Polyethersulfone antistatic composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of polyethersulfone antistatic composite materials and its preparation, can solve the problem that the specific surface area of carbon nanotubes is large, the excellent performance of carbon nanotubes cannot be fully utilized, and the coupling agent is difficult to play a role And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

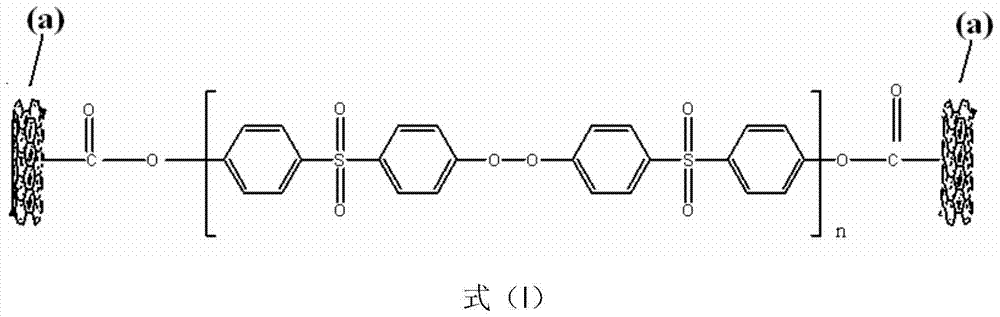

[0040] Furthermore, the preparation method of the polyethersulfone antistatic composite material: comprises the following steps:

[0041] (1) Take the raw material according to the molar ratio of the raw material: 4,4-dichlorodiphenyl sulfone: 4,4-dihydroxydiphenyl sulfone: potassium hydroxide: sulfolane: toluene=1: 1: 1: 5~6: 1.3~1.5;

[0042] (2) Ultrasonically disperse the acyl chloride carbon nanotubes in a solvent, and then 4,4-dichlorodiphenyl sulfone, 4,4-dihydroxydiphenyl sulfone, solvent, acyl chloride carbon nanotubes, dehydrating agent, catalyst Heating to reflux reaction, wherein the amount of carbonyl chloride carbon nanotubes is 10-15% of the mass of 4,4-dichlorodiphenyl sulfone;

[0043] (3) When the material temperature is 120-160°C, react at a constant temperature for 1-4 hours, then continue to heat up to 170-210°C to react until anhydrous is formed, then evaporate all the dehydrating agent, and continue to heat up to 255-265°C for reaction After 2-4 hours ...

