Method for carrying out catalytic conversion with high efficiency on cellulose at low temperature by utilizing compound ion liquid system

A composite ion, catalytic conversion technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, preparation of organic compounds, etc., can solve problems such as limited solubility, many intermediate steps, and complicated operations. Achieve the effect of reducing dosage, low cost and operating cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of bmimCl (methyl butyl imidazolium chloride) ionic liquid solvent:

[0028] Fully mix 0.1mol N-methylimidazole and 0.12mol 1-chlorobutane, stir at 40°C for 12h, then raise the temperature to 70°C, and continue stirring for 24h to obtain a mixed solution; the mixed solution is washed with ethyl acetate and vacuum Dry to get Cl - Anionic liquid solvent.

Embodiment 2

[0030] Preparation of acidic ionic liquid catalyst:

[0031] Preparation of methylimidazole bisulfate acidic ionic liquid: fully mix 0.1mol N-methylimidazole and concentrated sulfuric acid with a mass fraction of 98% and stir in an ice-water bath for 1 hour, then fully wash with anhydrous ether, The solvent was removed from the obtained solution, and vacuum-dried at 70° C. for 10 h to obtain an acidic ionic liquid of methylimidazolium bisulfate.

[0032] Preparation of methyl butyl imidazolium bisulfate acidic ionic liquid: Weigh 0.1 mol of the corresponding cationic Cl - salt ionic liquid and dissolve it in 100 mL of methanol; then weigh the amount of the substance as Cl - Salt ionic liquid 2x KHSO 4 , dissolved in 30mL of methanol; the above solutions were combined, stirred at room temperature for 24h, filtered, the filtrate was removed by rotary evaporation, washed with anhydrous ether for 3 times, and then dried in a vacuum oven at 70°C for 12h to obtain methyl butyl im...

Embodiment 3

[0035] (1) Preparation of composite ionic liquid: in autoclave, 20g embodiment 1 gained bmimCl ionic liquid solvent and 3.5mmol embodiment 2 gained acidic ionic liquid catalyst are in N 2 Fully mixed in an ice-water bath under protection to obtain a composite ionic liquid;

