Patents

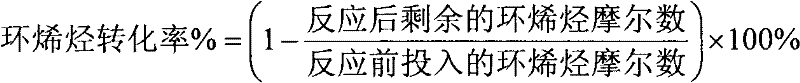

Literature

194results about "Carboxylic acid ester formation/introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

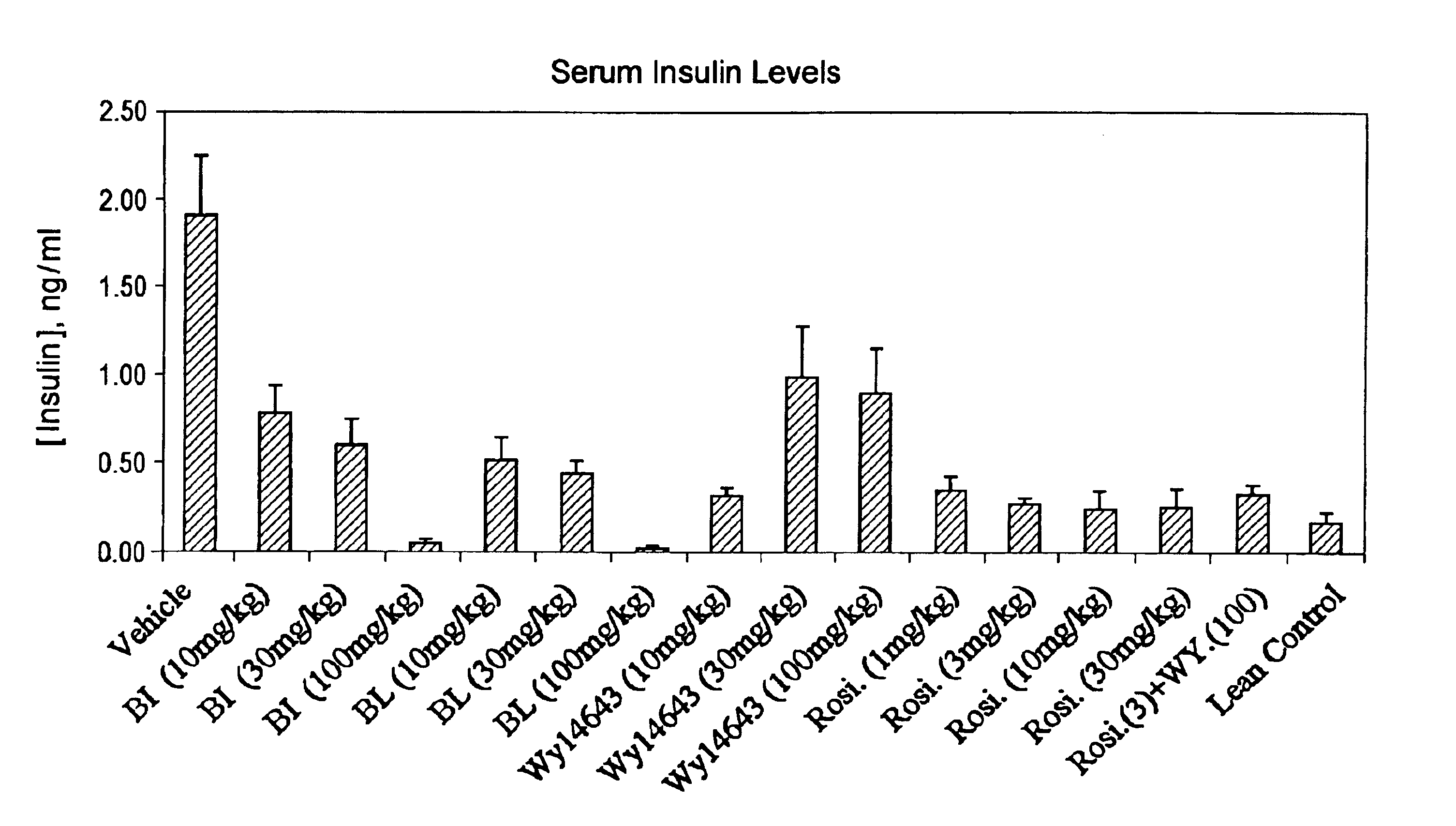

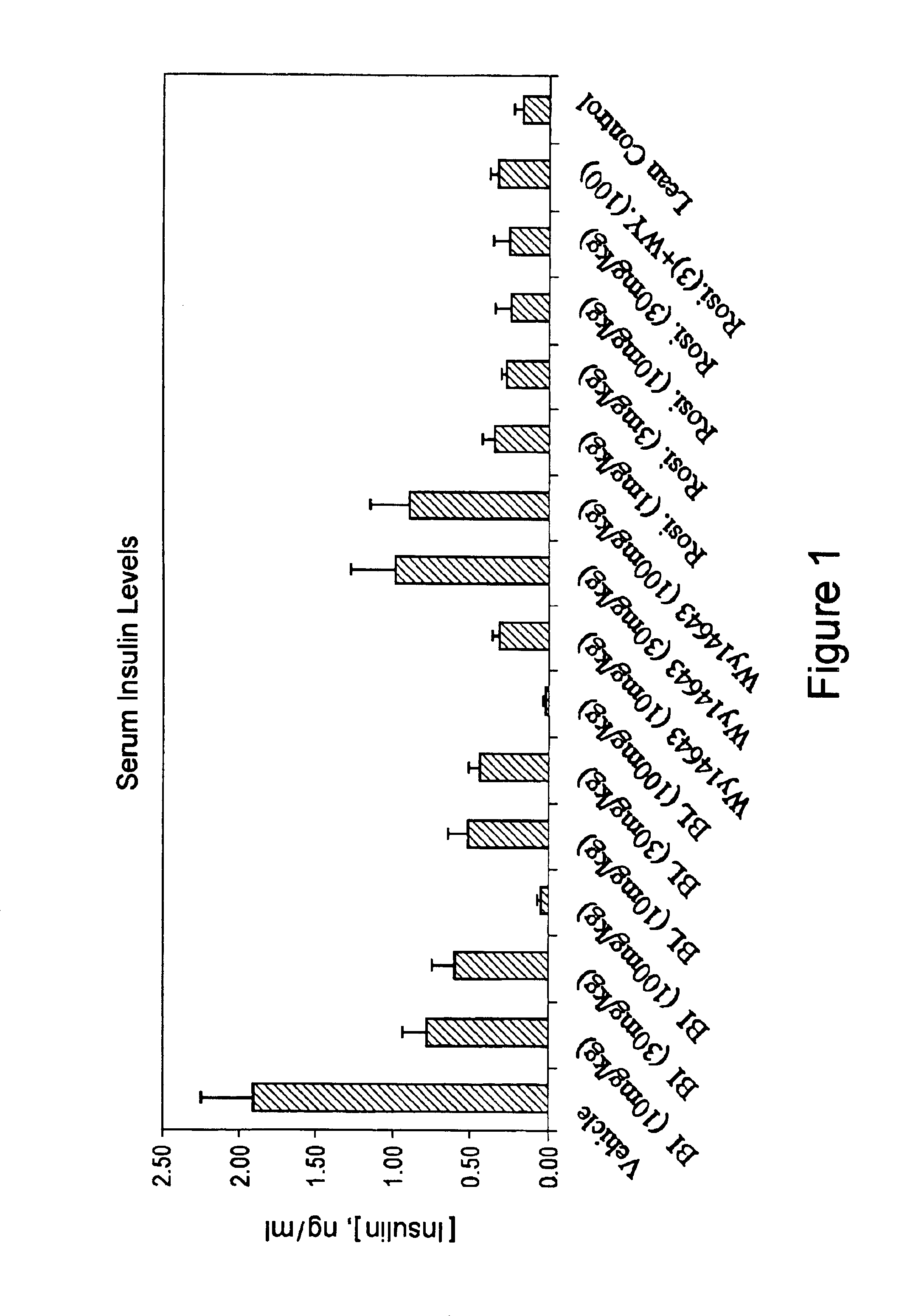

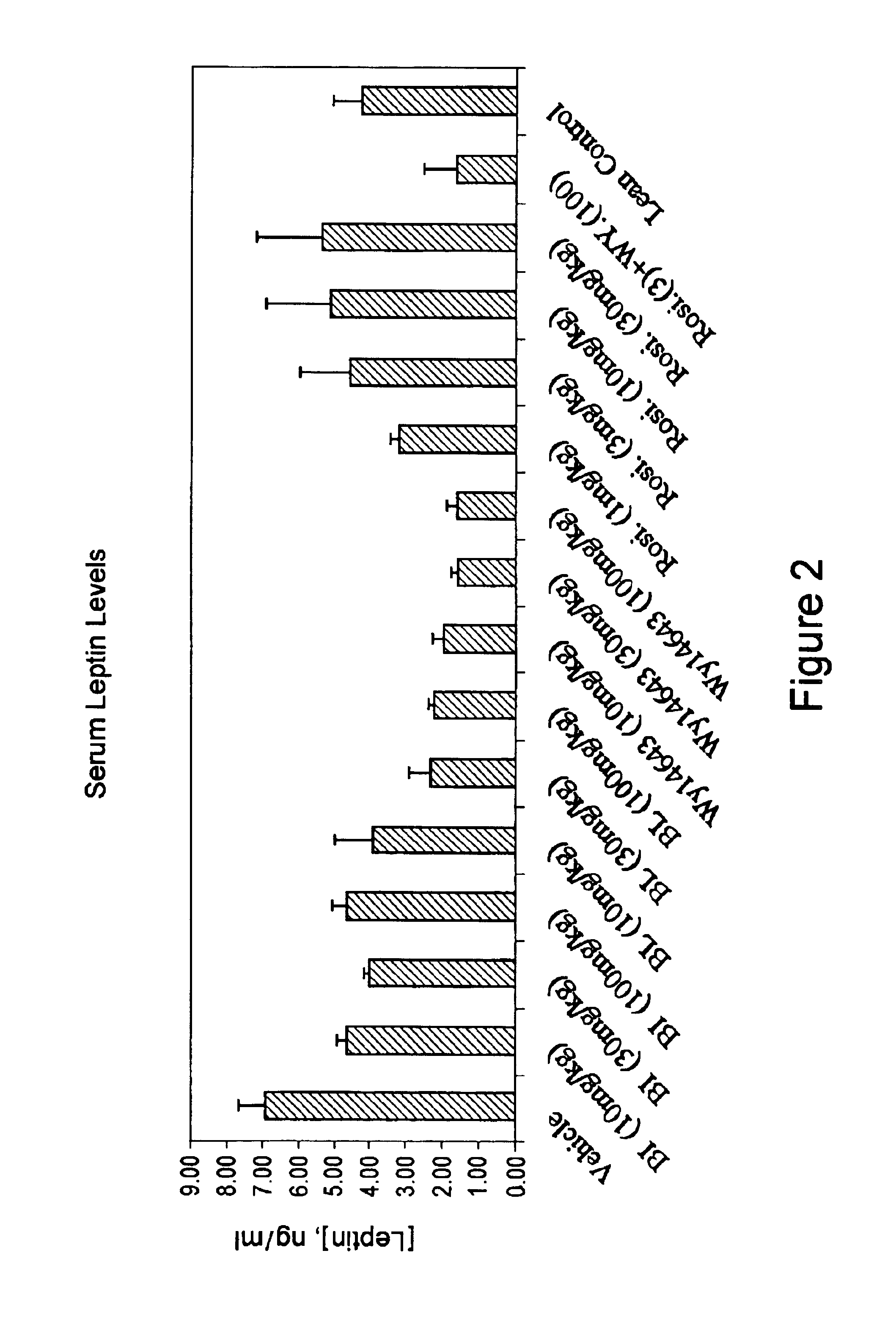

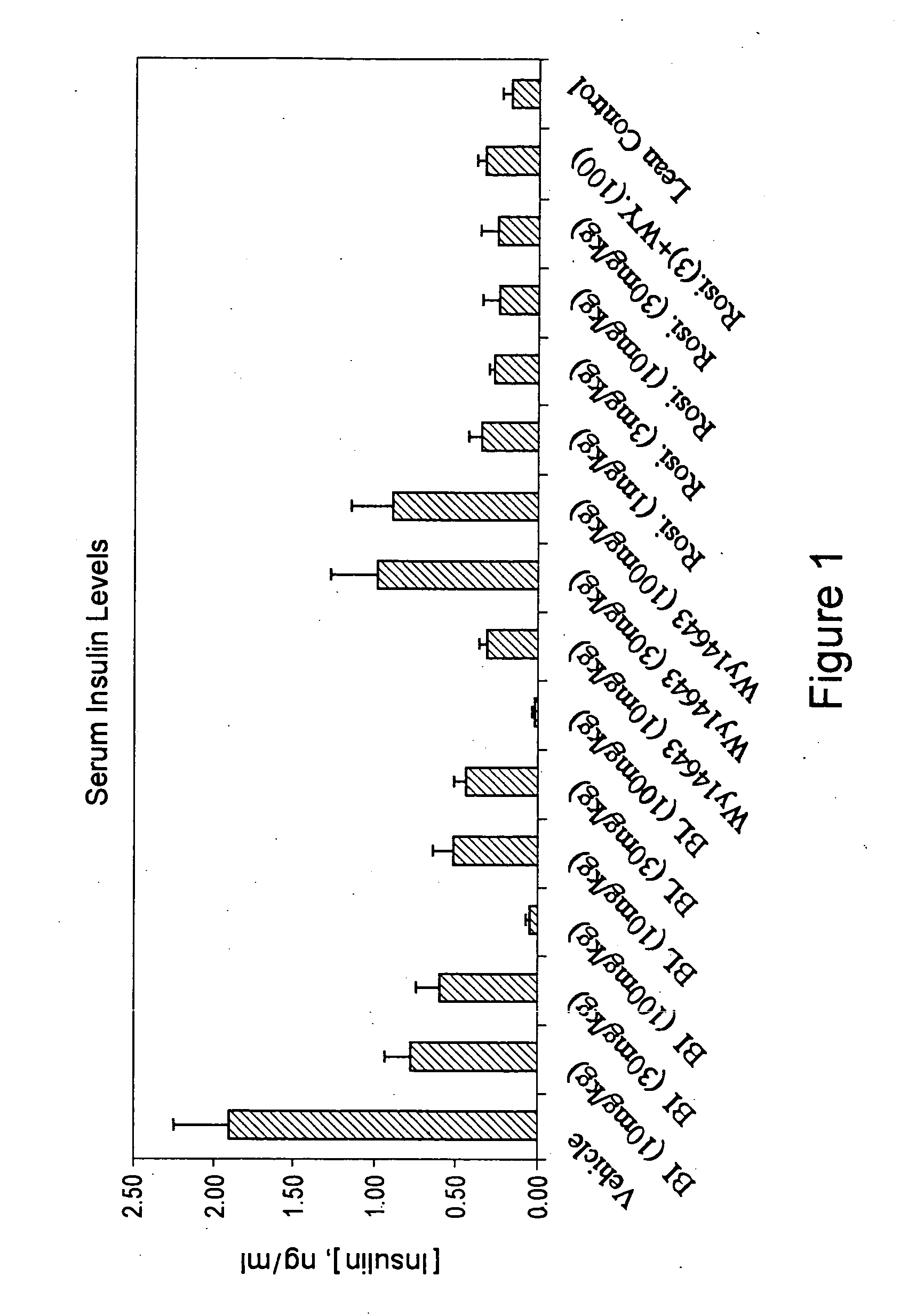

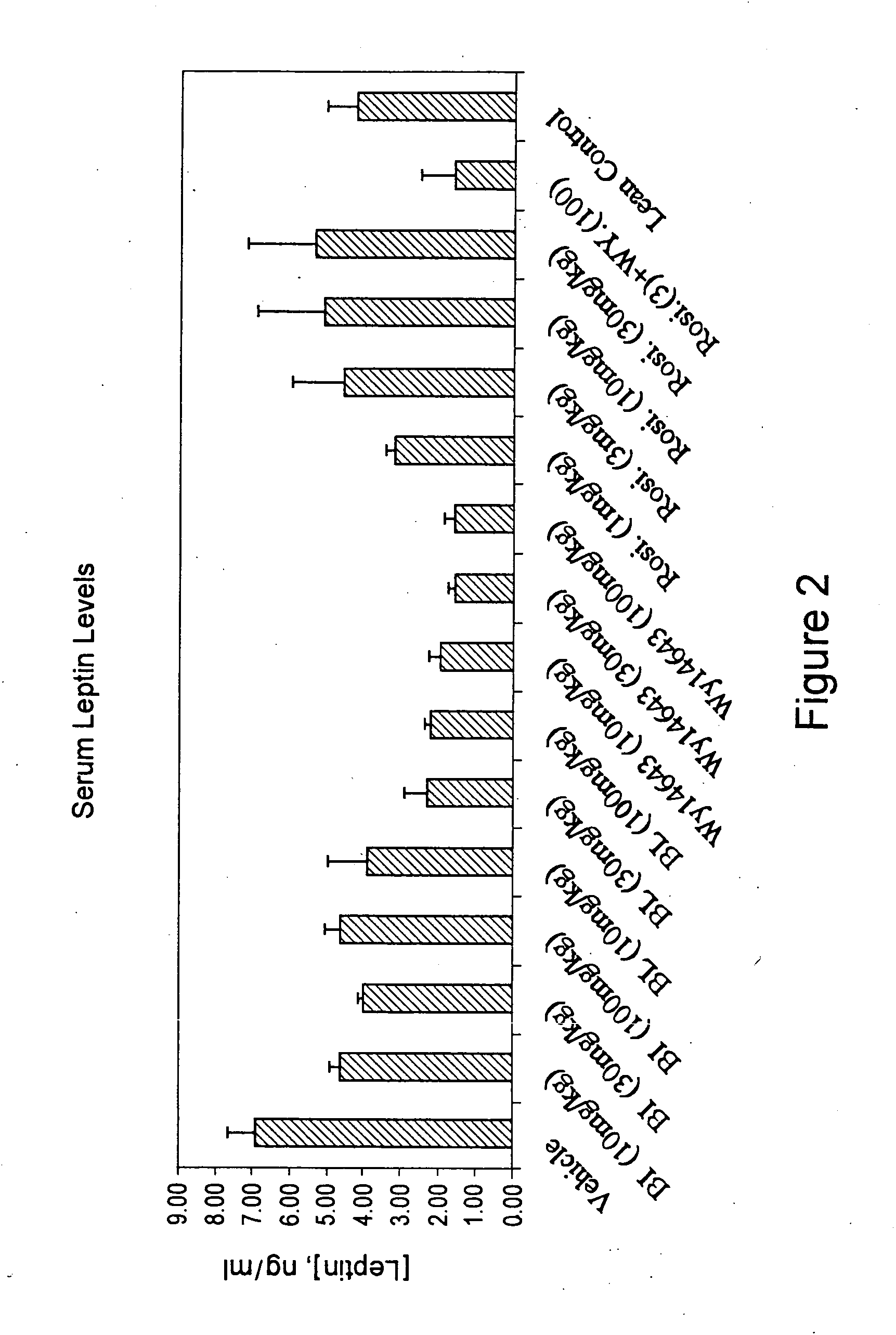

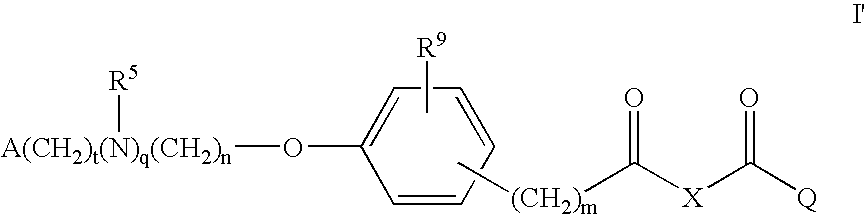

Compounds for the treatment of metabolic disorders

Owner:WELLSTAT THERAPEUTICS CORP

Compounds for the treatment of metabolic disorders

Compounds useful for the treatment of various metabolic disorders, such as insulin resistance syndrome, diabetes, hyperlipidemia, fatty liver disease, cachexia, obesity, atherosclerosis and arteriosclerosis, are disclosed.