Embodiment 1

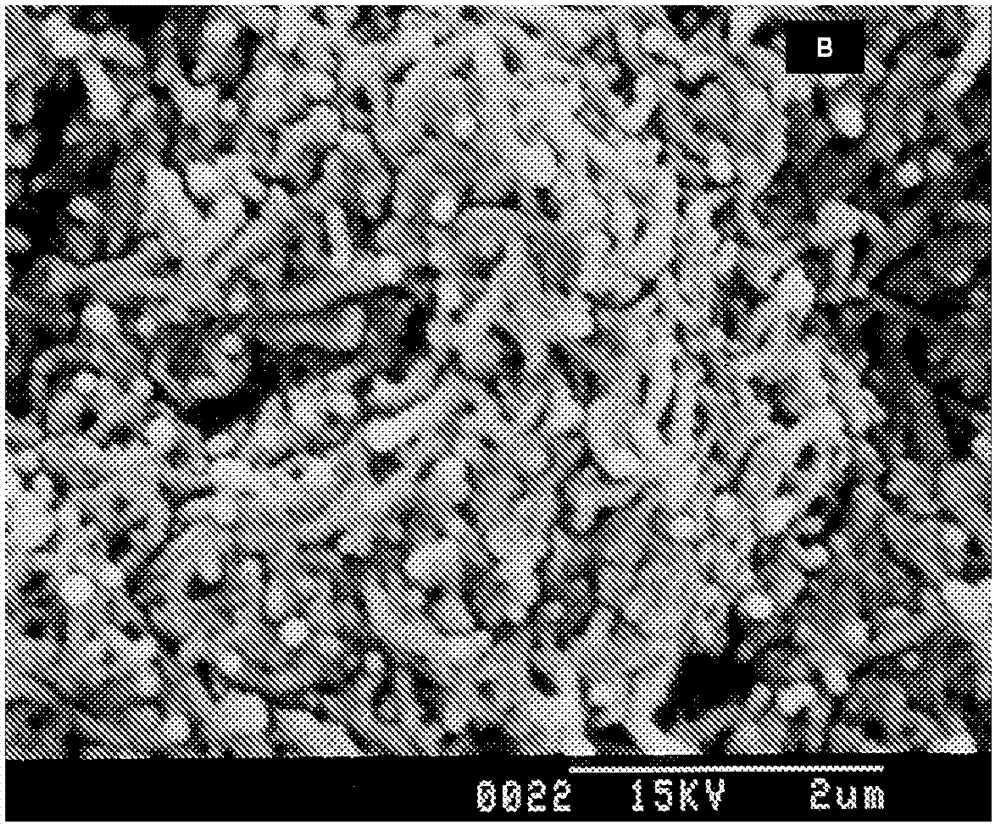

[0048] Embodiment 1 carbon nanotube surface acid chloride treatment

[0049] The first step is to acidify the carbon nanotubes: put 0.5g carbon nanotubes into 500ml mixed acid (concentrated sulfuric acid:concentrated nitric acid volume ratio is 3:1) for ultrasonic dispersion for 1 hour, react at 60°C for 24 hours and use After dilution with deionized water and suction filtration, the resulting precipitate was washed with deionized water until the pH value was about 5, and the product was dried in a vacuum oven to obtain surface carboxylated carbon nanotubes (MWNT-COOH). The second step is to add 0.2 grams of carboxylated carbon nanotubes to 200ml of thionyl chloride, then add 2ml of DMF as a catalyst, heat and reflux at 70°C for 24 hours, and use toluene to reflux to take out the thionyl chloride after the reaction. The recovered product in the lower layer was dried in a vacuum oven and then sealed and stored to obtain acid-chlorinated carbon nanotubes (MWNT-COCl). The SEM ph...

Embodiment 2

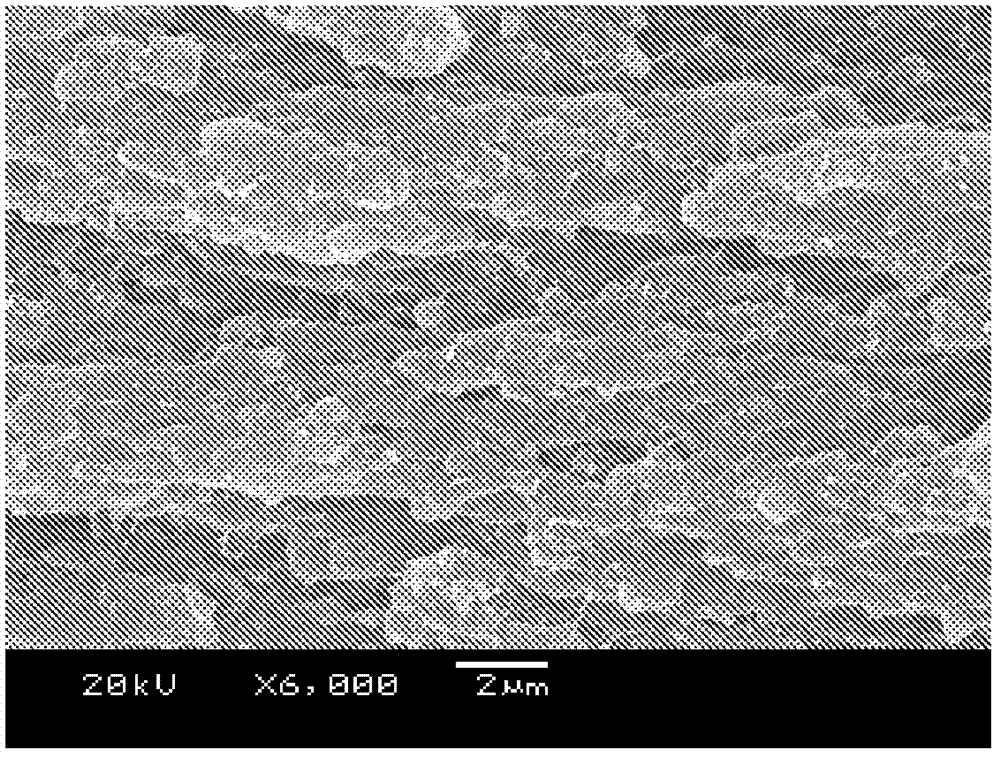

[0050] Embodiment 2 Preparation of polyethersulfone antistatic composite material

[0051] First, according to the following molar ratio: 4,4-dichlorodiphenyl sulfone: 4,4-dihydroxydiphenyl sulfone: sulfolane: toluene: potassium hydroxide=1: 1: 5: 1.3: 1 Weigh the raw materials, then weigh Take the 4,4-dichlorodiphenyl sulfone mass 10% carbon acyl chloride carbon nanotubes obtained in Example 1 and put them into the solvent sulfolane for ultrasonic dispersion treatment for 10 minutes, then 4,4-dichlorodiphenyl sulfone, 4,4 - Put dihydroxydiphenyl sulfone, sulfolane, carbon nanotube acyl chloride, toluene, and potassium hydroxide together into a reaction kettle with a reflux device, stir and heat under nitrogen protection. When the material temperature is 155°C, react at constant temperature for 2 hours, then continue to heat up to 190°C until no water is formed, then distill all the toluene, continue to heat up to 255°C for 2.5 hours, and then dilute and discharge. The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com