Method for preparing alpha-aryl carbonyl compound

A carbonyl compound and arylcarbonyl technology, which is applied in the field of preparation of α-arylcarbonyl compounds, can solve the problems of narrow substrate range and inability to contain β hydrogen, and achieve the effects of easy preparation, mild reaction conditions and stable substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

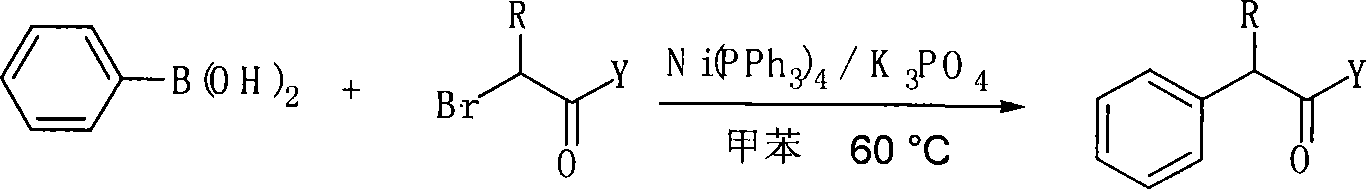

Method used

Image

Examples

Embodiment 1

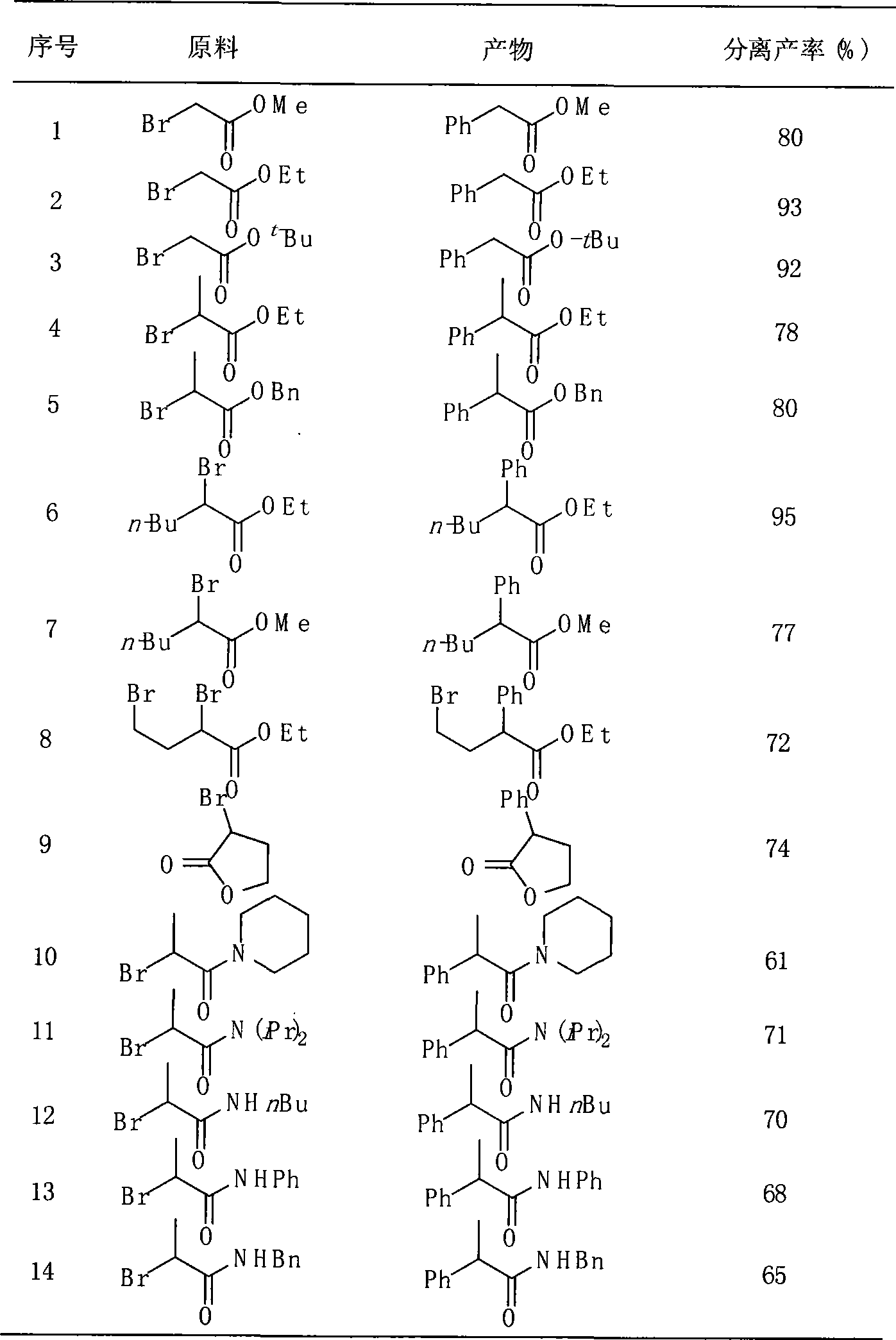

[0016] Example 1: Reaction of 2-Bromoesters or Amides

[0017] In a reaction system, add phenylboronic acid (243.8mg, 2.0mmol), 2-bromo ester or amide (1.0mmol), Ni(PPh 3 ) 4 (110.8 mg, 0.1 mmol), K 3 PO 4 (849.2 mg, 4.0 mmol), the system was replaced by nitrogen protection, 2 ml of toluene was added, and the reaction was carried out at 60 degrees Celsius for 16 hours. Stop the reaction, add 2 ml of 2M dilute hydrochloric acid to the system, add 5-10 ml of ethyl acetate three times for extraction, combine the organic phases, and dry over anhydrous sodium sulfate. The product 2-phenyl ester or amide was obtained by column chromatography, and the separation yield is shown in Table 1 below.

[0018]

[0019] Table 1 Arylation reaction of phenylboronic acid with 2-bromoester and amide

[0020]

Embodiment 2

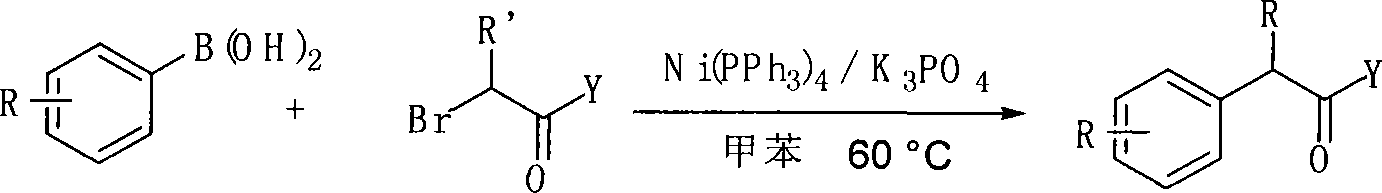

