Diazomethane on-line deriving method

A technology of diazomethane and p-toluenesulfonamide, applied in chemical instruments and methods, formation/introduction of ether group/acetal group/ketal group, formation/introduction of carboxylate group, etc., can solve method efficiency Efficiency and stability cannot be guaranteed, preparation and derivation have no continuity, and the safety of the bubbling method cannot be guaranteed, etc., to achieve the effect of improving the operability and reproducibility of derivation, enhancing safety and operability, and improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

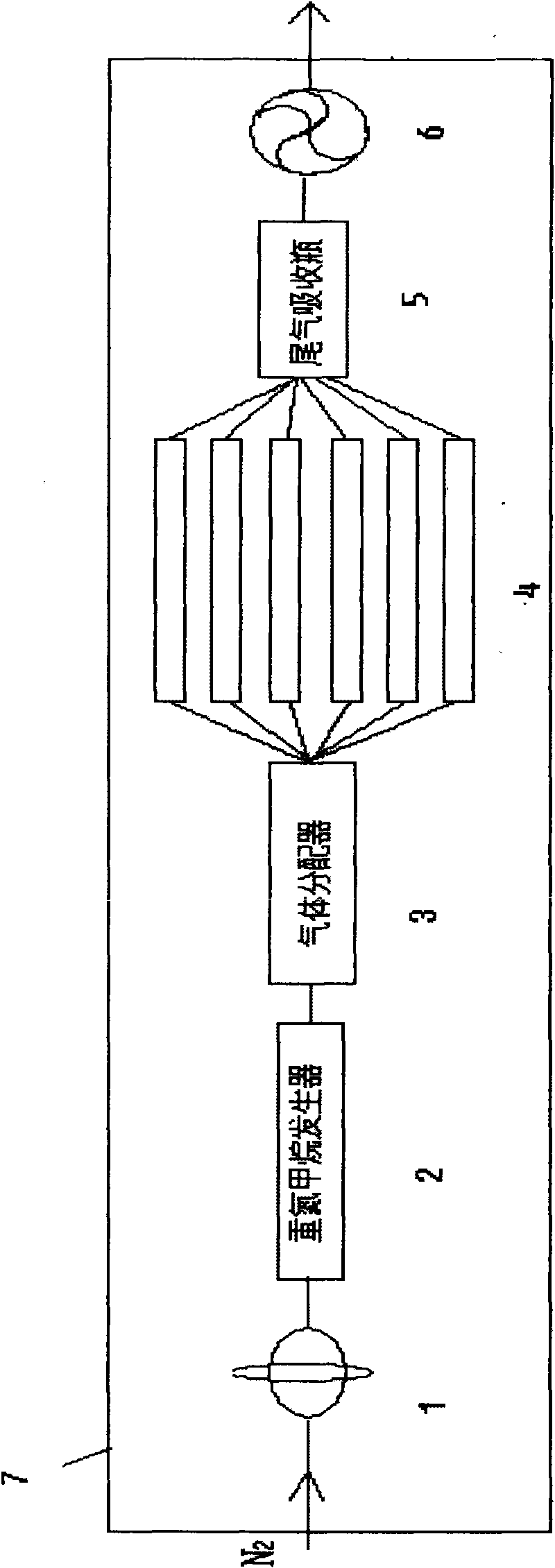

[0048] See attached figure 1 , figure 2 , a diazomethane online derivation method is characterized in that it comprises the following steps: (1), a diazomethane generation step; (2), a diazomethane derivation step.

[0049] (1) The diazomethane generation step includes: adding the mixed solution including potassium hydroxide, alcohol and ether mixture, etc. into the N methyl-nitroso-p-toluenesulfonamide solid at normal temperature to prepare diazomethane gas . (2) The diazomethane derivation step includes: reacting diazomethane gas with organic matter at room temperature to prepare corresponding esters. The diazomethane online derivation method is realized under the impetus of N2. After the (2) diazomethane derivatization step, a tail gas absorption step is also included. The absorbent used in the tail gas absorption step to absorb excess diazomethane is diethyl ether. (1) The N2 flow control step is also included before the diazomethane generating step. A diazomethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com