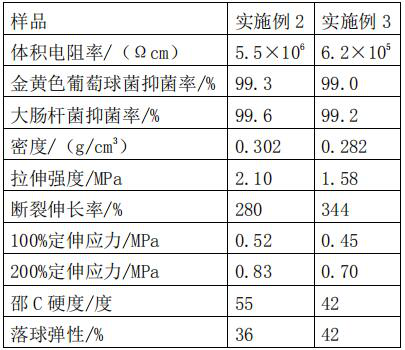

Embodiment 2

[0027] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0028] (1) Weigh 15g of nano-antimony tin oxide, heat and dry at 60°C for 4 hours, and obtain tin antimony oxide powder after grinding;

[0029] (2) Weigh 100g of tetradecyltributylphosphorus chloride and 0.25g of polyvinyl alcohol to prepare an aqueous solution with a concentration of quaternary phosphonium salt of 4mg / mL, and place tin antimony oxide in it to absorb to saturation (quaternary phosphonium salt keeps Excessive amount), after filtering, fully wash with deionized water, heat at 60°C for 4 hours, dry, and grind to obtain quaternary phosphonium salt modified tin antimony oxide conductive filler;

[0030] (3) Then add a solution mixed with 1.5g of titanate coupling agent and 30g of ethanol (the mass ratio of titanate to ...

Embodiment 3

[0034] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0035] (1) Weigh 15g of nano-antimony tin oxide, heat and dry at 60°C for 4 hours, and obtain tin antimony oxide powder after grinding;

[0036] (2) According to the mass ratio of polyquaternary phosphonium salt / polyvinyl alcohol = 100 / 0.45, prepare an aqueous solution of polyquaternary phosphonium salt with a concentration of 6 mg / mL, and place tin antimony oxide in it to absorb to saturation (keep the excess of quaternary phosphonium salt) , after filtering, fully wash with deionized water, heat and dry at 60°C for 4 hours, and grind to obtain polyquaternary phosphonium salt modified tin antimony oxide conductive filler;

[0037] (3) Then add the solution mixed with aluminate coupling agent / ethanol=5 / 100 mass ratio (the mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com