Method for synthetizing alcohol ester acetate by single step of ethyl acetate and alcohol ester exchange

A technology of ethyl acetate and alcohol acetate, applied in the synthesis field of alcohol acetate, can solve the problems such as inability to synthesize alcohol acetate product, increase production cost, inconvenience in popularization and application, and achieves a large market volume and a wide range and saves energy. , beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

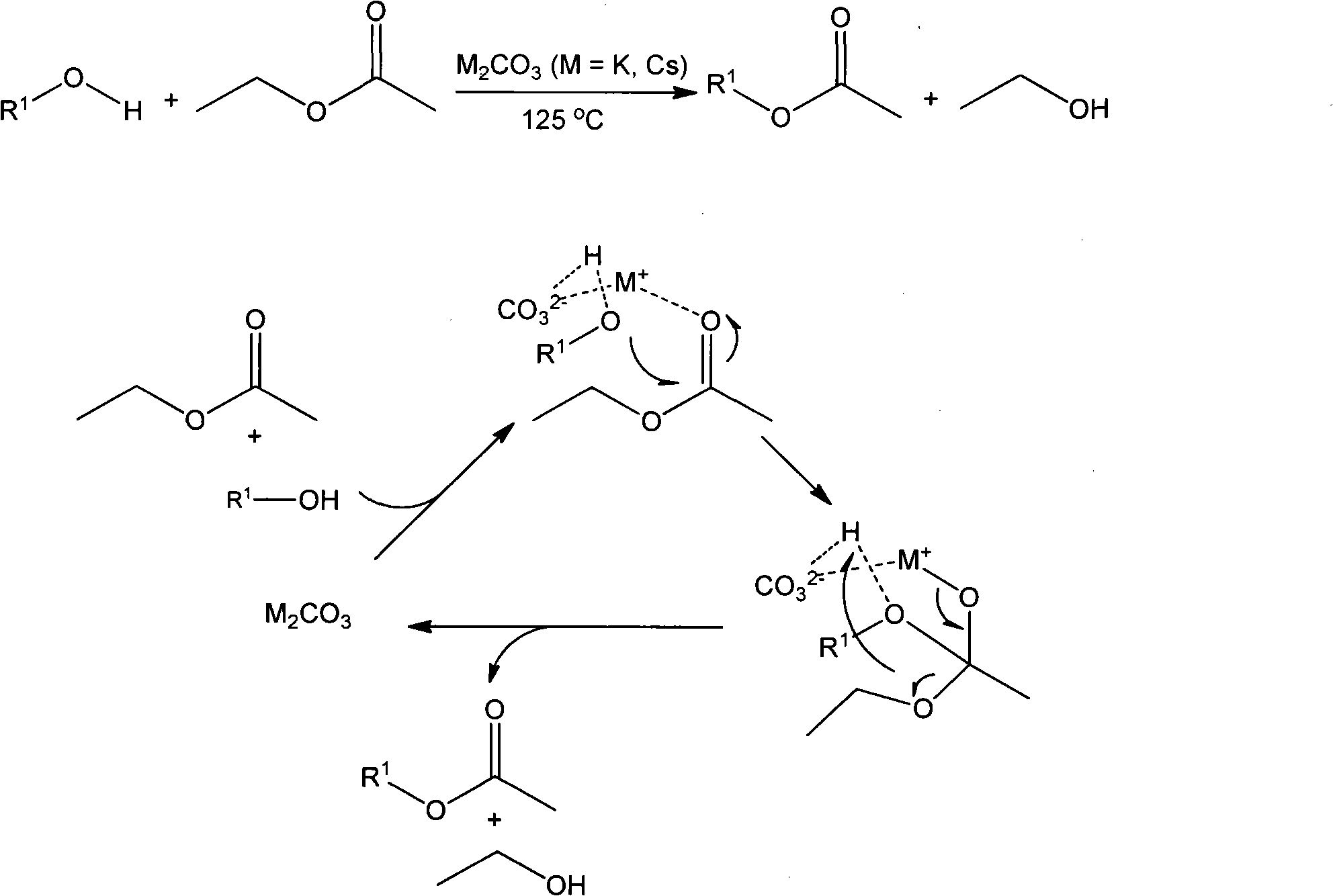

Method used

Image

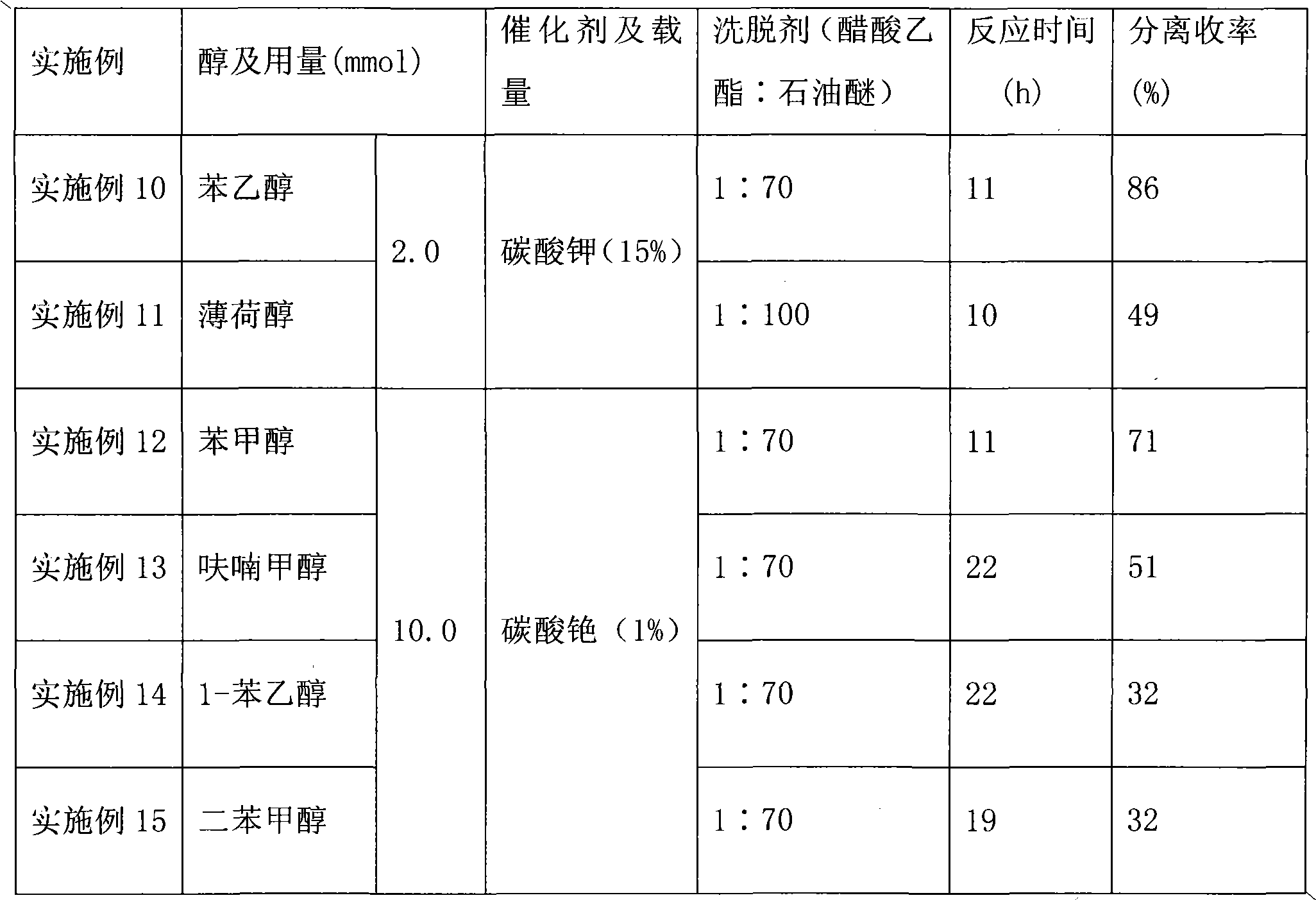

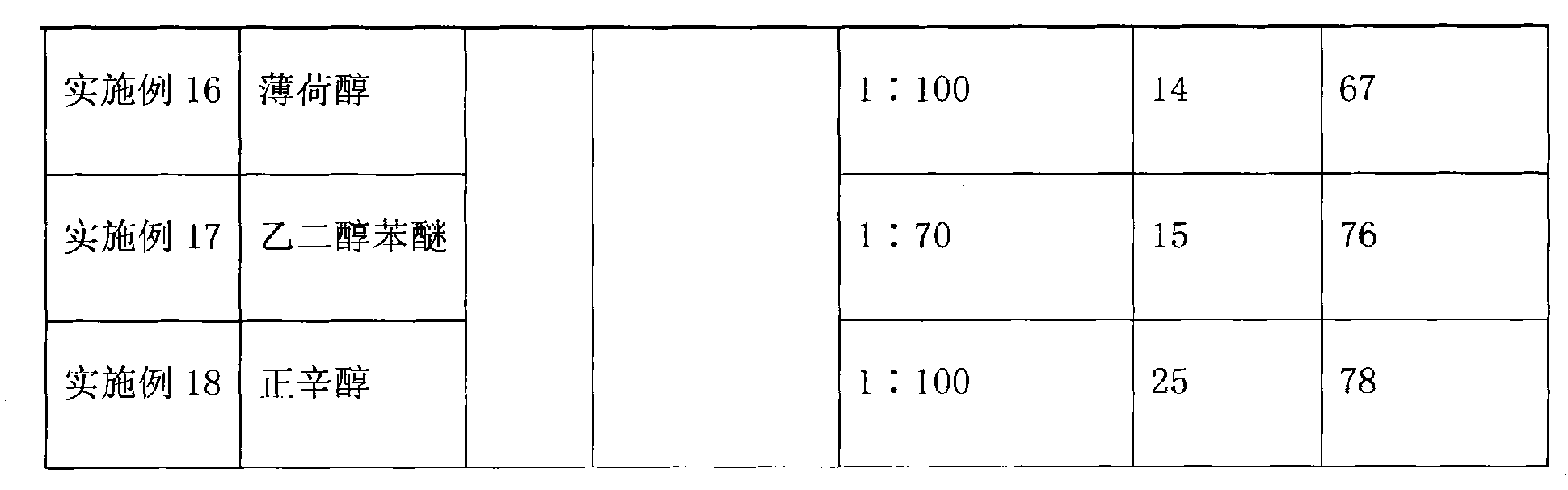

Examples

Embodiment 1

[0029] A kind of ethyl acetate and alcohol transesterification one-step method for synthesizing alcohol acetate, its concrete steps are as follows:

[0030] (1) Taking geraniol as a raw material, using cesium carbonate as a catalyst, taking ethyl acetate as an esterification reagent, and also as a solvent, according to geraniol (mmol): cesium carbonate (mmol): ethyl acetate ( Milliliter) ratio is the ratio of 1:0.05:1, in reactor, add cesium carbonate (32.6mg, 0.1mmol) catalyst and ethyl acetate solvent (2.0mL) earlier, under stirring, then add geraniol (308.5mg , 2.0mmol), after the addition was completed, the temperature was raised to 125°C, and the transesterification was carried out with continuous stirring for 25 hours.

[0031] (2) After the (1) step was completed, the alcohol acetate reaction solution prepared in the (1) step was cooled naturally in the air, and the condensing system of the reactor was flushed with dichloromethane, and the washing liquid was incorporate...

Embodiment 2

[0034] A kind of method that ethyl acetate and alcohol transesterification one-step synthetic alcohol acetate, its concrete steps are with embodiment 1, wherein:

[0035] In step (1), take phenylethyl alcohol as raw material, use cesium carbonate as catalyzer, take ethyl acetate as esterification reagent, and do solvent concurrently, according to phenylethyl alcohol (mmol): cesium carbonate (mmol): ethyl acetate (milliliters) ratio is 1:0.01:1 ratio, in reactor, add cesium carbonate (32.6mg, 0.1mmol) and ethyl acetate (10.0mL) first, then add phenethyl alcohol (1.2216g, 10.0mmol) under stirring ), continued to stir and carried out transesterification for 16 hours.

[0036] In step (2), the eluent was a mixture of ethyl acetate:petroleum ether with a volume ratio of 1:80 to obtain phenylethyl acetate (1.5382 g, yield 94%) as a colorless transparent liquid.

Embodiment 3

[0038] A kind of method that ethyl acetate and alcohol transesterification one-step synthetic alcohol acetate, its concrete steps are with embodiment 1, wherein:

[0039] In step (1), take n-octanol as raw material, use cesium carbonate as catalyzer, take ethyl acetate as esterification reagent, and do solvent concurrently, according to n-octanol (mmol): cesium carbonate (mmol): acetic acid The ratio of ethyl ester (milliliter) is the ratio of 1:0.025:0.75, cesium carbonate (162.9mg, 0.5mmol) and ethyl acetate (15.0mL) are added earlier in the reactor, then add n-octanol (2.6046g , 20.0mmol), and continued stirring for 6 hours for transesterification.

[0040] In step (2), n-octyl acetate (3.1006 g, yield 90%) was obtained as a colorless transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com