Owner:WELLSTAT THERAPEUTICS

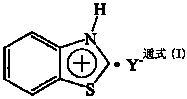

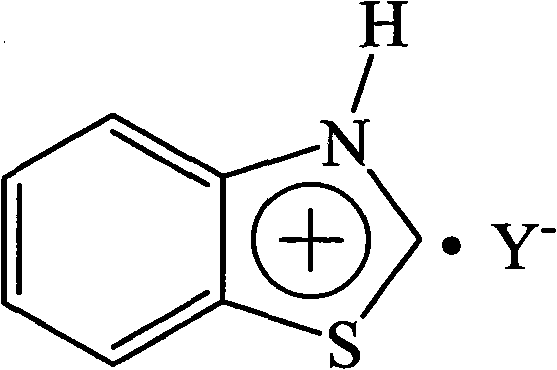

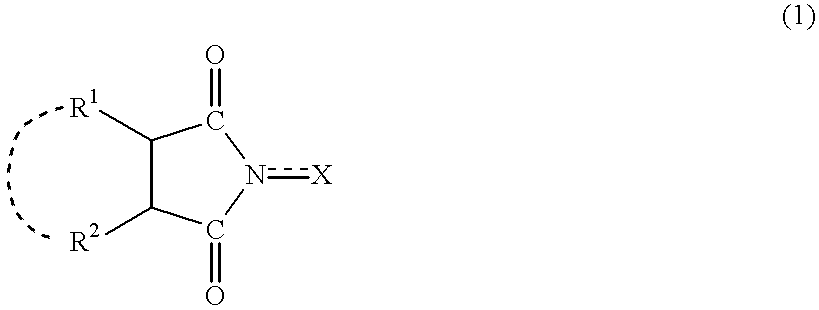

Preparation of temperature sensitive acidic ionic liquid and method of using the same in catalyzing alcoholic acid esterification

ActiveCN101863855AEasy to prepareLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityFiltration

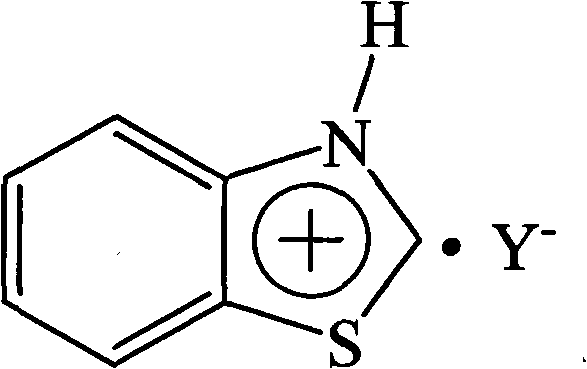

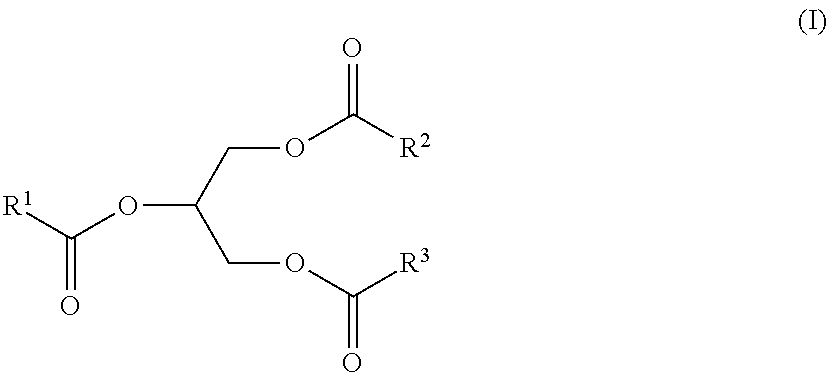

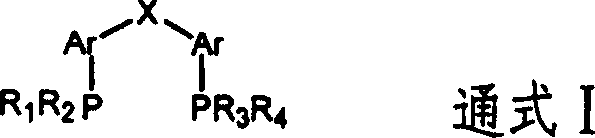

The invention discloses preparation of temperature sensitive acidic ionic liquid and a method of using the same in catalyzing alcoholic acid esterification reaction. A general formula (I) represents the structure of the temperature sensitive acidic ionic liquid which is formed by benzothiazole cations and sulfonic acid radical anions. The invention is mainly characterized in that the ionic liquidis in a solid state at room temperature, can be dissolved in polar solvent such as water, alcohol and the like and cannot be dissolved in low-polar or non-polar solvent such as ester, ether and the like; and particularly the solubility of the ionic liquid in alcohol is very sensitive to temperature, the ionic liquid is hardly dissolved in alcoholic solvent at low temperature and can be rapidly dissolved in the alcoholic solvent after temperature is increased, crystals are precipitated after cooling and the solubility of the ionic liquid is very sensitive to temperature. The method of using the ionic liquid in catalyzing esterification comprises that the temperature sensitive ionic liquid is used to catalyze the esterification between monohydric alcohol or polyatomic alcohol and organic carboxylic acid, the ionic liquid is rapidly dissolved in a reaction system after the ionic liquid is heated and homogeneous-phase catalytic esterification reaction is conducted. After the reaction is stopped, the obtained product is cooled, the ionic liquid is crystallized and precipitated from the reaction system and after filtration is conducted, ester products and the ionic liquid are respectively obtained. The invention has the advantage that the transformation process of the temperature sensitive ionic liquid from heterogeneous phase to homogeneous phase to heterogeneous phase in the catalytic system can be realized only through temperature variation. The general formula (I) is shown as the accompanying drawing.

Owner:成都市明典世家生物科技有限公司

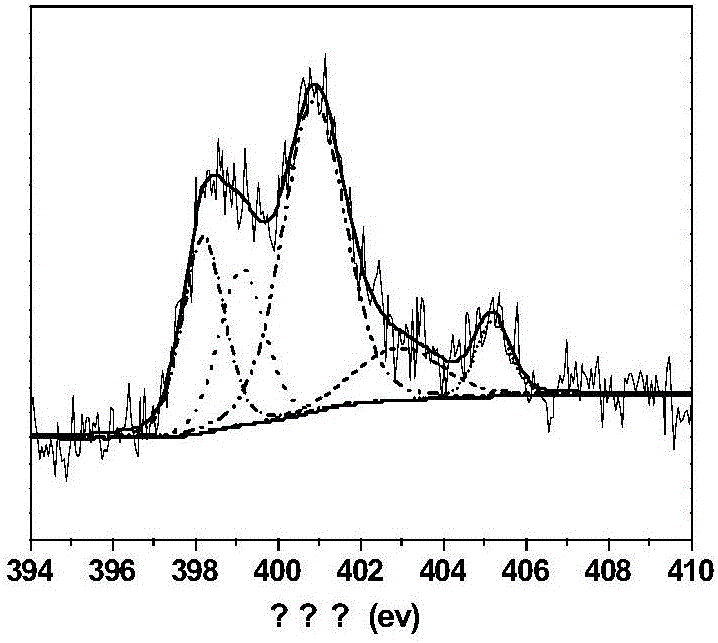

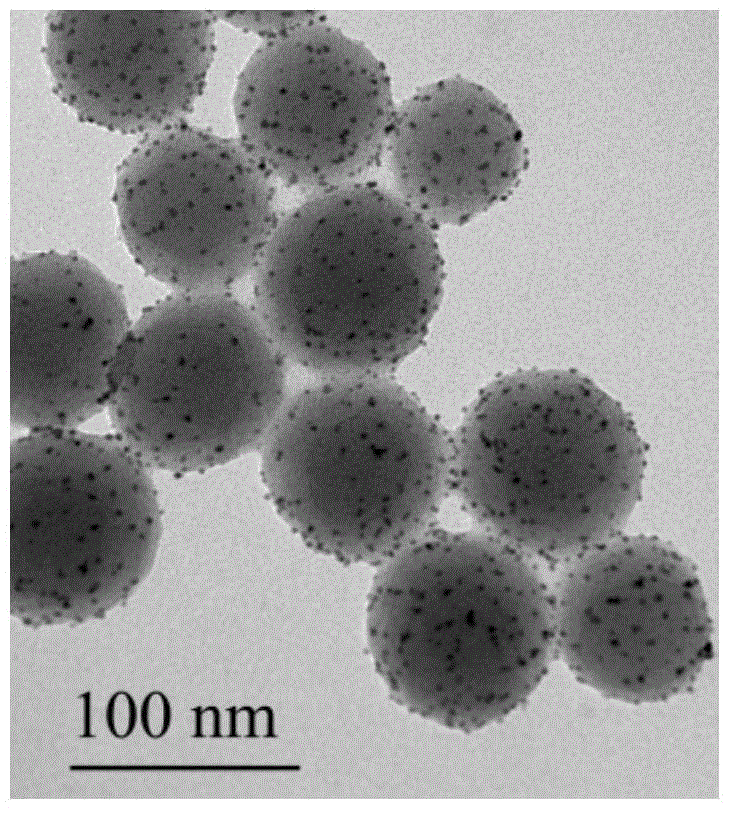

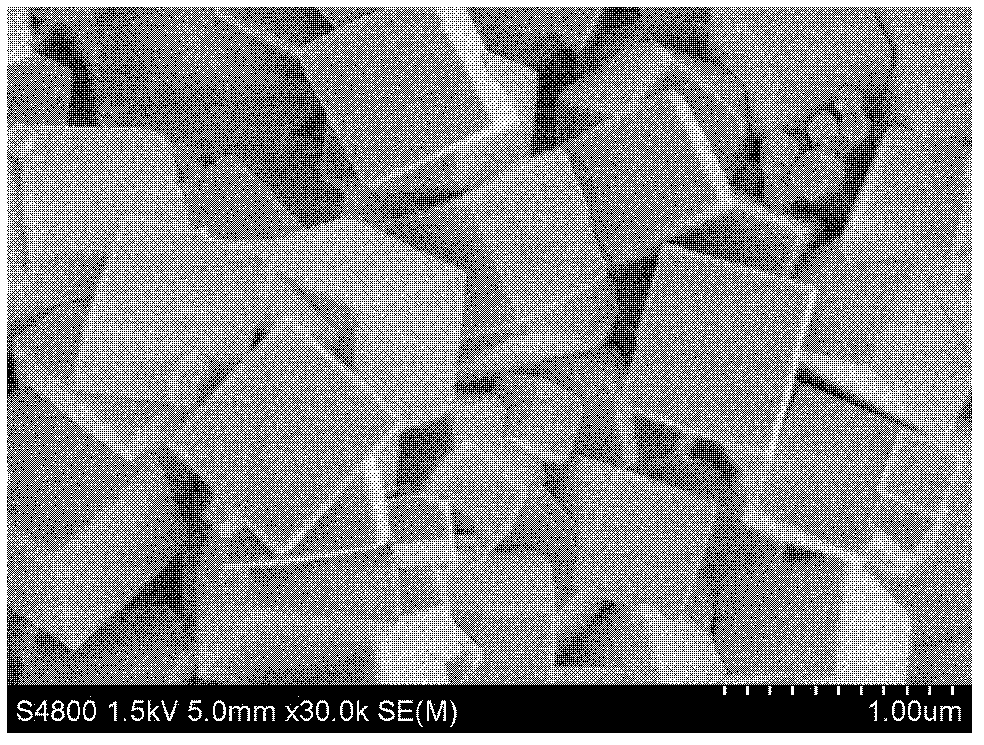

Cobalt-based catalyst for generating ester by alcohol oxidation, and preparation method and application of cobalt-based catalyst

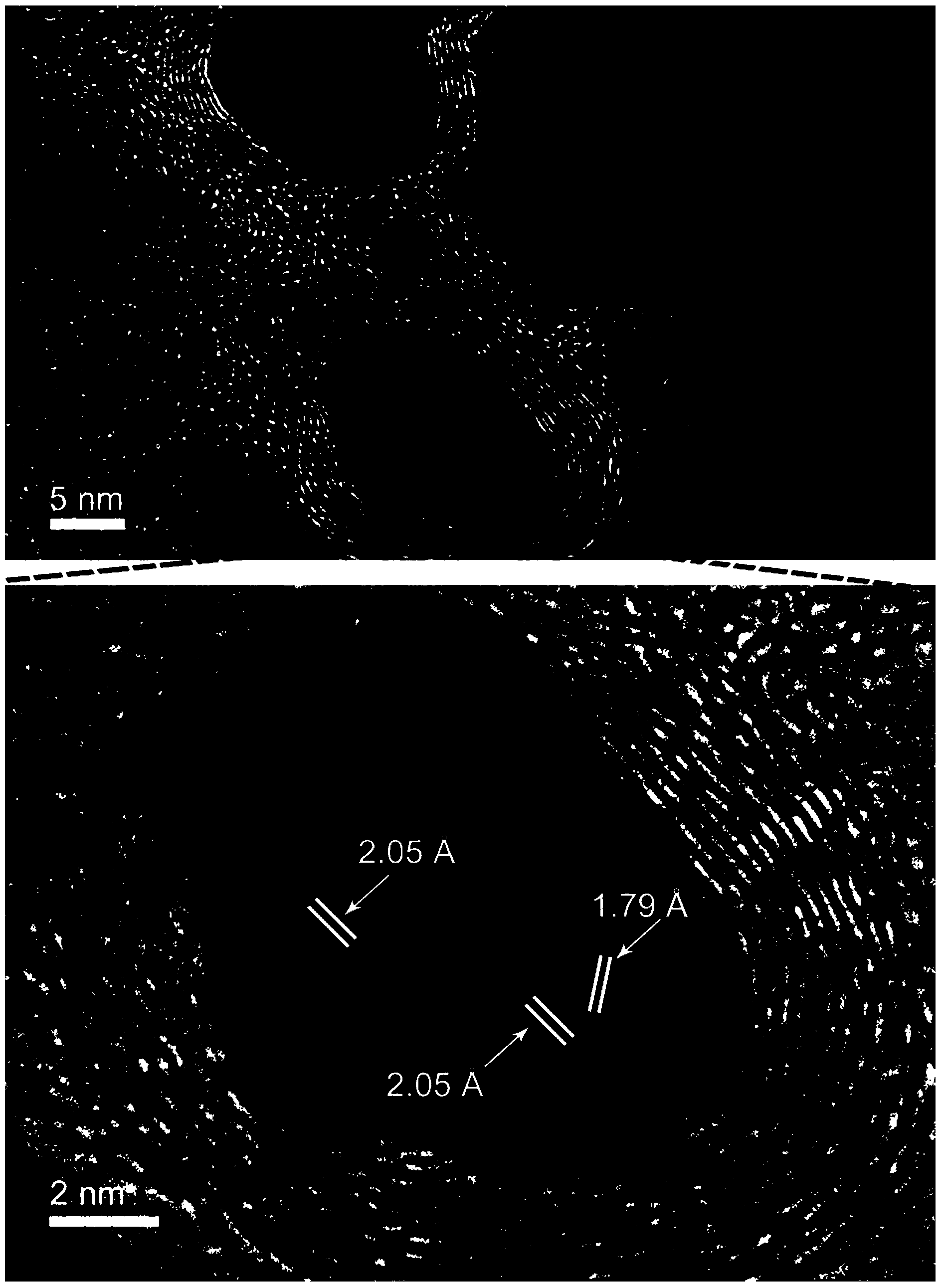

ActiveCN104069883AMagneticEasy to operatePhysical/chemical process catalystsOrganic compound preparationNitrogenCobalt

The invention belongs to the technical field of liquid phase oxidation, and discloses a cobalt-based catalyst for generating ester by alcohol oxidation, and a preparation method and application of the cobalt-based catalyst. The cobalt-based catalyst mainly comprises the following elements in percentage by weight: 27.0-50.0 percent of cobalt, 45.0-60.0 percent of carbon and 0.5-20.0 percent of nitrogen, wherein the particle diameter of cobalt nano particles in the cobalt-based catalyst is 5-40 nm. The cobalt-based catalyst is prepared in a pyrolysis mode in an inert atmosphere with ZIF-67 as a precursor. In the presence of the cobalt-based catalyst, alkaline aids are not added in the normal-temperature and normal-pressure atmospheric environment, and two alcohols react to prepare ester compounds. The cobalt-based catalyst is easy to synthesize in quantity, and is magnetic and recyclable. A method for catalyzing alcohol oxidation to generate ester in the presence of the cobalt-based catalyst has the advantages of low cost, simplicity in operation, environment friendliness, mild reaction condition, easiness in product separation and the like.

