Cobalt-based catalyst for generating ester by alcohol oxidation, and preparation method and application of cobalt-based catalyst

A cobalt-based catalyst, alcohol oxidation technology, applied in the preparation of organic compounds, physical/chemical process catalysts, preparation of carboxylate and other directions, can solve the problems of unsatisfactory reaction activity, unenvironmental reaction system, waste of resources and environment, etc. Good recycling performance, good substrate applicability, less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

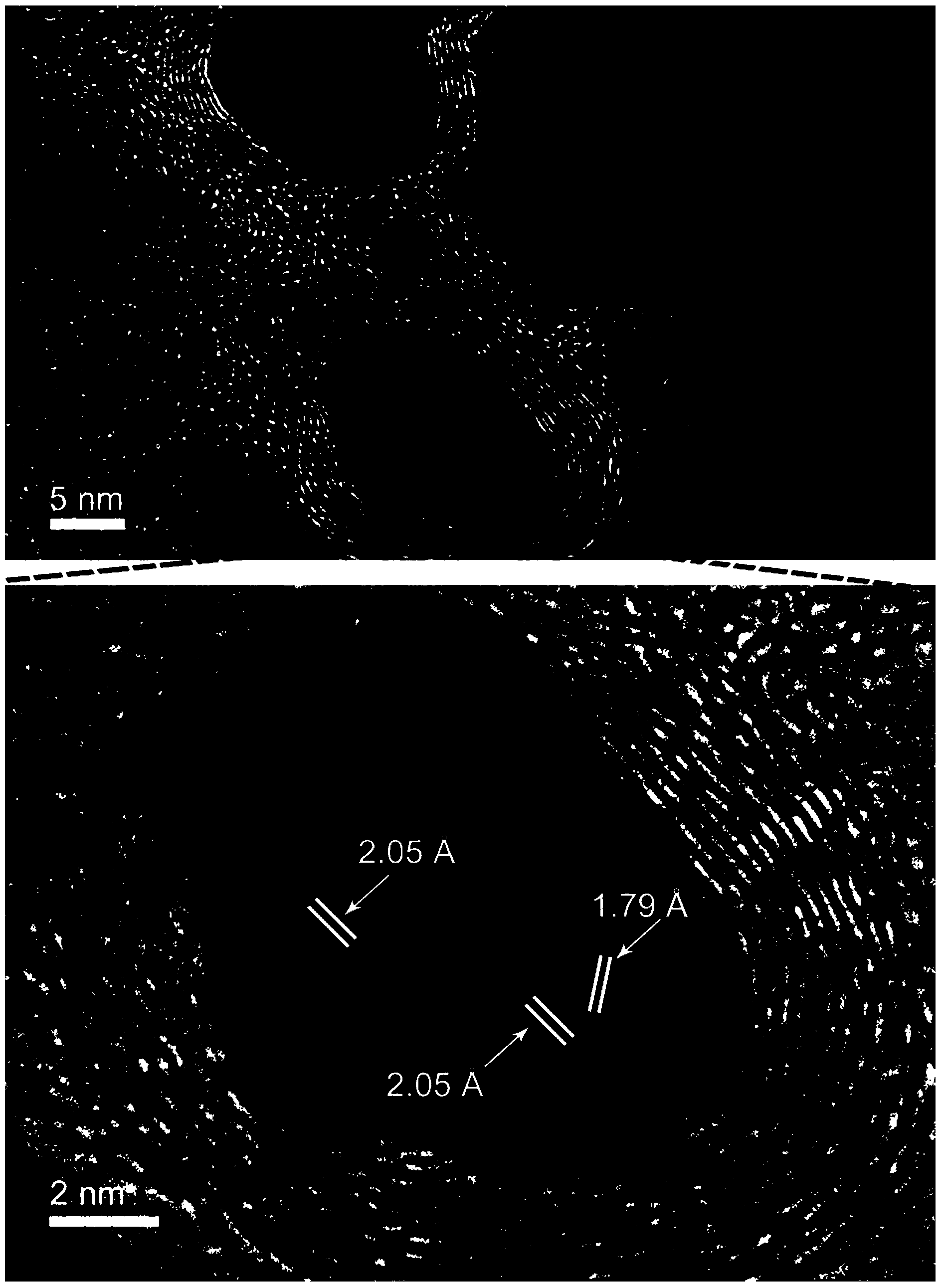

Image

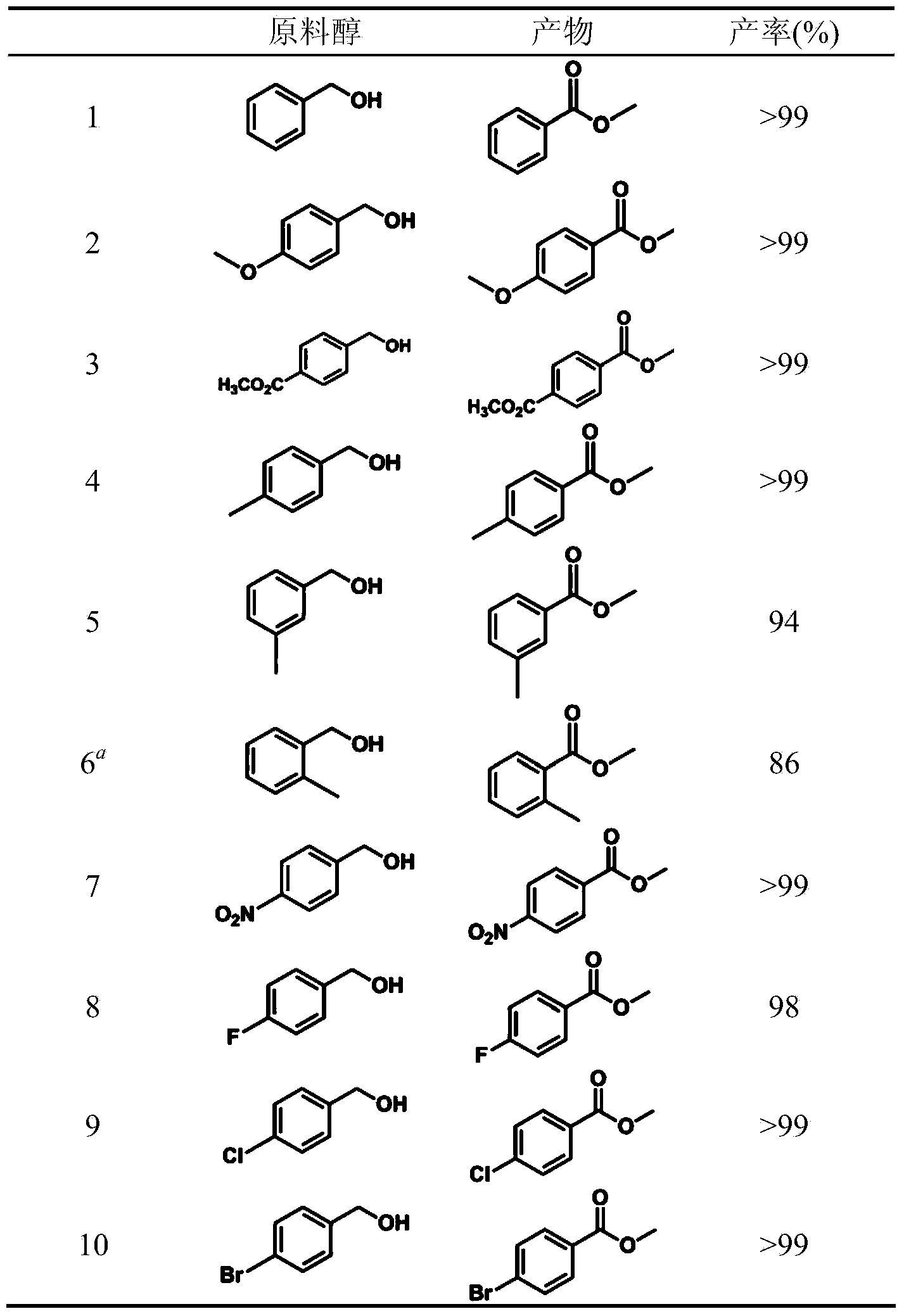

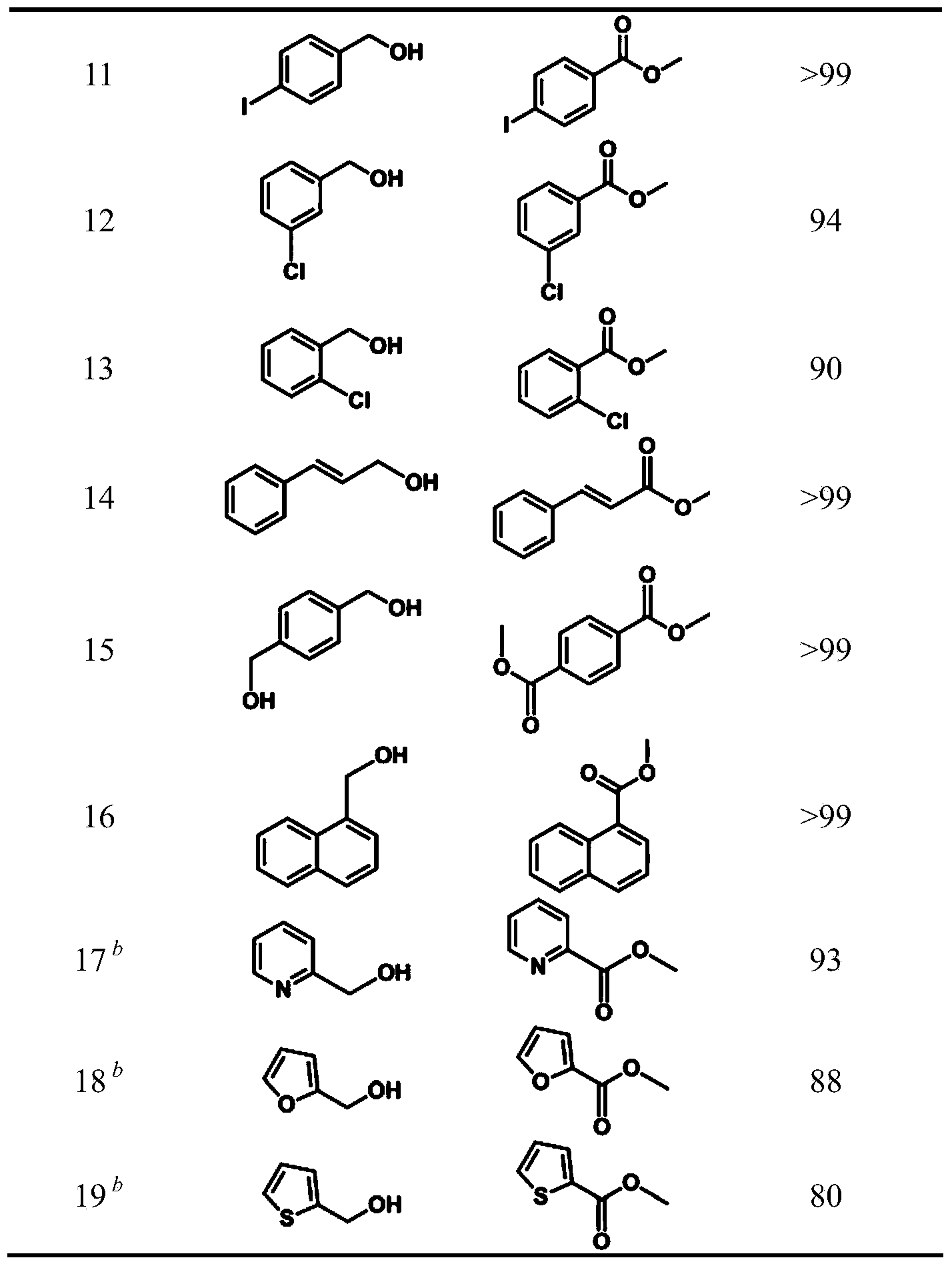

Examples