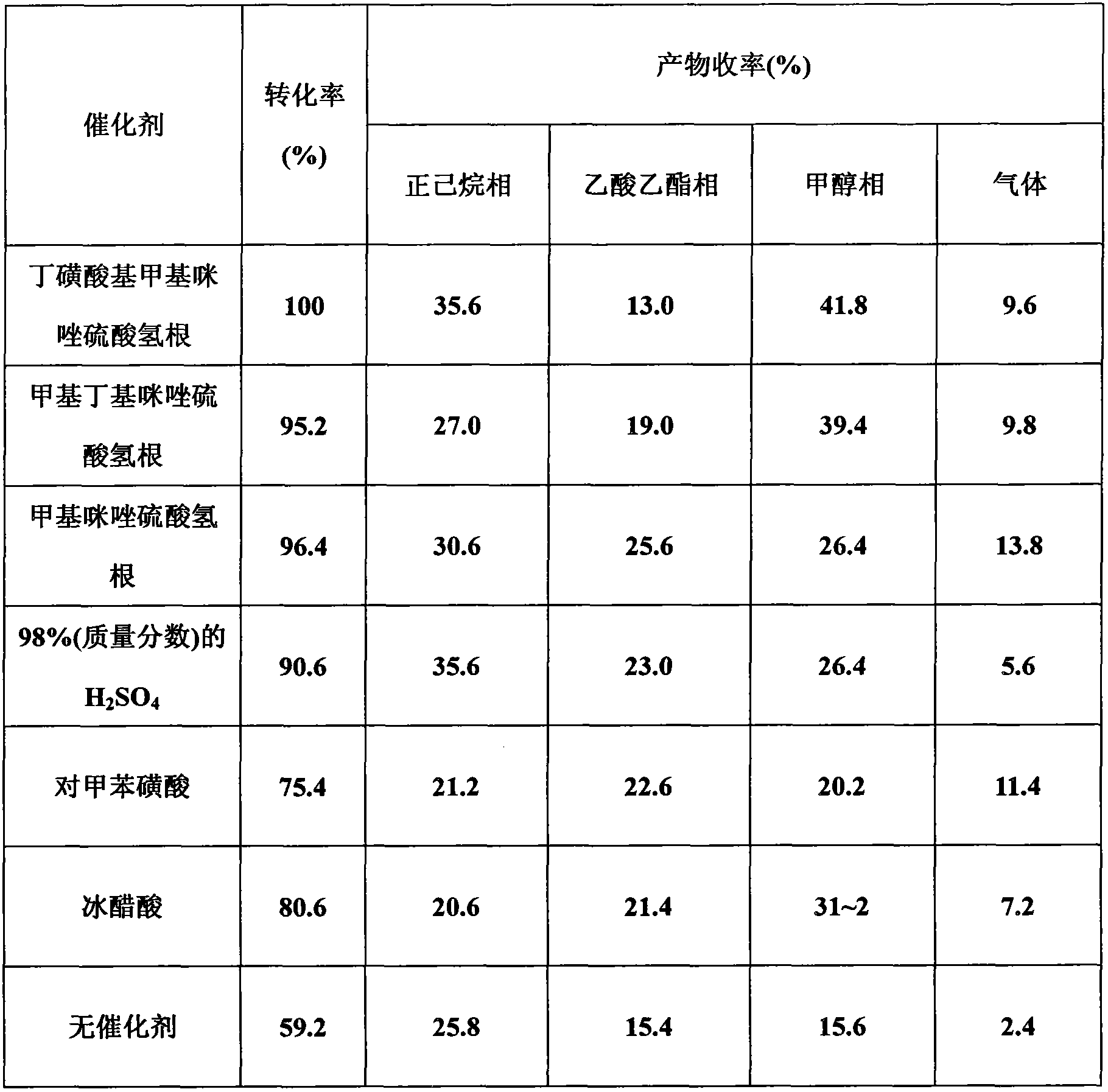

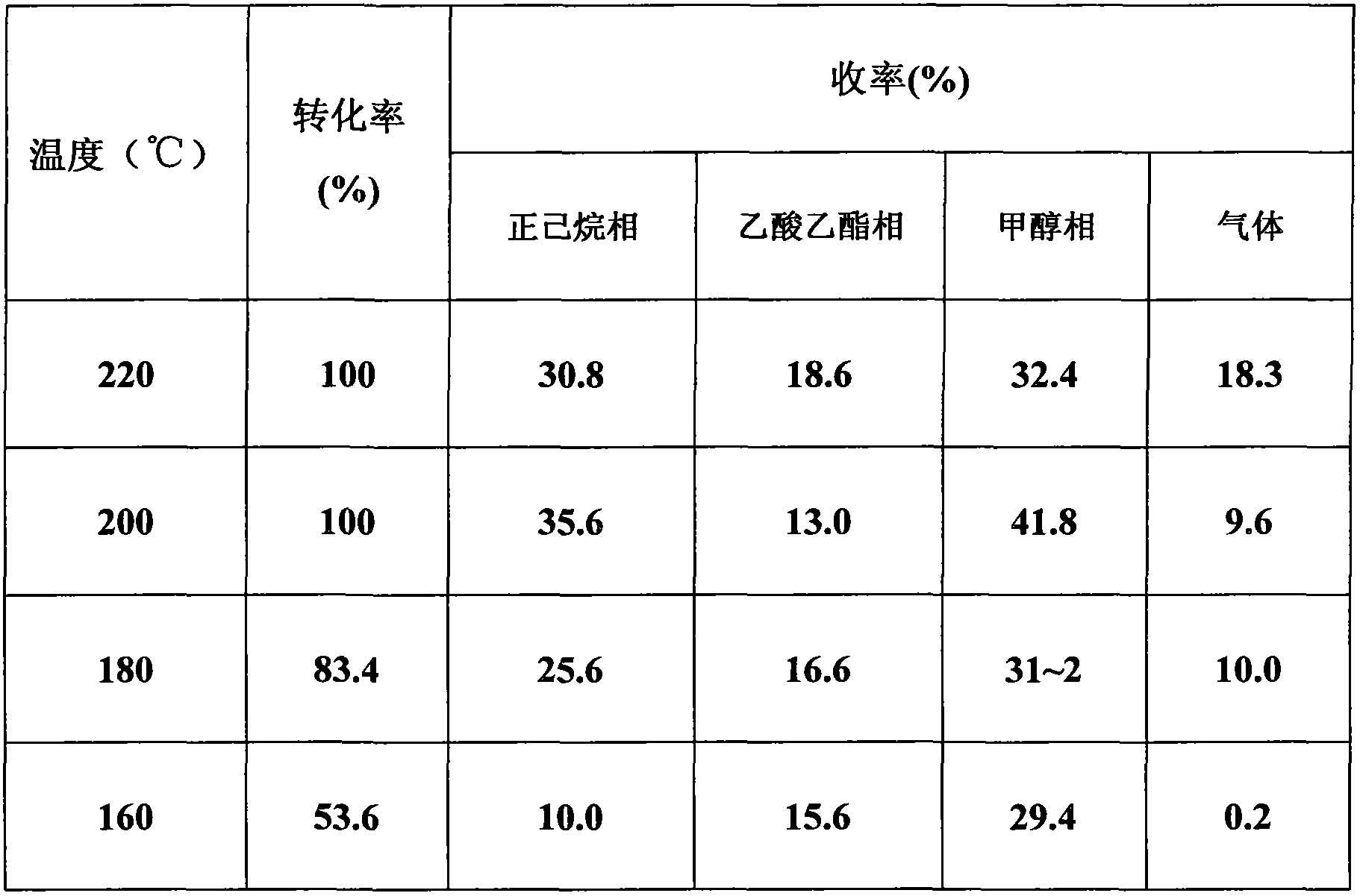

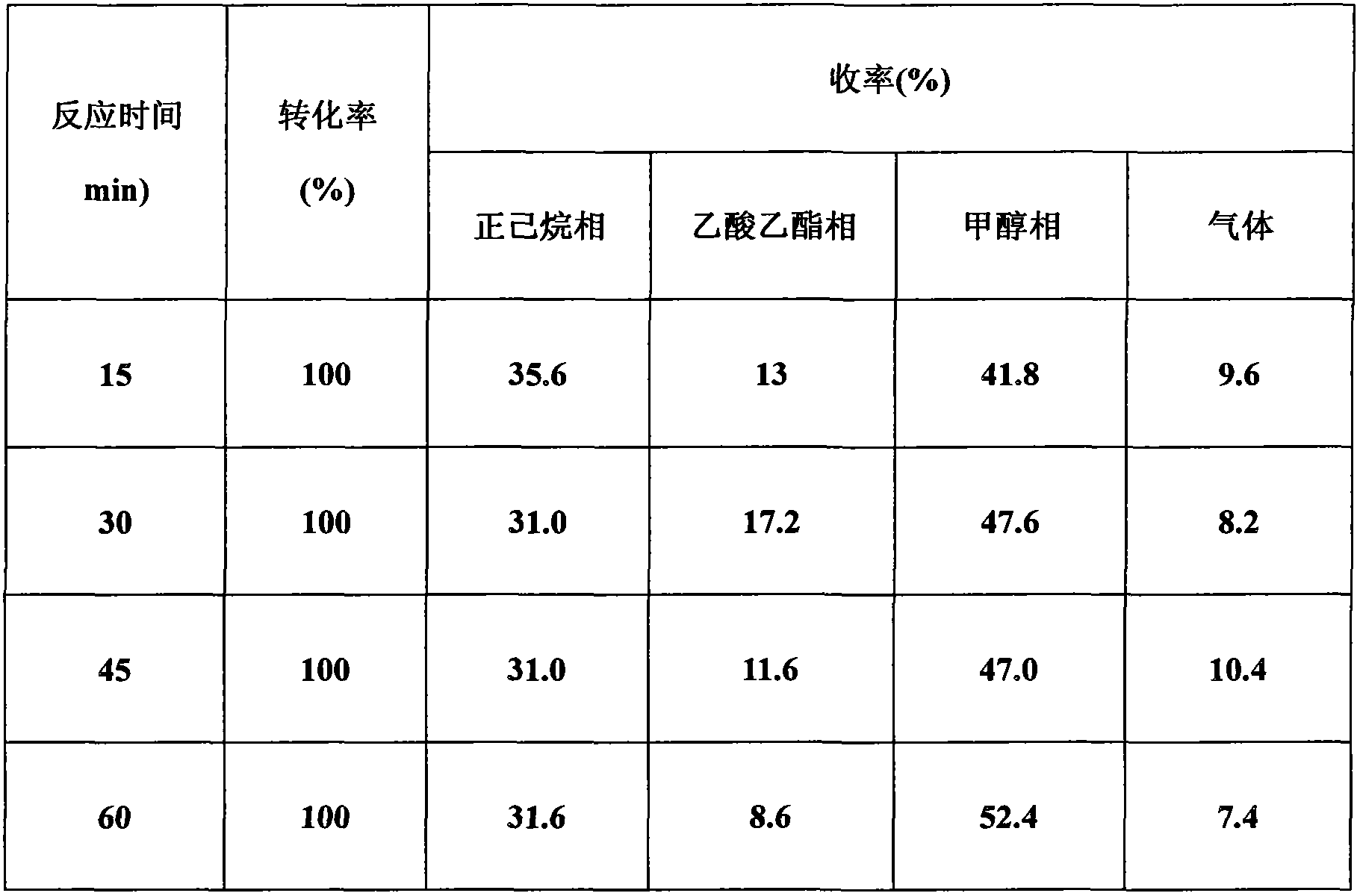

[0036] (2) Catalytic conversion of cellulose: the compound ionic liquid gained in step (1) is mixed with 5g microcrystalline cellulose, adds 80ml normal hexane, through N 2 After 3 replacements, heat to 200°C and react for 15 minutes under 300r / min stirring condition. After the kettle body is cooled to room temperature, gas is released. The obtained product is extracted with n-hexane and ethyl acetate in sequence, and 50mL of CH is added to the raffinate. 3 OH, suction filtration, residue with CH 3 OH was fully washed, dried and weighed to calculate the conversion rate. The conversion rate and the yield of each phase product under different catalyst conditions are shown in Table 1:

[0037] Conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com