Owner:SOUTH CHINA UNIV OF TECH

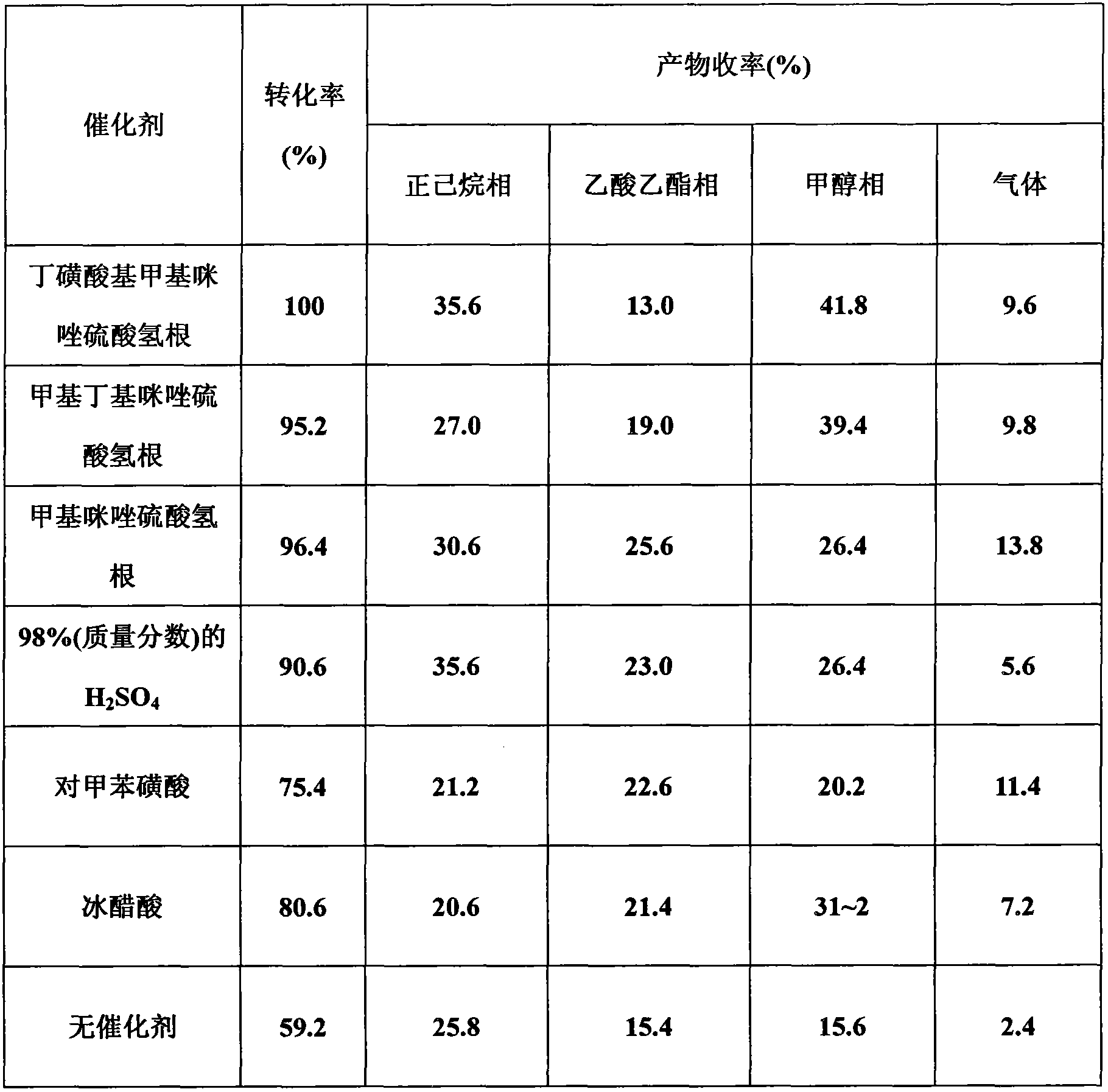

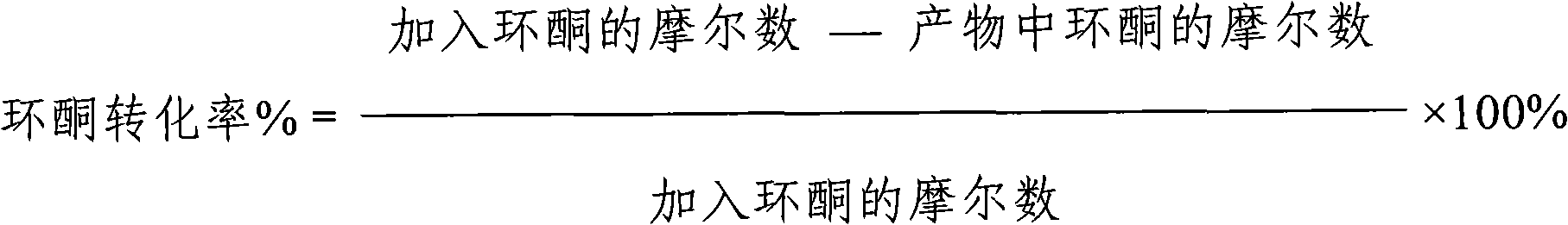

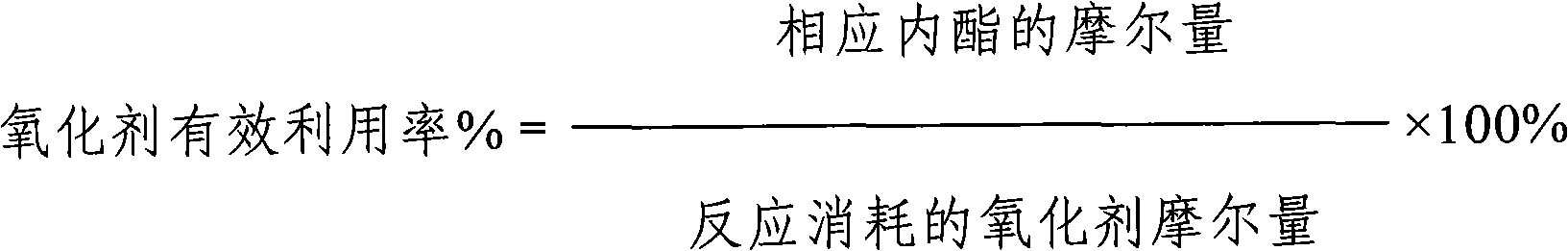

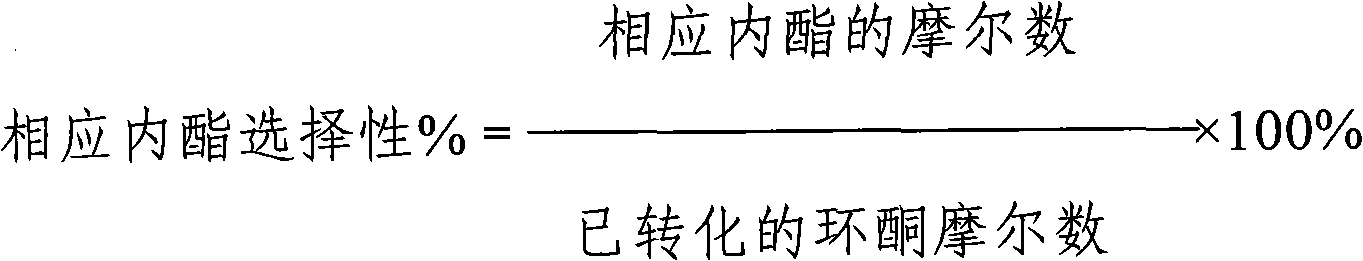

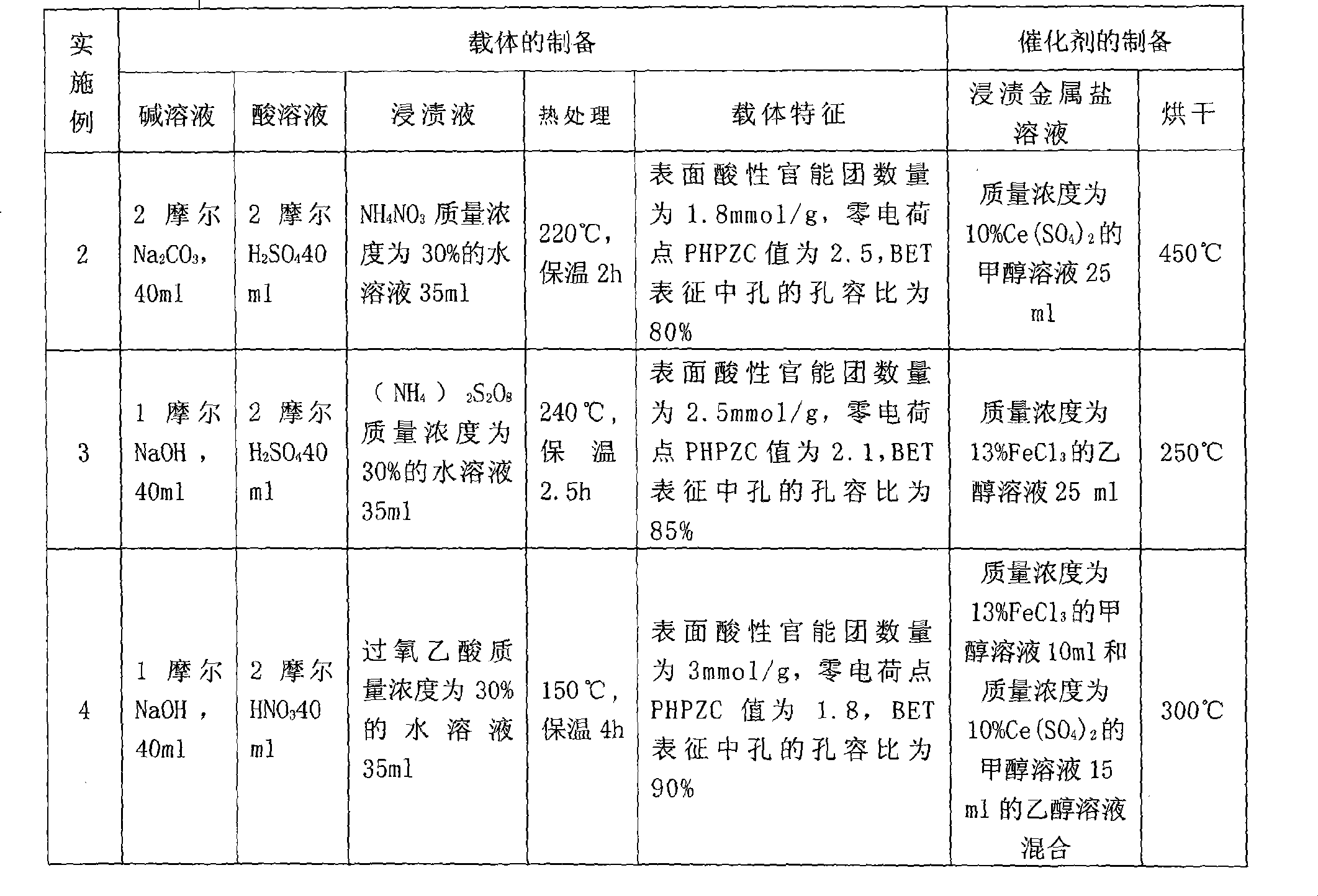

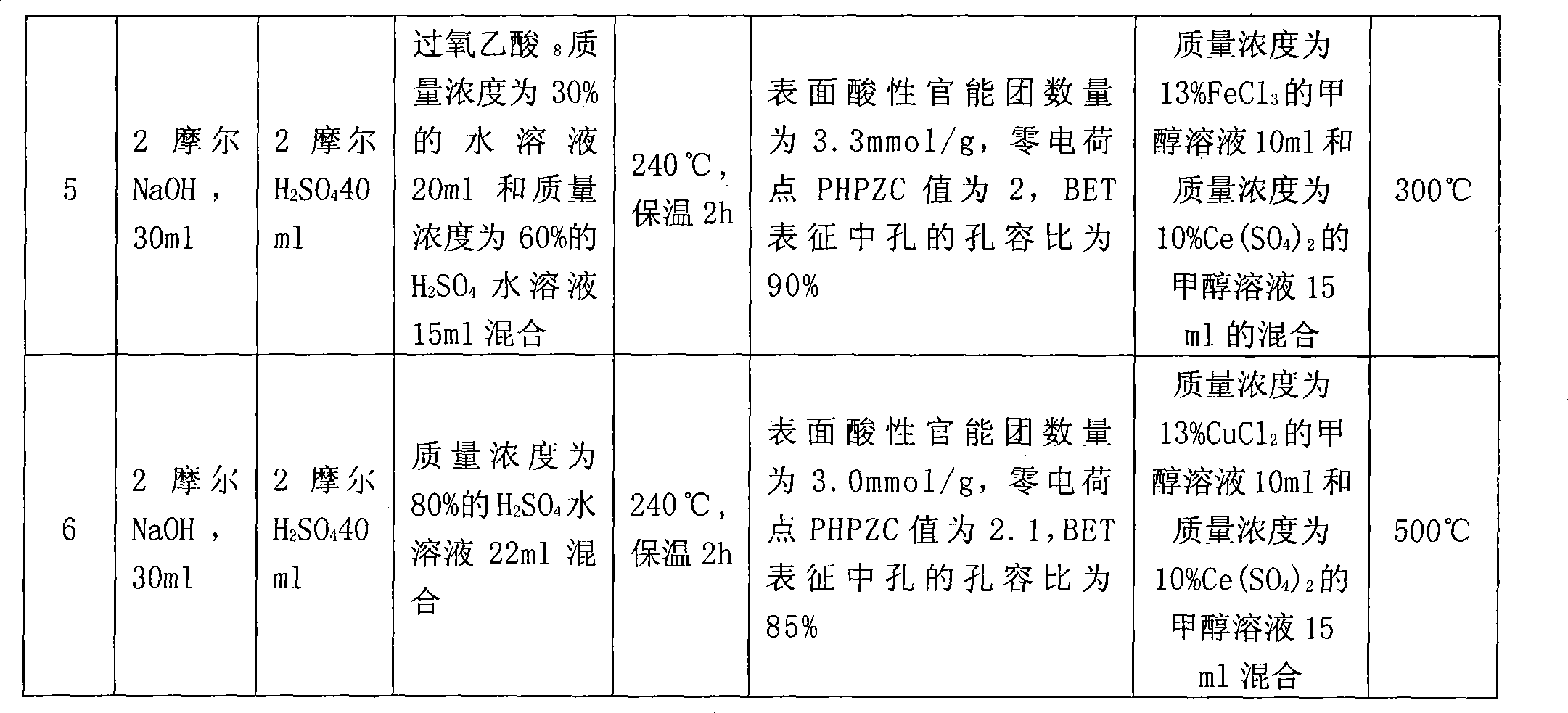

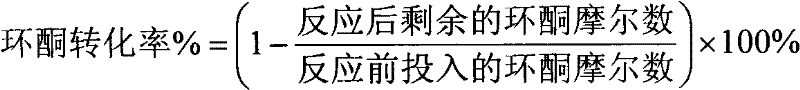

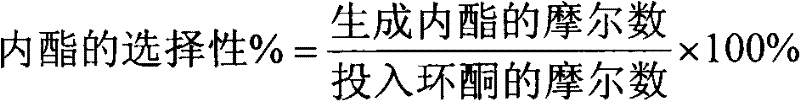

Method for catalytically oxidizing cyclic ketone

ActiveCN102452869AOvercoming complexityOvercoming equipment corrosionOrganic compound preparationCarboxylic acid ester formation/introductionMolecular sieveCatalytic oxidation

The invention provides a method for catalytically oxidizing cyclic ketone. The method is characterized in that reaction is carried out in the presence of a catalyst under the conditions that molar ratio of cyclic ketone to solvent to hydrogen peroxide is 1: (0-50): (0.2-20), temperature is 5-200 DEG C and reaction pressure is 0.1-3.0MPa, wherein the catalyst is a tin-supported pickled aluminum nano Beta-molecular sieve and the mass ratio of the catalyst to the cyclic ketone is 1: (5-300).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for carrying out catalytic conversion with high efficiency on cellulose at low temperature by utilizing compound ion liquid system

InactiveCN102060642AAchieve homogeneous transformationReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIce waterPhysical chemistry

The invention discloses a method for carrying out catalytic conversion with high efficiency on cellulose at low temperature by utilizing a compound ion liquid system, comprising the following steps of: (1) preparation of a compound ion liquid: fully mixing an ion liquid solvent and an acid ion liquid catalyst in ice water bath under the protection of N2 to obtain the compound ion liquid; and (2) catalytic conversion of the cellulose: mixing the compound ion liquid and microcrystalline cellulose, adding a nonpolar solvent, and after N2 replacement, heating, stirring and reacting for 5-75 minutes to obtain a biochemical product. The cellulose is one of main components of biomass, and due to the adoption of the method provided by the invention, the cellulose in the biomass can be converted and prepared into bio-oil and biochemical products so that high-efficiency recycling of the cellulose is realized. The method has the advantages of simple process, mild conditions, small amount of ion liquid and realization of recycling, and the conversion rate of the cellulose under the optimized condition can be up to 100%.

