Continuous reaction method

A reaction and reaction kettle technology, applied in the field of chemistry, can solve the problems of low equipment capacity, low conversion rate, high energy consumption, etc., and achieve the effects of increasing production capacity, reducing manual operations, and improving energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

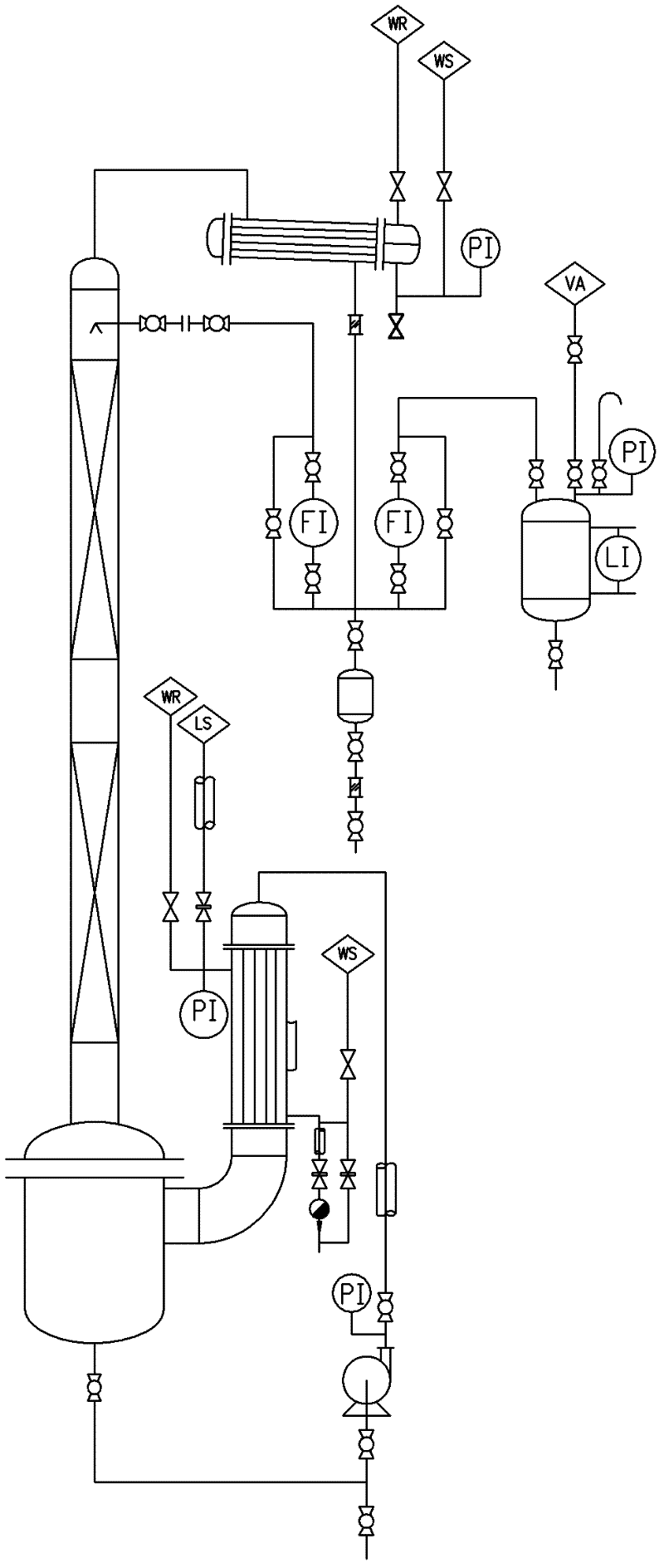

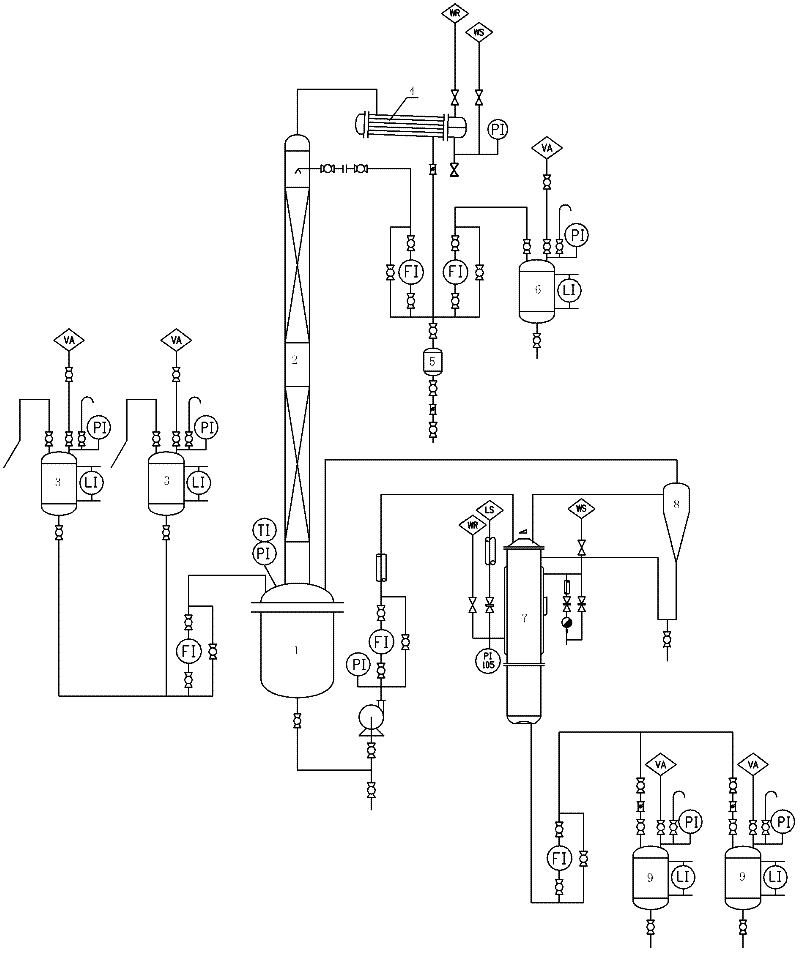

[0021] Synthesis of butyl ether : in such as figure 2 In the shown device, 300Kg of n-butanol and 1.2Kg of strongly acidic ion exchange resin catalyst are dropped into a 500L kettle. Open the jacketed steam for heating. When there is reflux at the top of the tower, reflux and divide water for 30 minutes at an internal temperature of 120-130°C. The vaporization amount is 80Kg / Hr, and the water is separated from the valve at the bottom of the water separator. After 30 minutes, turn off the jacket heating, turn on the circulation pump, turn on the scraped film evaporator, set the heating steam pressure of the scraped film evaporator to 0.35MPa, and set the feed flow rate to 120Kg / Hr. After the system is stable for 10 minutes, the output speed of n-butyl ether at the bottom of the wiped film evaporator will reach 30-40Kg / Hr. Prepare n-butanol in the raw material tank, switch operation, and feed continuously into the kettle with a feed flow rate of about 45Kg / Hr. At this time,...

Embodiment 2

[0025] Synthesis of isobutyl acetate: Pack 50Kg of supported solid acid catalyst at the bottom of the packing layer of the rectifying tower, and then fill with 4mBX packing. in such as figure 2 In the shown device, 210Kg of isobutanol, 150Kg of acetic acid, and 80Kg of cyclohexane are dropped