Embodiment 1 or 2

[0036] The metal-organic framework material ZIF-67 used in the present invention can be prepared according to the following example 1 or 2:

Embodiment 1

[0038] Weigh cobalt nitrate hexahydrate and 2-methylimidazole respectively and add to deionized water, the molar ratio is Co 2+ :Im:H 2 O=1:58:1100, stirred at room temperature for 6 hours to obtain a purple mixed solution; the purple mixed solution was centrifuged, filtered to obtain a purple precipitate, washed with a large amount of deionized water to remove unreacted ligands, and then washed with methanol The solution washed the purple precipitate three times; finally, the collected purple precipitate was vacuumized at 80° C. for 24 hours to obtain the metal-organic framework material ZIF-67.

Embodiment 2

[0040] Weigh cobalt nitrate hexahydrate and 2-methylimidazole respectively and add to deionized water, the molar ratio is Co 2+ :Im:H 2 O=1:58:1100, stirred at room temperature for 6 hours to obtain a purple mixed solution; the purple mixed solution was centrifuged, filtered to obtain a purple precipitate, washed with a large amount of deionized water to remove unreacted ligands, and then washed with methanol Wash the purple precipitate with the solution for 3 times; finally vacuumize the collected purple precipitate at 200°C for 24 hours to obtain the metal-organic framework material ZIF-67.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com