Owner:SOUTH CHINA UNIV OF TECH

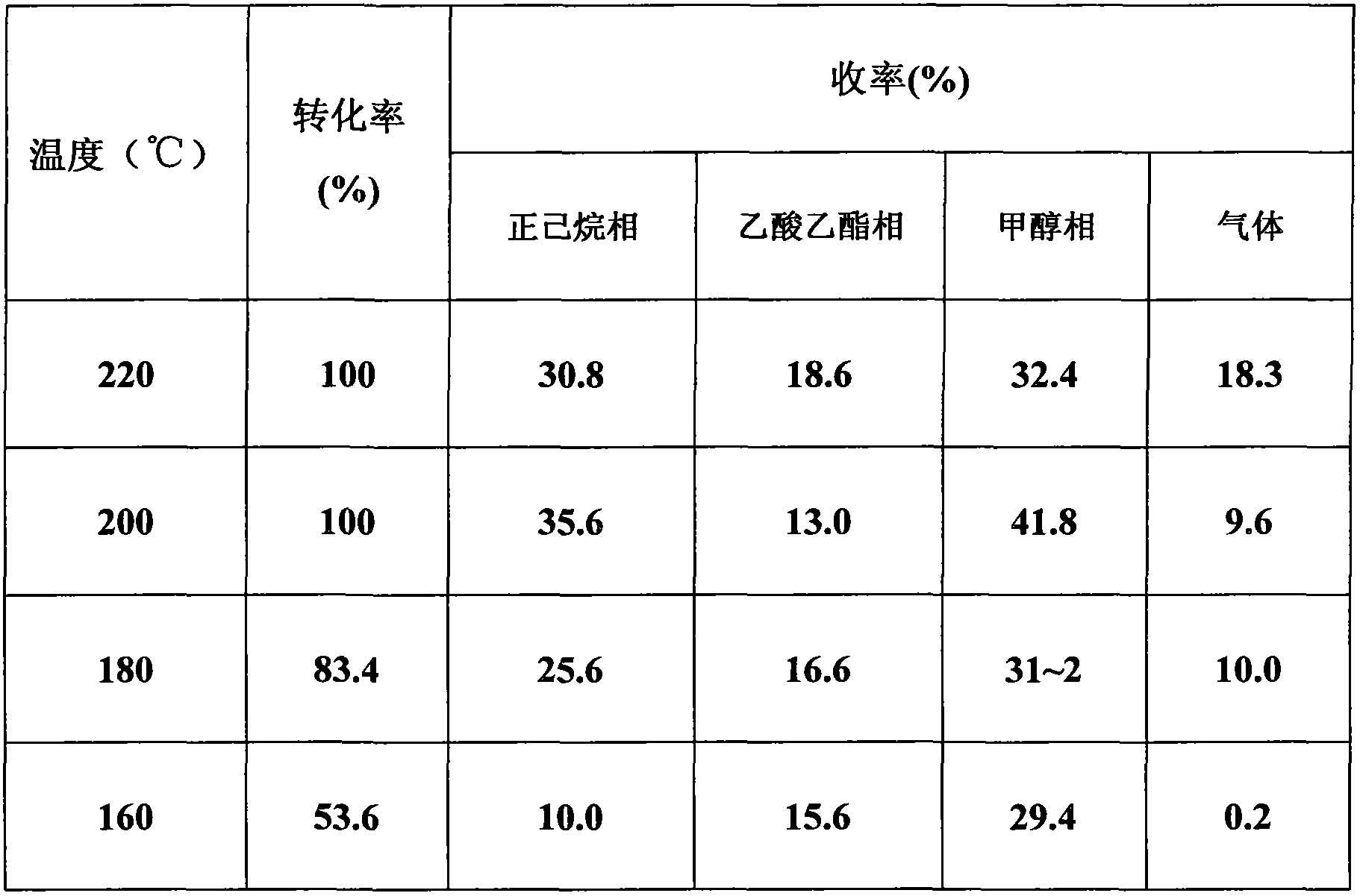

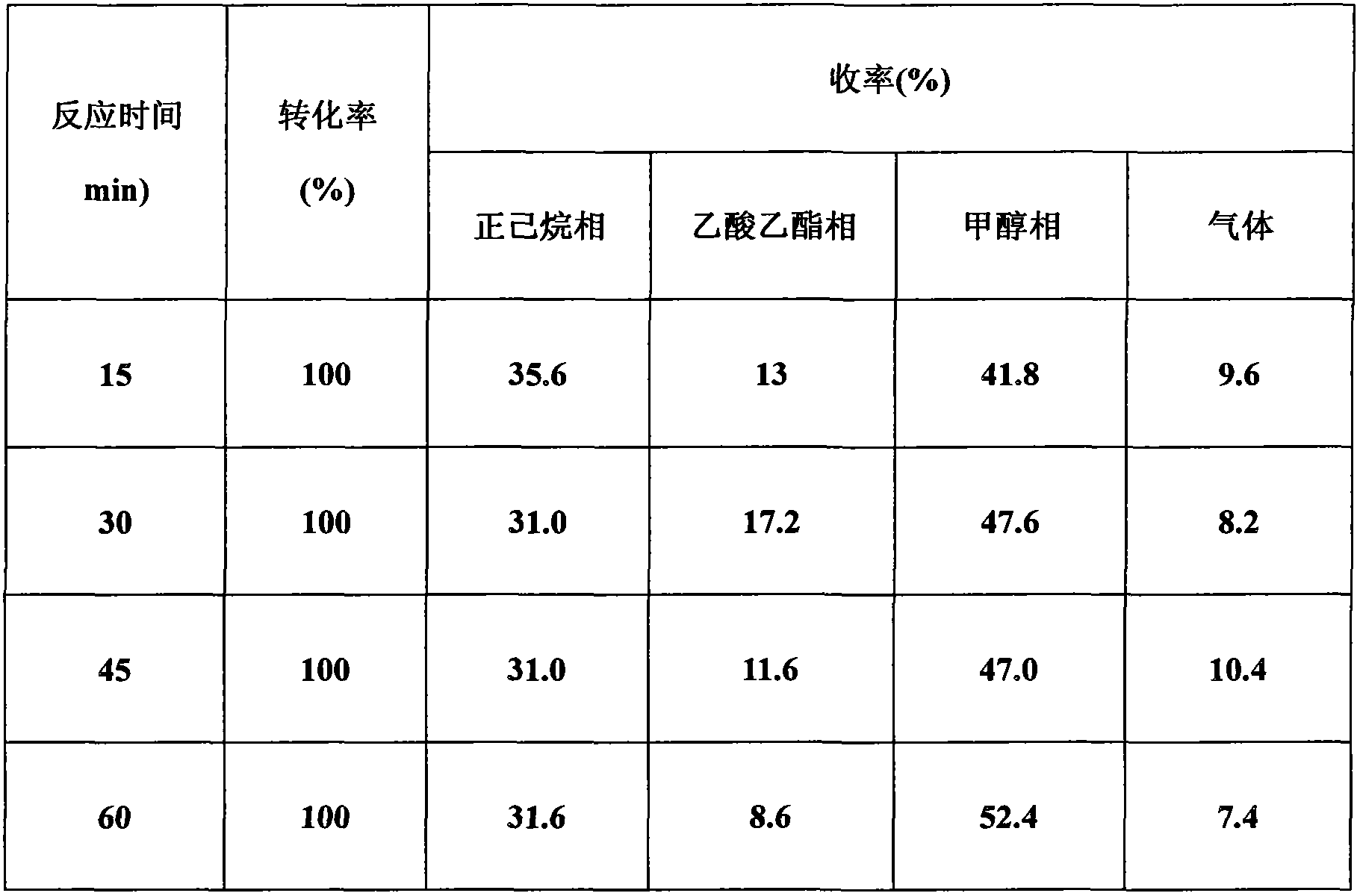

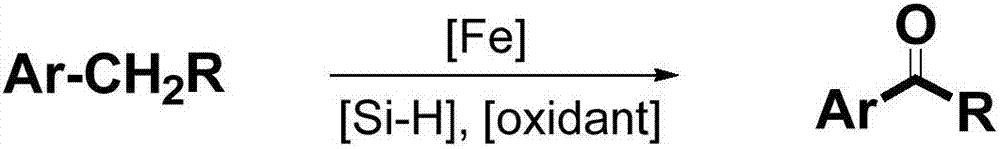

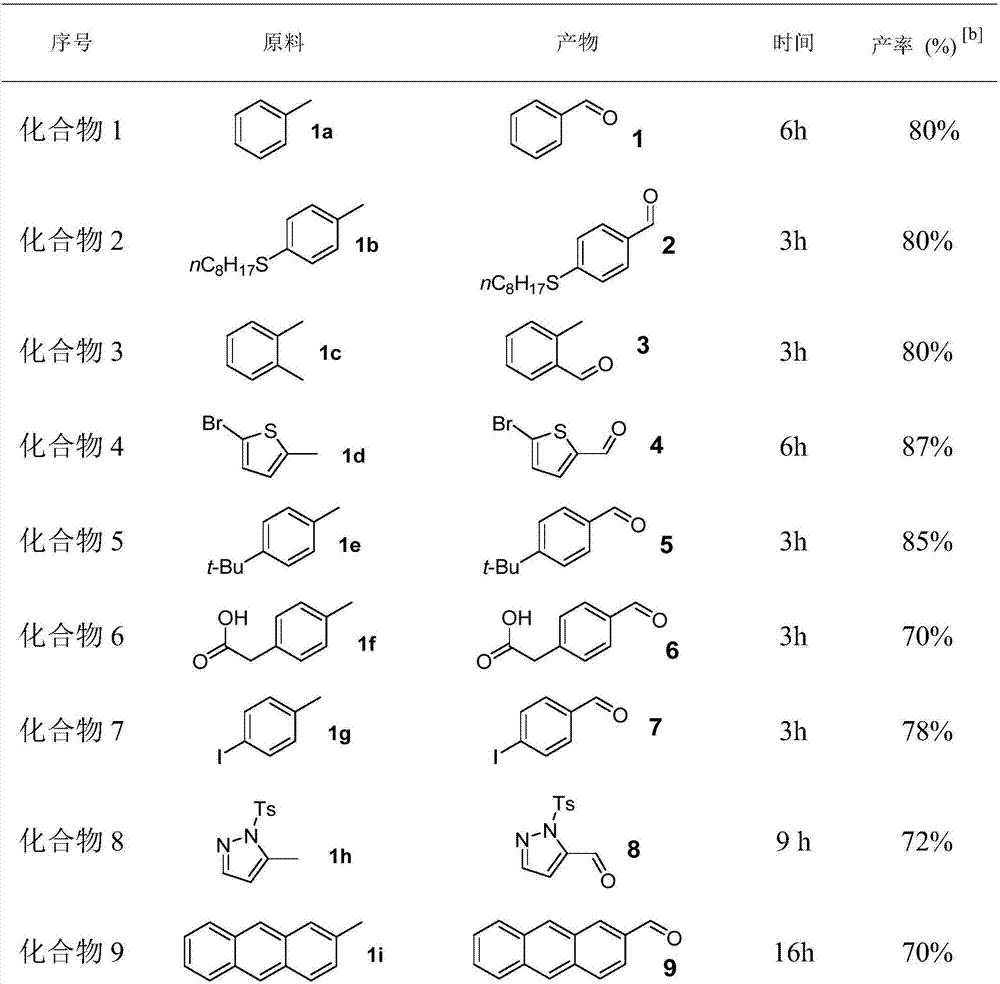

Method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing alkyl aromatic compound by iron

ActiveCN107216242ABroad compatibilityGood compatibilitySugar derivativesOrganic compound preparationSide chainCatalytic oxidation

The invention discloses a method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing an alkyl aromatic compound by iron, and belongs to the technical field of catalytic synthesis. According to the method, a low-cost and environment-friendly iron catalyst is used under a normal pressure; under the action of hydrogen and silicon reagents serving as an accelerant and an oxidant, a side chain of an aromatic hydrocarbon is oxidized into a carbonyl group for generating the corresponding aromatic aldehyde, aromatic ketone and aromatic ester. The method for preparing the aromatic aldehyde, the aromatic ketone and the aromatic ester through a catalytic oxidation reaction, which is provided by the invention, has numerous advantages that a catalyst, reaction raw materials, the oxidant and a silicon reagent are wide in sources and good in stability and is low-cost and environment-friendly; the alkyl aromatic compound is metered to participate in a reaction; the reaction condition is mild; the compatibility of functional groups is good; the scope of application is wide; the reaction selectivity is good; in an optimized reaction condition, the separation yield of a target product can be up to approximately 95 percent.

Owner:NANJING NORMAL UNIVERSITY

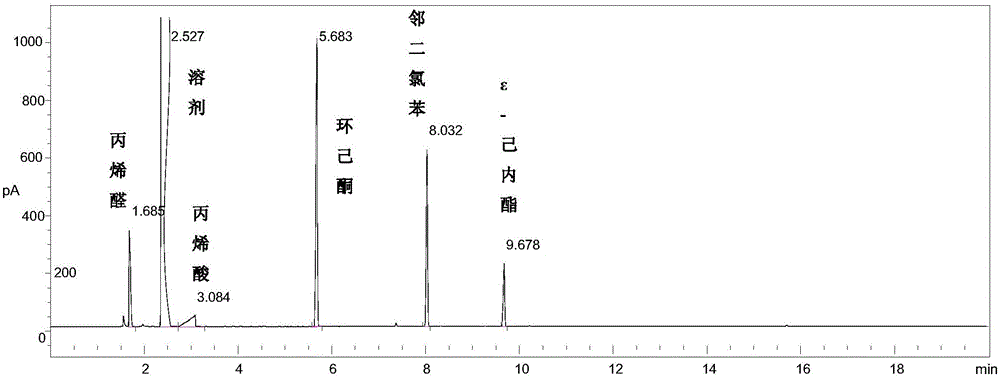

Method used for preparing epsilon-hexanolactone

ActiveCN106397386AHigh industrial valueReduce consumptionPhysical/chemical process catalystsCarboxylic acid ester formation/introductionCyclohexanoneOrganic solvent

The invention discloses a method used for preparing epsilon-hexanolactone. According to the method, cyclohexanone, an auxiliary oxidant, and a certain amount of a catalyst are added into a certain amount of an organic solvent, molecular oxygen is taken as an oxidizing agent, and stirring reaction is carried out for 0.1 to 24h at 60 to 100 DEG C under 0.1 to 2MPa, wherein the auxiliary oxidant is acrolein, and the catalyst is a carbon material. The method is high in auxiliary oxidant efficiency; the catalyst is simple, is easily available, and is convenient to recycle; the oxidizing agent is green, and is friendly to the environment; operation is simple; and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

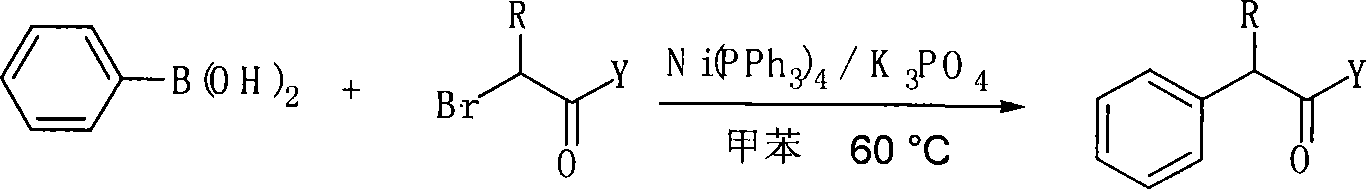

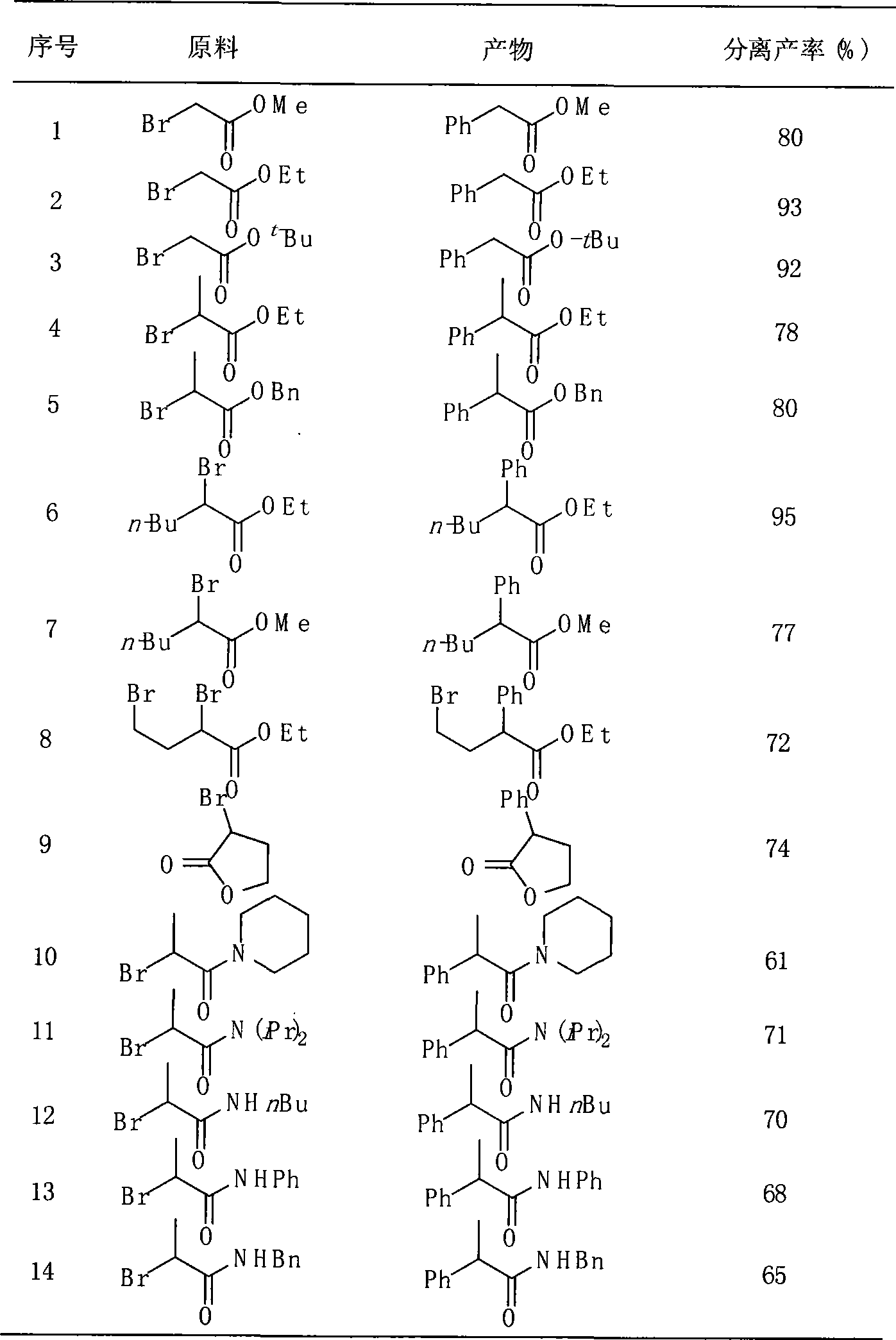

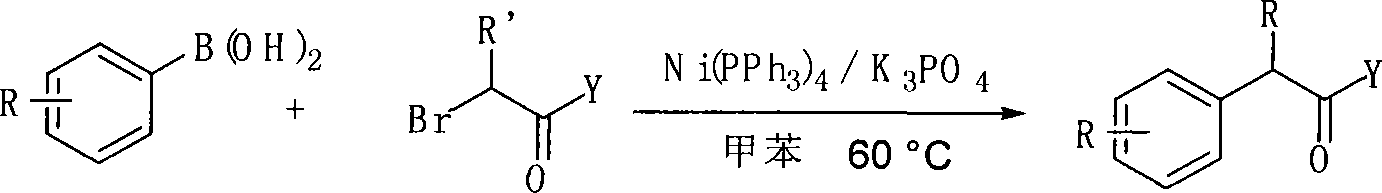

Method for preparing alpha-aryl carbonyl compound

InactiveCN101157590ASubstrate stabilizationCheap and easy to getOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl group formation/introductionKetonePhenylphosphine

The invention relates to a method of preparing alpha-aryl carbonyl compound. With the catalyst of four triphenylphosphine nickel or acetylacetone nickel ligand, the aryl boric acid, the alpha-halogenated carbonyl compound, the ligand and the additive are dissolved in toluene, and after reaction for 10 to 24 hours in 50 to 100 DEG C, the alpha-aryl carbonyl compound is obtained, wherein, the ligand is single-tooth phosphine ligand or double-tooth phosphine ligand; and the additive is absolute potassium phosphate or tri-potassium phosphate. The invention, which utilizes the catalyst with low cost, stable substrate, easy obtaining and gentle reaction conditions, can not only catalyze arylation of ester, amide and ketone, but also can be compatible with beta hydrogen, thereby greatly expanding the range of the substrate. Moreover, the invention possesses great application potential and can directly constitute the main framework of the steride.

Owner:WUHAN UNIV

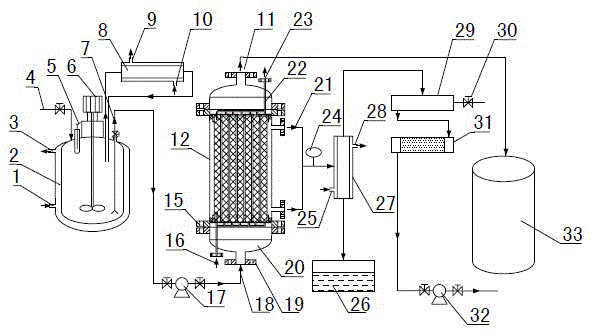

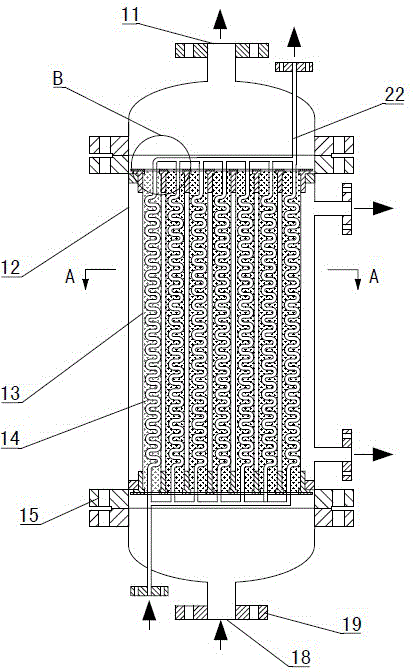

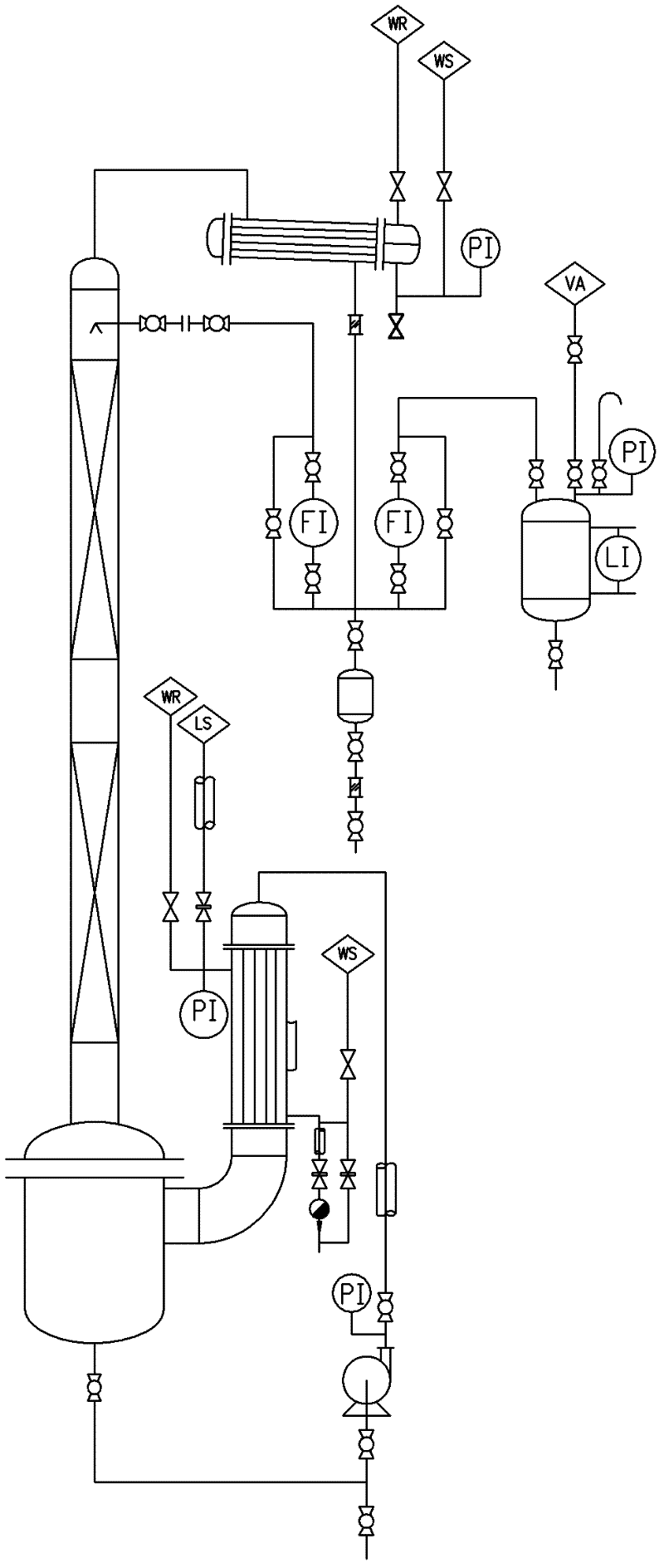

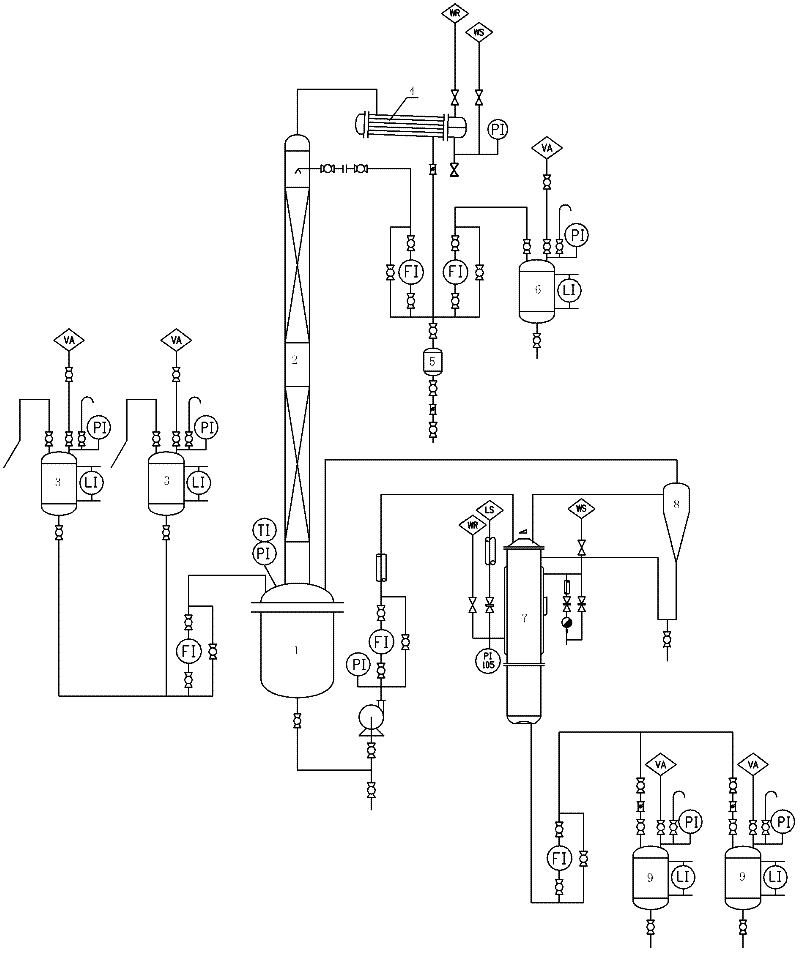

Continuous dehydration esterification reaction device as well as continuous esterification reaction method

ActiveCN103553921AIncrease profitIncrease contact surfaceOrganic compound preparationCarboxylic acid esters preparationMolecular sieveAlcohol

The invention discloses a continuous dehydration esterification reaction device as well as a continuous esterification reaction method, belonging to the technical field of esterification reaction. A membrane reactor comprises a vertically fixed cylindrical housing (12) and a plurality of tubular molecule sieve membranes (13) axially fixed in the housing (12), wherein a fixed bed catalyst (14) is filled in the tubular molecular sieve membranes (13); the charging hole (18) of the membrane reactor is arranged at the lower end of the housing (12) and communicated with a material mixing and preheating device; the discharging hole (11) of the membrane reactor is arranged at the upper end of the housing (12) and communicated with a storage tank (33). The continuous esterification reaction method comprises the following steps of: mixing and adding alcohol and oleic acid in a molar ratio of 1:1-12:1 into the material mixing and preheating device, heating up to 75 DEG C-85 DEG C and feeding to the membrane reactor; reacting alcohol and oleic acid under catalytic action of the fixed bed catalyst (14), extracting water generated in the reaction by a dehydrating device to promote the reaction to be carried out toward a positive direction, and storing reaction products in the storage tank (33) through the discharging hole (11) of the membrane reactor.

