Preparation method of methacrylate products

A technology of methyl methacrylate and methacrylic acid, applied in the field of preparation of methacrylate products, can solve the problems of high power consumption, no mention of the recovery of azeotrope methyl methacrylate, etc. Investment, easy automation control, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

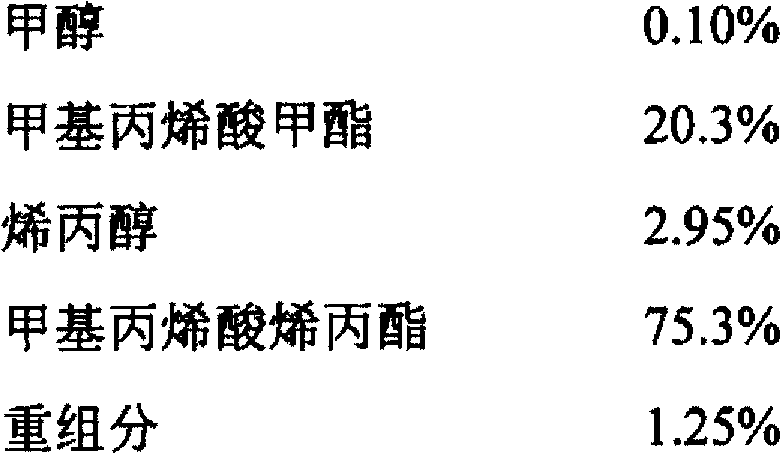

Embodiment 1

[0038] The reactor is two tank reactors in series, each volume is 5 liters, and the rectification tower is Φ50×2.5 and the height is 800mm. Light removal tower Φ50×2.5, height 1000mm. Weight-removing tower Φ50×2.5, height 800mm.

[0039] The raw materials are methyl methacrylate and allyl alcohol.

[0040] The catalyst is dibutyltin dilaurate.

[0041] The polymerization inhibitor is 2,2,6,6-tetramethyl-4-hydroxypiperidine-1-oxynitride free radical.

[0042] The entrainer is n-pentane.

[0043] Methyl methacrylate, allyl alcohol and the reused polymerization inhibitor and catalyst are mixed continuously with a metering pump and enter reactor A, wherein the flow of methyl methacrylate is 600g / h, and the flow of allyl alcohol is 260g / h , Catalyst and polymerization inhibitor flow rate 90g / h (catalyst concentration is 50%, polymerization inhibitor concentration 2%). Reactor A is heated up, and the azeotrope of methyl methacrylate and methanol generated enters the azeotropic ...

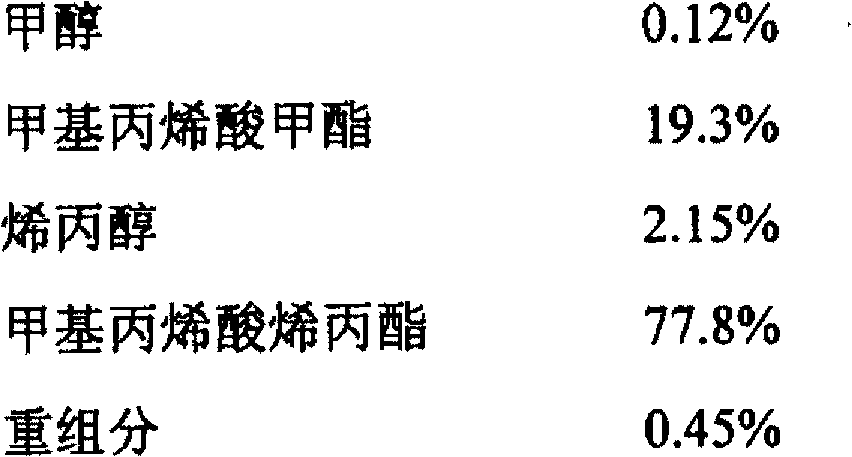

Embodiment 2

[0047] The reactor is two tank reactors in series, each volume is 5 liters, and the rectification tower is Φ50×2.5 and the height is 800mm. Light removal tower Φ50×2.5, height 1000mm. Weight-removing tower Φ50×2.5, height 800mm.

[0048] The raw materials are methyl methacrylate and allyl alcohol.

[0049] The catalyst is dibutyl tin dilaurate and allyl titanate, and the ratio of the two is 4:1.

[0050] The polymerization inhibitor is tetramethylpiperidine nitroxide free radical phosphite triester and hydroquinone, and the ratio of the two is 2:1.

[0051] The entrainer is n-hexane.

[0052] Methyl methacrylate, allyl alcohol and the reused polymerization inhibitor and catalyst are mixed continuously with a metering pump and enter reactor A, wherein the flow of methyl methacrylate is 600g / h, and the flow of allyl alcohol is 260g / h , Catalyst and polymerization inhibitor flow rate 90g / h (catalyst concentration is 50%, polymerization inhibitor concentration 2%). Reactor A ...

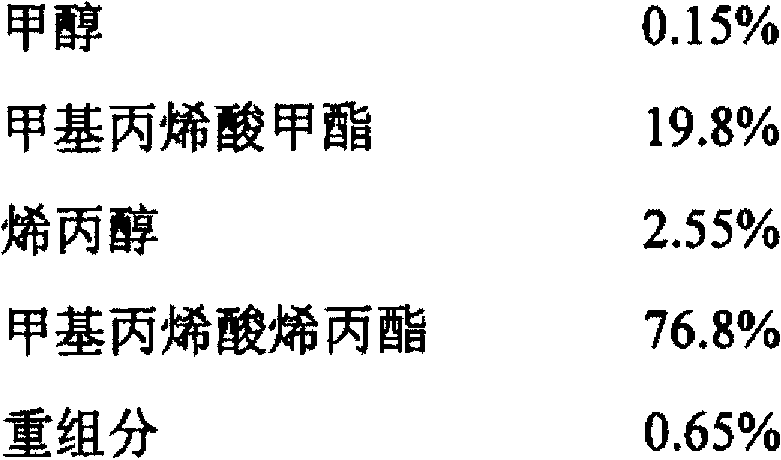

Embodiment 3

[0056] The reactor is two tank reactors connected in series, each volume is 6000 liters, and the rectification tower is Φ500×5 and the height is 8000mm. Light removal tower Φ500×5mm, height 10000mm. Weight-removing tower Φ500×5mm, height 8000mm.

[0057] The raw materials are methyl methacrylate and allyl alcohol.

[0058] The ratio of the catalyst dibutyltin oxide to allyl titanate is 4:1.

[0059] The polymerization inhibitor is copper dibutyldithiocarbamate and hydroquinone, and the ratio of the two is 2:1.

[0060] The entrainer is cyclohexane.

[0061] Use a metering pump to continuously mix methyl methacrylate, allyl alcohol and recycled inhibitors and catalysts into reactor A, wherein the flow of methyl methacrylate is 700kg / h, and the flow of allyl alcohol is 320kg / h , Catalyst and polymerization inhibitor flow rate 90g / h (catalyst concentration is 50%, polymerization inhibitor concentration 2%). The material in reactor A is heated up, and the generated azeotrope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com