[0022] In a reaction system, add substituted phenylboronic acid (2.0mmol), 2-bromo ester or amide (1.0mmol), Ni(PPh 3 ) 4 (110.8 mg, 0.1 mmol), K 3 PO 4 (849.2 mg, 4.0 mmol), the system was replaced by nitrogen protection, 2 ml of toluene was added, and the reaction was carried out at 60 degrees Celsius for 16 hours. Stop the reaction, add 2 ml of 2M dilute hydrochloric acid to the system, add 5-10 ml of ethyl acetate three times for extraction, combine the organic phases, and dry over anhydrous sodium sulfate. The product 2-substituted phenyl ester or amide was obtained by column chromatography, and the separation yield is shown in Table 2 below.

[0023]

[0024] Table 2 Reaction of substituted phenylboronic acids with 2-bromo esters and amides

[0025]

[0026] b The reaction temperature is 80 degrees Celsius

Embodiment 3

[0027] Embodiment 3: the reaction of 2-bromoketone or 2-chloroketone

[0028] In a reaction system, add arylboronic acid (2.0mmol), 2-bromoketone or 2-chloroketone (1.0mmol), Ni(PPh 3 ) 4 (110.8 mg, 0.1 mmol), K 3 PO 4 (1273.8 mg, 6.0 mmol), the system was replaced with nitrogen protection, 2 ml of toluene was added, and the reaction was carried out at 60 degrees Celsius for 16 hours. Stop the reaction, add 2 ml of 2M dilute hydrochloric acid to the system, add 5-10 ml of ethyl acetate three times for extraction, combine the organic phases, and dry over anhydrous sodium sulfate. 2-aryl ketone was obtained by column chromatography. The separation yield is shown in Table 3 below.

[0029]

[0030] Table 3: Nickel-catalyzed arylation of ketones

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com