Owner:SHANDONG UNIV OF TECH

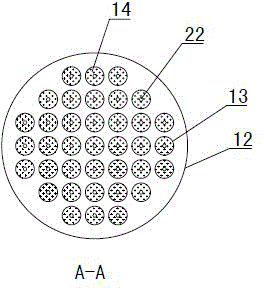

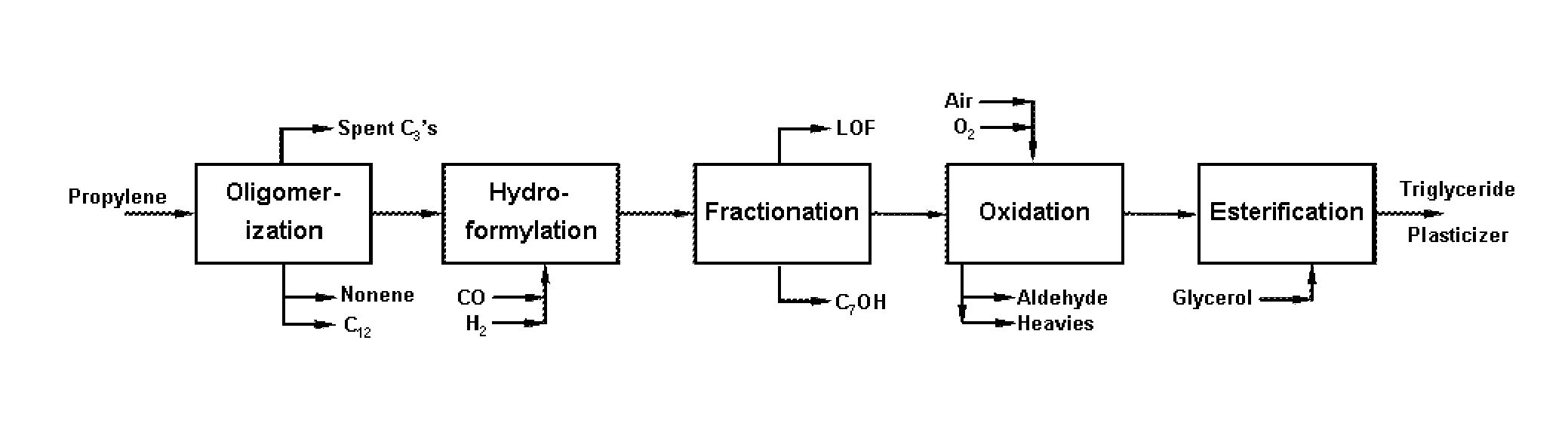

Polyol Ester Plasticizers and Process of Making the Same

InactiveUS20110021680A1Efficiency benefitLow toxicityOrganic compound preparationCarboxylic acid esters preparationCarbon numberGlycerol

Triglyceride and other polyol ester PVC plasticizers can be produced by recovery of branched C6 to C9 aldehydes from a hydroformylation product, optional hydrogenation to the alcohol, oxidation to the acid with oxygen and / or air, recovery of the resulting acid, and esterification with glycerol, ethylene glycol, propylene glycol or mixtures thereof. The branched alkyl chains comprise at least 10% methyl branching. Special triglycerides are derived from branched aliphatic acids having alkyl chains with average carbon numbers from 6 to 9 and at least 10% methyl branching. These triglycerides are fast fusing plasticisers if before esterification with glycerol, an aryl acid is introduced together with the aliphatic acids.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of methacrylate products

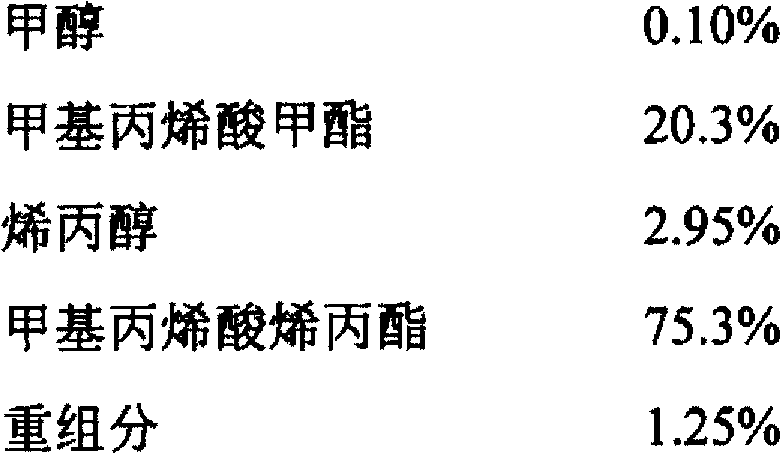

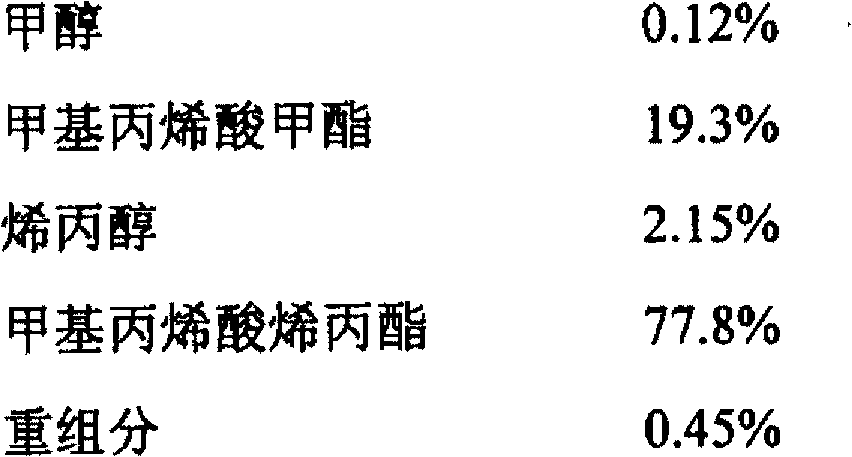

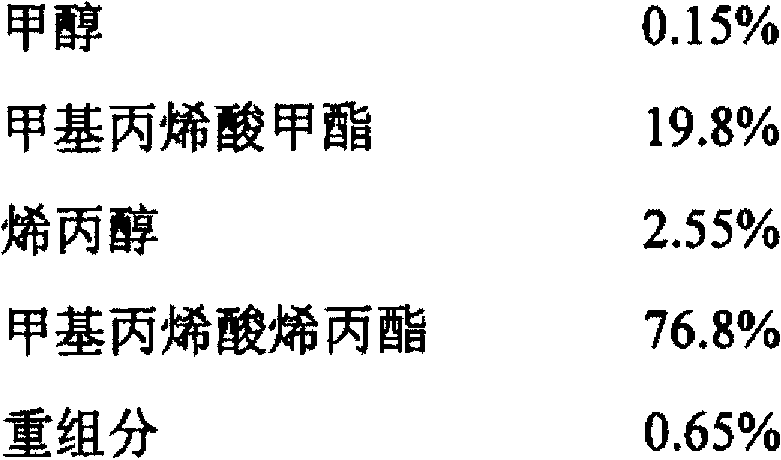

ActiveCN102850155ALess investmentEasy for industrialized continuous productionOrganic compound preparationPreparation by ester-hydroxy reactionMethacrylateAlcohol

The invention discloses a preparation method of methacrylate products, which comprises the following steps: adopting a reaction device comprising at least two reaction kettles connected in series, taking methyl methacrylate and alcohol as raw materials, using a catalyst and a polymerization inhibitor for assistance, placing the methyl methacrylate, the alcohol, the catalyst and the polymerization inhibitor into the reaction kettles, heating and reacting to generate the methacrylate products and methanol; then separating and purifying to obtain the products. The preparation method provided by the invention adopts a coupling process of reactive rectification and azeotropic rectification to couple the reactive rectification of the methyl methacrylate and the alcohol with the azeotropic rectification of the methyl methacrylate in an azeotrope formed in recycling of the methyl methacrylate and the alcohol so as to reduce the device investment, decrease the energy consumption and increase the yield rate. By adopting the technology provided by the invention, the proportion of the materials is decreased, the efficiency of the reactor is improved, the technological process is simplified, the reaction condition is mild, the operation is simple, the conversion rate is high, and the product quality is high and stable.

Owner:苏州和创化学有限公司

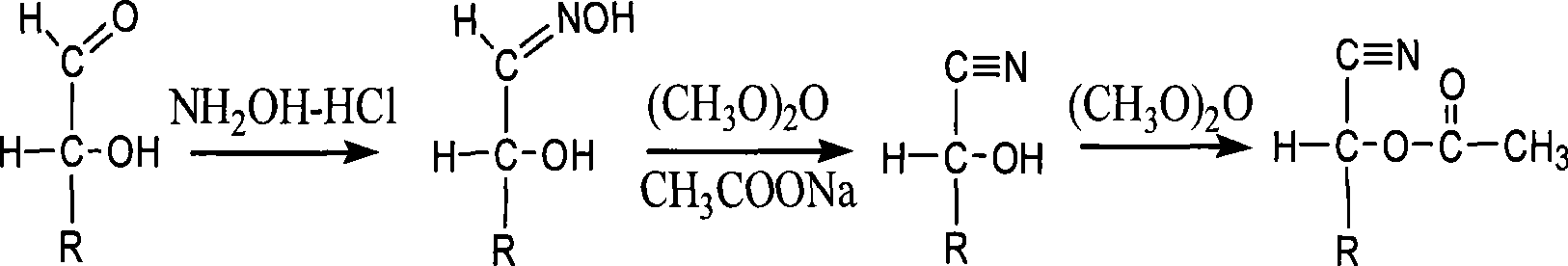

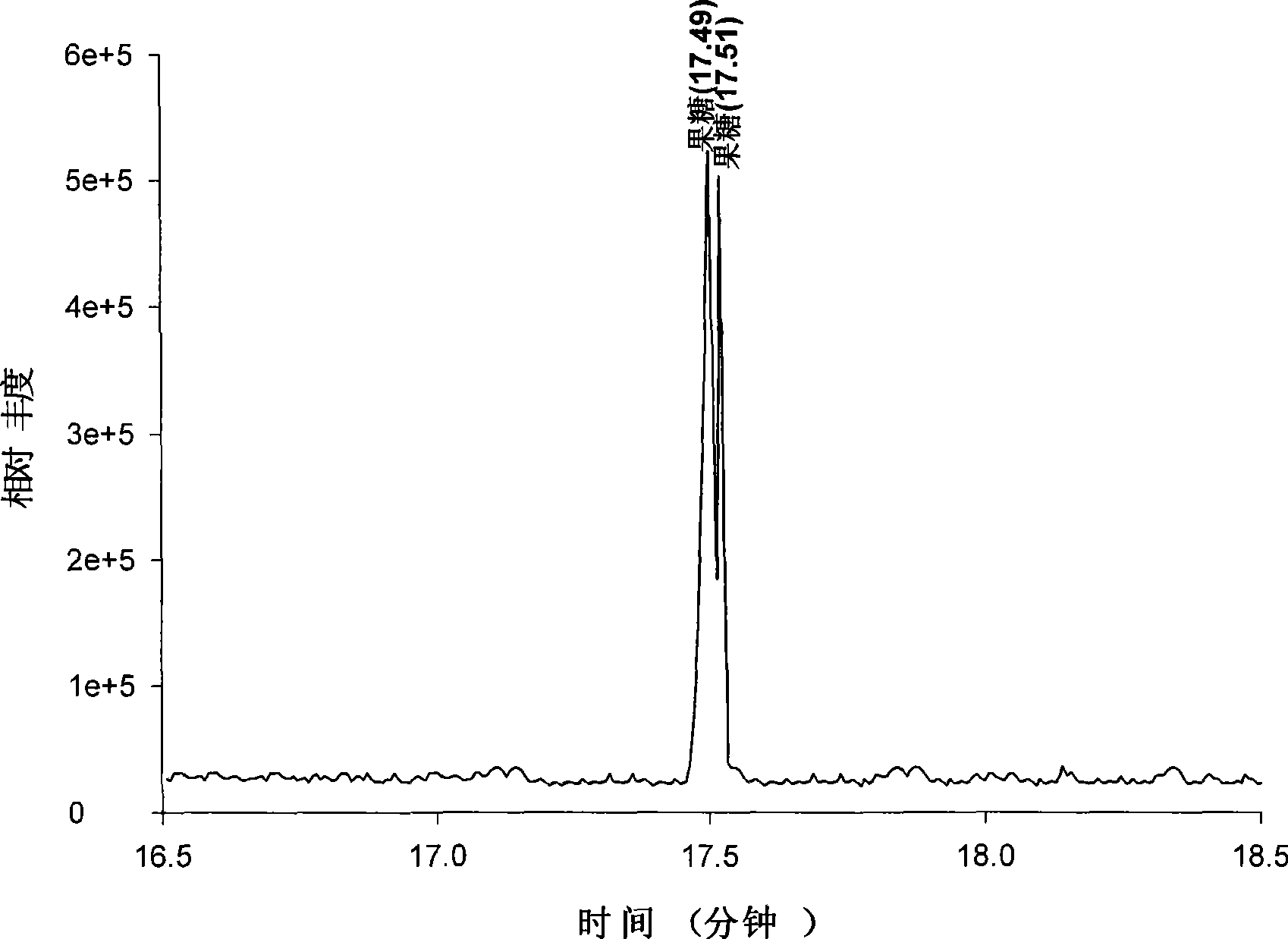

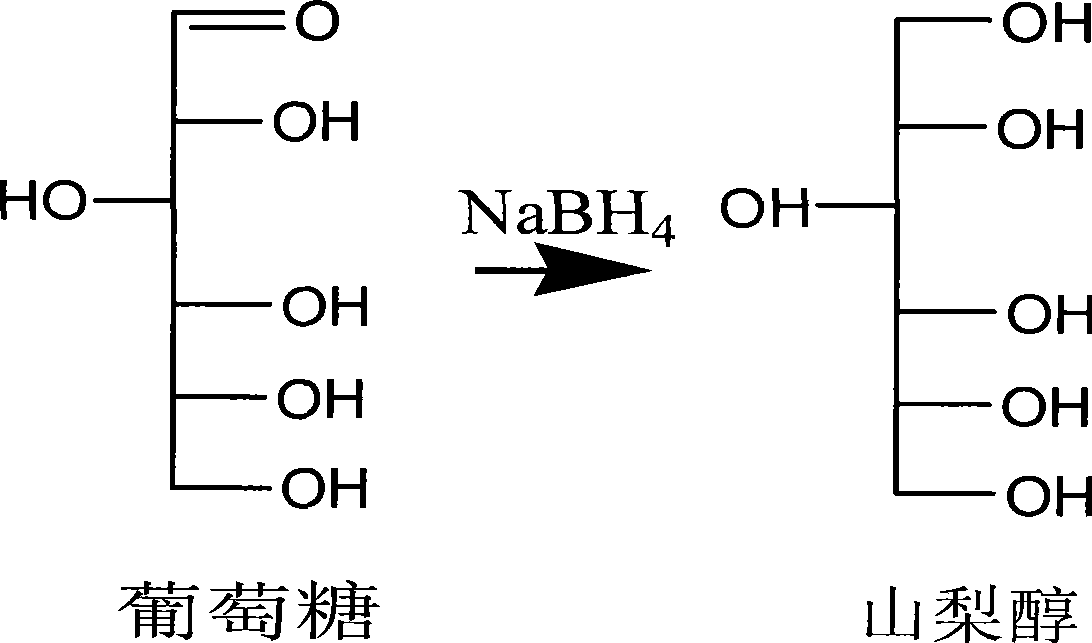

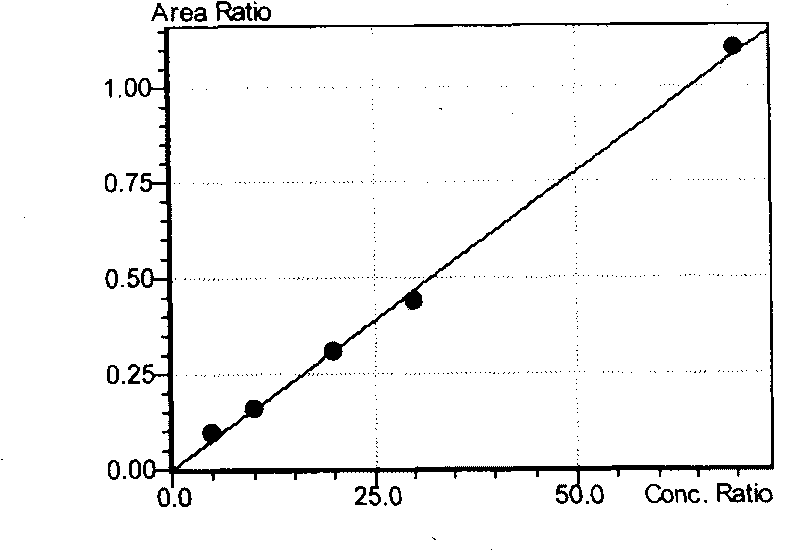

Derivatization method of qualitative or quantitative analysis for polyhydroxy compound

InactiveCN101531557ASolve problems with derivatization reaction conditionsAvoid the problem of poor choiceEsterified saccharide compoundsSugar derivativesAcetic anhydride1-Methylimidazole

The invention discloses a derivatization method for polyhydroxy compound. In the method, a sugar-containing sample is disposed in a reaction system using 1-methylimidazole as catalyst and acetic anhydride as derivatization reagent to have acetylation derivatization reaction. The method in the invention can carry out acetylation derivatization on the basis of maintaining native conformation of sugar, single derivatization product is obtained after derivatization, and qualitative or quantitative analysis can be accurately carried out on various simple sugars.

Owner:BEIJING FORESTRY UNIVERSITY

Continuous reaction method

ActiveCN102557849AIncrease production capacityEliminate time spent on non-productive operationsOrganic compound preparationCarboxylic acid esters preparationPhysical chemistryProcess engineering

The invention discloses a continuous reaction method. The conventional intermittent reaction is almost balanced reaction, conversation rate is low, the proportion of nonproductive time in the total production time is small, and unit capacity of equipment is low. The continuous reaction method comprises the following steps of: feeding raw materials for reaction into a reaction kettle, feeding the raw materials flowing out of the bottom of the reaction kettle into reaction heating equipment, starting the reaction heating equipment and heating, feeding vapor and liquid mixture flowing out of the top of the reaction heating equipment into vapor-liquid separation equipment, feeding raw material vapor obtained from the top of the vapor-liquid separation equipment into a reaction kettle, wherein a rectifying column arranged on the reaction kettle is stably in a refluxing state, and feeding light components flowing out of the top of the rectifying column into a light component collection tank; and feeding liquid flowing out of the bottom of the vapor-liquid separation equipment into the reaction heating equipment again, and feeding liquid flowing out of the bottom of the reaction heating equipment into a product tank. Common intermittent reaction is improved to continuous reaction, and unit capacity of equipment is improved.