into a 500L kettle. Open the jacketed steam for heating. When there is reflux at the top of the tower, reflux at an internal temperature of 110-115°C for water separation and reaction for 30 minutes. The vaporization amount is 100Kg / Hr, and the water is separated from the valve at the bottom of the water separator. After 30 minutes, turn off the jacket heating, turn on the circulation pump, turn on the scraped film evaporator, set the heating steam pressure of the scraped film evaporator to 0.22MPa, and set the feed flow rate to 135Kg / Hr. After the system is stable for 10 minutes, the discharge rate of isobutyl acetate at the bottom of the wiped film evaporator will reach 40-45Kg / Hr. ...

Embodiment 3

[0029] Synthesis of prenyl diprenol: in such as figure 2 In the shown device, 240Kg of prenol, 80Kg of prenal, 0.08Kg of hydrogen peroxide, and 80Kg of toluene were put into a 500L kettle. Open the vacuum valve on the condenser to control the system vacuum at -0.08MPa. Open the jacketed steam for heating. When there is reflux at the top of the tower, reflux and divide water for 30 minutes at an internal temperature of 80-100°C. The vaporization amount is 100Kg / Hr. It is a negative pressure operation, so a double valve is required to switch the water). After 30 minutes, turn off the jacket heating, turn on the circulation pump, turn on the wiped film evaporator, set the heating steam pressure of the wiped film evaporator to 0.30MPa, and set the feed flow rate to 120Kg / Hr. After the system is stable for 10 minutes, the acetal discharge rate at the bottom of the wiped film evaporator will reach 20-25Kg / Hr (because the whole system is operated under negative pressure, a liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com