Owner:ZHEJIANG NHU CO LTD

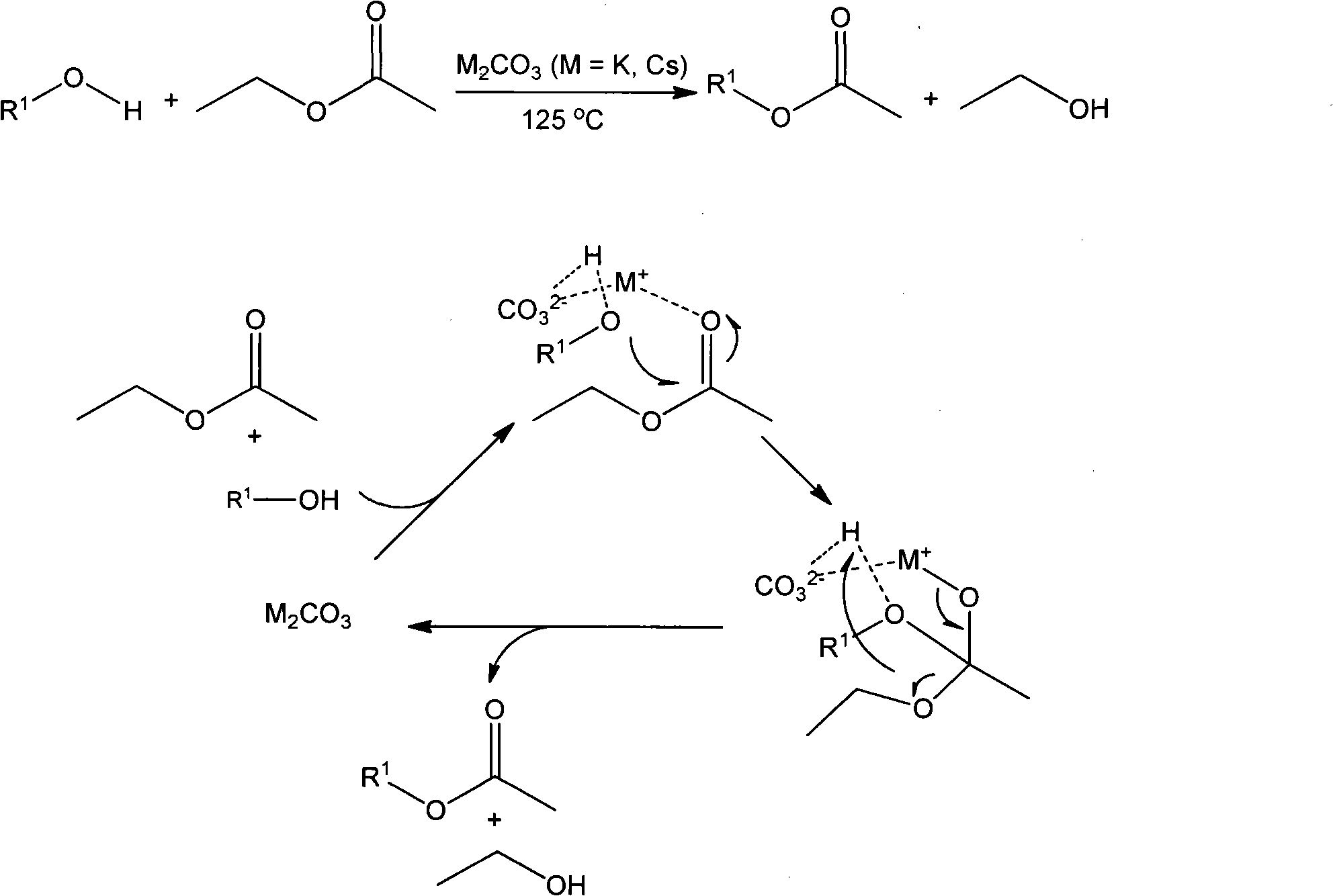

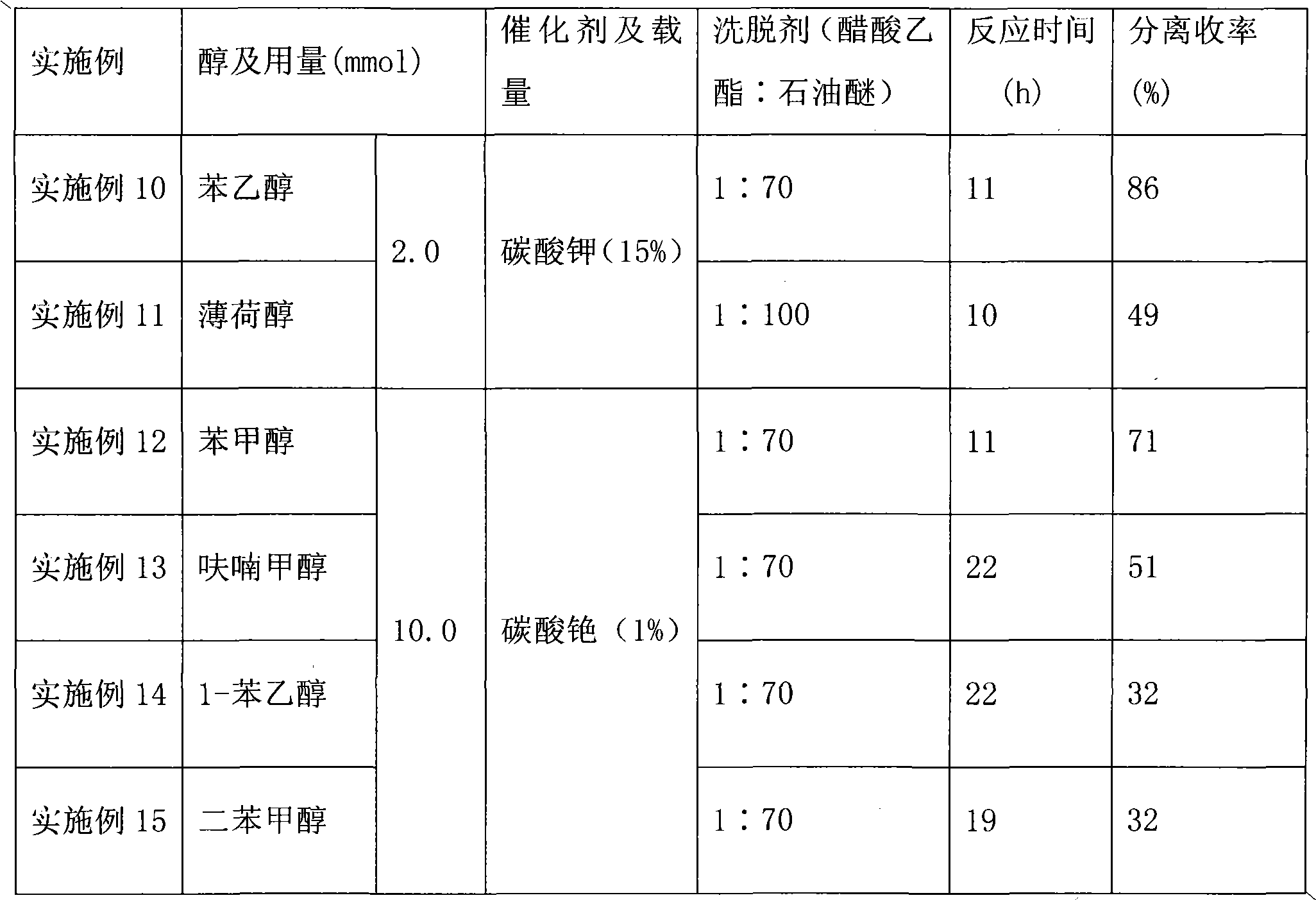

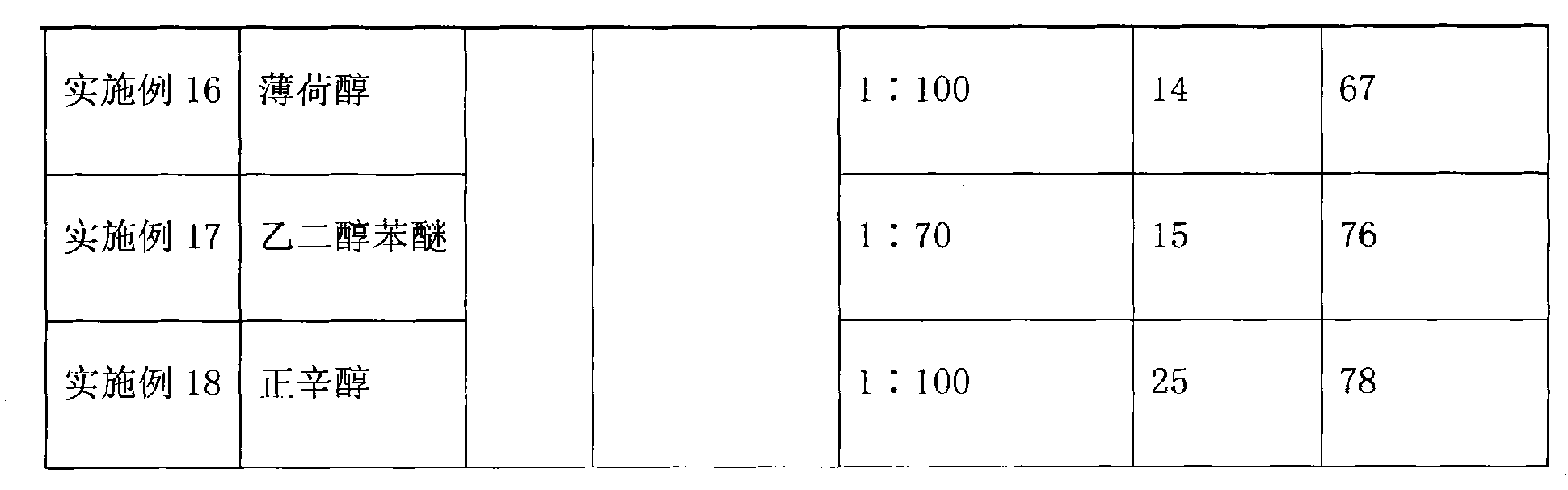

Method for synthetizing alcohol ester acetate by single step of ethyl acetate and alcohol ester exchange

InactiveCN101851159AWide variety of sourcesSimple structurePreparation by ester-hydroxy reactionCarboxylic acid ester formation/introductionSynthesis methodsFood flavor

The invention discloses a method for synthetizing alcohol ester acetate by a single step of ethyl acetate and alcohol ester exchange, which relates to a synthesis method of the alcohol ester acetate. The method obtains a finished product by taking various alcohol ester acetates as raw materials, carbonate as a catalyst and ethyl acetate as an esterification reagent through single-step ester exchange reaction and concentration and purification. The invention has the characteristics of simple method, simple and convenient operation, energy source saving, low production cost, convenient popularization and application and the like, and diversified alcohol ester products with high yield and good quality can be prepared by adopting the method. The method can be widely applied to the industrial production of the alcohol ester acetate; the products prepared by adopting the method can be widely used as various flavor types of food essences and cosmetic essences, the essences of fancy soaps, washing powders and laundry detergents, the good solvents of dyes and printing ink and the like, and thereby, the demands of high amount due to wide market plane are satisfied.

Owner:CHONGQING UNIV

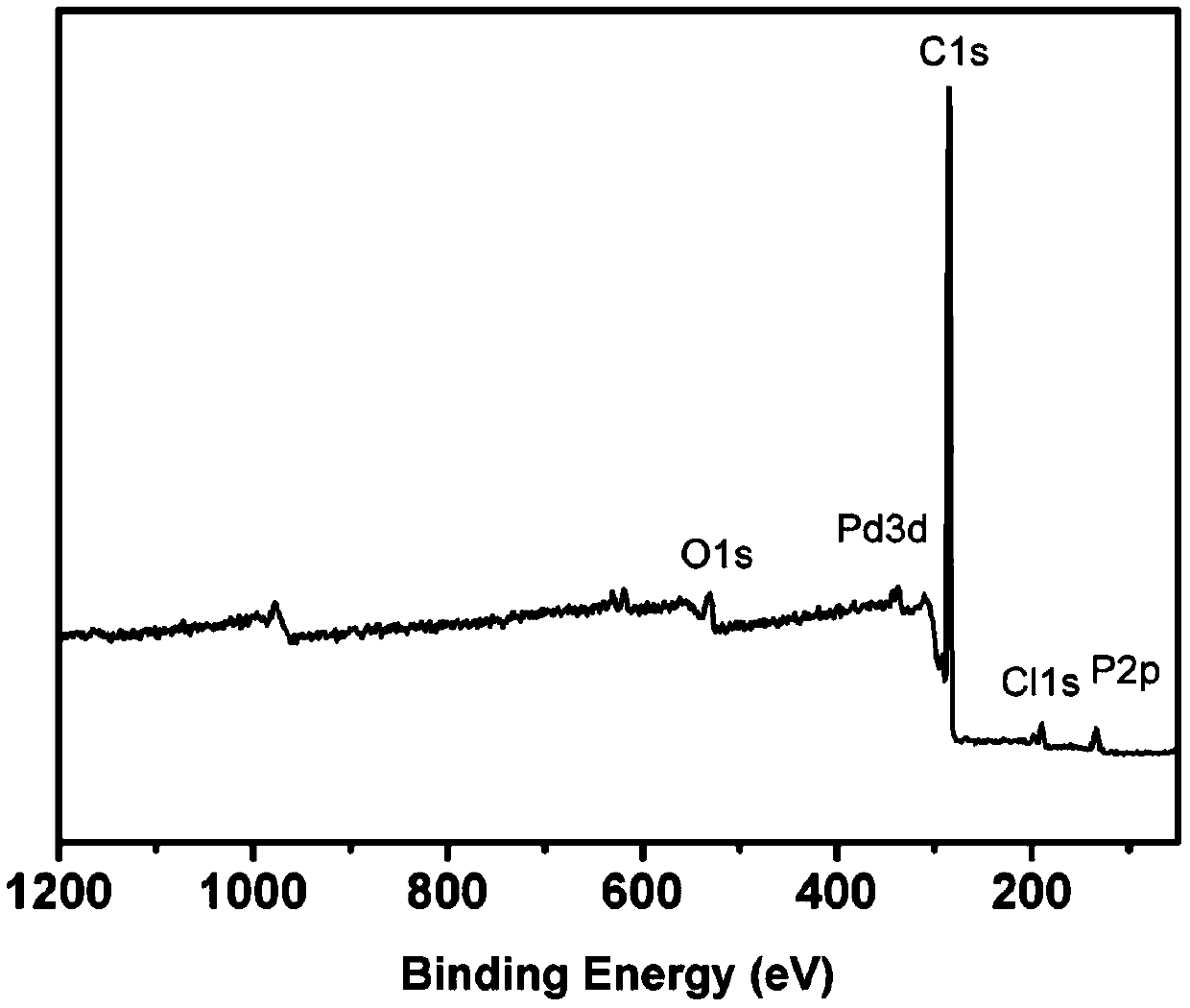

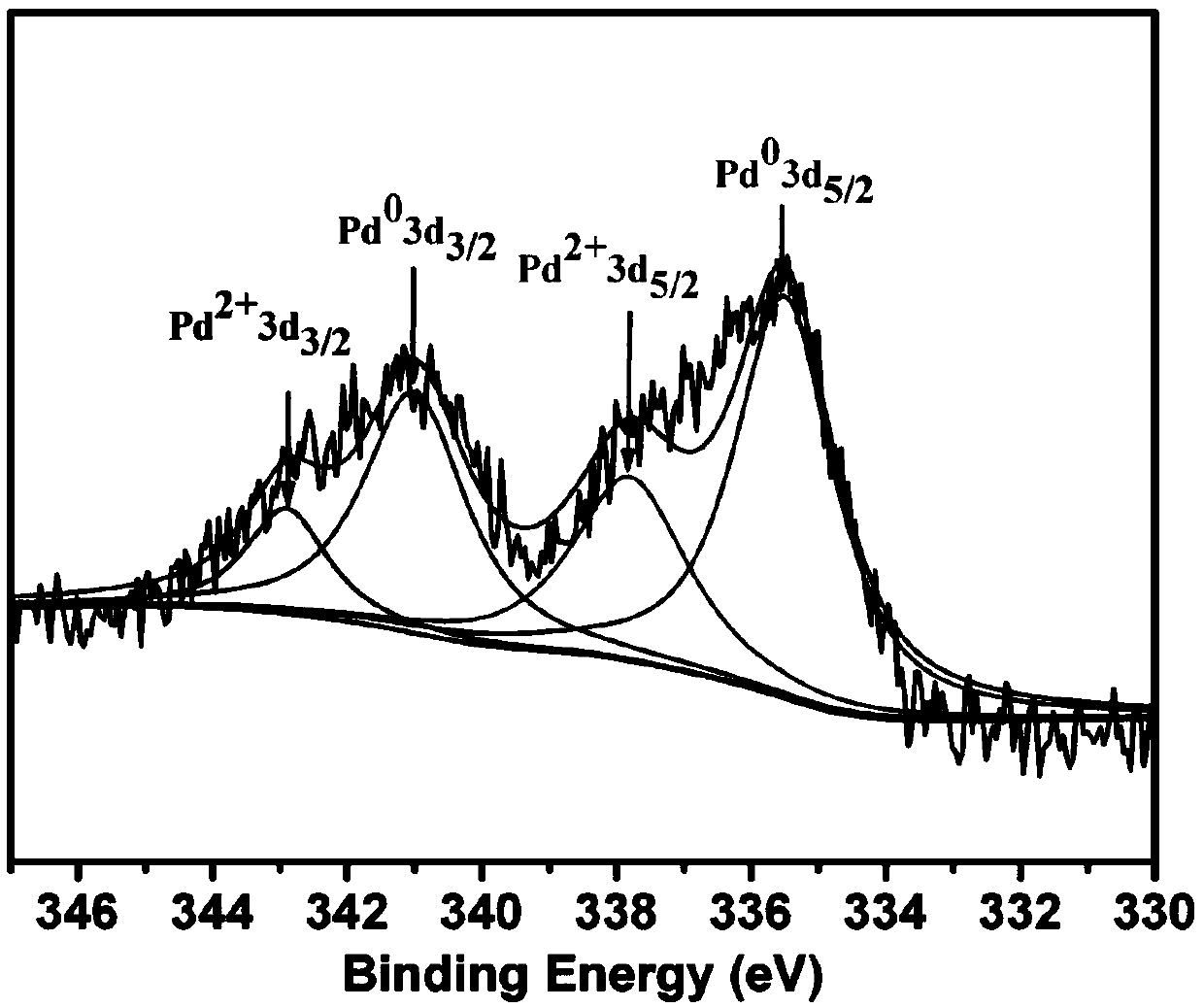

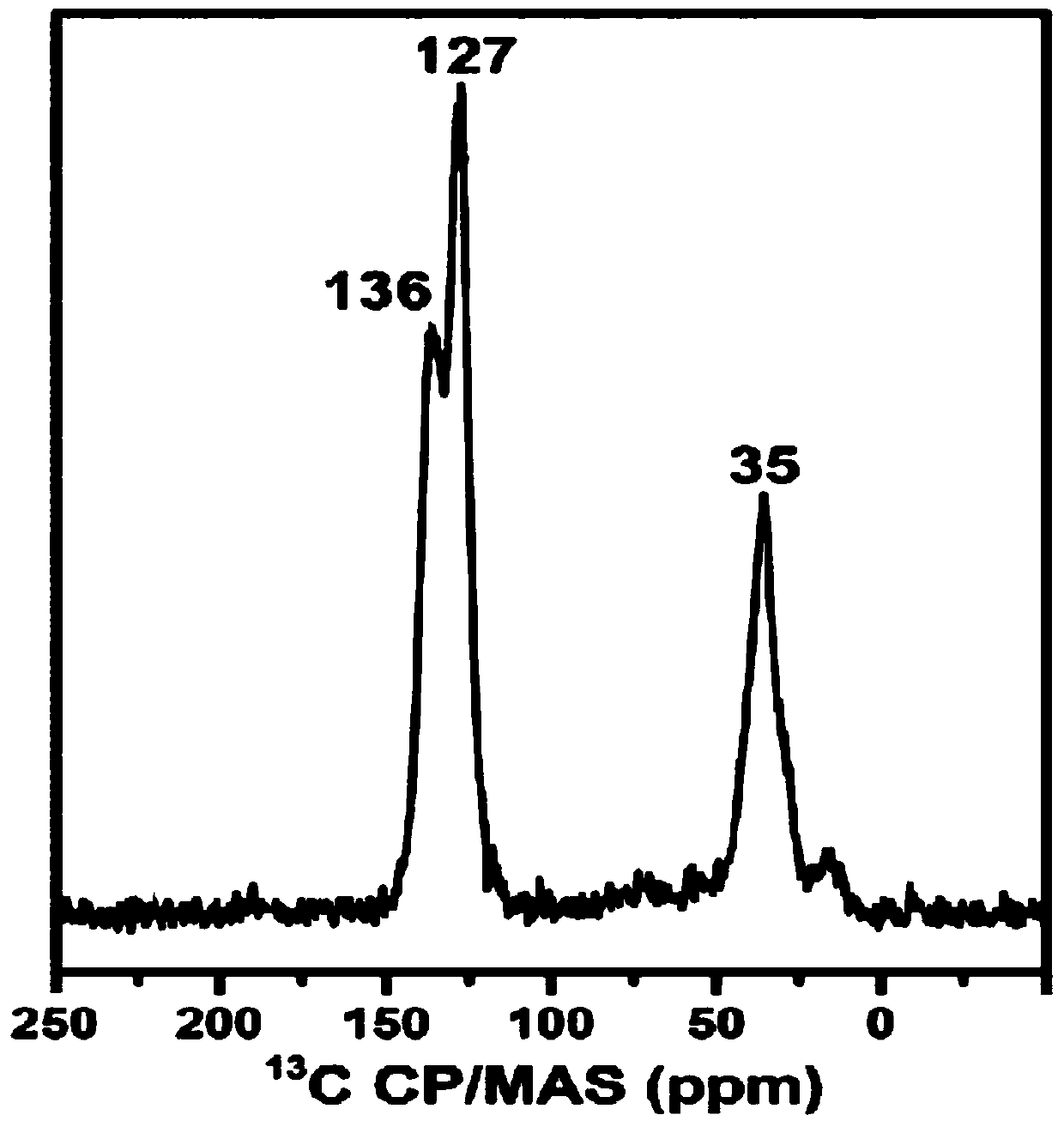

Organic porous polymer palladium-supported catalyst and preparation and application methods thereof

InactiveCN109746045AReduce churnLarge specific surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBromineCarbonylation

The invention relates to the technical field of preparation of catalysts, particularly to an organic porous polymer palladium-supported catalyst and preparation and application methods thereof. The organic porous polymer palladium-supported catalyst containing dichloro[9,9-dimethyl-4,5-bis(diphenylphosphino)xanthene]palladium functional units is prepared by taking dichloro[9,9-dimethyl-4,5-bis(diphenylphosphino)xanthene]palladium and 1, 3, 5-triphenylbenzene as copolymerizing monomers and through a one-step outer crosslinking method. The organic porous polymer palladium-supported catalyst canachieve efficient catalytic carbonylation of brominated aromatic hydrocarbons to synthesize aromatic carbonyl compounds, and meanwhile, is large in specific surface area, wide in pore size distribution range, mild in reaction conditions, high in yield and good in recycling performance, thereby achieving high application potential.

Owner:LIUPANSHUI NORMAL UNIV

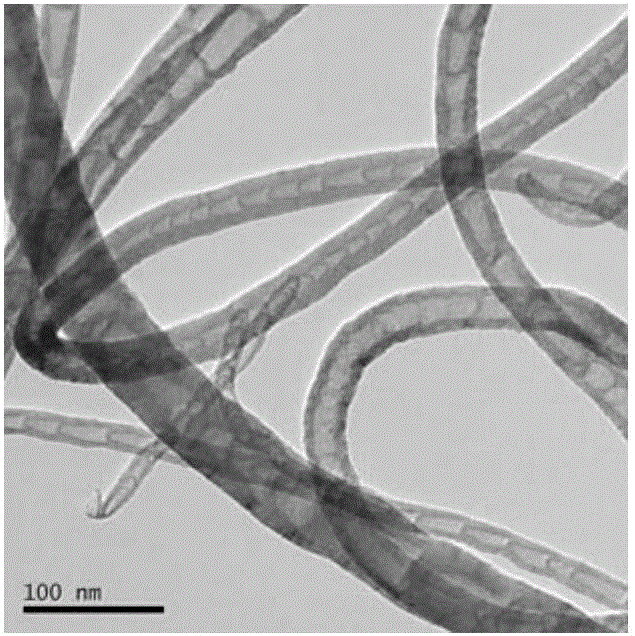

Method for preparing organic lactone by catalyzing and oxidizing organic ketone with carbon materials

InactiveCN102603446AImprove stabilityEasy to makeCarboxylic acid ester formation/introductionCarbon nanotubeCatalytic oxidation

The invention provides a method for preparing organic lactone. The method is characterized in that carbon materials are used as catalyst, the carbon materials may be graphite, graphene, carbon nano tube, active carbon and so on; organic ketone is used as substrate, oxygen or air is used as oxygen source, organic aldehydes materials are used as reductant, and organic solvent is added into reaction system. The method has the following advantages: the preparation for the catalyst is simple; the reaction condition is mild, secure, credible and environmental friendly; the selectivity and the yield of the obtained target products are about 100%; and the catalyst can be used repeatedly. The method solves the problem that the traditional preparation technology for lactone has poor security and low yield, and has good industrial application prospect.

Owner:HUNAN UNIV

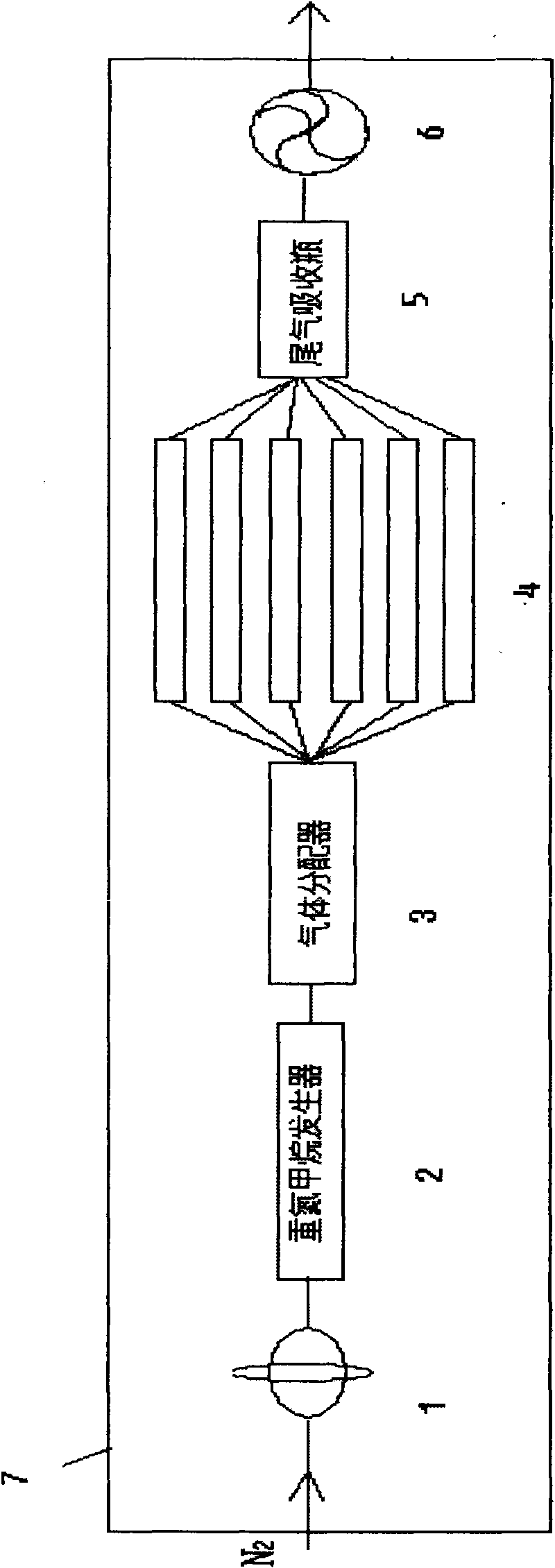

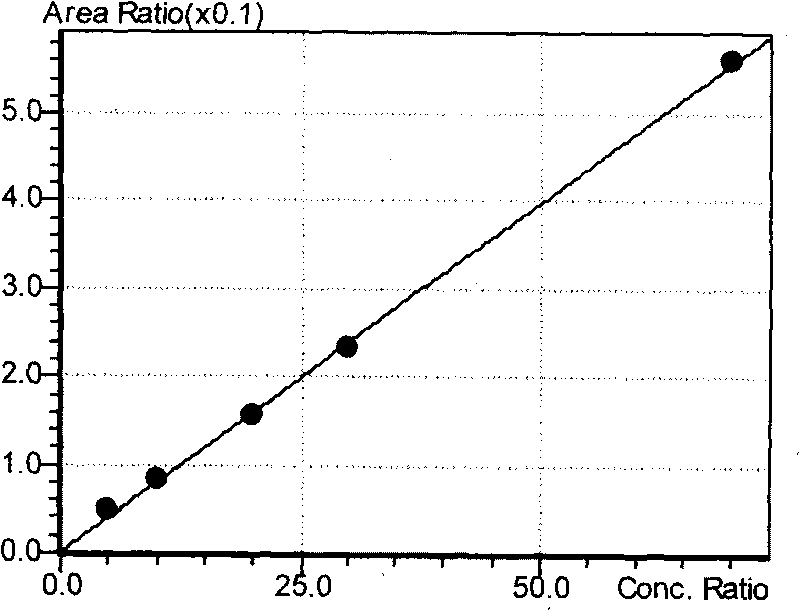

Diazomethane on-line deriving method

InactiveCN101704702AImprove securityEasy to operateOrganic compound preparationCarboxylic acid esters preparationMethaneChemistry

The invention relates to a diazomethane on-line deriving method, which comprises the following steps of: (1) a step of generating diazomethane; and (2) a step of deriving the diazomethane. The method can be realized under the action of N2. The method also comprises a tail gas absorption step after the step of deriving the diazomethane, wherein absorbent used in the tail gas absorption step for absorbing excessive diazomethane can be aether. The method also comprises a N2 flow rate control step before the step of generating the diazomethane and also comprises a diazomethane gas distribution step between (1) the step of generating the diazomethane and (2) the step of deriving the diazomethane. The method can be carried out in sealed environment. The diazomethane on-line deriving method can also comprise a step of exhausting the exhaust gas generated in the reaction from the sealed environment. The method organically integrates the preparation and the derivation of the diazomethane and has the characteristics of safety and high efficiency.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Process for cooxidizing organic compounds, process for producing epoxy compounds and process for producing esters or lactones

InactiveUS6229023B1Easy to operateMild conditionsOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsTetralinKetone

Owner:DAICEL CHEM IND LTD

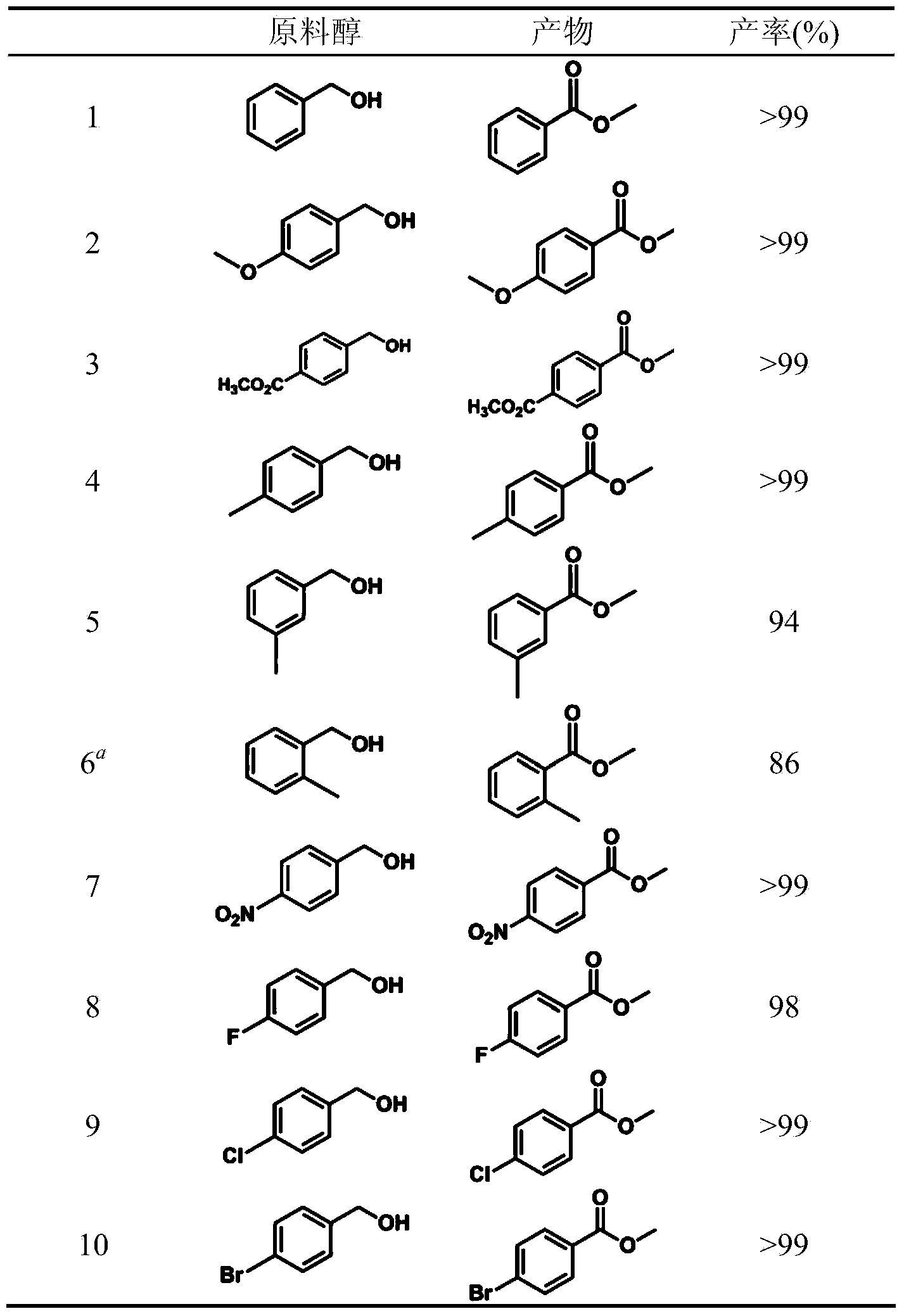

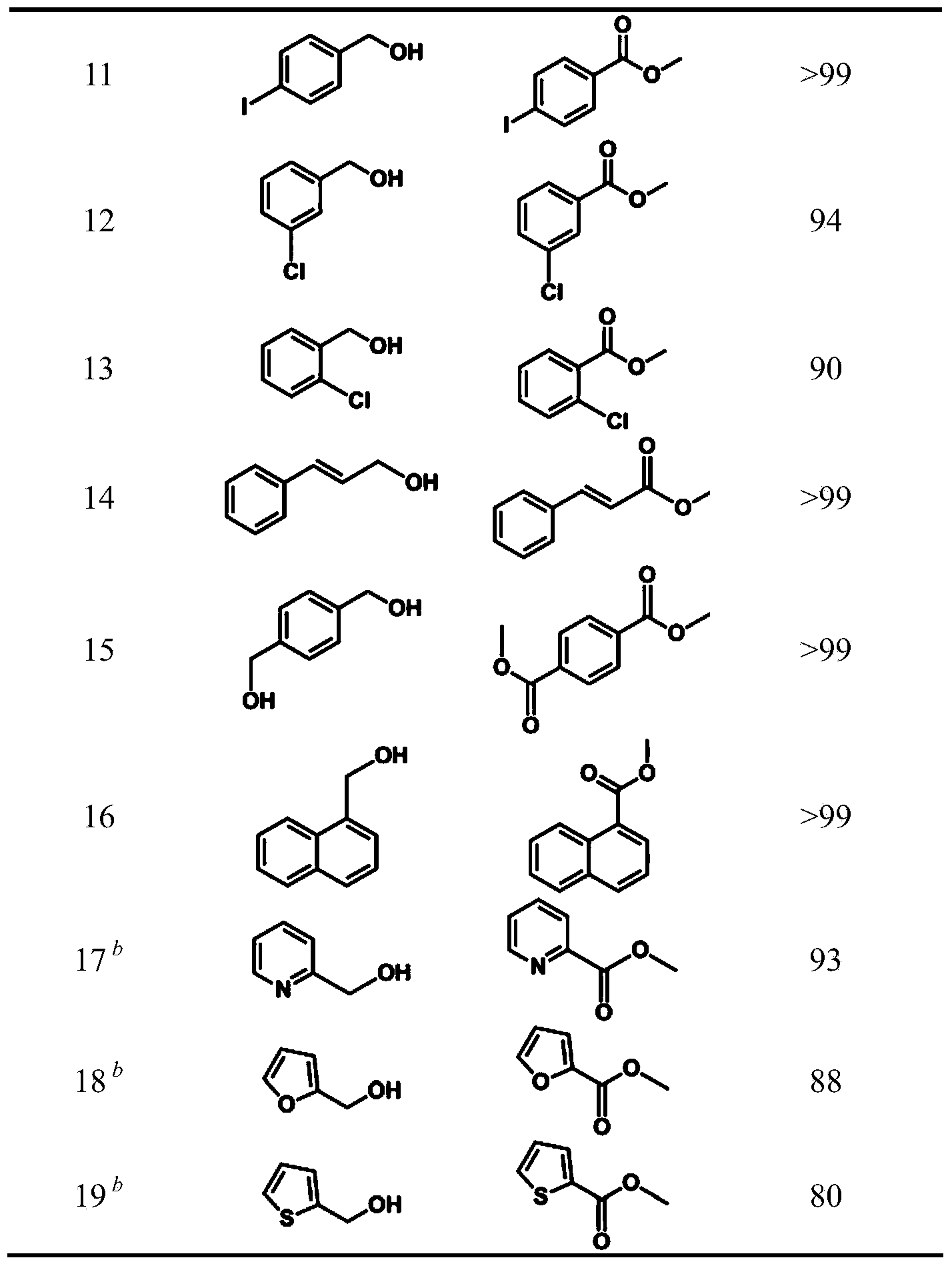

Method for preparing esters through primary alcohol oxidation

InactiveCN104945210AReduce dosageEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAfter treatmentOxygen

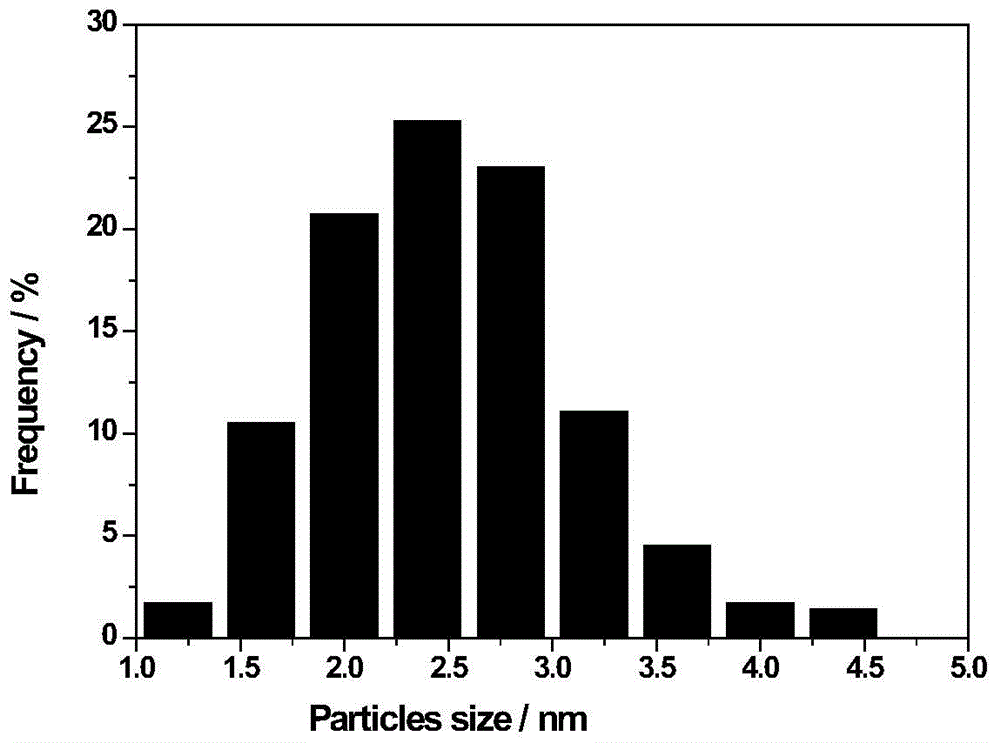

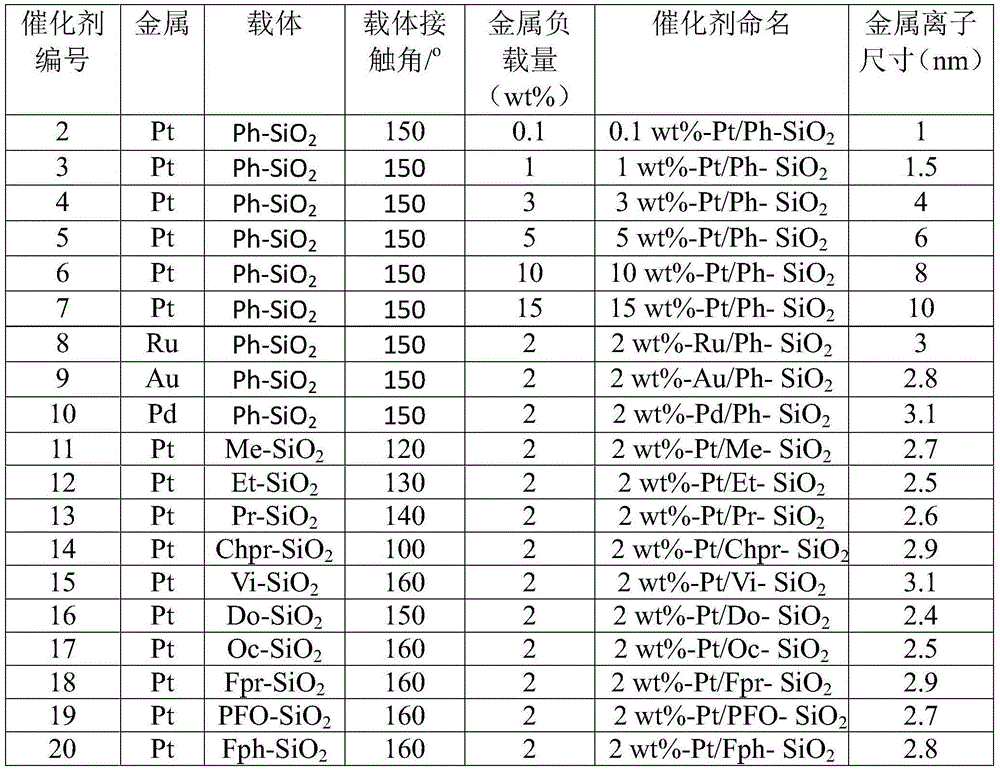

The invention relates to a method for preparing esters through primary alcohol oxidation. The method comprises the following steps: taking one or two of air and oxygen as an oxygen source, and oxidizing alcohols into esters under the catalytic action of hydrophobic carrier loaded metal nanoparticles. According to the method disclosed by the invention, the oxidation efficiency is high, and the product yield is high; the air or oxygen serves as an oxygen source, and the method is economic and environment-friendly; the product is separated from the catalyst, and the after-treatment is simple; and the catalyst is easily repeatedly used and has excellent application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing lactone by cyclic ketone

ActiveCN102336620AHigh selectivityImprove effective utilizationMolecular sieve catalystsCarboxylic acid ester formation/introductionMolecular sieveHeteroatom

The invention discloses a method for producing lactone by cyclic ketone. The method is characterized by comprising the following step of reacting cyclic ketone, oxidant, solvent and catalyst based on a mol ratio of the cyclic ketone to the oxidant of 1 to 0.5-15 and based on the mass ratio of the solvent to the catalyst of 0-500 to 1 under the conditions of a temperature range from 0 to 160 DEG C and a pressure range from 0.1 to 3MPa, wherein the catalyst and the solvent can be recycled, and the catalyst is a combination of a compound containing zinc and a heteroatom molecular sieve; the mass ratio of the compound containing zinc to the heteroatom molecular sieve in the compound is 0.01-20 to 1; and in the compound containing zinc, the mole ratio of the zinc to the heteroatom in the heteroatom molecular sieve is 0.05-50 to 1, and the mole ratio of silicon to the heteroatom in the heteroatom molecular sieve is 5-250 to 1.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing lactone through catalyzing oxidation of ketone compound

ActiveCN103274883AFix security issuesEasy to separateOrganic compound preparationCarboxylic acid esters preparationPtru catalystCarbon nanotube

The invention discloses a method for preparing lactone through catalyzing the oxidation of a ketone compound. The method which treats the ketone compound as a raw material and carbon nanotubes as a catalyst comprises a step of adding an organic solvent and an assistant, and a step of carrying out a catalysis reaction at 25-120DEG C under normal pressure to obtain a lactone compound in a high selectivity manner. The method has the advantages of simple process, mild condition, high selectivity, safety, easy catalyst recovery and the like.

Owner:山东尚正新材料科技股份有限公司

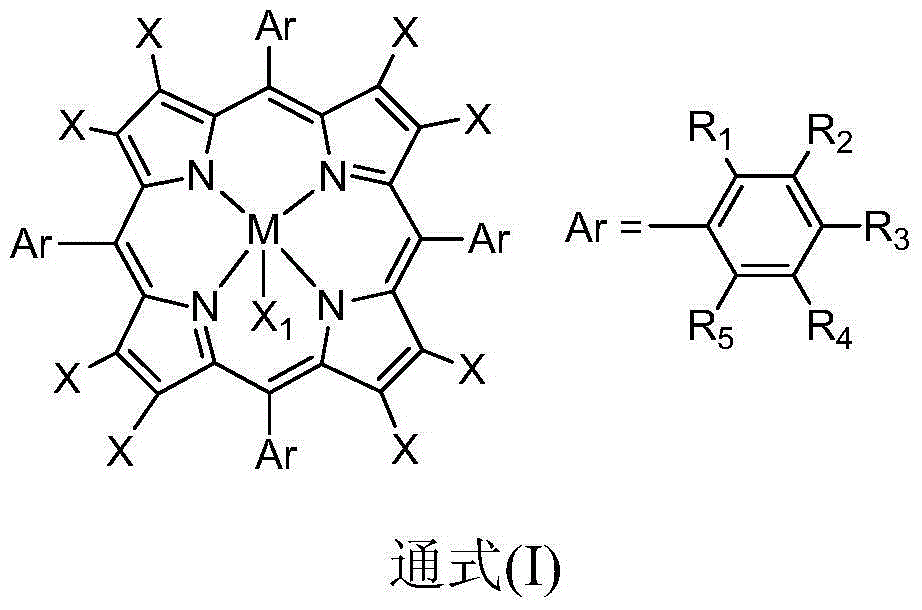

Method for preparing lactone through catalyzing oxidation of ketone compound, and its special catalyst

InactiveCN103980078AImprove utilization efficiencyPromote generationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventCarbon nanotube

The invention discloses a method for preparing lactone through catalyzing the oxidation of a ketone compound, and its special catalyst. The catalyst is a metalloporphyrin-carbon nanotube catalyst prepared through a pi-pi accumulation effect between the pi electron on the tube wall of the carbon nanotube and the pi electron on a metalloporphyrin ring. The method for preparing lactone through catalyzing the oxidation of a ketone compound uses a metalloporphyrin-carbon nanotube compound as the catalyst comprises the following steps: adding an organic solvent and an assistant, and carrying out a catalytic reaction at a reaction temperature of 25-100DEG C under normal pressure to highly selectively obtain a lactone compound. The method and the catalyst have the advantages of simple technology, mild conditions, high selectivity, safety and the like.

Owner:SUN YAT SEN UNIV

Method for preparing organic lactone

InactiveCN102603447AImprove stabilityEasy to makeCarboxylic acid ester formation/introductionMetal/metal-oxides/metal-hydroxide catalystsOrganic solventCobalt(II,III) oxide

The invention provides a method for preparing organic lactone. The method is characterized in that: cubic cobaltosic oxide is taken as a catalyst, and the catalyst is prepared with a hydrothermal method; and organic ketone is taken as a substrate, oxygen or air is taken as an oxygen source, an organic lactone substance is taken as a reducing agent, and an organic solvent is added into a reaction system. The method has the advantages that: the catalyst is easy to prepare; reaction conditions are mild, and the method is safe, reliable and environmentally-friendly; the selectivity and yield of an obtained target product are close to 100 percent; and the catalyst can be used for repeatedly. Due to the adoption of the method, the problems of poor safety, low yield and the like existing in the conventional lactone preparation process are solved, and the method has a good industrial application prospect.

Owner:HUNAN UNIV

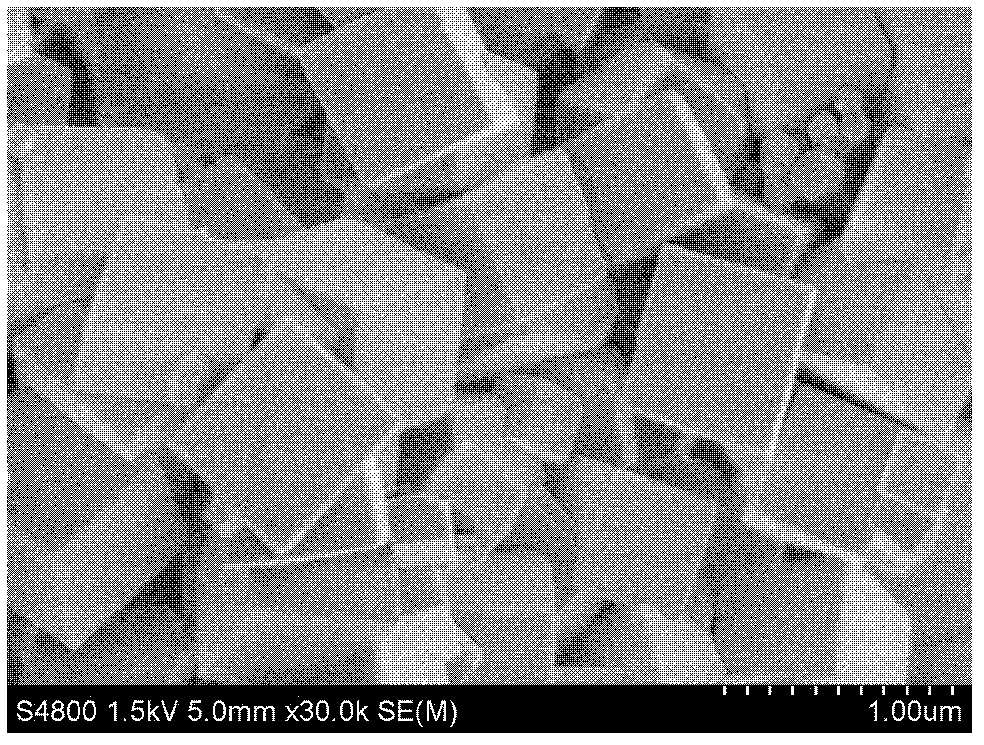

Absorbent charcoal based catalyst carrier, catalyst, preparation and uses thereof

InactiveCN101428239AImprove the phenomenon of severe desorptionHigh catalytic activityCatalyst carriersCarbonyl group formation/introductionActivated carbonSolid acid

The invention relates to a method for preparing activated carbon which is utilized as a catalyst carrier, as well as a method for preparing a catalyst by utilizing the catalyst carrier and the application of the catalyst. The technical scheme of the invention comprises the following steps: taking activated carbon as a raw material; pretreating with an alkaline solution and an acid solution in sequence; treating in an oxidation manner appropriately; modifying through the implantation of metal salt; structuring a compound polyacid center on the surface of the activated carbon; obtaining activated carbon solid acid catalytic materials with higher performance through a series of continuous processing steps; and taking the modified activated carbon as the catalyst to catalyze the synthetic reaction of acetal (ketone) and the like. The catalyst prepared by using the technical scheme achieves better effect on separate catalysis of composite ketal and can be used repeatedly, recovered and regenerated.

Owner:NINGXIA UNIVERSITY

Method for catalytic oxidation of cyclic ketone

ActiveCN102452871AOvercoming complexityOvercoming equipment corrosionOrganic compound preparationCarboxylic acid ester formation/introductionMolecular sieveCatalytic oxidation

The invention discloses a method for catalytic oxidation of cyclic ketone, wherein reacting cyclic ketone, solvent and hydrogen peroxide based on a mole proportion of cyclic ketone: solvent: hydrogen peroxide=1:(0-8): (0.2-20) at 5-20 degrees centigrade and a 0.1-3.0 MPa reaction pressure in the presence of a catalyst and recycling the product, wherein the mass ratio of the catalyst to the cyclic ketone is 1:(5-30), and the catalyst is a tin titanium silicate molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

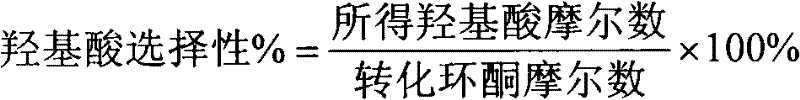

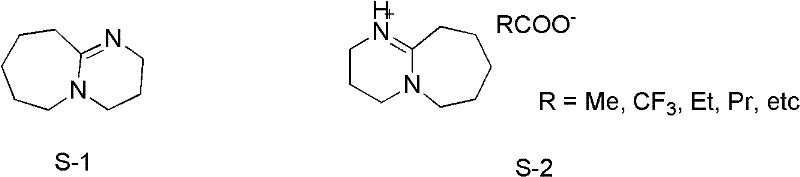

Method for acetylating catalytic hydroxyl

InactiveCN102391060ALow priceSolve problems with unpleasant odorsEsterified saccharide compoundsSugar derivativesAcetic anhydrideSolvent free

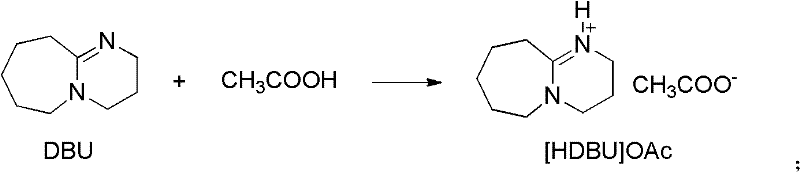

The invention discloses a method for acetylating catalytic hydroxyl, which comprises the following steps: using alcohol or phenol as a substrate, in the acetylating reaction of the alcohol or the phenol, using a Lewis alkaline ionic liquid [HDBU]OAc as a catalyst and acetic anhydride as an acetylating reagent, and carrying out a reaction in a solvent-free condition, wherein the reaction temperature is 40-80 DEG C, the reaction time is 0.75-3.0 hours, the mole ratio of the acetic anhydride to the substrate is 1.0-6.0: 1, and the mole ratio of the Lewis alkaline ionic liquid [HDBU]OAc to the substrate is 10%-30%; after the reaction is completed, adding diethyl ether, filtering, washing upper-layer extracting liquid in sequence by using a saturated NaHCO3 solution and water, adding anhydrousNa2SO4 to dry the upper-layer extracting liquid, and carrying out decompression rotary steaming on the dried upper-layer extracting liquid to remove the diethyl ether, so as to obtain a product. The method for acetylating the catalytic hydroxyl, which is provided by the invention, has the characteristics of moderate reaction condition, high yield and low cost, and the like, and the method is green and safe.

Owner:ZHEJIANG UNIV

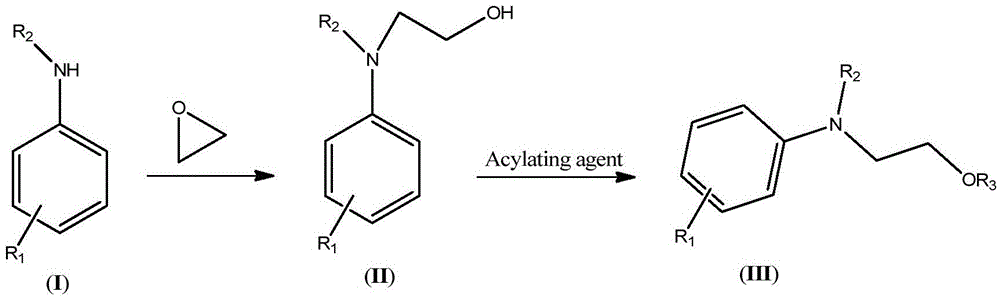

Synthetic technology of hydroxyethylaniline ester (III)

InactiveCN105481623AOvercome the shortcomings of flammable and explosiveMeet the requirements for safe operationCarboxylic acid nitrile preparationOrganic compound preparationEnvironmental resistanceChemical reaction

The invention discloses a synthetic technology of hydroxyethylaniline ester (III). The synthesis process is shown by a chemical equation shown in the description. The technology has the following advantages: 1, the advantage of few instant reaction substances of a micro-channel reactor is used, so the flammable and explosive disadvantages of a hydroxyethylation reaction in a routine kettle are solved, the process safety is increased, and current chemical engineering safety operation requirements are met; and 2, the advantage of high mixing efficiency of the micro-channel reactor is used, the reaction can be carried out under solvent-free conditions when a hydroxyethylation reaction raw material is liquid, and when the excess amount of ethylene oxide is very small, so a reaction solution obtained after the hydroxyethylation reaction ends can be esterified in the micro-channel reactor, serial operation of two-step reactions is realized, and manpower and three wastes are greatly reduced. The technology is a new technology with simplified processes, and accords with environmental protection and safety requirements.

Owner:SHANGHAI CHENGHOUFEI TRADE CO LTD

Method for catalytically oxidizing cyclic olefin

ActiveCN102452870AFlexible control of molar ratioOrganic compound preparationCarboxylic acid ester formation/introductionMolecular sieveCatalytic oxidation

The invention provides a method for catalytically oxidizing cyclic olefin. The method is characterized in that reaction is carried out in the presence of a catalyst under the conditions that molar ratio of cyclic olefin to solvent to hydrogen peroxide is 1: (0-80): (0.2-20), temperature is 5-200 DEG C and reaction pressure is 0.1-3.0MPa and products are recovered, wherein the mass ratio of the catalyst to the cyclic olefin is 1: (5-300) and the catalyst is a titanium-silicon molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

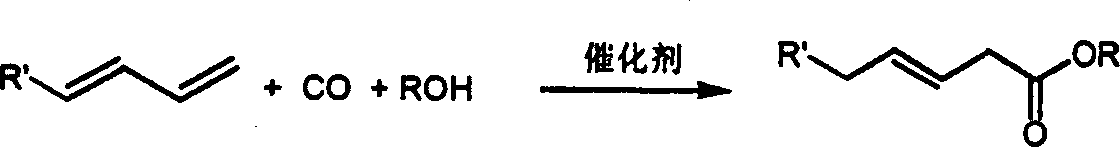

Method for preparing Beta, Gamma unsaturated ester

ActiveCN101003456AHigh TOF valueOrganic compound preparationPreparation by carbon monoxide or formate reactionDiphosphinesCarbonylation

This invention discloses a method for preparing beta-gamma unsaturated ester from conjugated olefin. The method adopts conjugated olefin, CO and hydroxyl-containing compound as the raw materials, as well as palladium compound and diphosphine compound as the catalysts. The raw materials react in nonpolar or weak polar solvent to obtain beta-gamma unsaturated ester. Under optimized reaction conditions, the conjugated olefin can be converted completely, and the selectivity of the target product is higher than 96%. Besides, the catalysts can be recycled, and the TOF value of the catalyst system in a single use is up to 1432 h-1.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com